One of the major reasons I purchased this particular machine was for its vision system. The device comes with two cameras; an upwards facing fixed camera, and a downwards facing camera attached to the mount. The down camera is used for various things, but the up camera is only used for component centering.

For my BlueBasic project, I have a very small boost converter chip (2mm by 1mm) which is packaged a little loosely in its tape. After some initial experimentation without vision it became clear that I needed vision to accurately place this device. However, despite my best efforts, I could not get the vision system to recognize the chip. I tinkered with the light, I changed the various vision settings, I tried masking the camera in different ways, but nothing worked reliably. Occasionally the vision system would do the right thing, but then would stop.

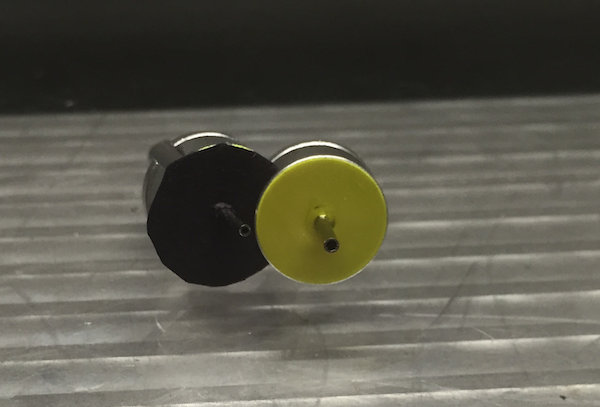

Eventually, after watching the (then untranslated) videos several more times, I noticed that all the vision examples used a larger nozzle, while I was using a smaller one. That didn't seem so significant except that the small nozzles had a yellow background, while the large ones have a black/grey background. I'd originally assumed that a black chip against a yellow background should be fine, but in my desperation I put a disc of black paper over the yellow and tried again. And it all works! Here's a before and after photo:

So, I don't know why any of the nozzles have yellow background, but I suggest you replace them with black paper.

One other note - once the Vision video was translated, about 30 seconds in they tell you this fact! Oh well.

12/2/14: A late addition. Apparently I'm a bit blind because on the front of the machine are three little dials. Turning them changes the light intensity. Wish I'd noticed earlier.

Tim Wilkinson

Tim Wilkinson

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.