Bipolar dudes

A group for those who want to build their own bipolar transistors

A group for those who want to build their own bipolar transistors

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

RFT1.jpgTelefunken Experimental Germanium Point Contact Transistor- 1953JPEG Image - 291.88 kB - 10/19/2018 at 20:55 |

|

|

One reason we love old equipments/parts/technologies is they are more "graspable", easier to understand. They are not a magic black box and we can "see" them working. That's why we love relays, flip-dots, and other electromechanical devices so much, despite their ridiculously poor performance or efficiency. This is a bit less so for vacuum tubes, though "microphonics" (?) effect can be observed in some conditions, but for transistors, which are usually metal-canned or epoxy-potted, forget it. You can't "see" a circuit working, unless you add LEDs for examples (extra kudos for Tim with his #LCPU - A CPU in LED-Transistor-Logic (LTL)). But still, this is far from a completely direct observation of the circuit's working.

Then I got a batch of OCP71 on eBay.

They are a variation of the vintage OC71, Germanium PNP in glass housing, with 2 modifications to make them useful as photo-sensitive transistors, or even phototransistors : no black paint, and the filler silicon is transparent (unlike the diffusing and opaque sludge of the standard OC71). This makes any circuit using them sensitive to light, so expect a lot of drift and weird bugs in "normal conditions". Already the OC71s' characteristics are altered when exposed under intense light (the black paint can't block everything, particularly infrared).

But the photo-electric effect is reversible ! This means that with the right equipment, one could observe the junctions' emissions when the circuit is working. The new problem is that it is not visible by the naked eye.

For example, https://www.rp-photonics.com/band_gap.html says that Ge is an indirect bandgap semiconductor with an energy of about 0.67eV at ambient temperature, translated to a 1.84 μm wavelength. To visualise the circuit, one would need a camera that is sensitive to the 2µm-1.8µm band. This is in the medium infrared, larger than 1µm (the near infrared that your TV remove uses) but smaller than the far IR, or thermal infrared, that is used by thermal cameras for example. Germanium is in theory active around 95THz or an equivalent black-body of 1600K. So it will not be enough to remove the IR filter of a CMOS camera, or use a temperature imager...

The cameras for 1.8µ are much less easy to source cheaply. Worse, mid-IR is a band with military interests : PbS at 3.34µm was used as the first "heat seeking" sensor in Sidewinder missiles, for example. And the exotic chemistries make such cameras expensive AND probably suspiciously considered.

I would love to have a small, cheap camera to record images of a circuit made of the transparent OCP71 transistors and make videos, or even live demos (to kids and old kids) but sourcing the old glass-germanium PNPs was only the easiest part.

I need your help to find, source and get such a camera, if it exists. I have found some but they are either "out of band" or very expensive ("industrial grade"). And I don't see the point in buying expensive gear that I'm not going to use a lot or regularly.

Before you ask, “Why make your own transistors at home??” – read my Manfiesto for Why.

Most of the homebrew community has been focused on fabricating Field Effect Transistors (FETs) at home. Sam Zeloof and Jeri Ellsworth are probably wiser to try and ‘etch FETs’ because they are much better suited to fabricating Integrated Circuits (ICs). ICs were a real revolution in electronics because they miniaturised sometimes enormous circuits into small, convenient packages. Discrete circuits also do not last as long as integrated circuits, because it is expensive to render them mechanically inert. ICs can be completely encased in plastic, shielding their components from dust, and heat, and other kinds of physical mechanical interference.

But, from studying the work of Ellsworth and Zeloof, and following up on their references, it seems that manufacturing the kind of transistors they have, in the ways they have, may still be too expensive and difficult for hackers. So in this article I am going to argue that one option for hackers is to fabricate not silicon, planar process FETs, but germanium, alloy-junction, Bipolar Junction Transistors.

Alloy-junction BJTs are a much older and more primitive type of transistor to fabricate than the planar process transistors that Ellsworth and Zeloof talk about, but I will argue that alloy-junction transistors present themselves as an attractive option for hackers who cannot afford expensive equipment and materials, and who have to push most of the cost of hacking onto using their own labour in order to get things done.

Alloy-junction transistors are not the earliest and most primitive kinds of transistors, but they are one of the earliest and most primitive. These kinds of transistors are necessarily discrete transistors. I argue they present themselves as an attractive kind of transistor to fabricate at home in a DIY, homebrew setting because:

Now, I will describe the rough process of how to fabricate this primitive type of transistor.

