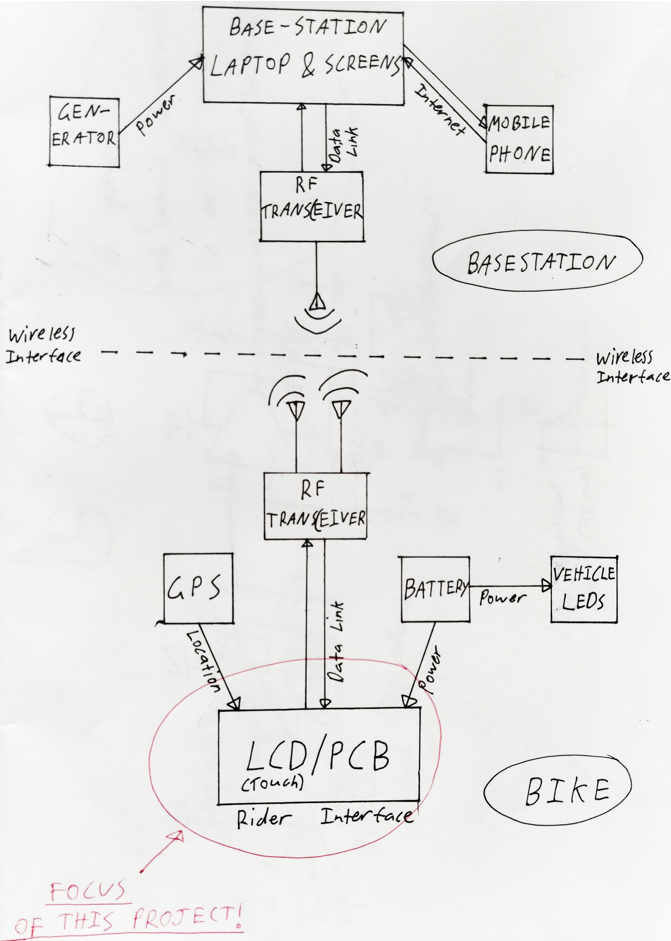

First an overview of the entire Pedal Prix telemetry system that the team has developed:

My task and focus is the development of a PCB for the rider/bike side that integrates the other modules together.

The PCB will incorporate the following features:

