OUR TARGET IS TO MAKE DRIVETRAIN TECHNOLOGY ACCESSIBLE TO EVERYONE

To bring motion into an application a lot knowledge and time was mandatory.

Our smart Servomotors makes it possible to clearly distinguish between the drive and the application. Thus you can fully concentrate in the logic - the HDrive will take over the drivetrain technology for you.

our main benefits are:

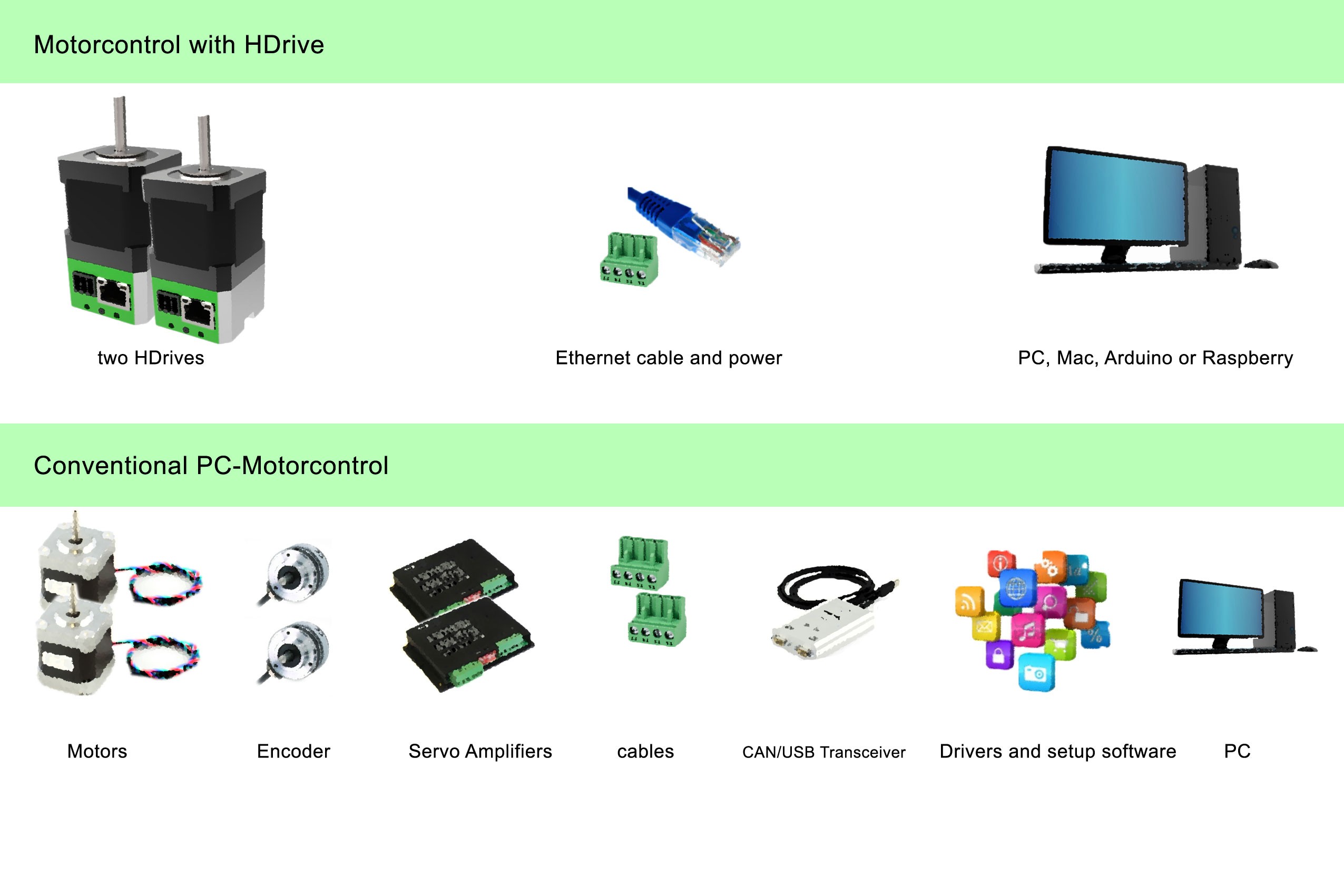

- Easy and fast implementation, no expert knowledge mandatory

- Directly driven by Ethernet, no cable adapters nor software drivers are mandatory

- Motor can be controlled with only three lines of Matlab code

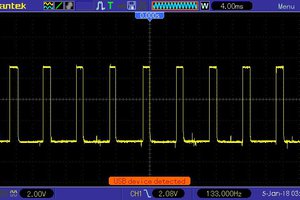

- Very high communication frequency up to 500 Hz. This means you can send a new target position or read out the digital I/O's every two milliseconds

- Slim design with multiple mounting possibilities

Communication

To set a new target position you have to send an XML formatted ticket over an TCP Socket connection:

"<system position=”500″ speed=”100″ torque=”50″>" This will command the motor to go to the position 50.0° with a speed of 100 RPM and a max torque of 0.5Nm.

This command can be send with only a few lines of code in most programming languages. The most simple example would be to open a telnet connection and to send the commands in it.

