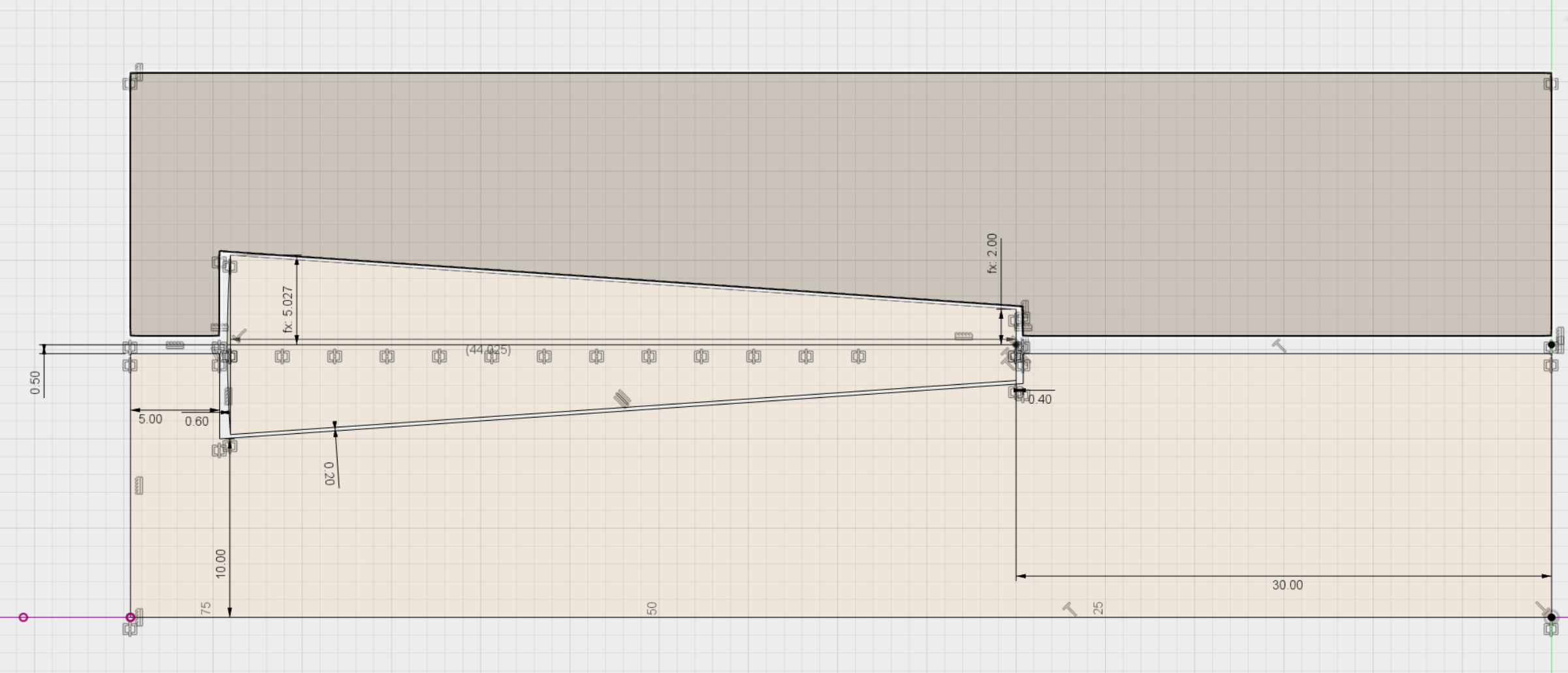

Turns out that the chair’s problem was twofold. First, the beams that the chairs rested on had ripped free, probably during shipping. That was fairly easily remedied by a C-clamp and some screws, but the bearing was filled with lint and other gunk that was making it hard to turn. Unfortunately it was riveted together so cleaning it out was impossible to do. I promptly removed it and faithfully took the dimensions of the holes in the wood and the base that it rested on.

