Making mistakes ..

At the beginning I just wanted to remove my glove box in order to change a blown fuse, unfortunately I also broke a plastic hinge in the process.

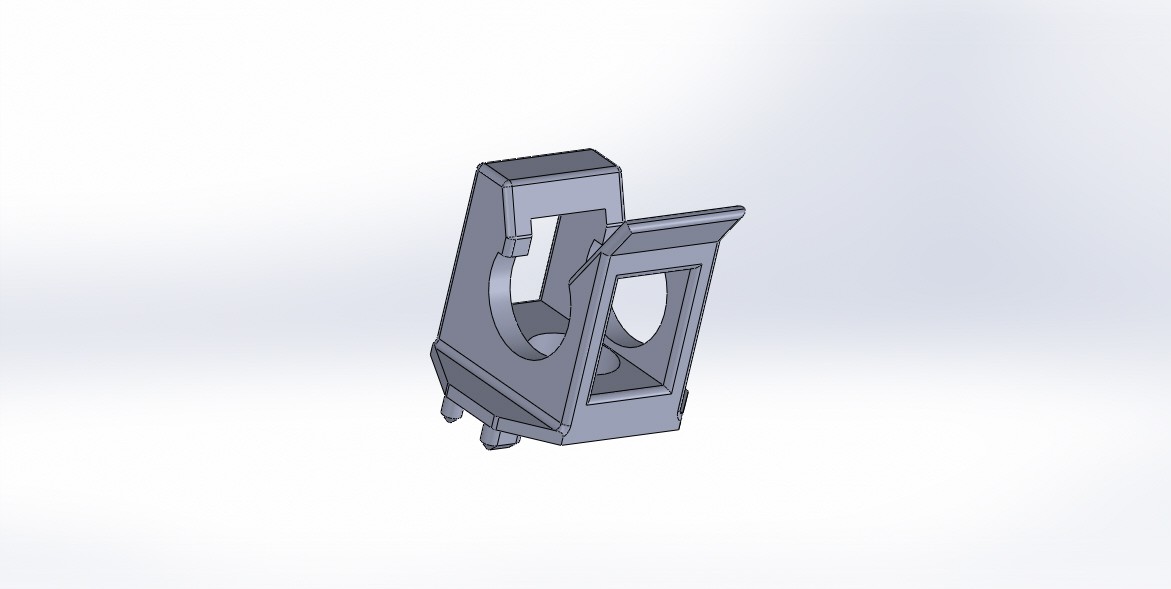

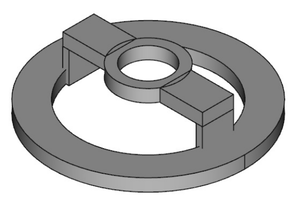

The glove box area, the blue part is the replacement, the black one is the original.

I looked on ebay for a cheap replacement, nothing was available. One specialized website offerred a complete glove box replacement but it was really expensive. Crazy glue didn't work very well as the part must be a bit elastic when the glove box is inserted or removed.

Thankfully, the right hinge survived, like an endangered species, I was able to clone it

Since I had almost unlimited access to Up Box 3D printers witch print fantastic ABS parts, I thought 3D printing could be my saviour.

The design

I decided to take measurements and recreate the part using 3D printing. Since the pastic i'll be using has different characteristics, I didn't do an exact copy. Also injected plastic parts are usually complex for various reasons including being moldable, reduce plastic volume etc ...

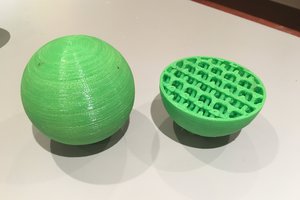

The 3D print

I printed two copies with various orientations, one broke right away as expected because the Z axis orientation made the legs very fragile. I installed the second one 3 years ago, it's still does its job perfectly as of today.

The 3D printed clone, who said clones were color accurate !?

Brieuc du Maugouër

Brieuc du Maugouër

Liam_Thompson

Liam_Thompson

Aidan Leitch

Aidan Leitch

Katie G

Katie G

Hello, Believe it or not, a dirty car can have a slight impact on fuel efficiency. When dirt and grime accumulate on the exterior, it can create additional drag, making the engine work harder and potentially increasing fuel consumption. Keeping your car clean can help maintain optimal aerodynamics and potentially save on fuel costs visit azureautodetailing.com/