Chassis:

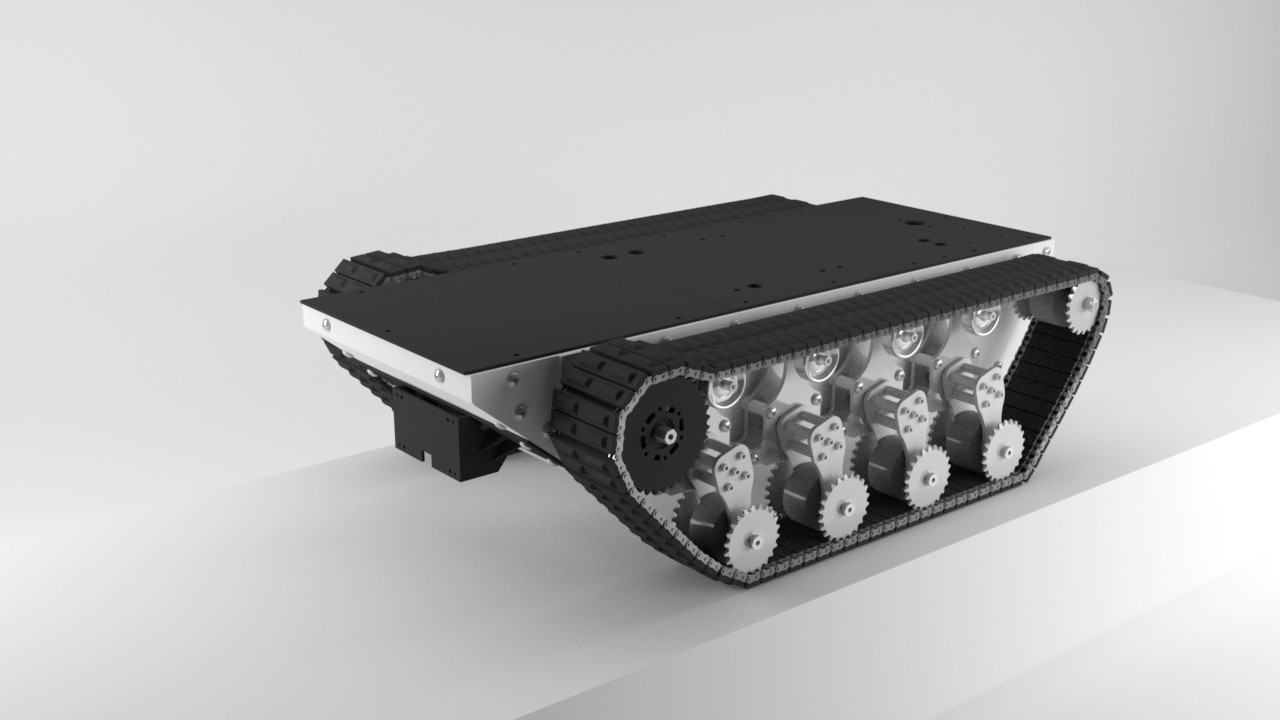

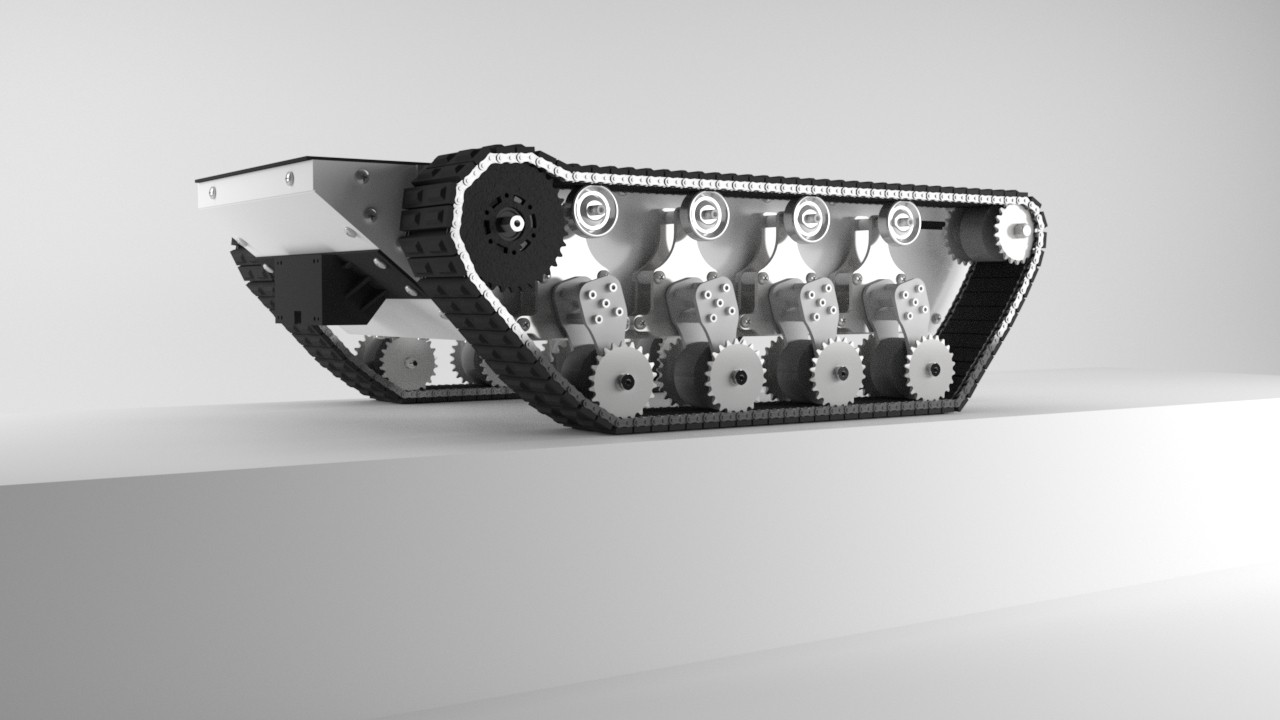

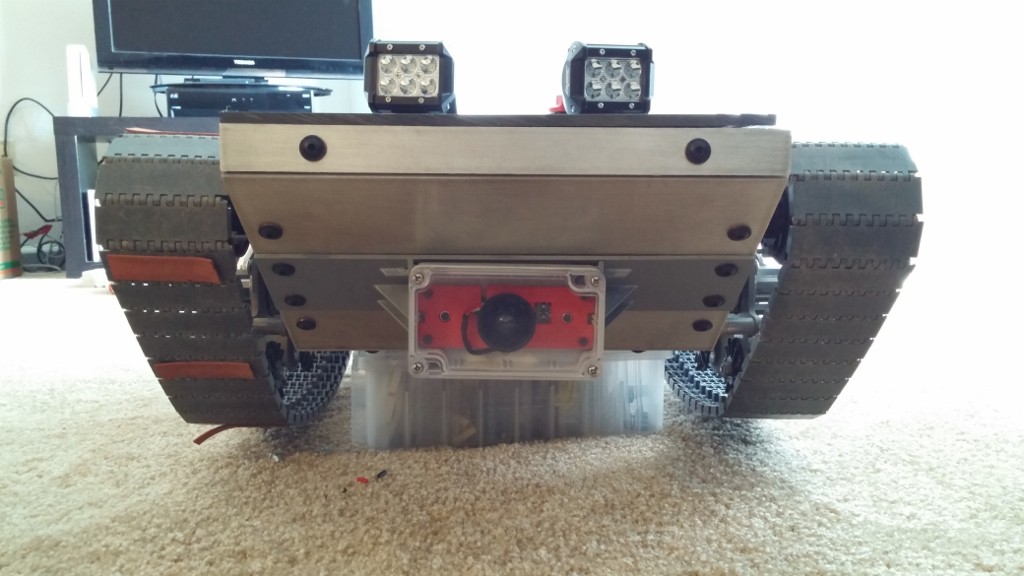

The frame of the robot is composed of aluminium 8020 bolted together using a combination of off-the-shelf and custom brackets. Onto this frame waterjet cut 1/8" aluminium panels are bolted, which creates a strong but lightweight and easy to repair chassis.

The entire frame was model in Autodesk Inventor to ensure a proper fit. (3DS Max was used for the renderings)

The entire frame was model in Autodesk Inventor to ensure a proper fit. (3DS Max was used for the renderings)

Suspension System:

