Why do we need this?

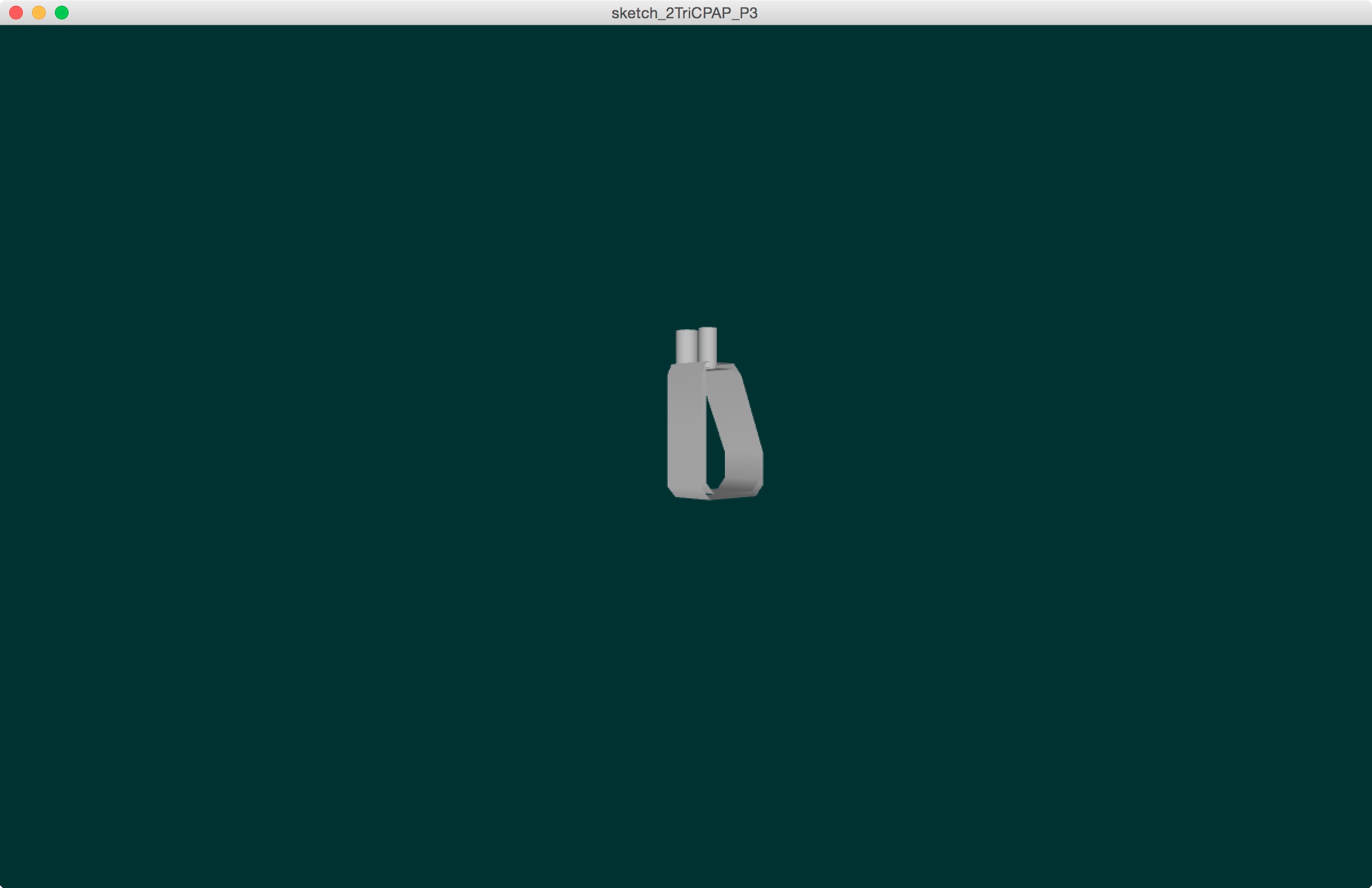

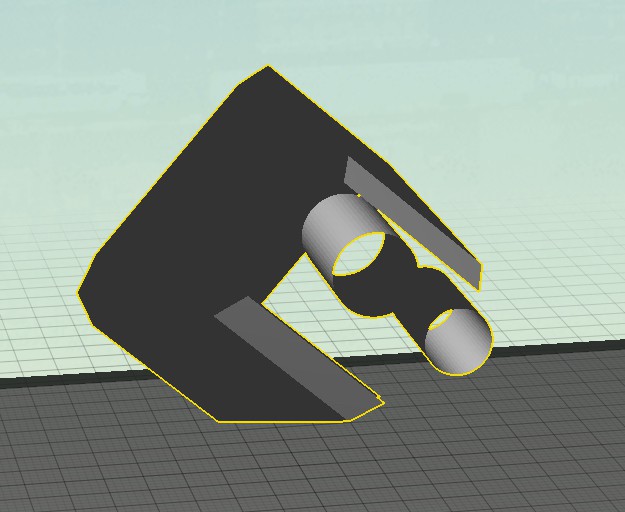

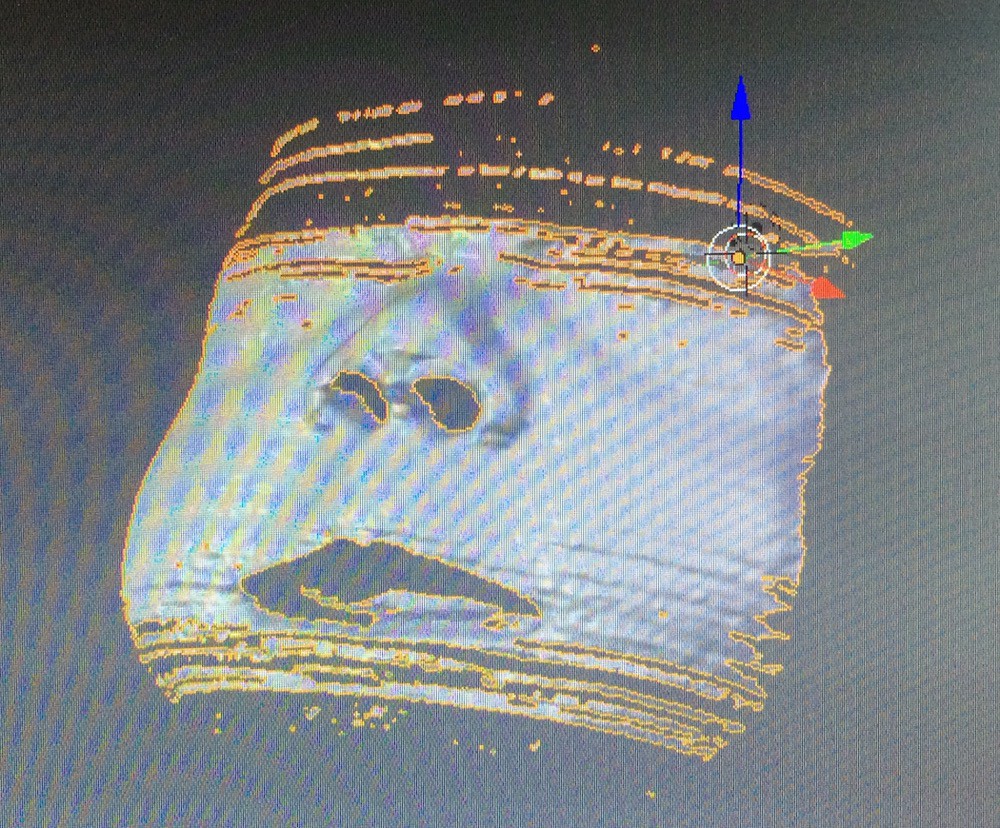

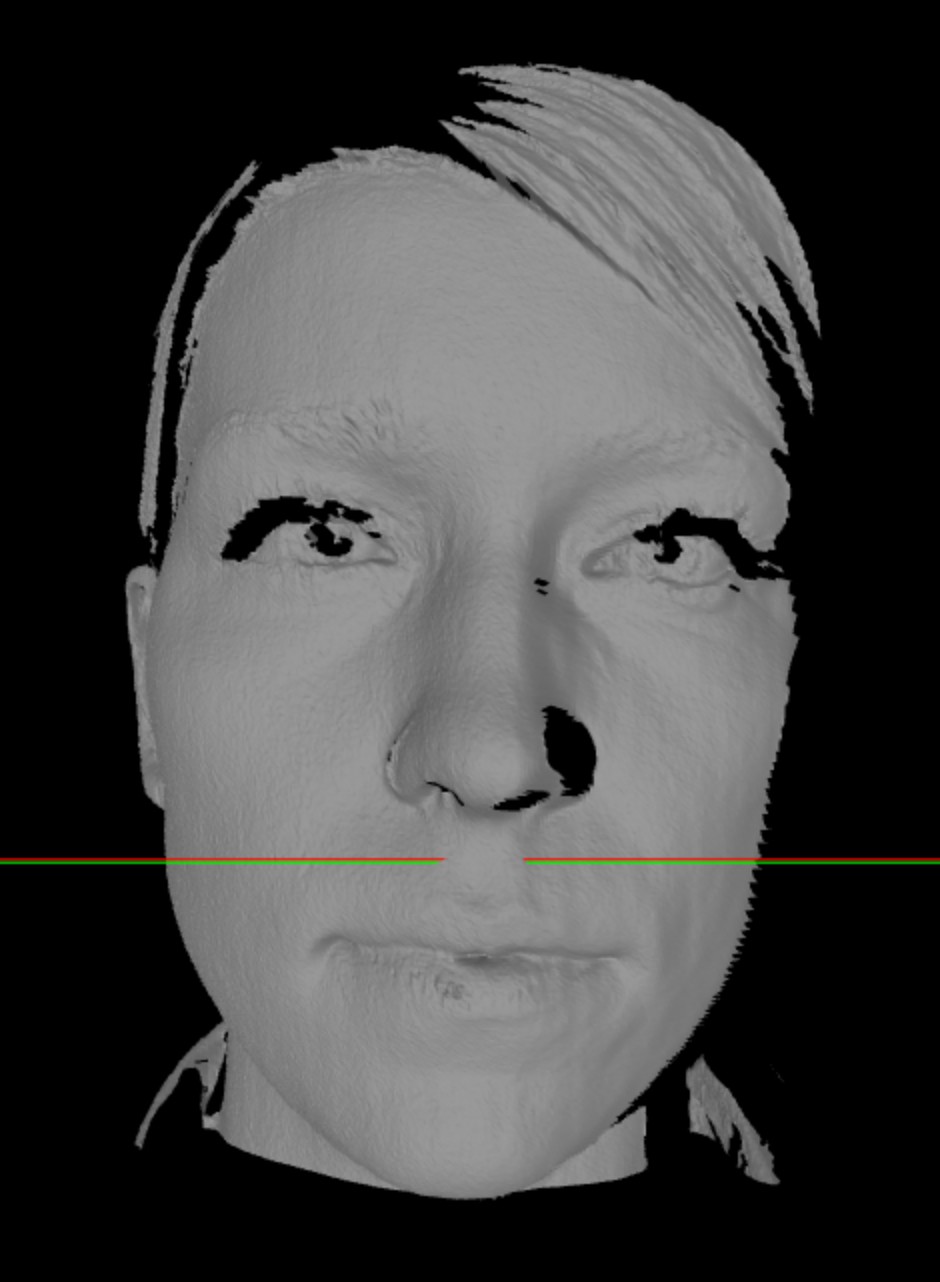

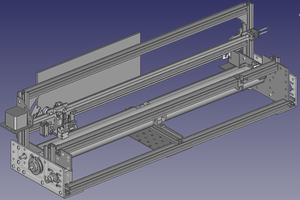

Most preterm kids require ventilation support during a NICU stay - these kids may weigh