Problem Statement

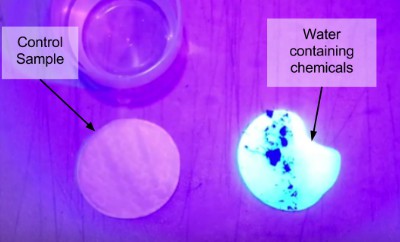

While water is all around us in the form of oceans, lakes and rivers, only 2.5 percent of it is freshwater. Furthermore, only 1 percent of that freshwater is accessible, the rest being trapped in glaciers and ice caps. This small amount of water has the huge responsibility of meeting the needs of all living creatures on the planet. With freshwater supply quickly diminishing, it's more important than ever to ensure that the water that we do have is pure, clean, and available for human use. Clean water also affects many animals, whether they drink the water itself or live in it as a habitat. Identifying bodies of water that are polluted is an area of great importance as we go forward in securing our world’s water sources.

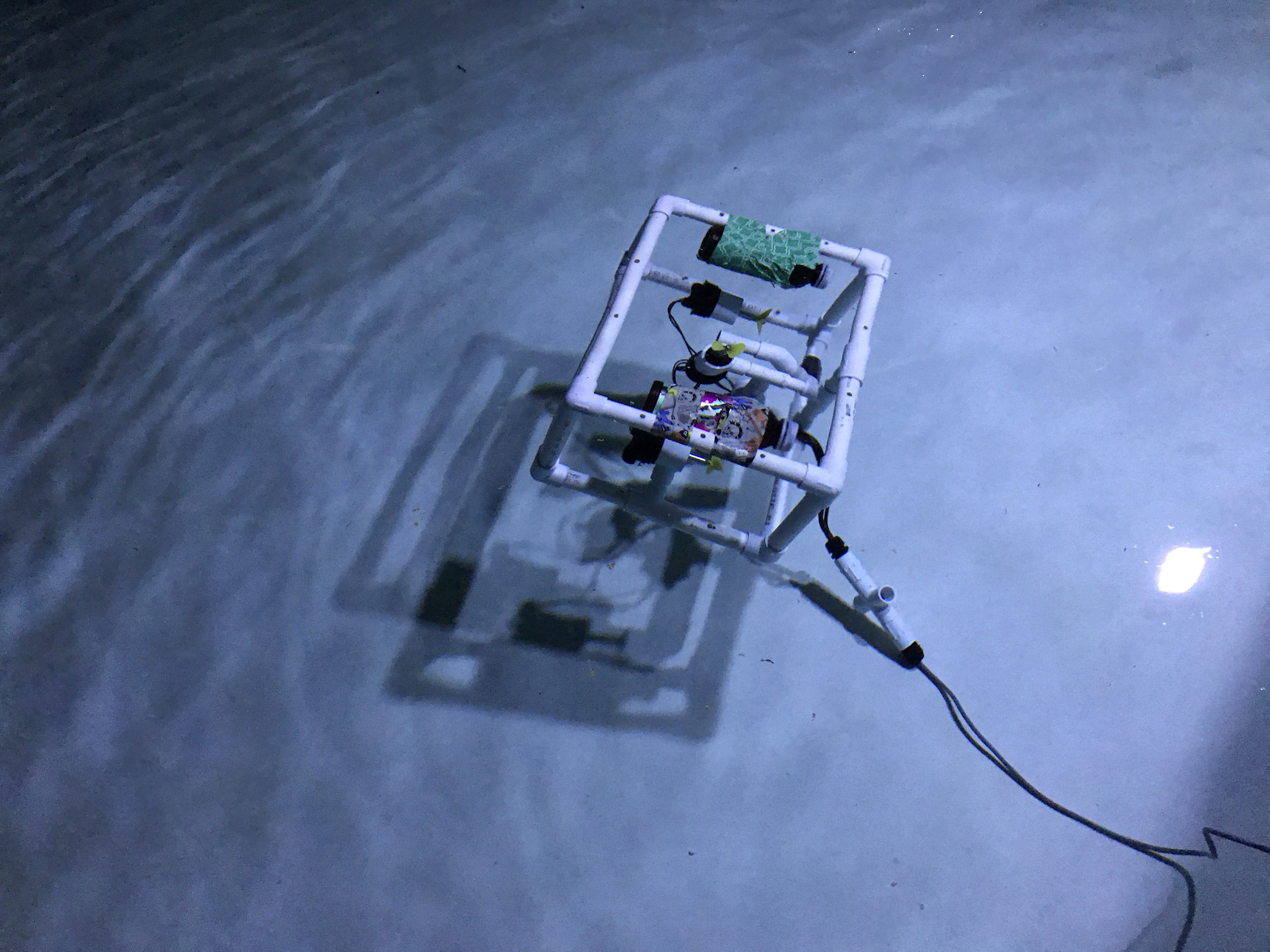

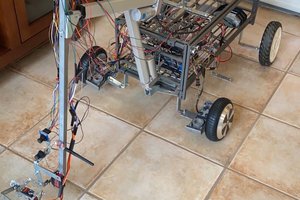

Remotely Operated Vehicles (ROVs) are the perfect robotic applications to detect marine pollution in hard-to-reach places in bodies of water. ROVs extend the capability of human divers and allow us to detect pollution and concentrate efforts where they’re needed. However, existing ROVs are either expensive, multi-million dollar scientific systems designed for deep sea navigation or cheap, inefficient systems that are ill-adapted for targeted pollutant detection. A lot of people would agree that underwater pollutants are a huge problem, but the state of current technology puts practical ROV systems that can tackle these problems out of reach for communities that need it the most.

Objective

Rogue Robotics aims to start a worldwide crowdsourcing campaign in utilizing low-cost, self-assembled ROVs to detect underwater pollution in local communities.

The World-Changing Underwater ROV

