The CL2909 is fairly easy to crack open once you know what you are dealing with.

Basic access can be performed via the following:

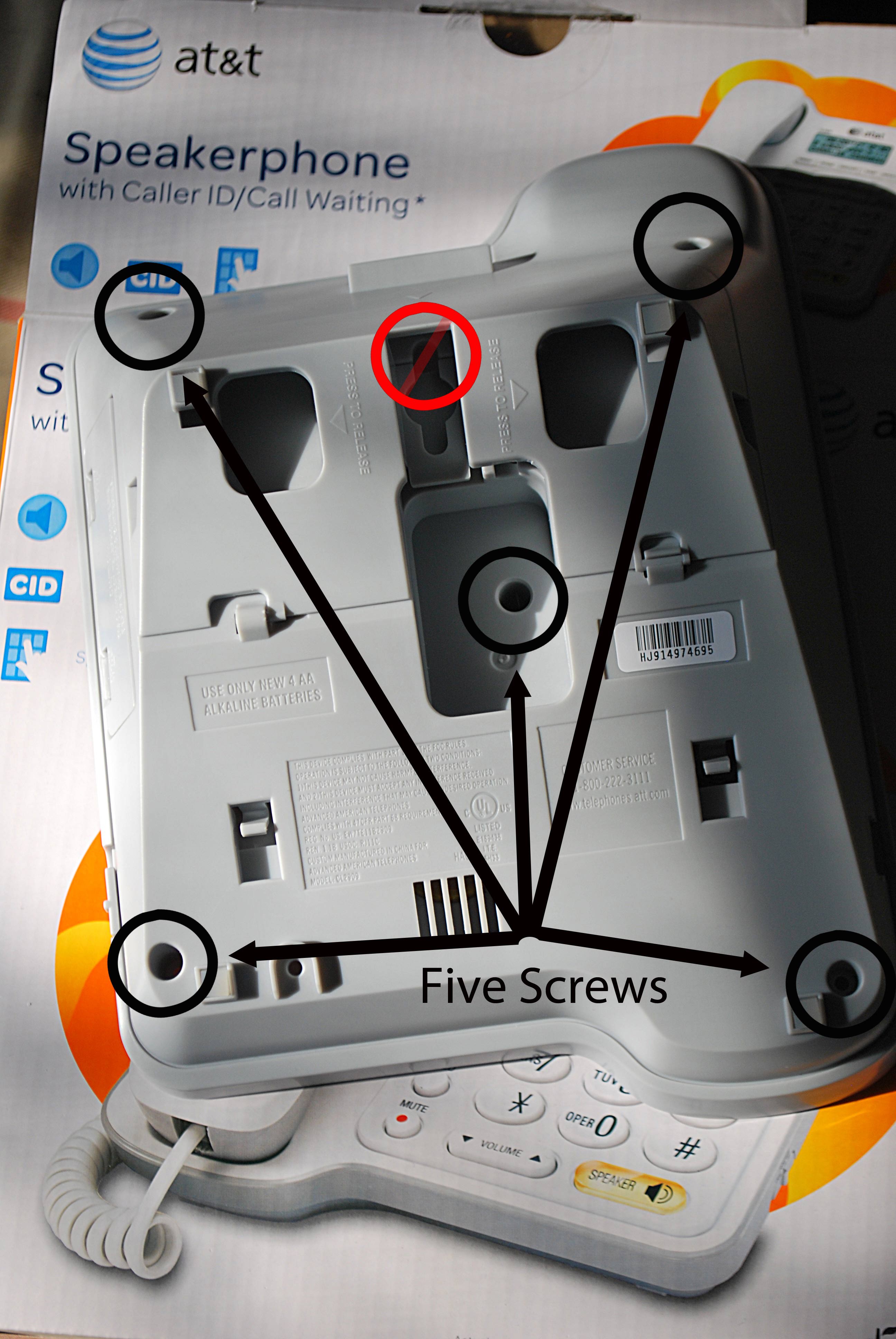

- Turn the phone over on it's front and remove the following five screws. The 'observant' or 'curious' will realize at this point the front 'sunk in' casing just 'almost' wants to pop out at this point but not quite, and thus will notice a deep sunk screw in the red 'verboten' area as marked. Just ignore this.

![]()

- Turn the phone back over, front-facing side and one will notice the right side front cover will lift, but the left will not. Gently leverage the right side with a flat screwdriver, etc.