as little as 500g at birth and require months of ventilation support. Ill fitting nasal cannula can reduce the effectiveness of the therapy and in some cases can cause significant injury and disfigurement to the nasal septum of these kids.

Surely we can do better?

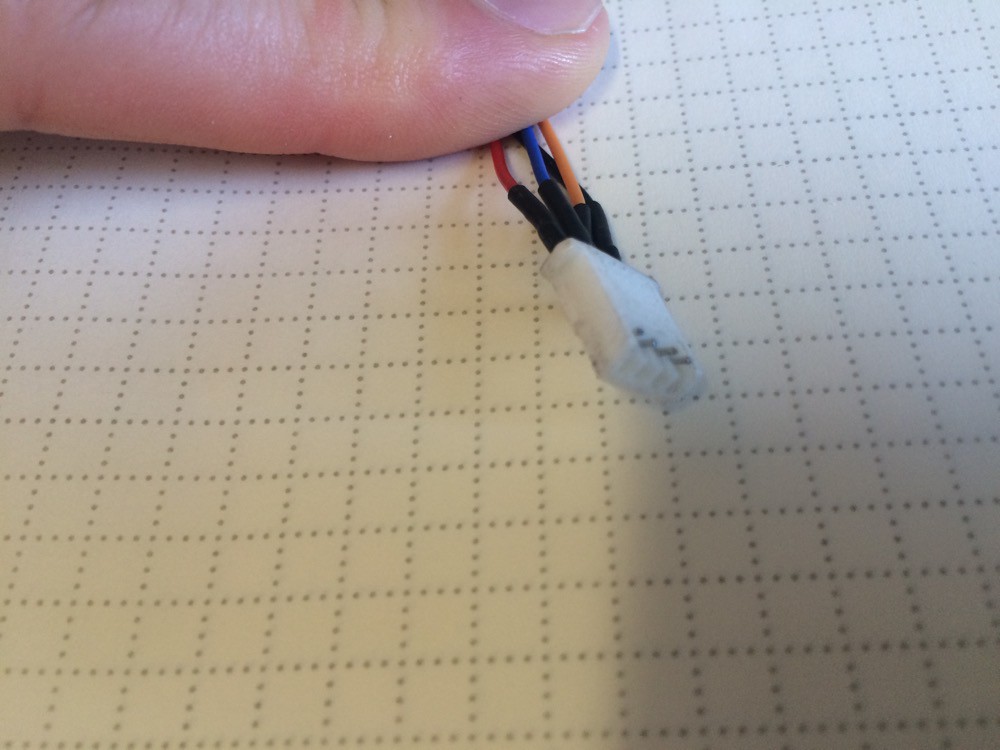

In true hackaday spirit this will be attempted by myself (Ben) - I work in a NICU but have no programming or electronics experience. What could possibly go wrong?

On that note - advice and input are welcome.

Ben Hartmann

Ben Hartmann

Sam Ettinger

Sam Ettinger

Madaeon

Madaeon

Kārlis

Kārlis

Mike Szczys

Mike Szczys