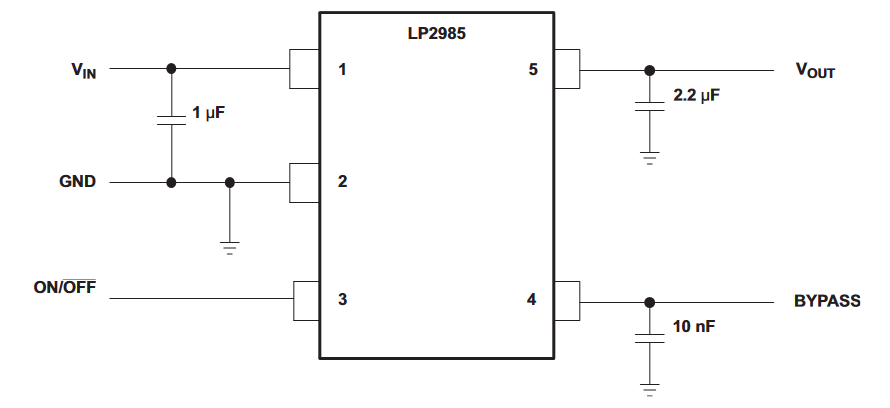

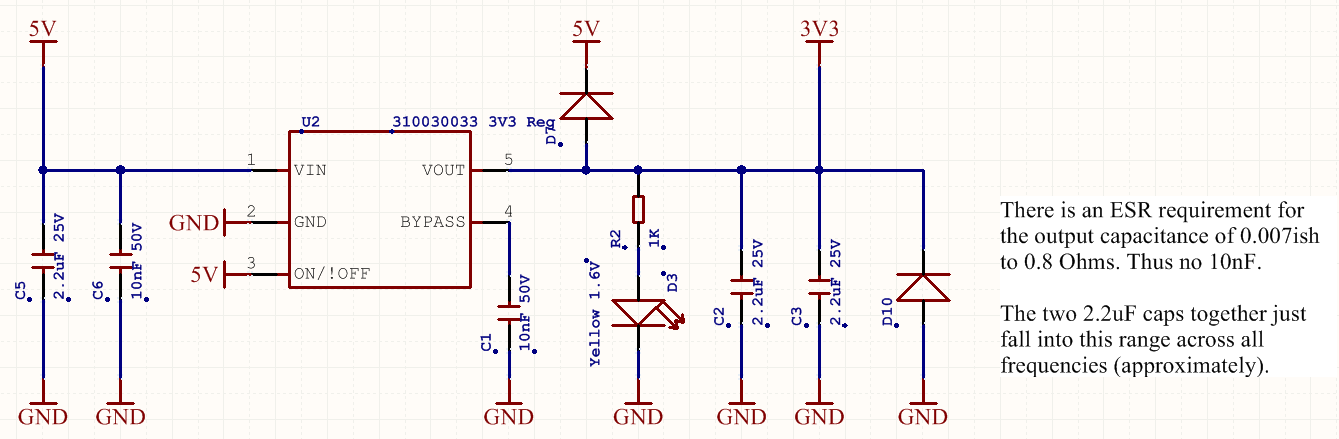

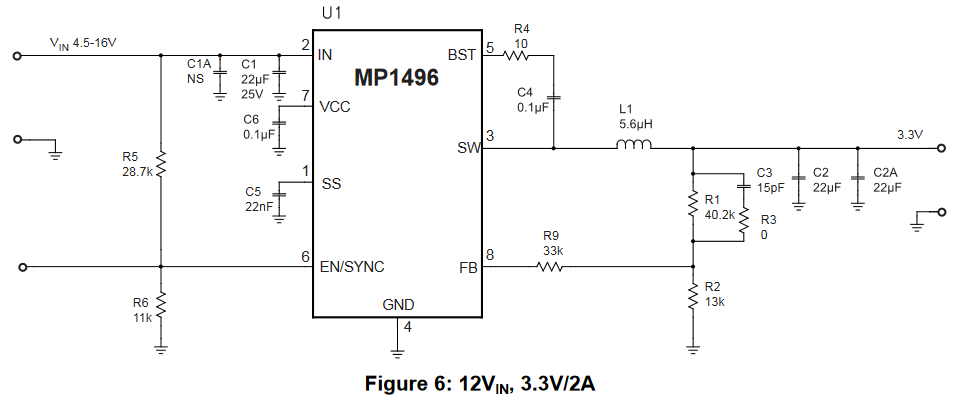

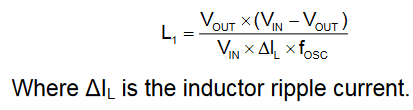

