If you need more precision than you get from switches and pots, you'll need to move to common ICs. Fortunately, we can use parts readily available at the store formally known as Radio Shack (too soon?) Parts like transistors and 555s will allow us to control the speed & direction of BDC motors with decent accuracy + reliability.

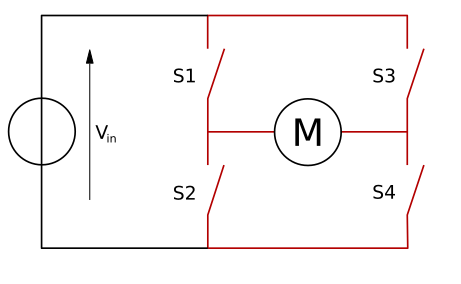

The key concept here is the humble h-bridge: an arrangement of transistor pairs that can toggle the flow of power in both directions of a motor. Oh, and it looks like an H in diagrams.

What type of transistor you use depends on the current draw of your motor (look at stall current.) Small hobby motors with light loads can use common BJT PNP/NPN-type transistor (NPNs are cheaper and active-high.) But for anything remotely power-hungry, you'll want to use Power Mosfets. P-channels are a go-to for high-side switching and something like a FQP27P06 can handle 27A with proper heatsinks. That's a hefty motor.

There's also readily available H-Bridge ICs. Some have nicer features like dual H-Bridges for 2 motors, built-in diodes & overheat protection but they're effectively the same as rolling your H-bridge. Pick from the following depending on your load requirements, but note there are tons of other options from an array of vendors:

If you're using an H-Bridge part and need more power, you can actually use them in conjunction with a Power Mosfet. I like to think of them as motor control megaphones.

So what about speed control? Recall that we said BDC motors are voltage-senstive devices. A PWM signal should be a familiar representation of voltage and are easy to generate and vary. An astable 555 can be our generator. And like the discrete solution, we can use a fixed resistance for fixed speed, rotary switch for finite gradients and a pot variable speed. We could just use a pot here but a PWM signals is more power-efficient since it off part of the time.

What about free-running & braking? Like speed control, we can coast by removing power, ie opening all transistors, and braking by enabling either the upper or lower part of the "h" - but never both!

Jonathan Beri

Jonathan Beri

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.