Here are links to download custom parts:

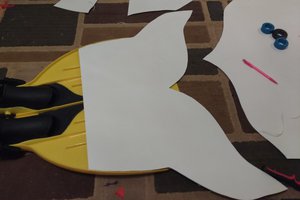

STL files for 3D printing (untested, but I bet it would work fine)

http://s000.tinyupload.com/index.php?file_id=09098959973777174112

STEP files for machining or import into CAD for mods:

http://s000.tinyupload.com/index.php?file_id=00751233921801579441

Notes:

- The arbor press I used has a 1.5" x 1.5" square ram, this may be different on your arbor press and will require a tweak to the design.

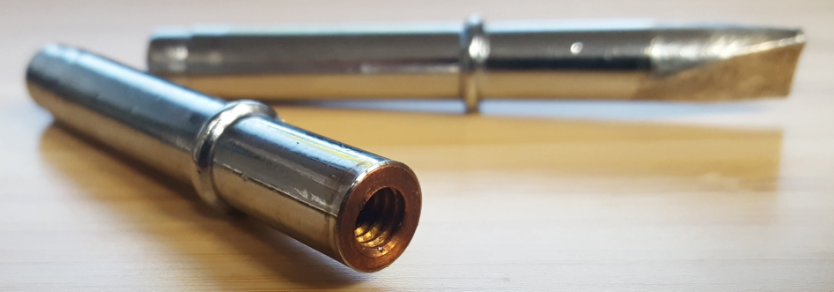

- You will need a #4-40 tap to add the threads necessary to assemble the parts.

- For consistent press depth, install a shaft clamp to the top of your arbor press ram and clamp it down where you want the press to stop its downward travel. I have linked to a shaft clamp in my components list. Make sure you get the right size for your arbor press though.

Alex Rich

Alex Rich

Quinn

Quinn

Supplyframe DesignLab

Supplyframe DesignLab

Michael Barton-Sweeney

Michael Barton-Sweeney

Hey Alex,

I'm interested in building something like this, but the files are gone from the links you provided. Can you upload them to the project files section?