- I've tried to highlight the seconds that are impeding opening the device on the left side-- really just some very minor/slight tabs at three contact points. I've tried to highlight both. One could either approach this side with a second flat screw driver or just keep in mind that the cover must be lifted off gently from the right side to preserve reassembly. However one goes about it, in my experience it always helps going in to know where the stress/contact points are rather than having at it blind.

![]()

![]()

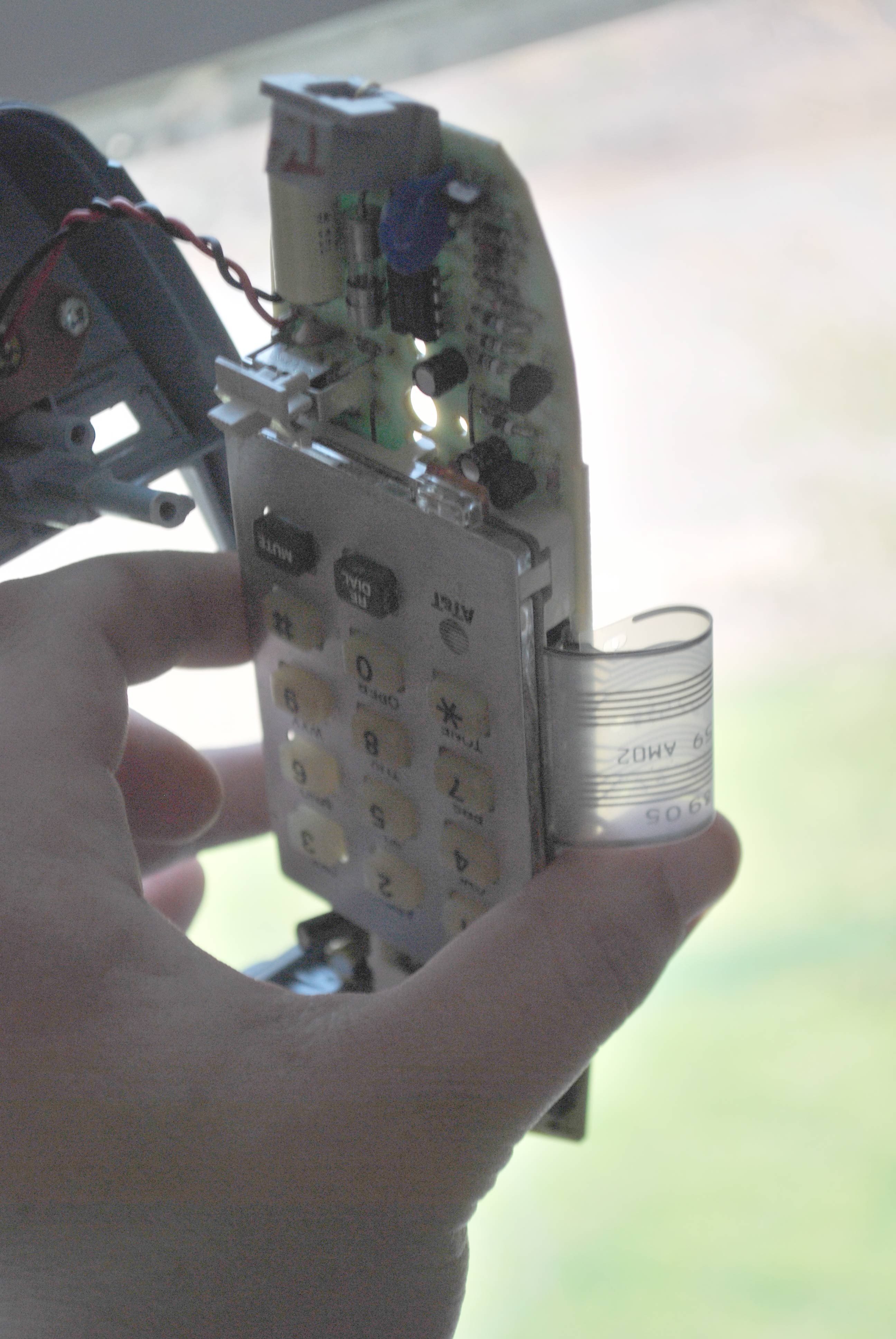

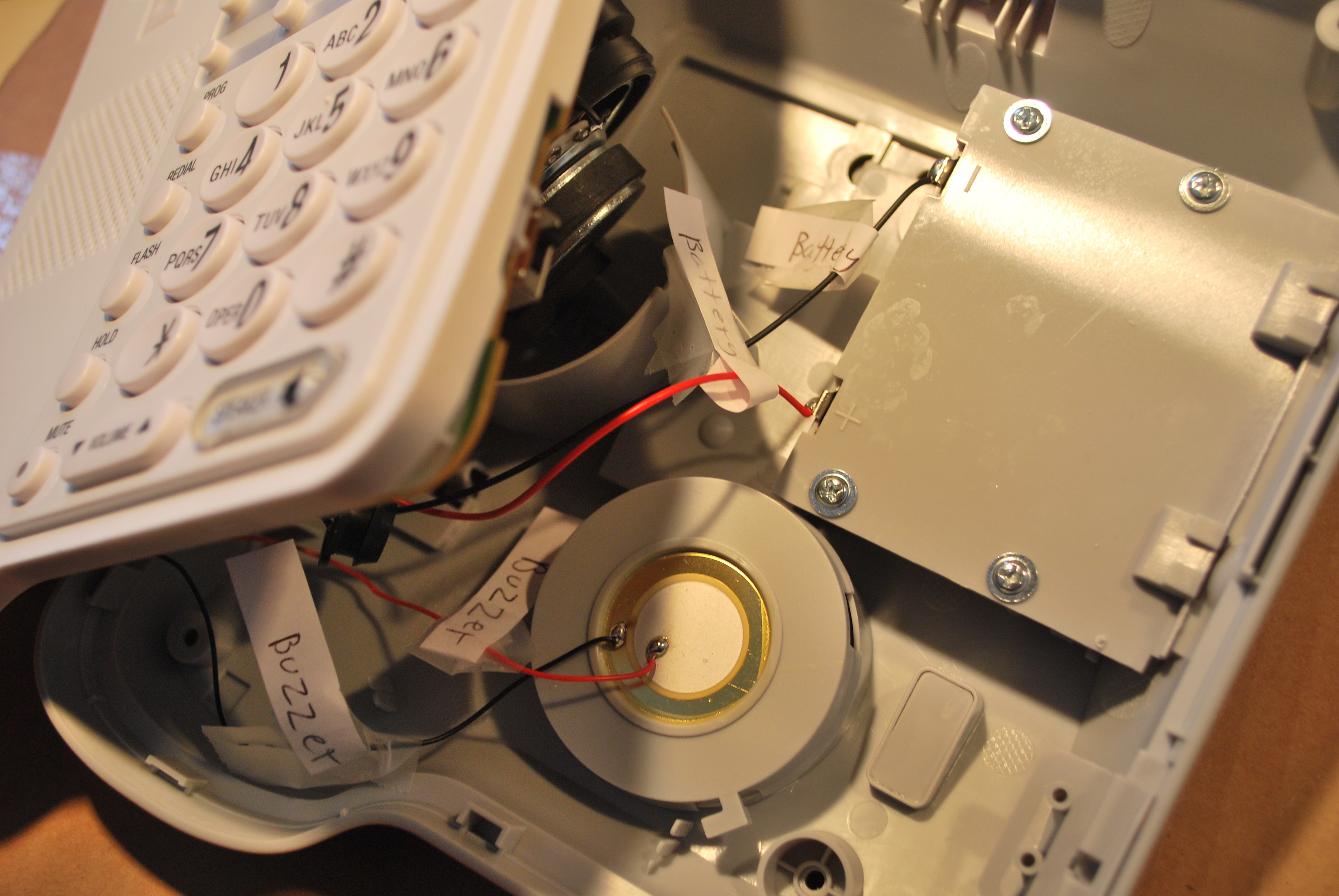

Once the device is opened, the next step is actually 'optional', but I find much easier to deal with (and as well as a couple of points not covered here, but should be obvious upon reaching this step-- That is, the handset rocker switch [which is encased], the 'Ringer' volume switch, and the handset jack itself on the side).

First one will find two (or three, depending) 'restraining' connection +/- wire pairs going to off-board elements. In this particular case, with this revision, the device is exceptionally 'good' about it as it is clearly stated on the silk screen which pair go to what (buzzer/battery), but always good to take the time to market/label them before removal.