First, a wafer of germanium made of a single crystal is formed. This can be done by yourself with great amounts...

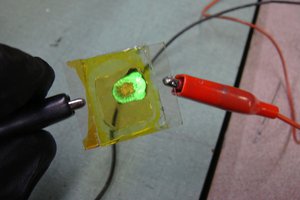

Read more »I got a germanium disc from ebay, and I did a quick test by and found that pointing a scalpel to it it works as a point contact diode!

It is a bit rough but it works!

From someone who discussed with the author of "Instruments of Amplification":

"Friedrichs also had tinkered with cuprous oxide transistors.

What he didn't tell in the book: only one of 10 cuprous oxide transistors had worked as intended,

and they tend to die at 5V+ or so. He wasn't aware of this when testing them with a curve tracer."

But still, 5V is not a crazy working voltage and many circuits use 3.3V.

Create an account to leave a comment. Already have an account? Log In.

Wow, really cool. It features Jim Early who described the Early-Effect.

I really love the rigerous analytical analysis they did of device physics back then. Today, people would just throw it into their numeric device simulator.

Funny, I had not noticed this project before. When I was still in school I also looked into options of making my own semiconductor devices at home. I never took this up again, though, maybe because I had the opportunity to do this professionally for a while.

Some general comments about Silicon vs Germanium: One property of silicon that is often underappreciated and maybe was only fully understood much later, is its ability to form very stable and stoichiometric oxides in a well controlled process by thermal oxidation. (There is the famous Deal-Grove paper). Germanium oxide is water soluble and many metals have oxide formations processes that can form non-stoichiometric oxides. This fact alone makes silicon perfectly suitable for field effect transistors, while this is extraordinarily hard with germanium. (The caveat is high temperature, which you pointed out)

Eutectic alloying is a very interesting doping process, but notoriously hard to control. You basically melt part of the semiconductor and recrystallize it again during cooling. The way it recrystallizes is very important to get a well behaved junction. Consider that you need to control your junction depth very well for a bipolar transistor, not so much for a field effect transistor.

I am aware of two places were alloy-doping is still used in production today: Al-(B) alloying for back surface fields in solar cells and AuAs alloying for photodetectors and some discrete semiconductors. In both, these processes are a constant source of process deviations and require very tight control of process parameters including temperature ramp rate and atmosphere.

In short: It's not easy at all :)

One very interesting avenue that does not require high temperature processing could be II-VI group thin film transistors (Which is what I looked into back then). The channel can be formed by a chemical depositon process (chemical bath deposition) or low temperature spray-pyrolisis. The best behaving channel material is CdS, but Cu2S couild also be interesting.

There is one ancient reference to homemade CdS transistors in a Scientific American article:

http://www.1010.co.uk/materials.html

https://brainwagon.org/2011/05/20/diy-fethome-made-transistor-scientific-american-june-1970/

Thanks for these precious data points ! I guess that makes you "one of us" now...

From https://hackaday.com/2019/02/20/retrotechtacular-how-not-to-design-with-transistors/

“Tubes and Transistors: A Comparative Guide” (PDF link).

I would love to put DIY transistors to use.

If we could come up with our own TTL plant that would be so awesome.

I barely remember seeing amateur magazine describing DIY amateur transistor built of two "cat whisker" diodes, dated from early 50's or so.

Yes, this is the route most people take.

Let's see if some HaDers can do it as well :-)

If you feel adventurous, why not make such a group yourself ? Be careful to avoid a FETish pun ;-)

This is awesome.... I reeeeeeeally want to see this happen!

I want to witness this too !

If this works we could even make a whole computer out of them ;-)

So let's gather information, resources, raw material... like true pioneers :-) I'm already trying to train with a bunch of lousy OC70 :-P

DIY fets seem to be a thing already on the web, but there is basically nothing about BJTs. And if it is possible at all, it would be nice if one could avoid evil chemicals such as hydrofluoric acid.

Become a member to follow this project and never miss any updates

Matt Moses

Matt Moses

Michael Barton-Sweeney

Michael Barton-Sweeney

Ian Hanschen

Ian Hanschen

Brainy.Baboon

Brainy.Baboon

https://www.youtube.com/watch?v=5x6Ob3EYkcg Thank you Fran Blanche :-)