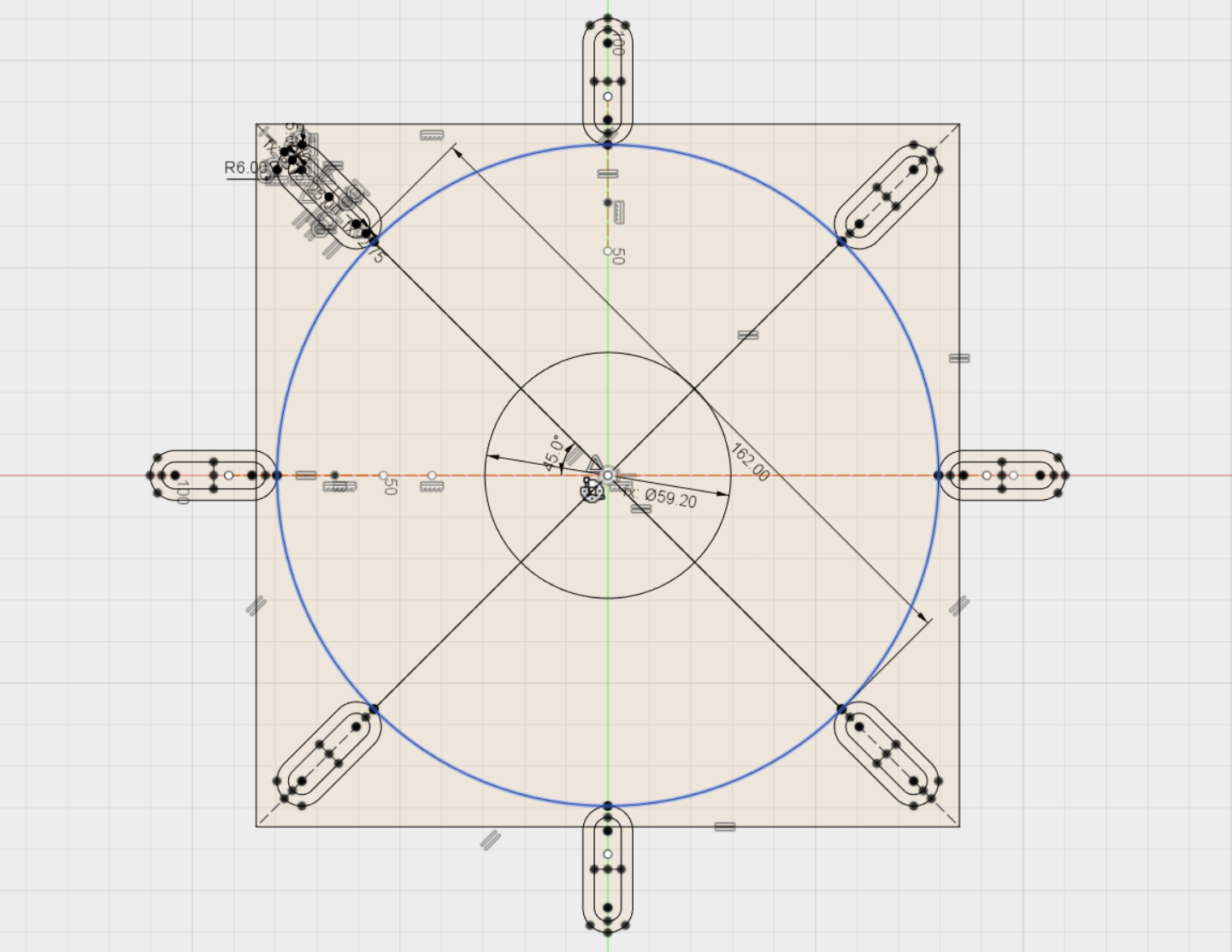

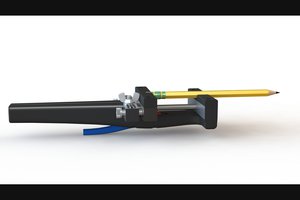

It was inside my 3D printer’s build area by about 10mm. I knew I had found my repair candidate. There was a problem, however. Anyone who has tried to print a ball bearing can tell you that the support material underneath the balls as well as the layer lines of the print make it very hard to print a functional ball bearing. My cheap i3 clone isn’t exactly a precision machine either, compounding the problem. I elected to do a different approach. I decided to use cones tilted on their side as a substitute, and made the taper of them such that the number of rotations of the thicker end was the same as the number of rotations on the thinner end. This should in theory make the cones run in a circle.