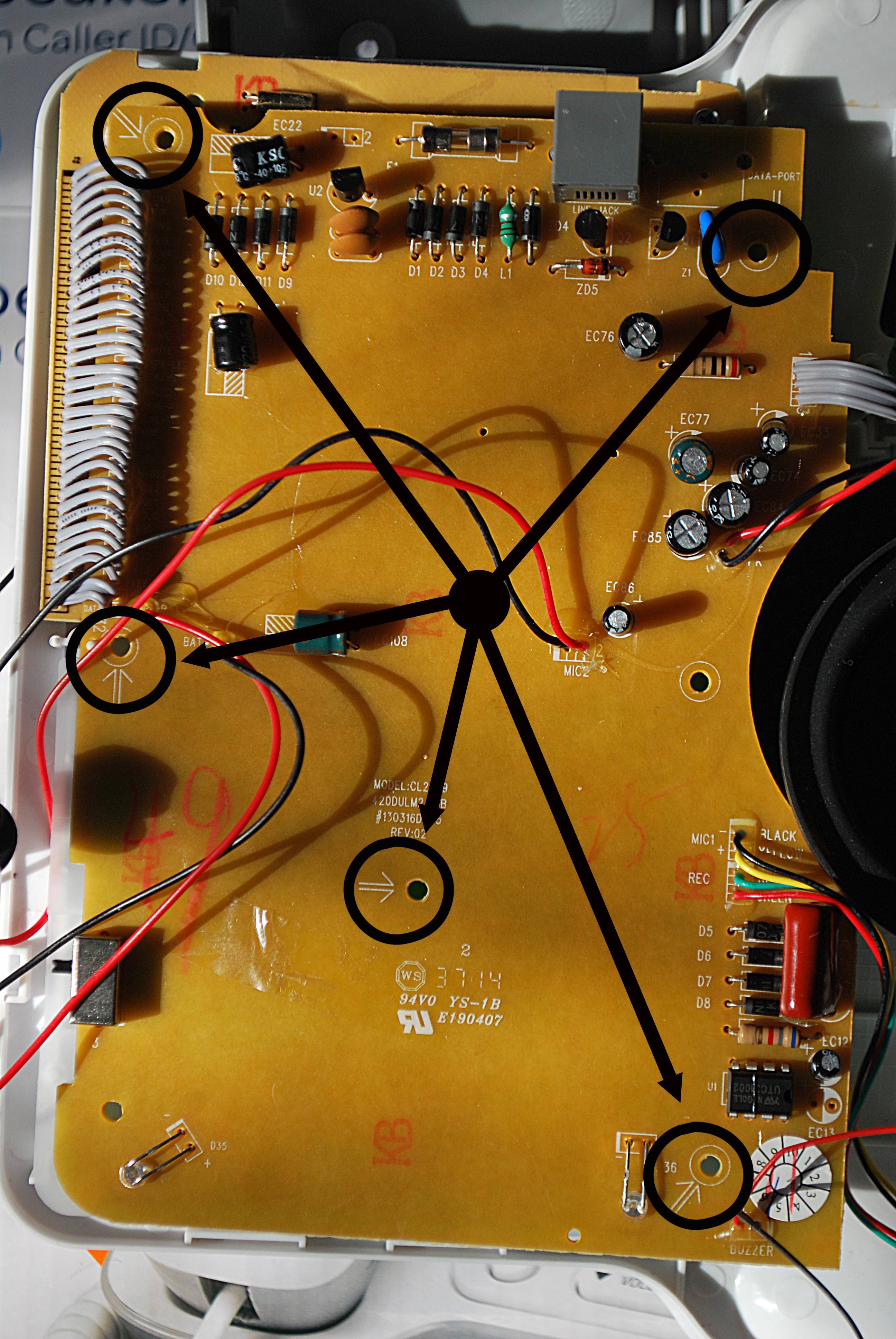

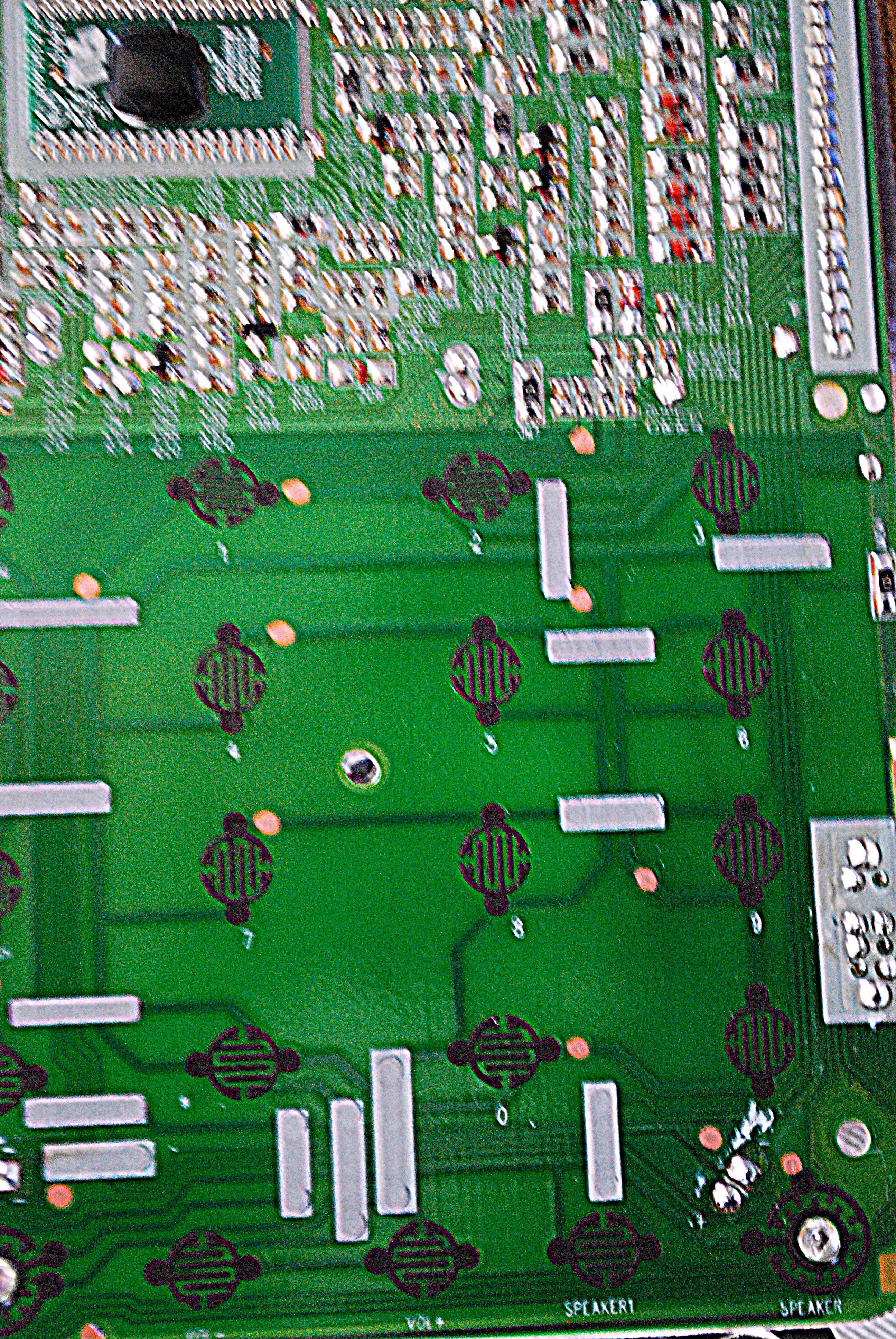

Turning the front panel face down now we need to remove, again, five screws, which are pretty clearly referenced on the solder mask of the board but I have pointed out below for reference.

At this point, it is interesting to note, from my originating statement the combination of SMT/SMD and through-hole devices used here.

At this point, it is interesting to note, from my originating statement the combination of SMT/SMD and through-hole devices used here.

As mentioned, a similar late 70's/early 80's style device I first tried to work with:

