The requirements for this project were very simple:

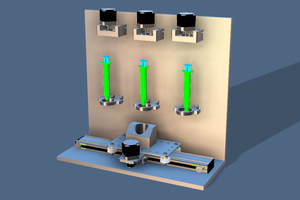

- Hold an SSD without any additional fasteners

- Fit in case's 3.5" drive bays

- Be easy to slide in and out

The first requirement was met by measuring the diameters of and distances between the threaded mounting holes on the bottom of the SSD, and making short truncated cones that would align with those holes. By doing this the thinner tips make alignment easy, and the taper towards the bottom ensures a bit of friction once given a good press.

The second requirement was met by measuring the case, namely the height of the rails and the width of the drive cage. One area for future improvement is to make the rails thinner on the printed bracket, because this is where most of the printing time was taken up.

Having extrusions that curve outward from the bracket provide an easy way to grip the bracket and slide it out without having to touch the drive itself. Every surface the user would reasonably touch is rounded over so that it feels nice.

Simple project, but very useful!

rohanoman

rohanoman

Quinn

Quinn

Peter Buckley

Peter Buckley

hui <ahref="https://www.melamandi.com/dogs-puppies/q-german-shepherd-puppies-for-sale">german shepherd puppies for sale</a>