There are a few other low-cost ROV systems available for use, but Volturnus has a unique focus on underwater pollution and implementing cheap ways to detect it. Volturnus is designed with a philosophy of minimalism: Volturnus implements a few features but implements them well. Thus, Volturnus has the benefits of expensive ROVs, but also remains affordable. Not only does this result in an effective, uncluttered design, but it allows for users around the world to easily construct and modify their own devices. Volturnus may not be perfectly adapted to every single aquatic situation around the world, but by opening up the technology to any many people as possible, Volturnus has the potential to spark similar innovations across the globe.

Links:

- https://www.youtube.com/watch?v=HP5CmJx7S-8

- https://github.com/allai5/volturnus-rov

- https://roguebotics.weebly.com/

- https://skfb.ly/69ysR

- https://drive.google.com/file/d/0B7m7FUmix0-IOENyRV9fQl9hLU0/view?usp=sharing

- We began by researching various material types that can be used for the frame. Finding the best material requires finding an appropriate balance between performance and cost, as our goal is to develop an efficient apparatus accessible to the public. We summarized our research into a decision matrix.

Table 1. Decision matrix for frame material selection | ||||||

Material | Neutral Buoyancy | Strength | Weight | Price | Ease of Use | Total |

PVC | 4 | 3 | 4 | 5 | 5 | 21 |

HDPE | 4 | 4 | 5 | 3 | 4 | 20 |

ABS Plastic | 4 | 4 | 5 | 3 | 3 | 19 |

Aluminum | 1 | 5 | 3 | 2 | 2 | 13 |

- After deciding on using PVC piping, we discussed the ideal frame shape and size. We wanted to keep dimensions and weight to a minimum, as a smaller vehicle maneuvers more easily through water. We also placed a high emphasis on simplicity because simple designs are easier to develop and troubleshoot. The mechanics team sketched the frame layout on graph paper, including locations of thrusters, cameras, and tether attachments. We ultimately decided on a simple four motor orthogonal structure that maximizes space within the frame.