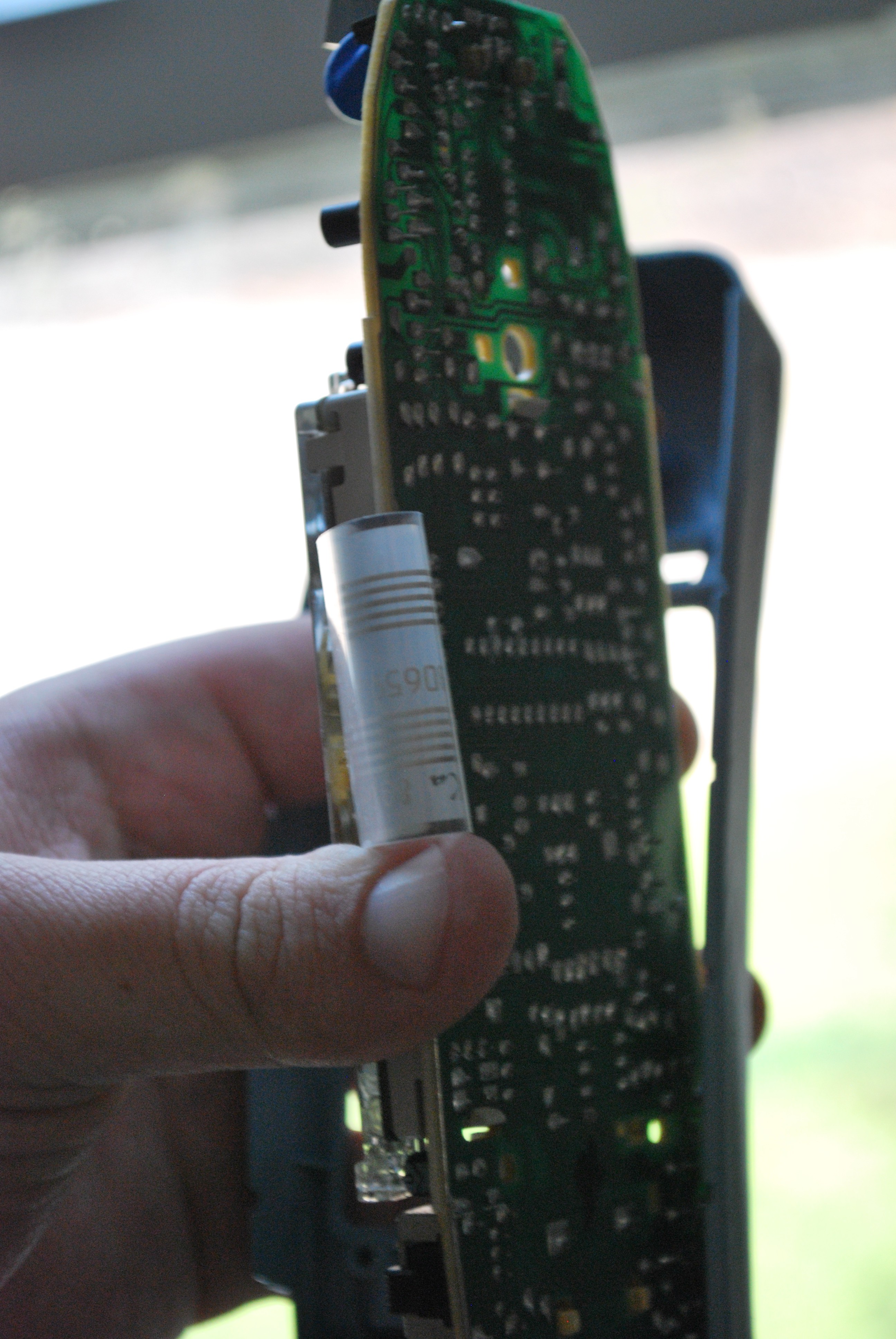

In contrast, here all 'appearances' suggest this is a really but a 'one layer' board but with very different technologies on either side... Above, side (A) (in brown), with 'through hole parts' [but notice no traces] and below, overturned, side (B), full of SMT/SMD parts.

I found this interesting as the combination between the two component types tends to be rather rare today, especially in 'hobbyist' devices, but the inspiration is on the order of shaving pennies of cost on several million devices. Or this board has only single side traces, which are much cheaper, and since there is 'extra space' in the case itself through hole caps and fuses are used on the reverse side of a single board layer layout.

More on the button layout and activation (for someone new to this at first one might ask, what is that ?! Captive touch ?! But it is just a traditional silicone rubber type, again frequently found in industry but perhaps less so in the hobbyist market.

Plus, then we will also properly reveal the traces (what the fiberglass pencil is all about-- and though I had heard of this before, let me tell you it is *amazing* at lifting solder mask without damaging traces. I am surprised it is not available at places like Digi-Key, etc, but should be a vital tool in your kit for hacking/PCB rework) once they are all proofed out.

Anthony

Anthony

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.