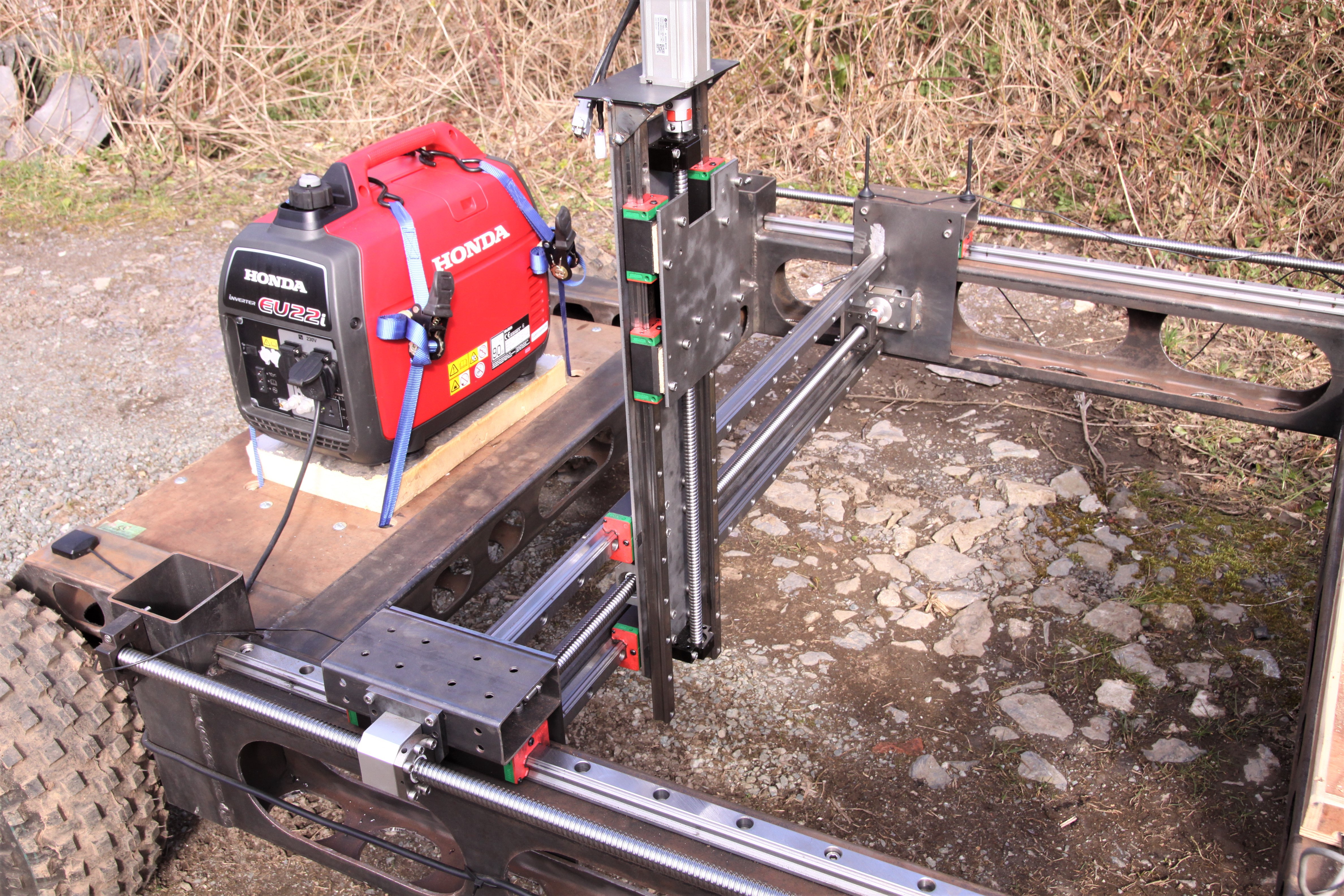

And just to remind ourselves of the build process:

Strangely, it's actually looking very similar to the CAD design.

Although the CNC build went quite smoothly, I did make one critical error by getting the Z axis ball screw out by 20 mm. It really has to be correct to about +- 1mm. Optimistically, I took the screw and nut assembly to my friendly local machinist to remove 20mm and we looked at the nut quizzically. It would not fit in the lathe with the nut on. Should we remove it? After some debate, we decided to remove the nut, aware that a load of bearing would fall out which would need to be captured and replaced after the machining was finished. We successfully caught all the bearings, but could I get them back in again? I tried for several hours but no success. Fortunately, I've got another delivery from Fasttobuy in the offing, so managed to get a replacement screw and nut kit for $30 and no additional postage. Hopefully it will now be the correct length from the factory.

Replacement ball screw kit and additional motors should arrive early next week together with some drive motor upgrades so should be able to make the machine drive a lot faster!

Capt. Flatus O'Flaherty ☠

Capt. Flatus O'Flaherty ☠

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hello, I started following your project yesterday. What I find really interesting is that your build will end up having many uses. A simple, powerful X Y movement has been on my mind for years; glad to see the Weedinator project come along.

The only thoughts that I have right now to put forward is this: Once the Weedinator in this form is perfected how about improving the ground clearance and adding additional X Y movements to the sides? I also imagine the top X movement to be modified to change the device width in conjunction with a dedicated overhead track system.

I weld & tinker if you want an accomplice; I need to be brought up to speed on the motors and control software though.

Have a good day.

Brett

Are you sure? yes | no