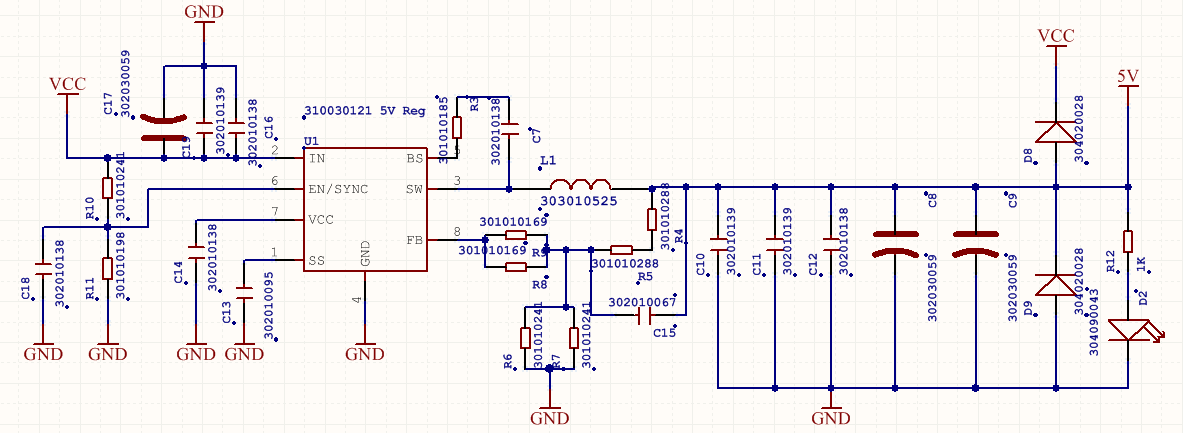

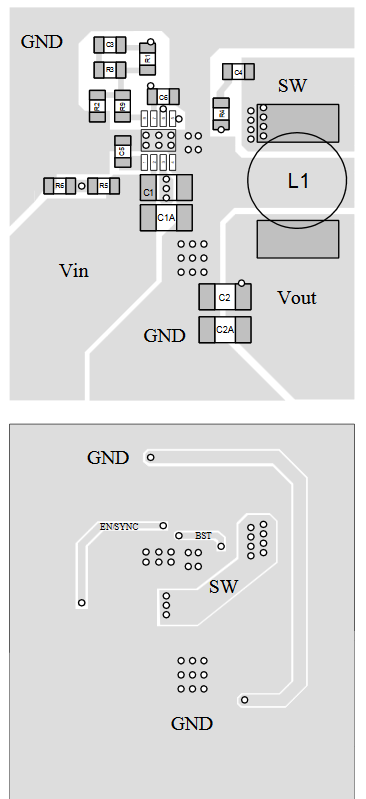

- Power supplies

- Micro-controller

- Touch screen LCD (the PCB will be mounted to the back of the screen)