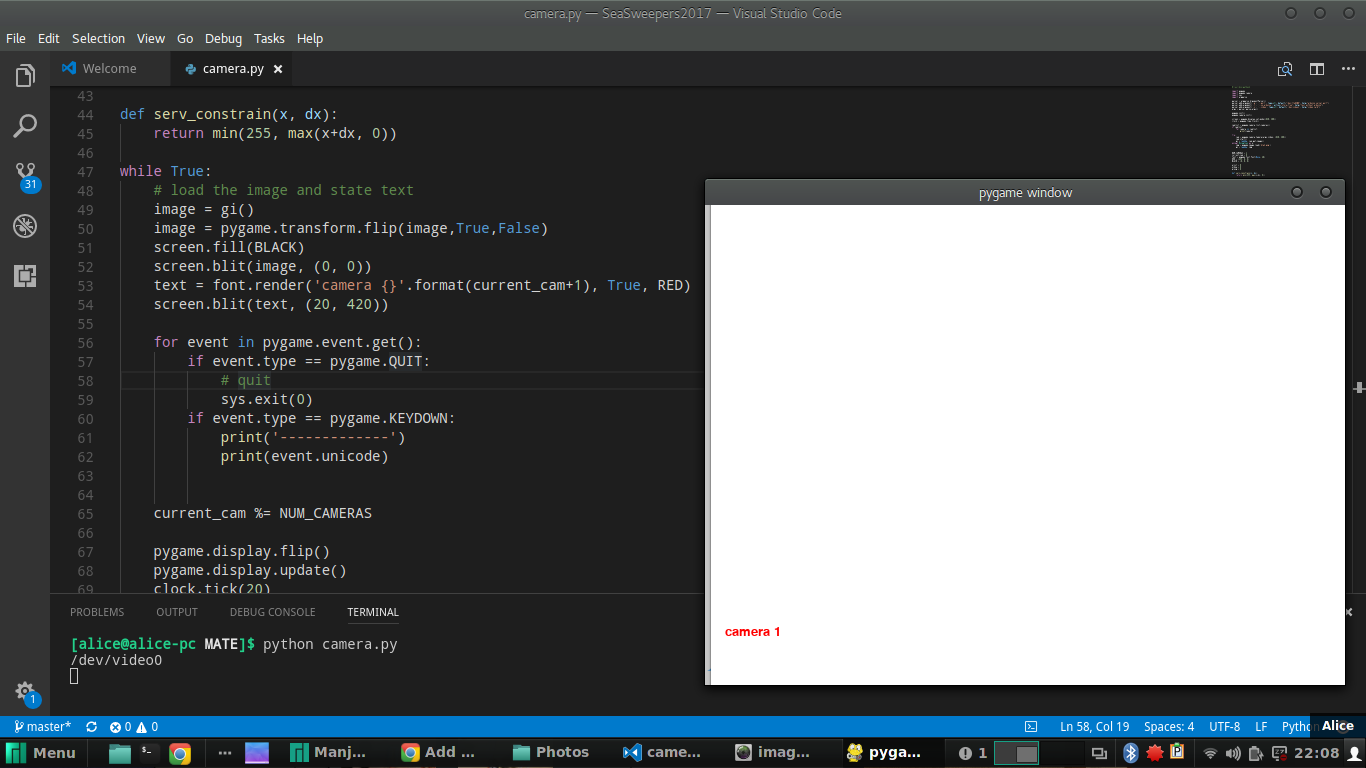

- We then created a CAD model of our proposed frame in Autodesk Inventor. Creating a CAD model prior to construction allows us to visualize the design and confirm the idea is achievable. We first created individual Inventor parts, including 90 degree elbows, tee connectors, and PVC pipes of specific dimensions. We assembled the parts together based off of sketches, making sure to leave...

allai5

allai5

maloneth4

maloneth4

Russell Cameron

Russell Cameron