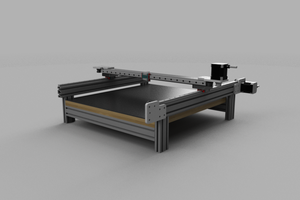

The goal here is to have a machine the requires no babysitting. We want to hit run job, and continue working on other tasks. The video below will show current progress on the unit.

Our latest test video is above. This is the official release video for our pick and place project. You can see everything here that we do. Auto tool changing, multi-board placement, feeders, trays, cut tape, computer vision, software/UI, and more. It doesn't end here either. This is a product we will be using ourselves we have a vested interest in updating it, and keeping it as awesome as possible.

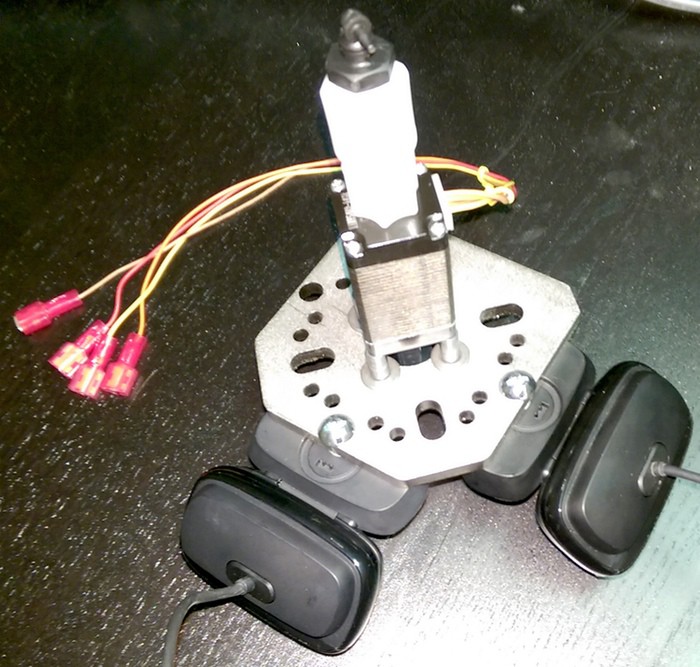

As you can see in the video the machine goes to the part, aligns over top, and picks. Then, aligns again for placement. This gives us very accurate placement of small parts, and low pitch parts. In the video you can kind of see our feeder working. All parts are picked from the same feeder position. The feeder feeds the part into the well, and peels the clear plastic back all automatically.

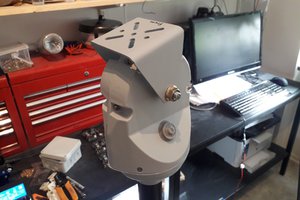

The unit currently places at about 800 components per hour, has automatic tool changing for different sized parts, has breakthrough computer vision, and robust automatic feeders. Also, the software is very easy to use.

There is still work to be done, so continue to check in, and see the progress of the machine :D

Here is a demo of the UI.

As you can see we have two camera views. From each camera we select an area of interest, and from that area we use the CV to make sure that any offset is corrected. Also, you can import any PCB layout to the "Job Details" area. In our case we used KiCad.

ProtoVoltaics

ProtoVoltaics

Juha Kuusama

Juha Kuusama

Daniel Nikolajsen

Daniel Nikolajsen

anthony.webb

anthony.webb

anyone who would like to improve machine let us know we can supply with powerful diode lasers (Endurance)