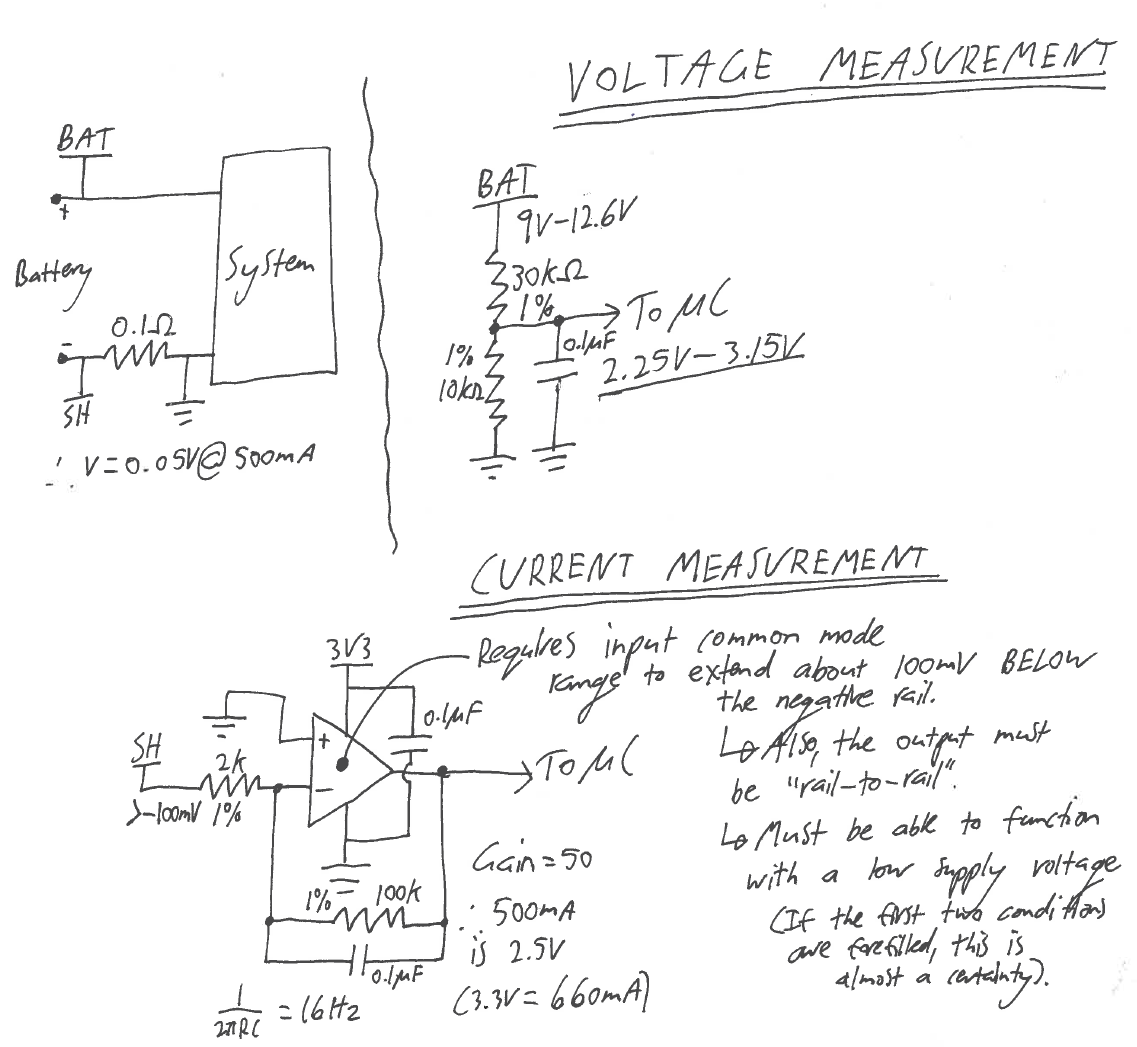

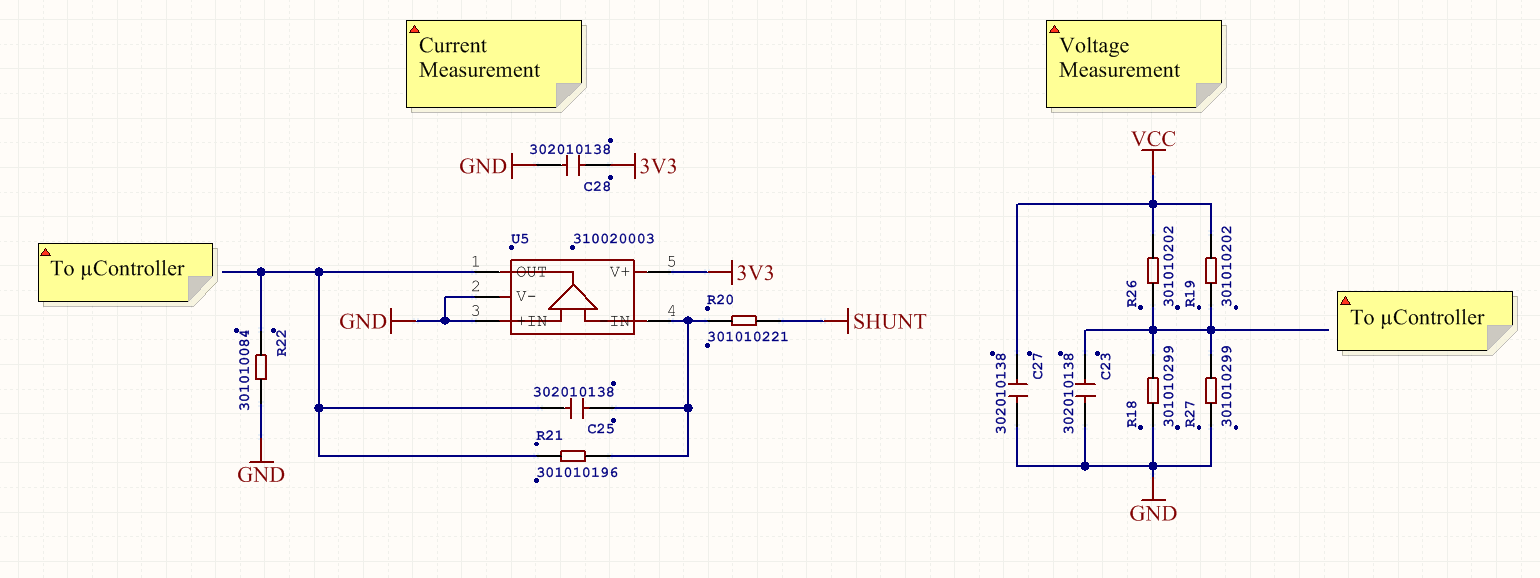

- Complete power measurement (not just voltage)

