This was a succesful investigation into graphene synthesis and application.

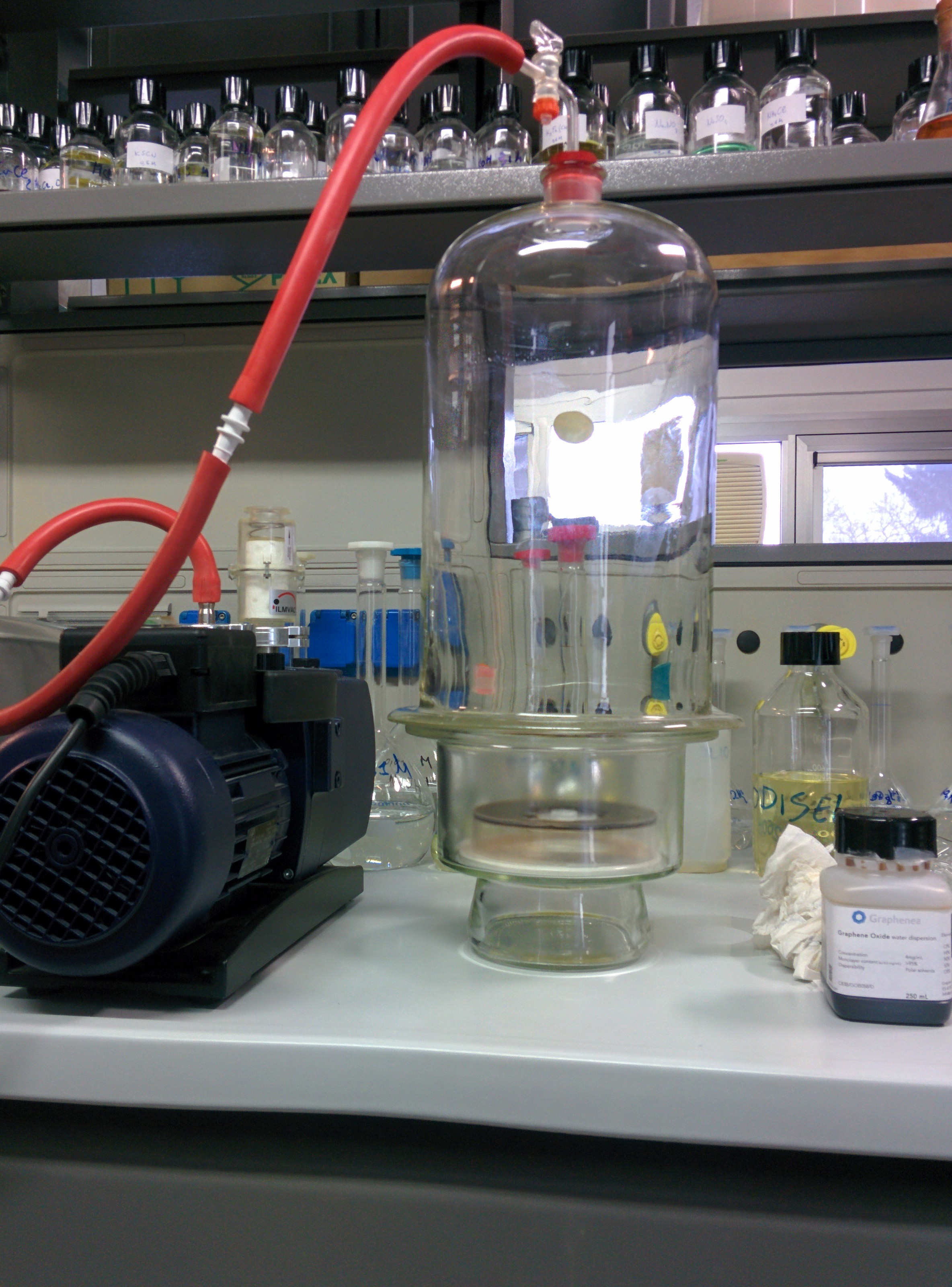

Materials used include:

Standard Lab equipment (glassware and the like)

PET film

Solid Graphite Oxide

A "lightscribe" enabled CD drive, along with CDs.

Solid polyvinyl alcohol

80% phosphoric acid

Repositionable adhesive

Other various apparatus (Clamps, hot plate, vacuum pump, sonication equipment etc)

Process:

Solid reduced graphite oxide (Hummer's method) was prepared in a solution at 4 mg/mL, then left under sonication overnight. The subsequent single layer dispersion of graphene oxide solution was drop cast onto PET substrate cut to to size for the lightscribe discs. The assembly was vacuum formed, then dessicated. Using repositionable adhesive, the prepared substrate was affixed to a lightscribe compatable disc, and irradiated six times. The presence of synthesized graphene is visually apparent, but also confirmed with a resistance of ~9 kOhms, compared to nonconductive RGO. In reference to El-Kady SEM imagery, the LSG is not single layer, but a network of expanded single layer sheets, which is functionally equivalent.

Next, two small rectangles of LSG were cut from the irradiated disc. A polymer gelled electrolyte was prepared by hydrating PVA powder, then combining at a 10:1 ratio with concentrated phosphoric acid. The resulting gel was cooled, then applied in a thin layer to both sections of LSG. The halves were combined, and allowed to dry, forming a solid state capacitor. Measured Resistance was ~11 kOhms, and capacitance was ~14 microFarads, predictable due to the extremely small active area. The capacitor was then charged to one volt, and a dischage curve was obtained, which agreed with theoretical calculations from the RC constant.

Aron Molnar

Aron Molnar

Brainy.Baboon

Brainy.Baboon

M. Bindhammer

M. Bindhammer

Adrian Freed

Adrian Freed

Have you tried on make carbon nanotubes?