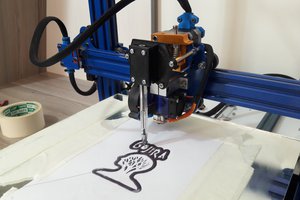

Looking at the different types of fused deposition modelling 3D printers out there, I noticed thatt they fell into two broad categories:

- they needed 3D printed or injection molded parts

- they were made from laser cut MDF

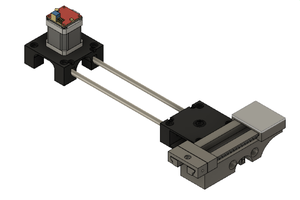

As I didn't have a 3D printer or an MDF laser cutter, I thought about a structure that could be (mostly) made from lengths of square tubing and threaded rod.

The plywood variant would use plywood rectangles for the base and base cover instead of the more stylish square tubing supporting laminate flooring cut-outs for the electronics to sit on and as a protective covering.

I figured that if I could get the lengths right and the holes in the right places then it might be doable!

Philip Ashmore

Philip Ashmore

T. B. Trzepacz

T. B. Trzepacz

Dave

Dave

setCREATE

setCREATE

Not sure if you know this trick, but if you thread a nut onto the rod, THEN cut it, you can unscrew the nut through the cut bit and reform/deburr the threads so it's easier to screw nuts onto it.

Another tip is to put 2 nuts on either side of the cut line and use them as a guide for your hacksaw so your cut is at a right angle.