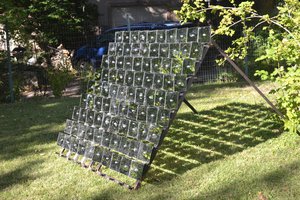

The subtle thing is the rotational axis has to be parallel to the Earth's axis, but the panels must be angled (0 at the equinoxes, +/-23.4 at the solstices). The sun angle would only need to be adjusted about every week and then only at the equinoxes so could be done manually. But you'd need an axle so it could rotate (more than 180 degrees since the sun goes from northeast to east to south to west and sets in the northwest during the summer).

I'm in an area that is sunny 2/3 of the time, but that isn't the whole story. For an "optimized" fixed mount, the panel would be in shade during the first three hours of the day as the sun would be north and not very high up (my north window bedroom needed blackout drapes since the bright summer sunrise would shine right through).

It is usually sunny through the early afternoon, but it varies. That is why the mount. Many places have different weather including mid-day clouds or rain. A fixed mount will get at best 50%, and only if it is sunny mid-day. With the mount, I'll get almost all the energy when the sun is shining.

Solar panels are expensive, PVC is cheap. Instead of adding 2x or 3x panels to get more power, I just point the ones I have directly at the sun.

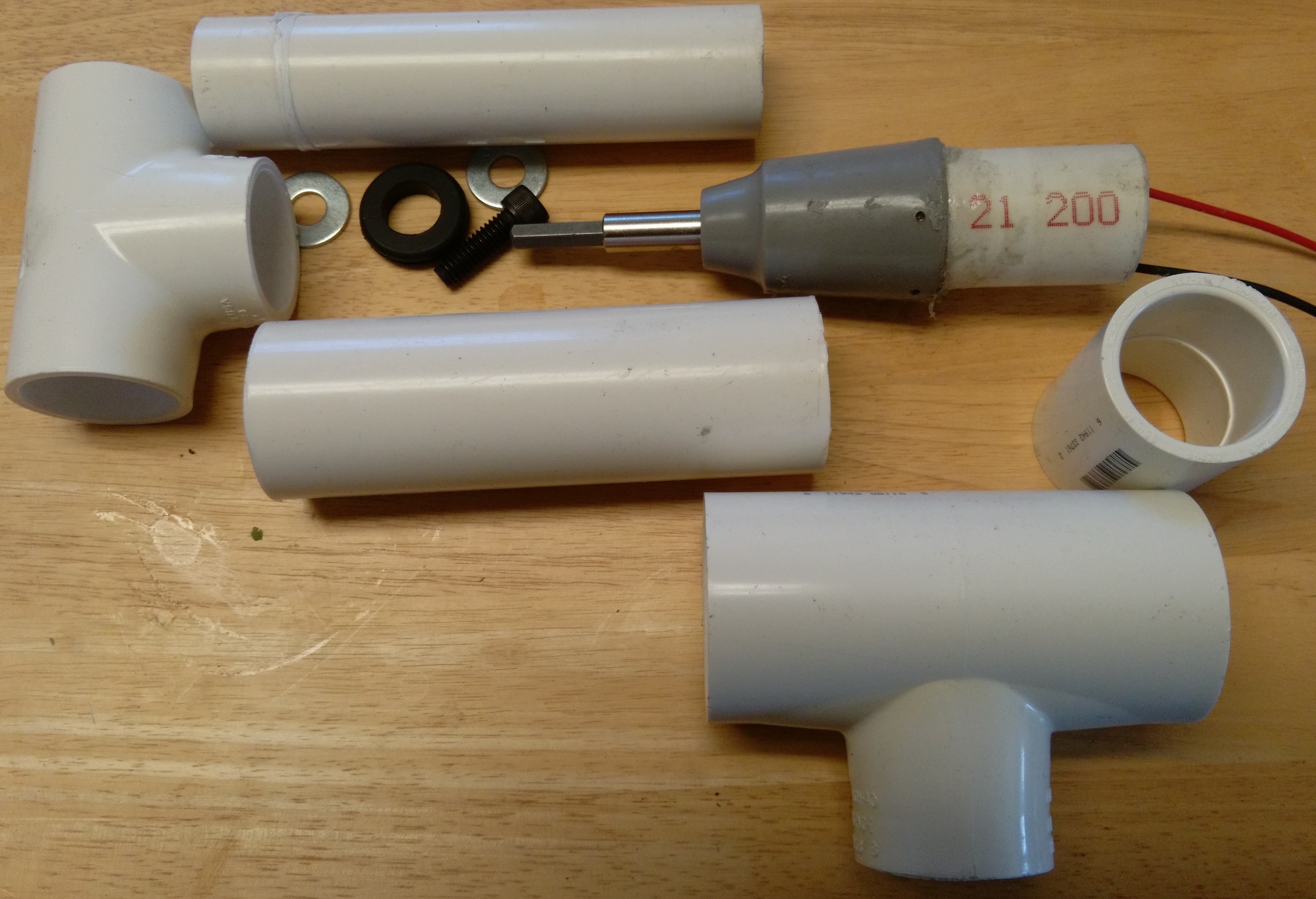

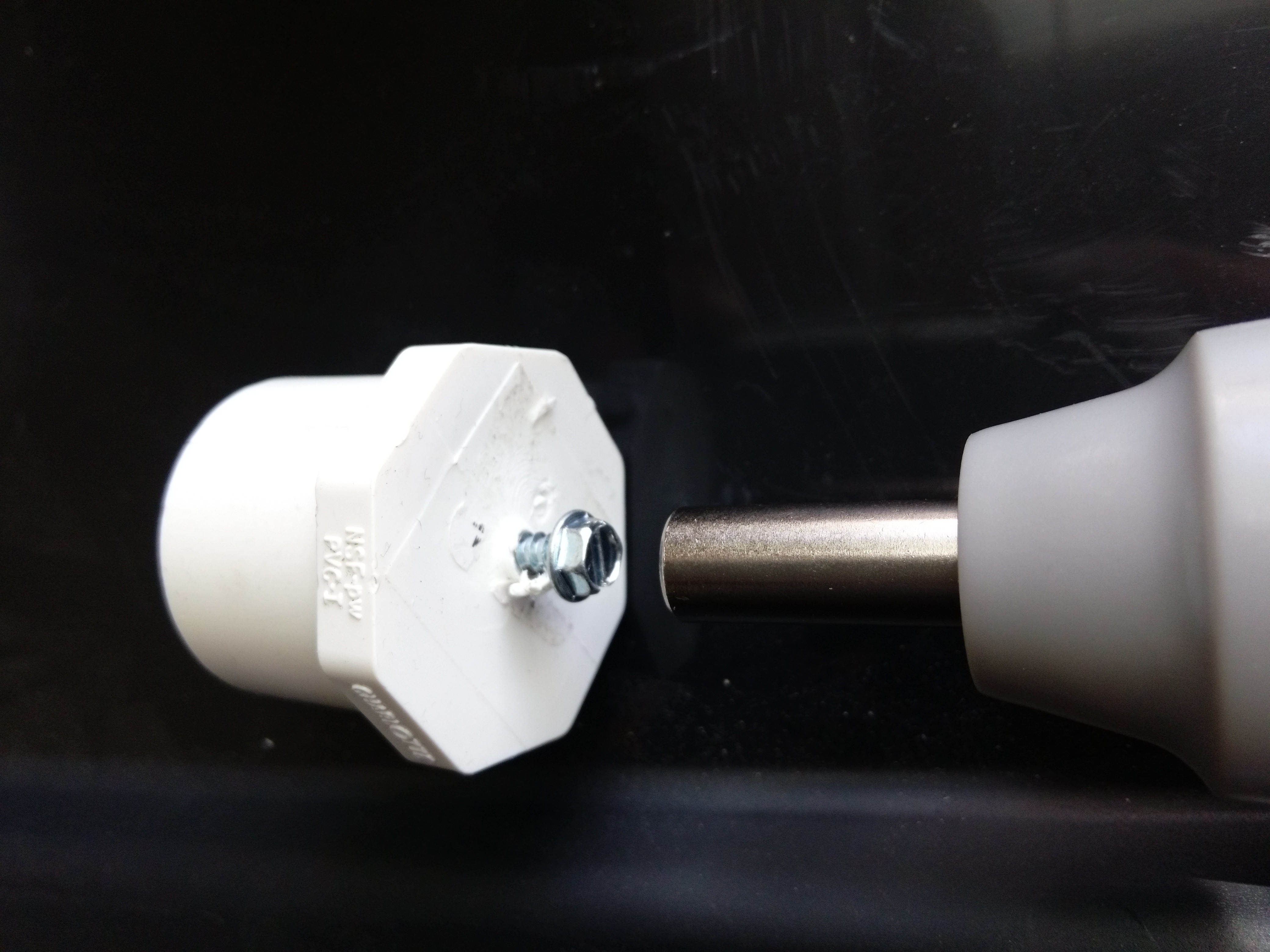

My local ACE Hardware has inexpensive PVC pipe and the 1-1/4 inner diameter will fit a 1" inner diameter pipe inside where it can spin (and they have a second "1 inch" light, thin, but stiff version).

One key is to balance the panels so they won't put much force to turn.

I'm still tweaking the geometry, but have most of it designed and am ready to cut pipe and get the joints. I doubt all the material (except for initial errors) should cost about $50. Lightweight and portable. It would be set up for my Latitude (right near 45 degrees) but if I get too far off, I can place it on an incline to compensate.

For winds and stability, they are pipes which I can fill with water or sand, or put sandbags or weights on them.

There are already commercial "sun tracking" bits of hardware, or I could use GPS or something else to get it to point to the sun - the harder part is the mount and that is what I'm trying to solve.

tz

tz

jellmeister

jellmeister

Joel Fairstein

Joel Fairstein

wkpsahl

wkpsahl

LEDs or photodiodes are an alternative. Put a load (small value resistor) on solar cells and voltage depends on current (E=IR). Current depends on illumination.