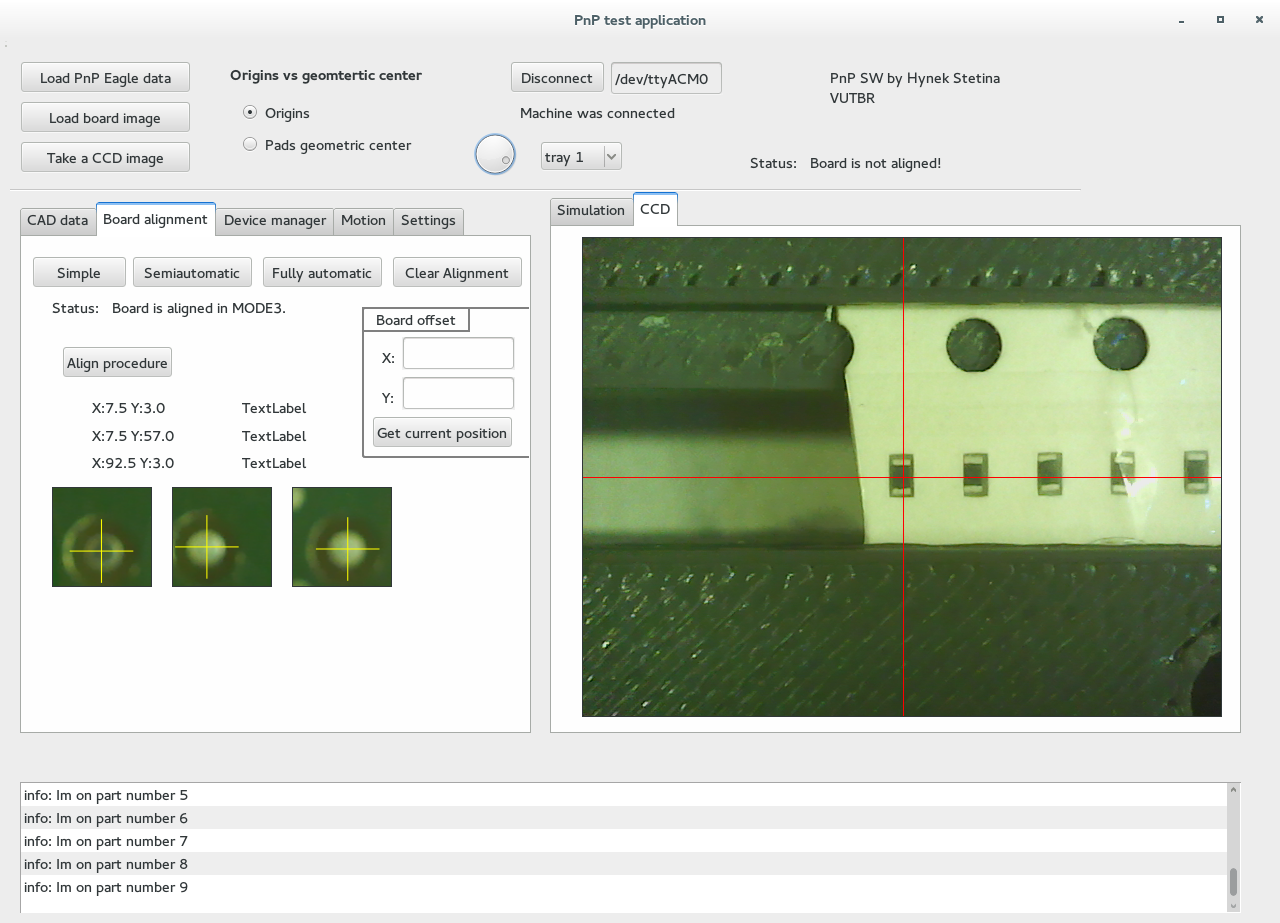

Project goals:

