The basic machine comes with a west feeder consisting of 20 8mm feeders. I added an additional north feeder which comes with an assortment of 8mm, 12mm and 16mm feeders (I like to have options!). I'd watched the videos and, looking at the machine head, I could see the pointer head which was used for dragging the tapes through the feeders. But how does the machine know where the feeders are?

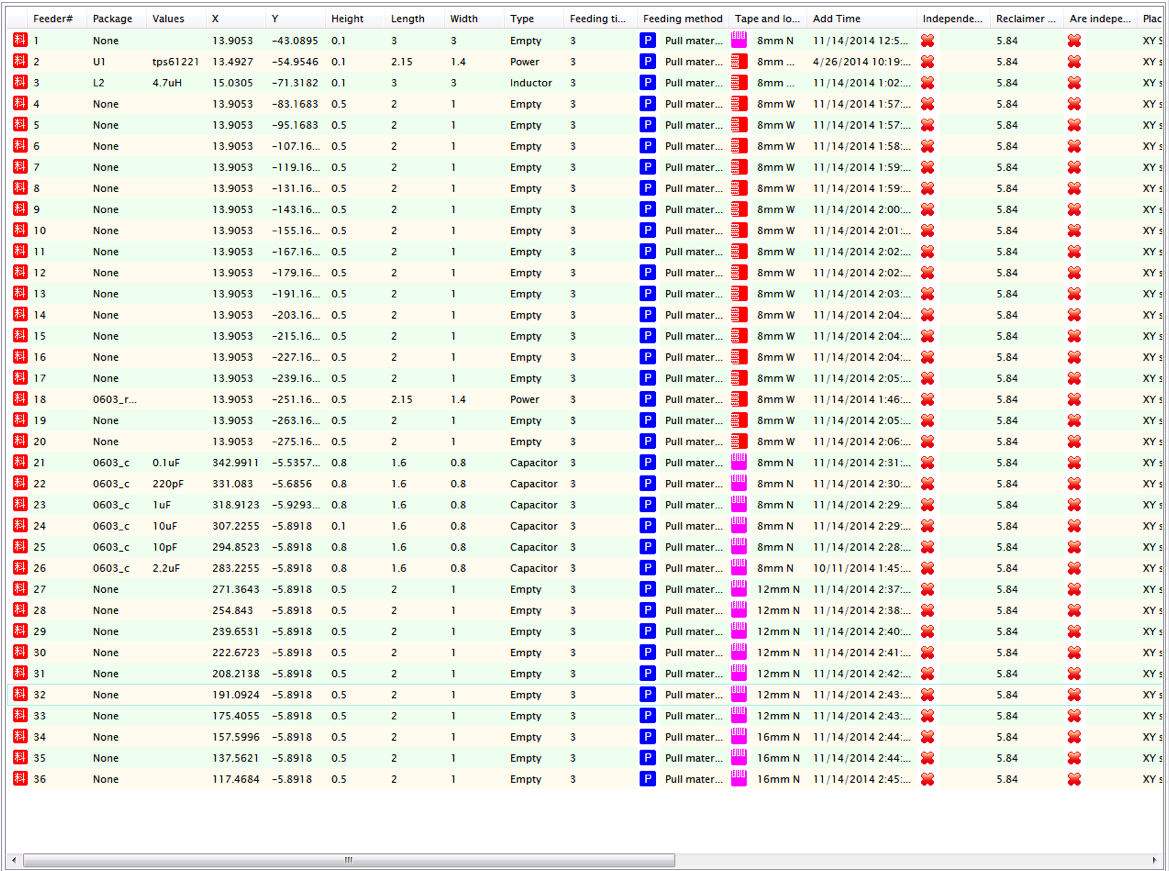

On the top bar of the app you'll find a button "Feeders" (or you will if you're using my translations). Pressing that opens up the feeder pane. This one shows many feeders already configured:

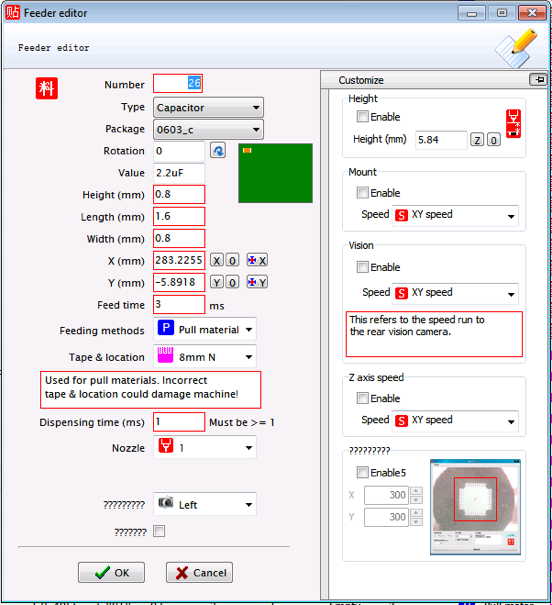

As I recall, the default project which comes with the machine only defines two of the 36 available feeders; the rest you have to define by hand! This isn't that hard to do once you've worked out how to move the machine head around and have the MARK camera working. However, it is rather tedious. As a starting point I've added my feeder configurations to the GitHub repo. These are part of the project database and you can find if here https://github.com/aanon4/SMT50/blob/master/OURSMT/config/Project_smt.cfg. When it comes time to use an actual feeder for components, you'll probably need to tweak the values a little depending on the tape properties, component size, etc. To do this simply right click on the feeder line and select "Modify feeder" from the popup menu.

Feeders are number 1-20 north-west to south-west, and 21-36 north-east to north-west. This isn't that sensible really, but it fitted with the numbering scheme of the two originally defined feeders and, at the time, I thought the numbering might be significant. It isn't, and you can number them anything you want.

Modifying feeders

The feeder modification popup looks like this:

Tim Wilkinson

Tim Wilkinson

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

dear friend please oursmt software send to me. i have oursmt. but my oursmt bad english launguge and config. please fikretduru@gmail.com send. thank you

Are you sure? yes | no