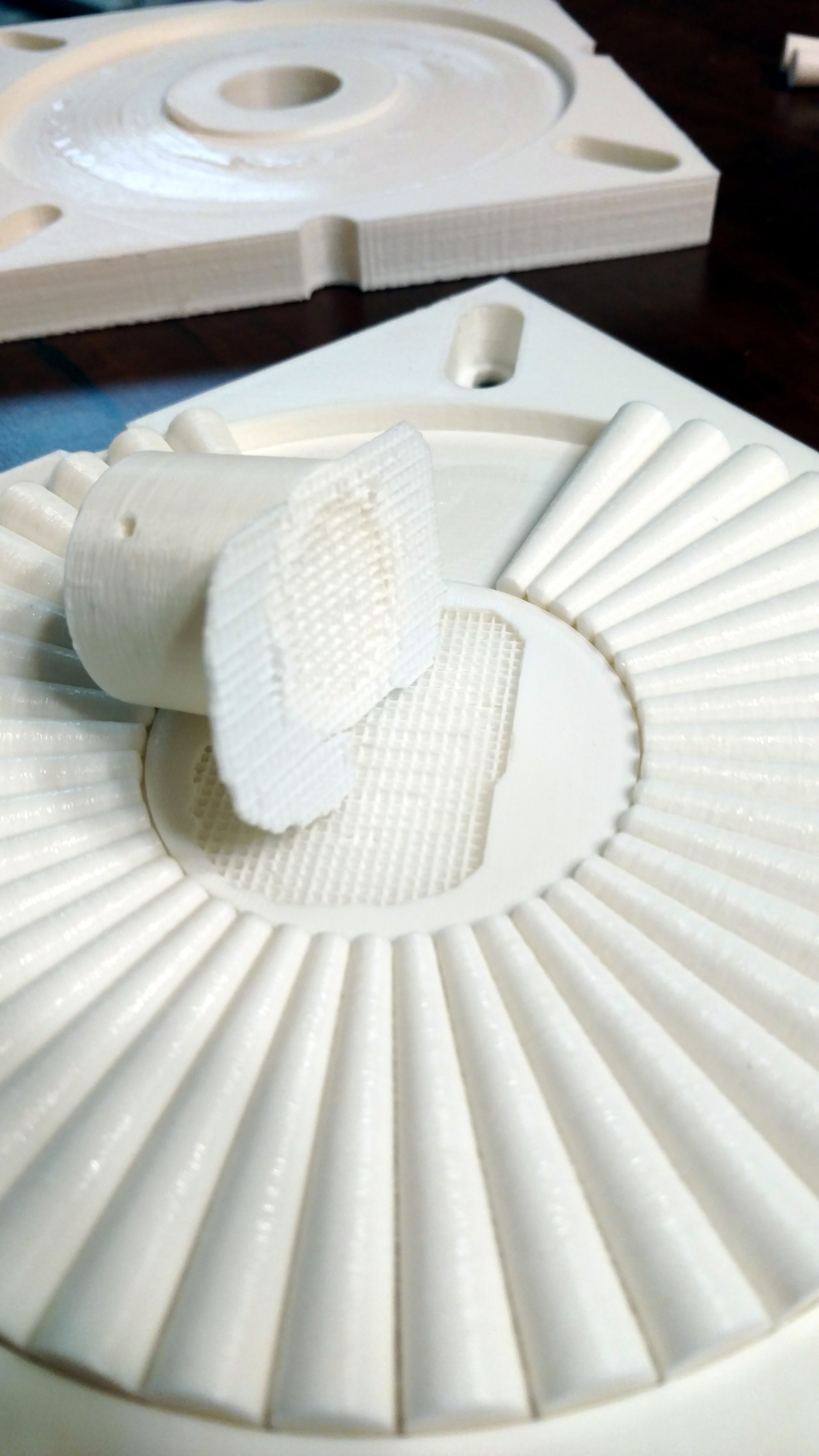

I printed a proof of concept bearing about 70mm in diameter. Much to my surprise(and relief) It worked perfectly!

It rotated very smoothly, and when I was convinced a scaled up version would work, I tried standing on it. I was positive it would break since it was only 10-20% percent infill and I am a well built person, but it didn’t seem to mind the weight at all. The next step was scaling it up to work on a chair. It took a few iterations to get the dimensions of the holes right, but the third time's the charm in this case, and the third iteration fit.

Another problem with designing a scaled up version for the chair was that it needed to be able to hold itself together when it wasn’t being compressed. I attacked this problem with the simple solution of using 2mm steel rod as a linchpin. This is where things started to fall apart… literally. The larger version didn’t seem to turn nearly as well as the smaller prototype. I initially chalked this up to it needing to be broken in, so I attached it to the bottom of the chair anyway. When I tried using it though, it started locking up and was very hard to rotate. When I flipped the chair over, I found that the rod through the middle had been torn off by the leverage of the base.