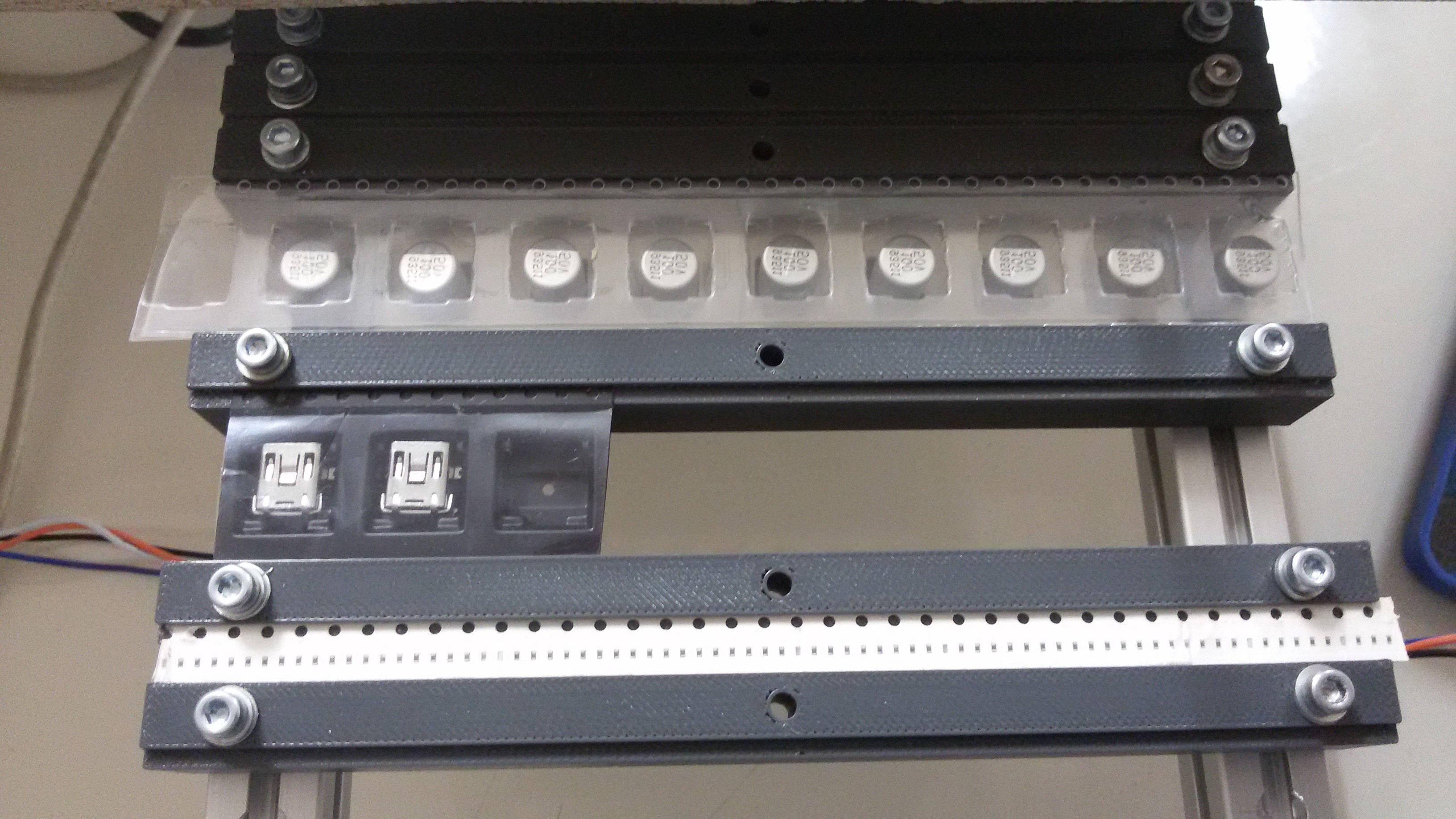

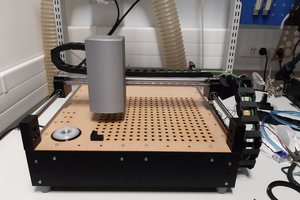

- at least one 250x150 mm PCB

- must be able to handle with 0603 components

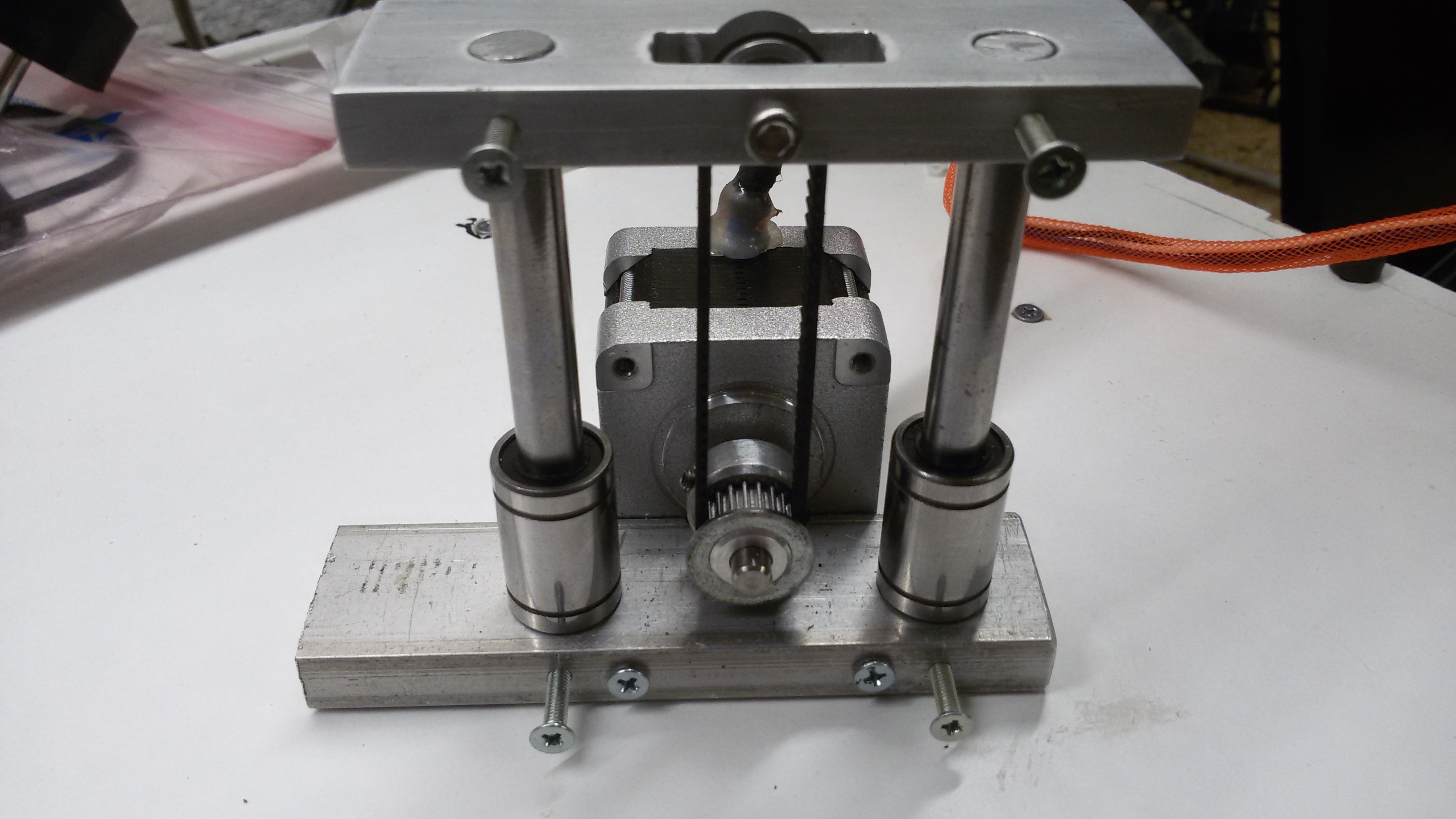

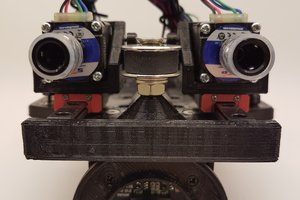

- one picking head

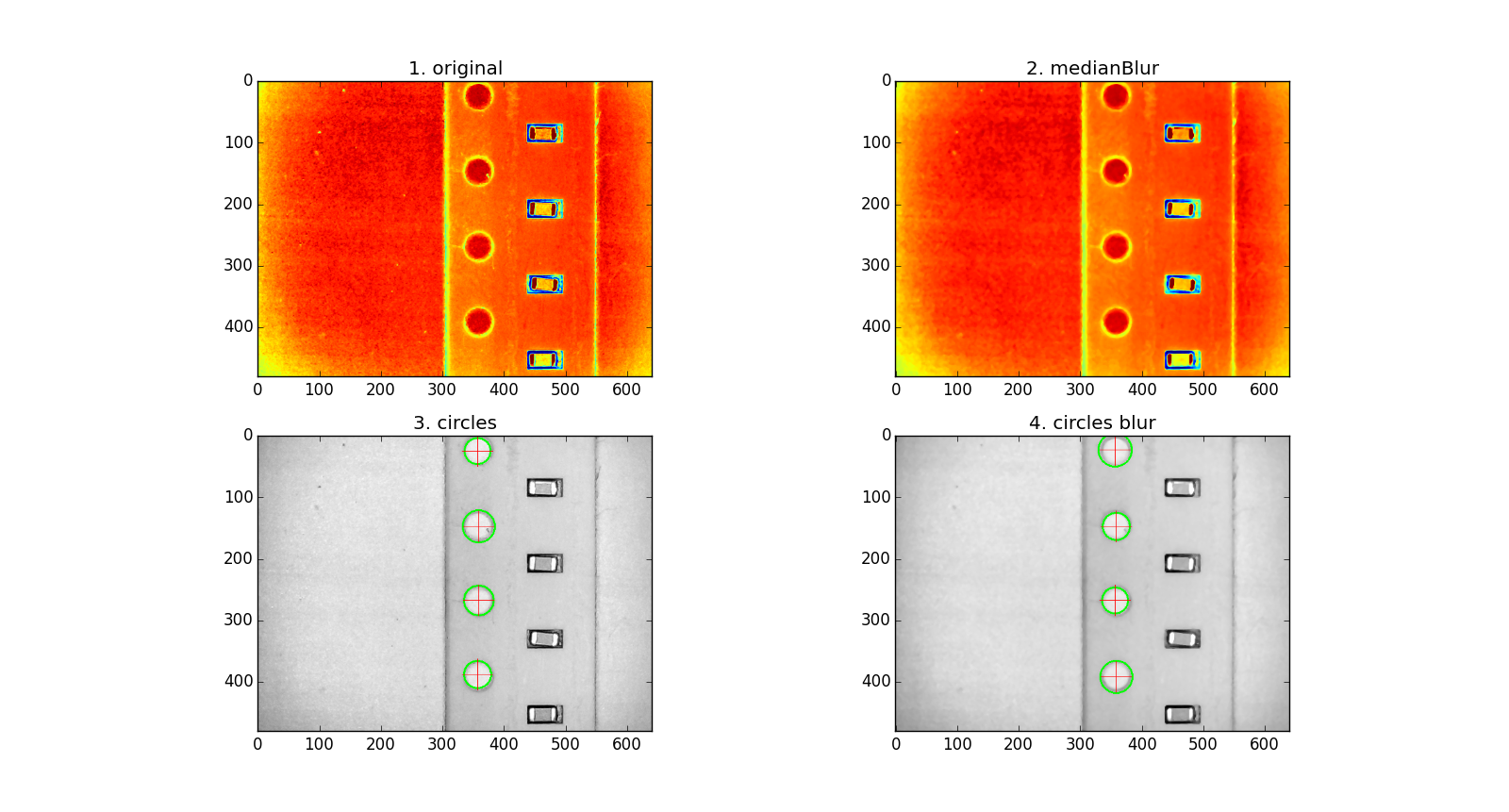

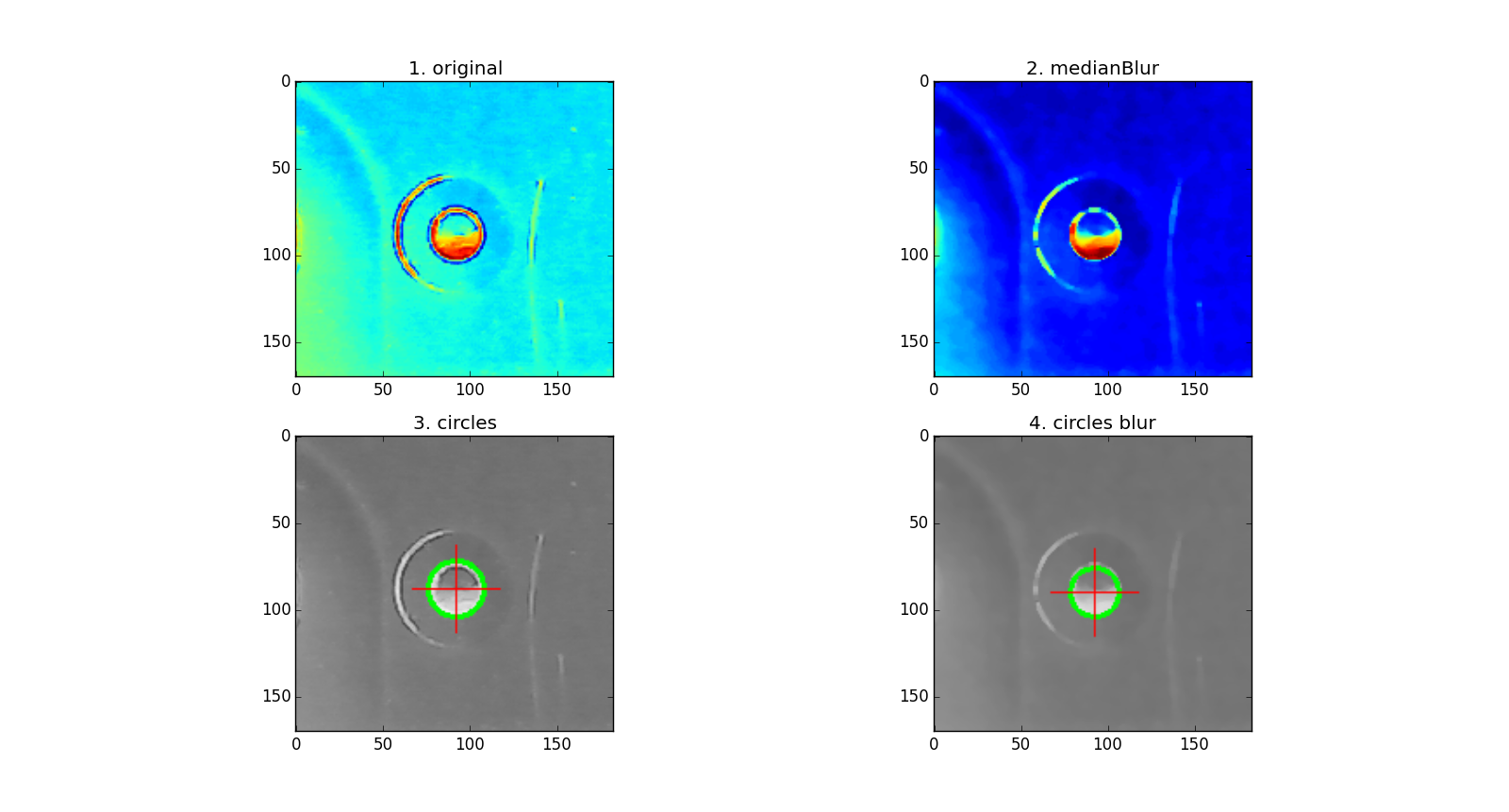