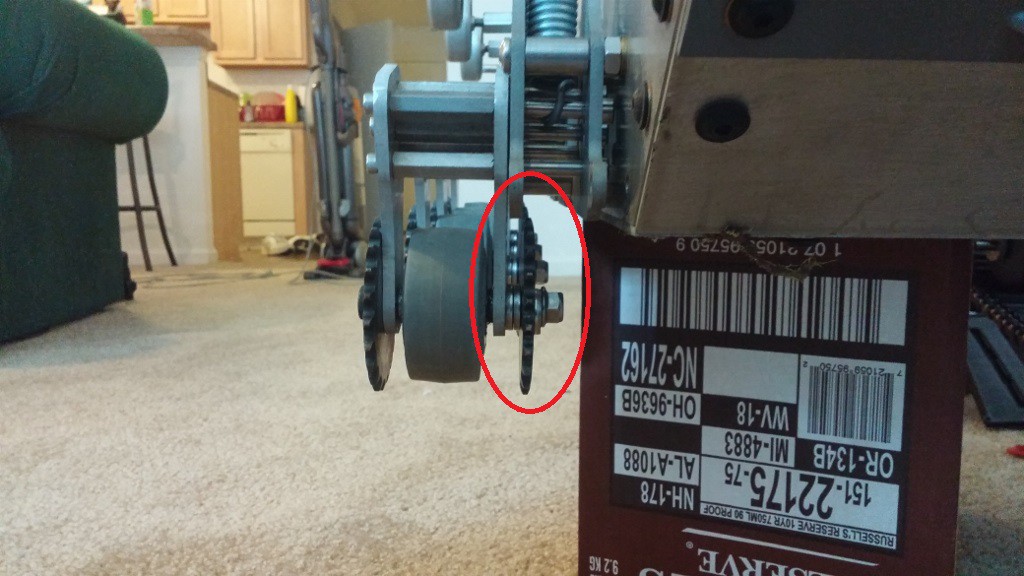

The suspension system is composed of cut aluminium and stainless steel plates which pivot on shoulder screws. An early simulation can be found here: https://youtu.be/ClKLkGF4tBQ

A single spring provides the force which returns the wheel carriage to the upright position.

All pieces were first prototyped out of acrylic to act as a "proof of concept" and to ensure proper tolerances.

Eventually I will have a video to show the suspension in action.

Drive Train:

In order to simplify the overall design, a self-contained off-the-shelf drive train was selected created for FRC robotics competitions. A mini-CIM and versa-planetary gearbox along with talon speed controller.

While adapting the motor to work with the gearbox reduced the key-way significantly, it was worth it just to make everything much cleaner and easier. Plus the mini-CIM motors are sealed which is a plus. The combination provides 700 in-lbs of torque.

The treads are made from delrin, and are industrial conveyor belts.

A custom square bore cog interfaces with the belts, so a 3D printed adapter is used with a standard 1/2 Hex shaft and off-the-shelf FRC wheel hubs to get the torque to the treads. 3D printed parts are also used to help keep the belts aligned with the wheels and maintain proper tension.