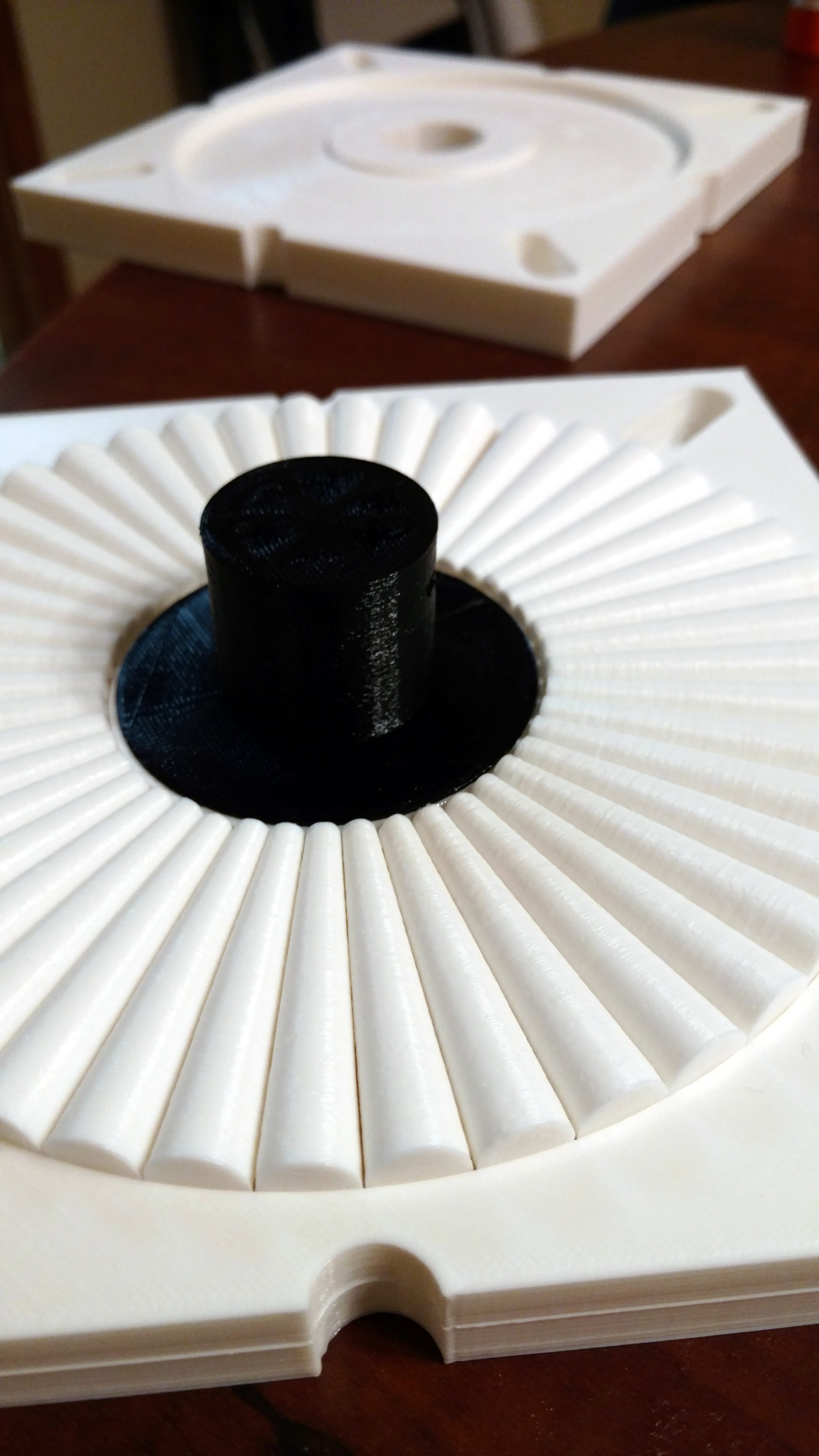

I printed a TPU replacement rod, hoping that would make it more flexible. And while I am being more careful now, It does seem to have done the trick in repairing my repair. Repair-ception, if you will.

I also applied some PTFE based lubricant to try to get it to turn more smoothly, which it certainly did.

It is still not quite as good as the small version I printed, but certainly good enough. So in the end my repair worked, you have to sit up straight and try not to rock back and forth, which is unfortunate. But I don’t think that it will be forever doomed to not work as well as the original. A larger diameter bearing would probably perfect its functionality, but for what it is I think it does a perfectly fine job.

P.S. I did a bit of Googling and couldn’t find a bearing design like this. If you know what it is called, please leave a comment below. Thanks!

Alex Rich

Alex Rich

Myles Eftos

Myles Eftos

Sam Ettinger

Sam Ettinger

Dan Maloney

Dan Maloney

I think what you are looking for is a "lazy susan" chair bearing. Most are ball bearings and not rollers.

https://www.rockler.com/3deg-tilt-swivel-select-standard-or-deluxe-swivel?sid=V9146?utm_source=google&utm_medium=cpc&utm_term=&utm_content=pla&utm_campaign=PL&gclid=CjwKCAjwza_mBRBTEiwASDWVvnc5WCAsWFH4LK2LhA4CNv3_CBLTCwdxv4_6T7KxXI0QxiCv6LMFCRoCK7EQAvD_BwE