Licencing and IP

All codes/scripts are hosted at: www.MichaelRatcliffe.com/projects

[Will be updated before the 22/9/2015]

Everything is released as Copy Left, For more info:

Project Preface

about me: Graduated with a Degree in Mechanical Engineering and a Masters in Electrical Engineering currently finishing my gap year and taking some time to design an automated greenhouse and small allotment type garden to provide a yearlong hassle free supply of food and a test bed for novel nutrient sourcing Aquaponics grow system.

Want to see the test bed setup that is used to test most of these techniques:

The HAD Competition

Build Something that matters

This project addresses how technology and creative thinking can be used to create better Food Security, Reduce Water Pollution and optimise Energy usage.

In this Project there is a lot of complimentary information to support the projects, to make seeing the Electronic portions of the projects, the link are followed by:

Completed Electronics Projects are Marked [C]

Projects with Expected Update are Marked [P]

Complimentary Information is Marked [I]

Just Want to see the cool Projects: Skip to Making Better Use or Plugging Leaks

Problem: World hunger

Learning how to farm from your father as he did with your grandfather is no longer going to cut it, the world is changing, the demand is increasing and the methods are staying firmly the same, the number of people on the verge of starvation and suffering malnutrition is climbing and climbing fast.

So who will solve the problem, the government, me, you? We need modern solutions to modern problems, step in a hacker. A hacker see’s a problem differently than the average person,where many see waste they will see opportunity. The Hacker Way is an approach to building that involves continuous improvement and iteration. Hackers believe that something can always be better, and that nothing is ever complete.

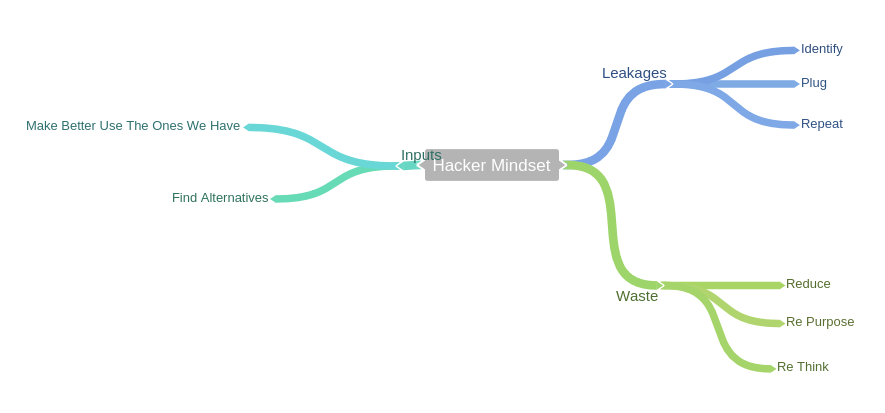

So what is a hacker’s solution to world hunger, take something that is free and use it to solve a problem. See it as a computer code/ flow chart, what are the inputs, outputs and leakages in the food supply? Plug the leaks, find alternative inputs and find a use for the waste.

I have seen world hunger first hand in Africa and China, The poor people in these countries are seeing a problem that we in the west have not seen yet [But it is coming and approaching fast] starvation. So I took a little time to see what the problem was, surprisingly they had access to large volumes of water, they had sunlight the limiting factor was poor nutrient sources and soil. Hmm I have been growing with Aquaponics for years now, problem solved?

Maybe not, in Aquaponics the food to feed the fish is relatively expensive for a person surviving on two dollars a day. We need to be a bit more creative to solve this solution.

Making Better Use

The First thing we can look at is how technology, particularity automation and control can improve the productivity of farms [Fish farm for this project] using traditional food sources.