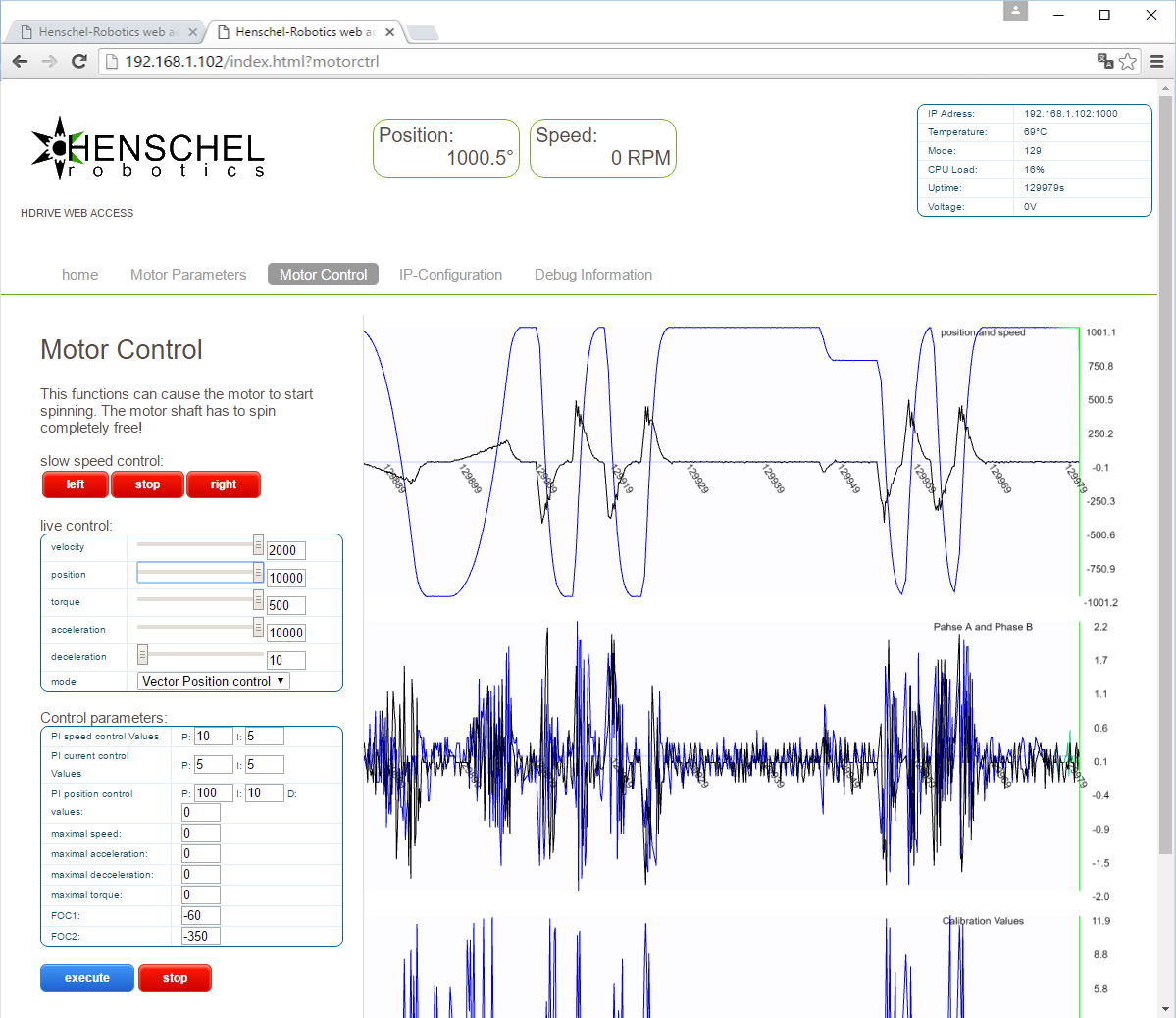

Webinterface

We decided to program the main GUI into a webpage. This brings many advantages because the only thing you need to see the motor states or to control the whole Motor is a Web browser. The web interface is very responsive. All data received from the Motor are shown in real-time. The data is transferred binary from the Motor to your Desktop within 100Hz.

This is great to tune the motor to find the right PID values for your application. With a mobile device you could stand next to your machine for tuning now.

Industrialisation

We started the development four years ago. Since then we have build lots of prototypes and have tested many different motor and amplifier technologies. Now we have chosen to use a stepper motor with a field oriented control. This kind of control combined with an accurate position measurement is turning the stepper in a high end servo drive. Thus the motor is behaving like a normal DC motor - minimized torque ripple and no jerks as seen in conventional steppers do appear.

Company funded

Recently we have funded the company henschel-robotics. Please take a look at our website: www.henschel-robotics.ch

Motor running @ 10'000 RPM, please have a look:

Our last prototype batch has arrived and is running great. The final speed of the motor could be increased to be around +/- 5000 RPM. We think we could reach the 20'000 with about 60V, just for fun.

In the Video you can also see the newest web-interface and a bit of the look and feel of the motor.

Chris

Chris

nicoud jean-daniel

nicoud jean-daniel

Frank Herrmann

Frank Herrmann

Scott Duckworth

Scott Duckworth

There is more information about the project, please read our press release on Linkedin: https://www.linkedin.com/pulse/novel-servo-drive-technology-henschel-robotics-chris-henschel