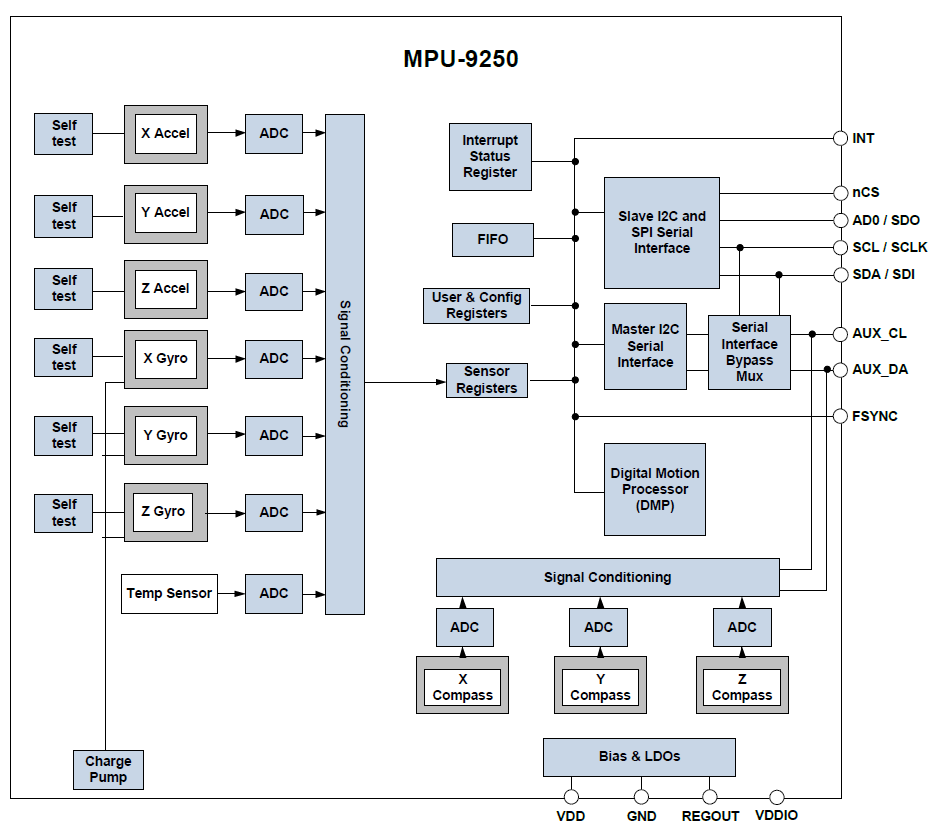

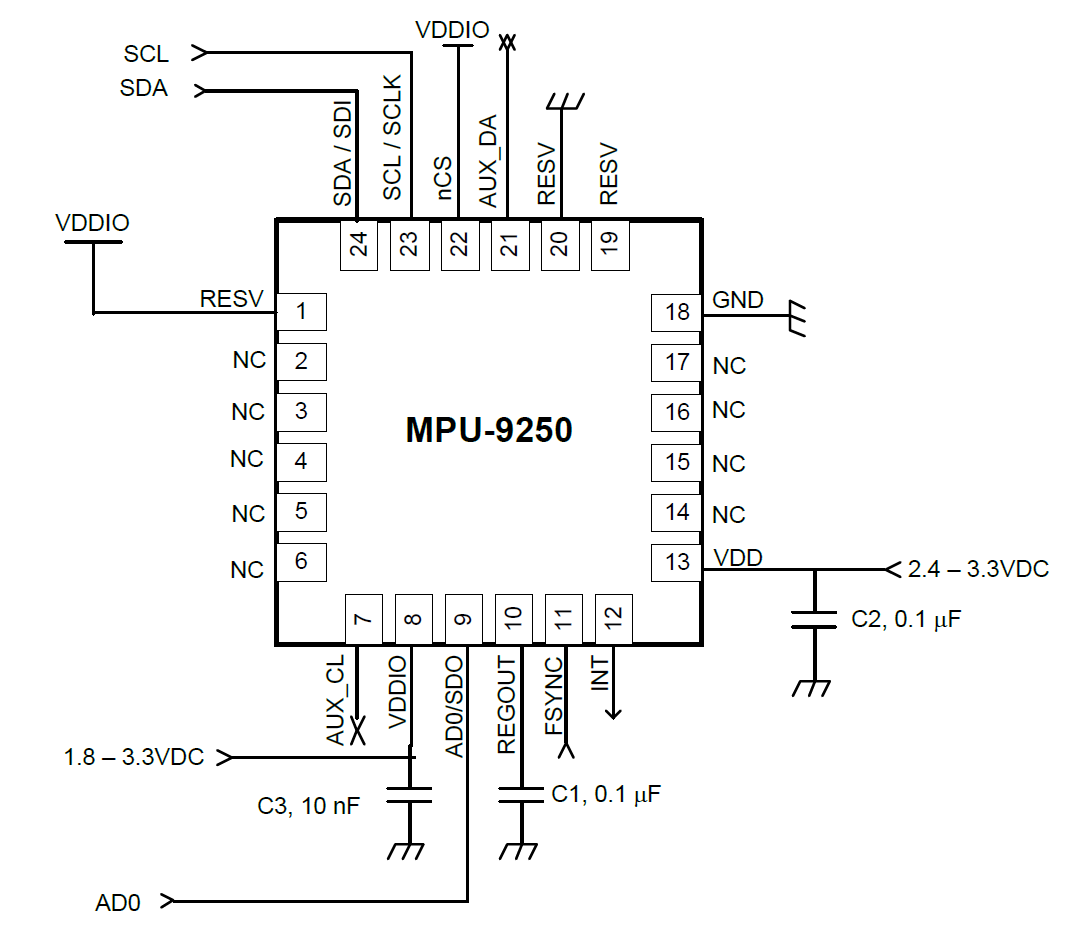

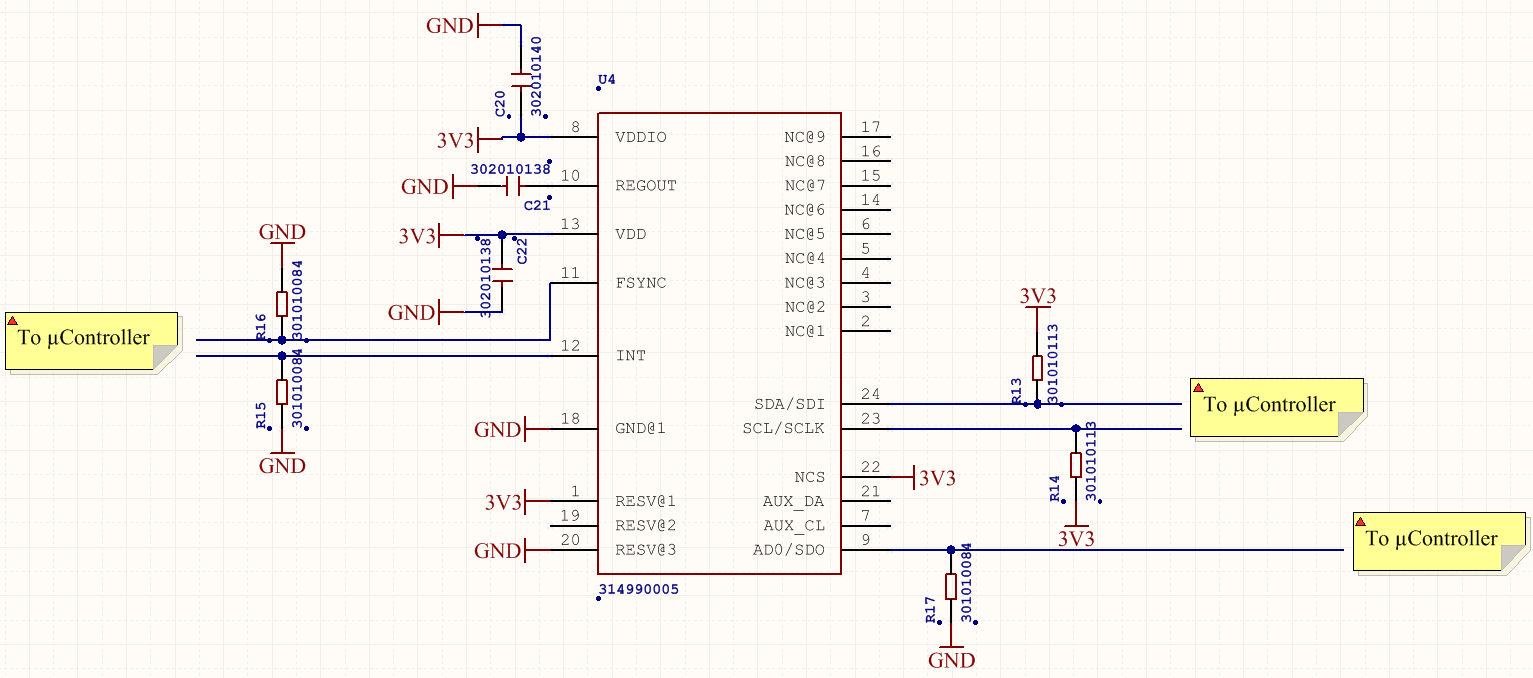

- A “9-axis” IMU - Allowing for absolute orientation measurement (plus PCB temp!)

- Power protection features (i.e. polarity and fusing)

- Plug for wind speed measurement probe (potentially)

Due to the complexity of the RF link (digital multi-node modem) and the location requirement of the GPS antenna, these key functionalities will exist as modules. However, the volume reduction achieved by eliminating the power supply and micro-controller boards will be significant and worth the endeavour!

Project Logs:

David Scholten

David Scholten

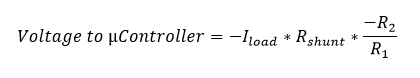

Where the maximum voltage of 3.3V represents 660mA for the µcontroller in the presented system. It is important to note that the exact resistance of the shunt needs to be known.

Where the maximum voltage of 3.3V represents 660mA for the µcontroller in the presented system. It is important to note that the exact resistance of the shunt needs to be known.

Lithium ION

Lithium ION

Elia

Elia

Kuba Sunderland-Ober

Kuba Sunderland-Ober

mihai.cuciuc

mihai.cuciuc