Fish Feeders of the Future

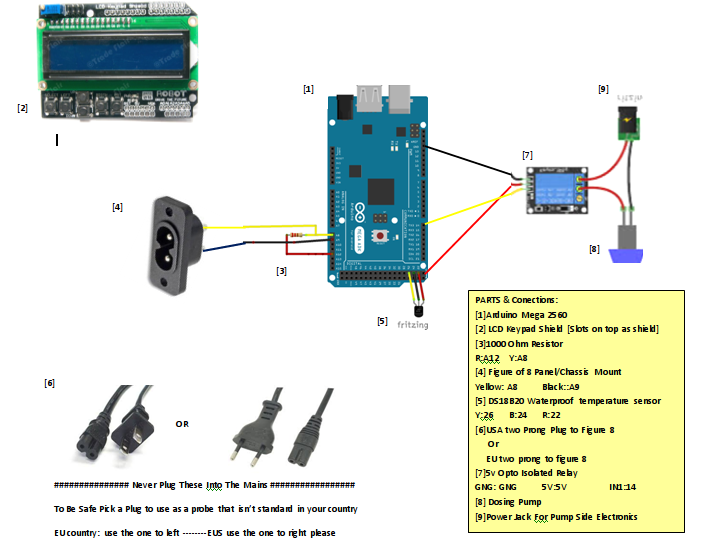

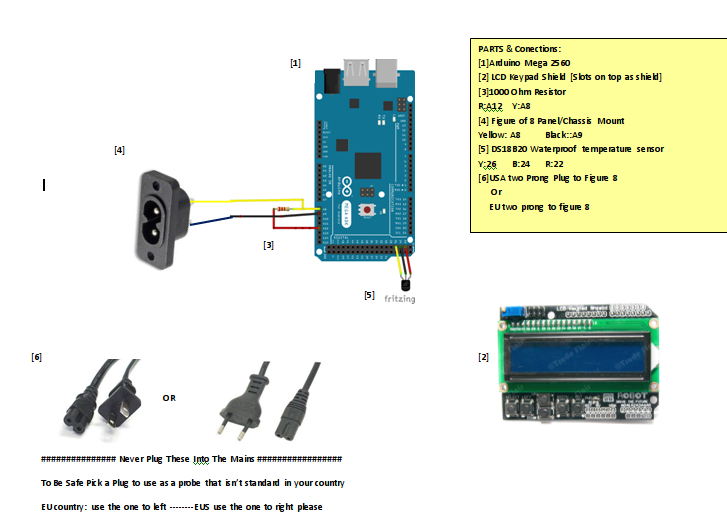

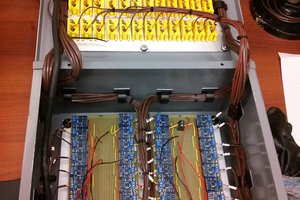

This was the Product submitted to the Best Product Challenge, it is a set of controllers providing modern solutions to modern problems. All aimed at taking the next great step towards automation of food delivery for maximum food efficiency and fish growth to feed the next billion.

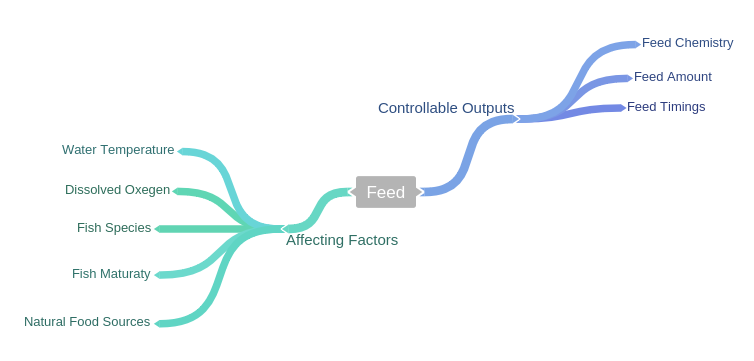

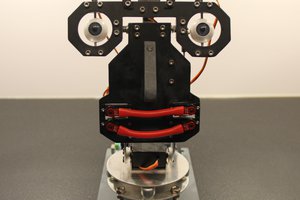

The daddy of the controllers is the vision based feedback system aimed at fisheries using floating food [mainly the up and coming aquaponics industry]. However many fisheries don't use floating food, the product for this implements a well defined open-loop solution fine tuned for your environment.

Some Basic Information:

>156 Billion KG of fish reared annual [that is more than beef!] [1]

>Optimum feeding regimes can increase productivity by 40%, food efficiency by 20% compared to conventional once per day feeding [2]

>There are many variables to consider when feeding fish [3]

Here is a quick video of the systems in action:

Michael Ratcliffe

Michael Ratcliffe

M. Bindhammer

M. Bindhammer

rockfishon

rockfishon

AndyMac

AndyMac

Daren Schwenke

Daren Schwenke

Hey man, nothing since 2015?

How is the project going? I'm beginning something that ties in with what you are doing. My focus right now is remote monitoring the AP system, and advising on how to operate the system.

Problem, aquaponics is a lot of time, education and effort, owners are tied to their systems and are unable to care for it on holiday or when working long hours. Some people need information spoon fed at the correct time.

Something like this: people enter the parameters of their system, climate, GB and fish tank volumes. The app will advise fish type, stock density, optimal temperature and PH. Then monitor and notify owner with a suggested course of action if something is amiss.

I am currently getting familiar with RasPi and learning about the probes and my options.

I've got 2 years teaching myself programming and web dev.

Let me know if you're interested in chatting.

Trev