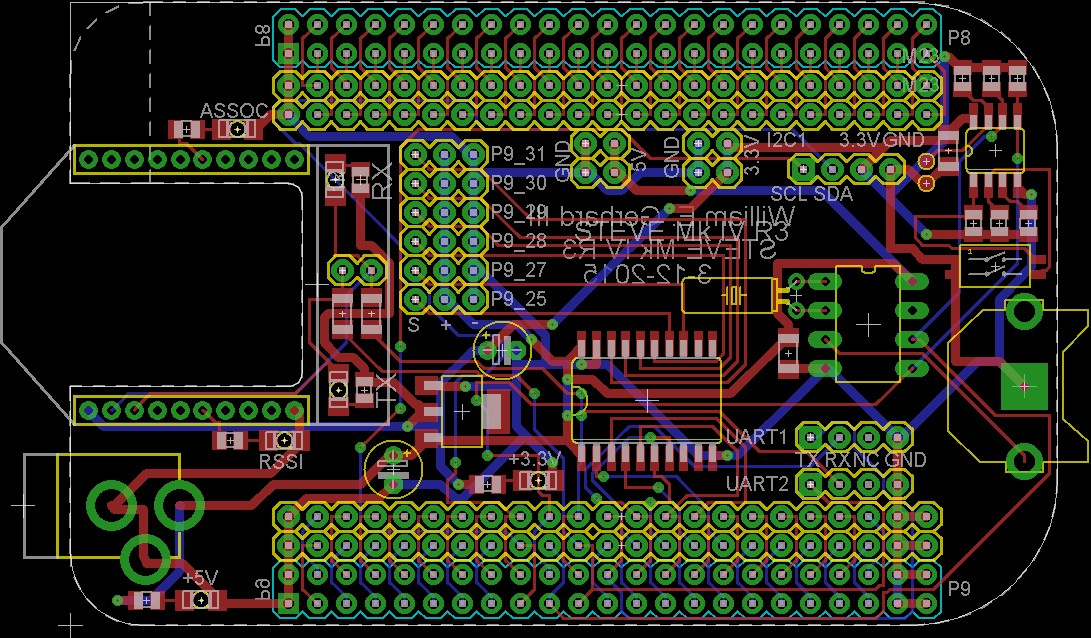

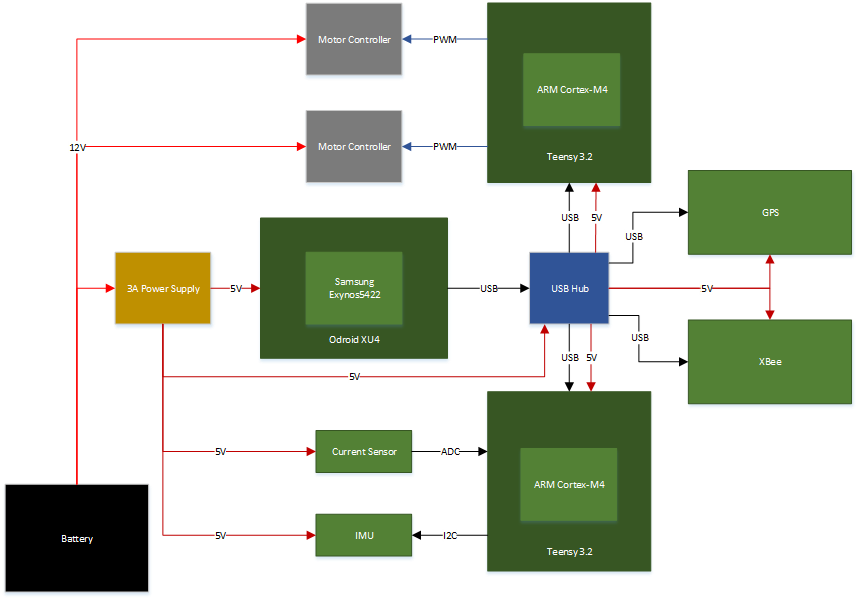

Electronics:

Main controller is a Beaglebone Black. It controls the motors, handles motion planning and remote controlled operations.

A custom cape interfaces the 3.3V board with the 5V external peripherals and adds an Real TIme Clock (DS1307) an Xbee radio socket.

The main power source for system comes from a 26 Amp-Hour lead acid battery and the motors are controlled by two FRC Jaguar motor controllers control by PWM.

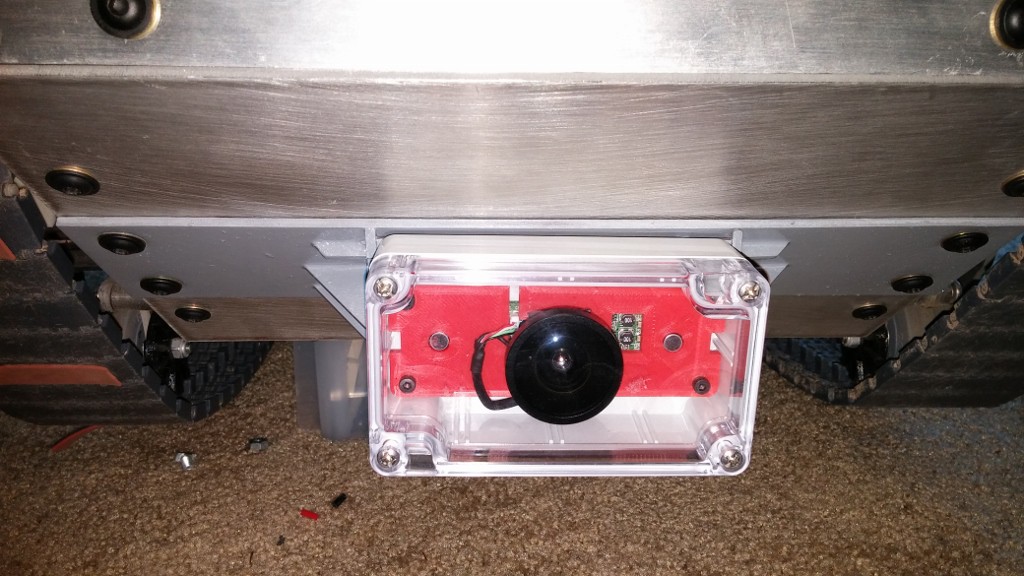

Water Proofing

In order to actually be a usable, the robot must be able to work in wet conditions. While sealing the entire chassis is an option, it would make replacing panels difficult. Instead all electronics will be enclosed inside of IP67 or higher enclosures and interconnected with waterproof circular connectors. This both makes the electronics much more durable, and easier to replace or upgrade.

More specific details and updates will be in the project logs.

williamg42

williamg42

(sorry for the potato quality photos, took these on my phone before I left for spring break)

(sorry for the potato quality photos, took these on my phone before I left for spring break)

Raphaël Casimir

Raphaël Casimir

EK

EK

Joshua Elsdon

Joshua Elsdon

saw this one on eBay the other day. can't help but notice the similarities.

http://www.ebay.com/itm/Full-metal-tank-car-chassis-big-size-load-large-obstacle-surmounting-tank-/182232412413?hash=item2a6de5f0fd:g:ih4AAOSwARZXpGYz&nma=true&si=YVk0OyTIPJmKjDceEEWl%2FqERMBE%3D&orig_cvip=true&rt=nc&_trksid=p2047675.l2557