- vision system (top and bottom camera)

- reasonably fast and accurate

- This will be a pick and place machine - So don't expect any 3D printer/laser cutter addons.

- Custom electronics, no Arduino at all.

- only static feeders for components (or adopt something from FirePick)

- use as most of the stock parts as possible

- Intuitive SW

- Deadline is set to 1st May (So i have about two months to finish)

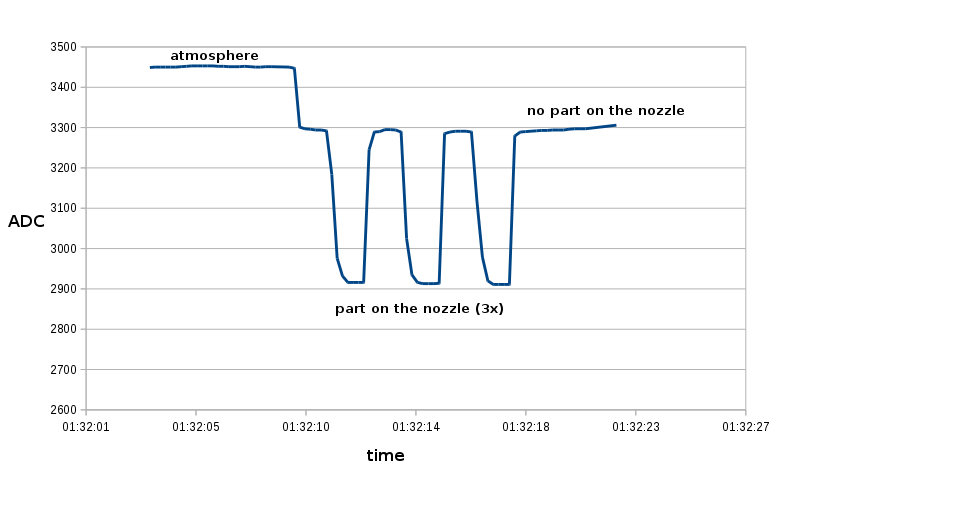

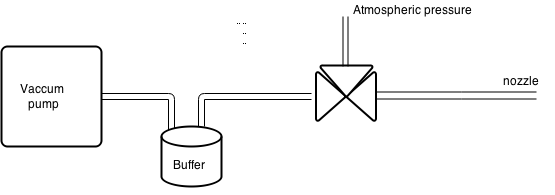

Output is set to 3V at atmospheric pressure and goes down to 2V when pump is directly connected. This should give me enough range to detect presence of components.

Output is set to 3V at atmospheric pressure and goes down to 2V when pump is directly connected. This should give me enough range to detect presence of components.

Giovanni

Giovanni

Fabian

Fabian

Douglas Miller

Douglas Miller

Miroslav Zuzelka

Miroslav Zuzelka

Great project looking forward to seeing it progress!