The device is mean to replace common tools for measuring distances. It would be easy for someone to have this in their backpack or tool bag and use it to quickly estimate distances. This tool would be handy for people who need rough estimates such as contractors or real estate agents. It would much easier to use this device instead of a measuring tape or meter stick.

Distance Analyzer 3000

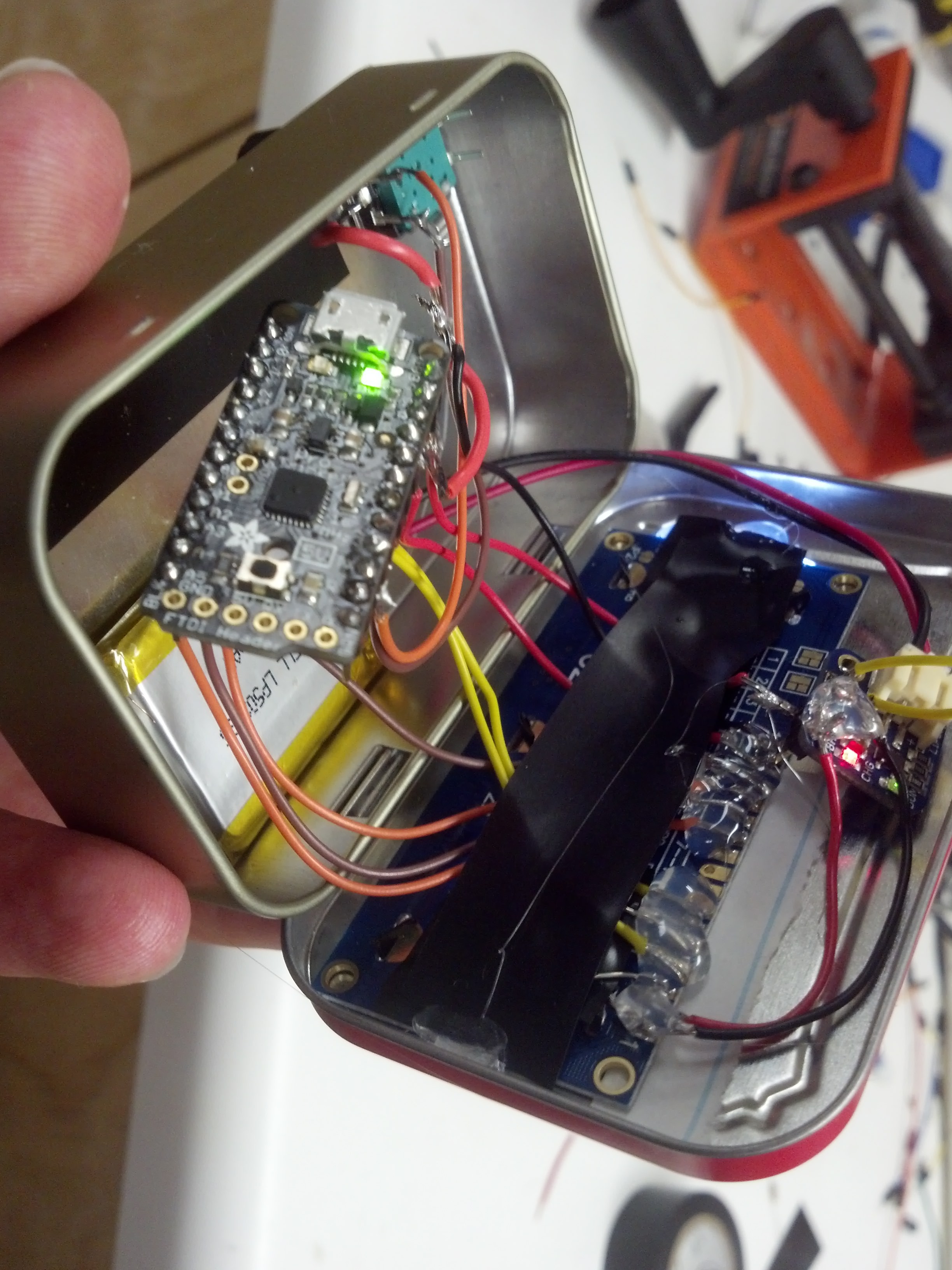

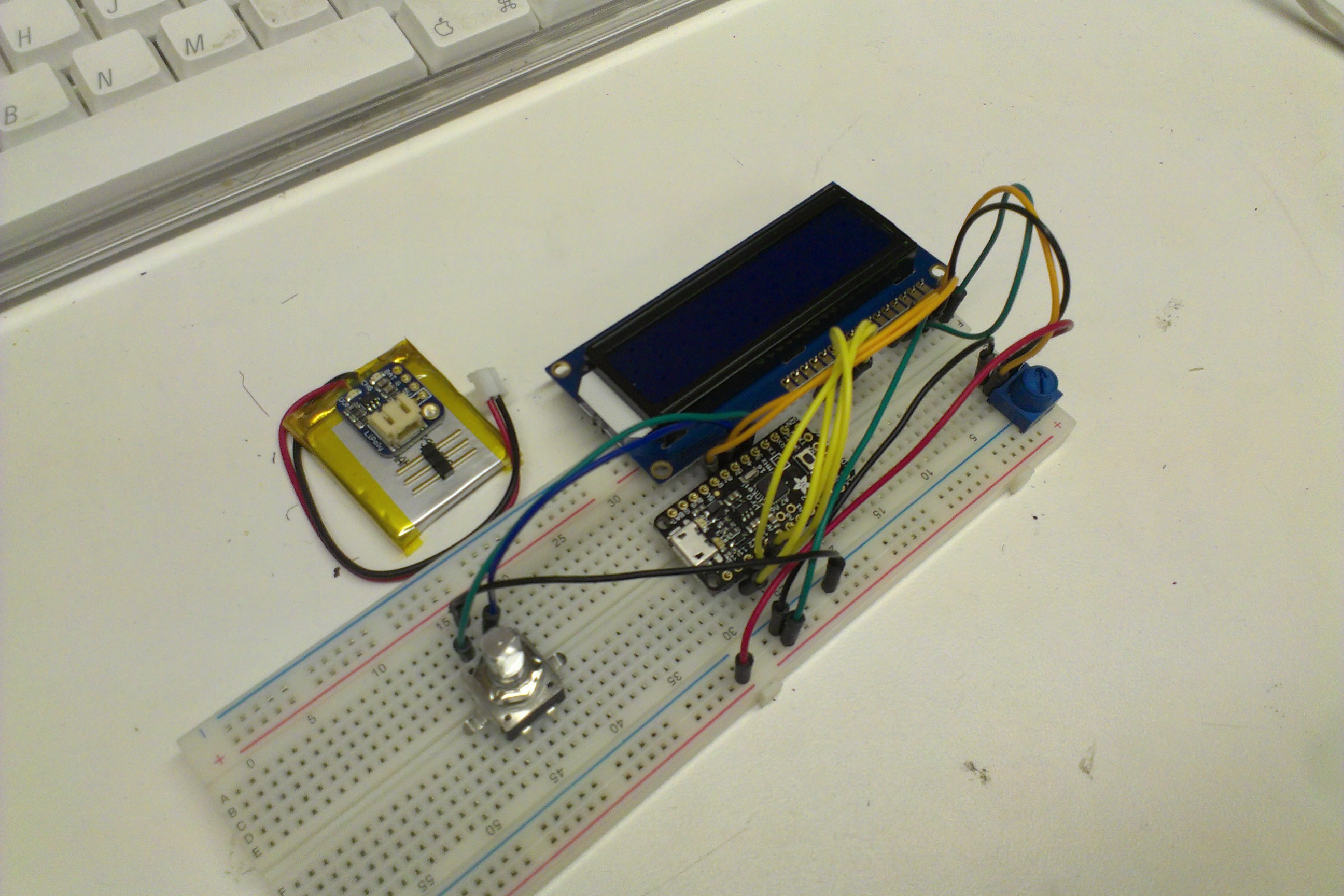

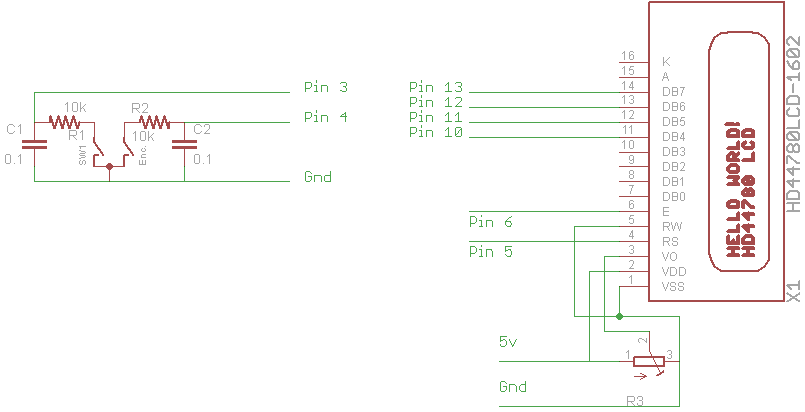

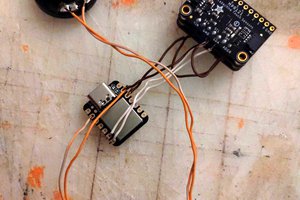

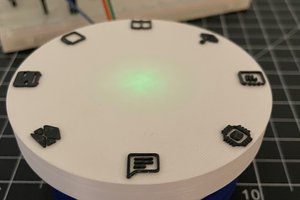

Measuring device housed in an Altoids tin. Uses a rotary encoder with a wheel to estimate distance and display measurements on an LCD.

Kal

Kal

conradcn

conradcn

Virgilius1995

Virgilius1995

this is funny, but I'm working on building another hackaday.io project someone showed recently. Theirs is a trinket hid caliper. I then suggested adding a rotary encoder, optical encoder to them do the hid output. As a community we can build an all in one accurate measuring device. Set up sensors on table saws, and you can have digital record of measurement and current position.