When testing I noticed that my wiring of the 75HC595 shift registers was based on an old, and not that great, example I found some time ago and that it needed to be tweaked. Sadly due to the tight placement of the surface mounted components and their tracks I had to lift a couple of the legs of the shit registers and run bodge wires to rectify the situation - which would make the units unusable for usability testing... Well, shit happens and I instead rebuilt the new design on a breadbord to verify the changes. (This is why it's a must to keep a stock of older thru-hole components even if you only use surface mount stuff in the final work!)

The two minor changes meant I had to ripup most of the board, but I started and although it went fine initially I quickly ran in to what I call "ugly routing" and I did a ripup and started again... and again... A few hours later the bottom ground plane stopped pouring and now I was both tired and frustrated because I really try to do all of my projects from scratch in order to learn and I rarely copy existing designs. Yes, I know I'm re-inventing the wheel every time but I want to learn something and not just copying!

In the end I felt I was stuck with a mess and I really want to be able to offer the Timstock Slim to all of those who really need it out there in the world, and quality is way more important than my ego or me doing every little bit myself so I one again decided to ask the ever so kind user kizzap over att EEVBlog forum. Back when I started this project about two-ish years ago I got superb help from him, and a few others, and before this I didn't know what I was doing in Eagle. I'm a software developer with 20+ years in the telecom industry but my exposure to hardware has all been learned at home from tinkering and repair, but making my own circuits and such I only started with about three years ago so I still have a lot to learn.

Anyhow, I sent the files to kizzap and asking him for some routing help and perhaps some pointers where I went wrong? I explained what I was trying to do and that I was a bit stuck at the moment...

Today I got a message back from kizzap and not only had he looked at my routing - he had given the whole project an experts overhaul and done a really good job! I'm ever so grateful for the kind help he gave me and this is also why I'm writing about it here in detail because he really deserves credit for his contribution! Thank you kizzap! It means a lot to me getting the kind help, and it will help the project to reach its goal :)

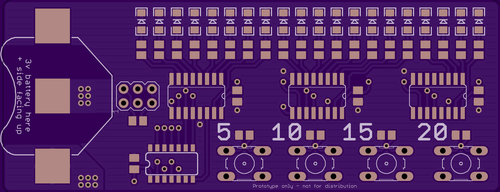

New boards have just been ordered from OSHPark - my favourite pcb supplier! Not the cheapest, certainly not the fastest with regards to shipping to Sweden, but they have the best preview order system IMHO and it makes it a lot easier for us who still have some experience to accumulate...

The board is now 5 mm longer but the layout is less compact and the components are spaced better. kizzap also did some magic where the battery holder goes in order to make a better connection by removing copper around the contact surface, and thus making sure the contact will be good. He also moved the ISP header and soldering these new boards will be a lot simpler.

The first units will be delivered to Barnhabiliteringen in Ystad, Sweden, for evaluation with autistic kids in various ages during the summer and feedback from them will be implemented and respun (hw) if needed. At some stage I'll need to make a custom enclosure as well in order for the Timstock Slim to be attached to a keyring or a lanyard around the neck. Perhaps it might be possible to do some conformal coating in order to protect the components and traces from shorting out but every little extra step will affect the cost, so an optional enclosure (which can be easily 3D-printed) will be the way to go. I don't know how many units I have to order for injection moulding starts to pay off, but that's not something I need to think about at this stage...

I'm now glad I ran in to a bit of trouble with Eagle because the overhaul kizzap did for me has put the project in a much better state with regards to quality - and that it has been reviewed by an expert certainly feels great for me as I keep pushing on!

p.s The cock on the bottom silk screen is my first Brahma cock that I hatched when I bought my old farm 8 years ago and he kinda became the mascot of where we live! He's now sadly no longer around since Mr. fox got him a few years ago, but his offspring are running around free here and chickens are part of our life ever since. Great responsibility for two boys as well since there are eggs to collect and food and water to be catered for.

jens.andree

jens.andree

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.