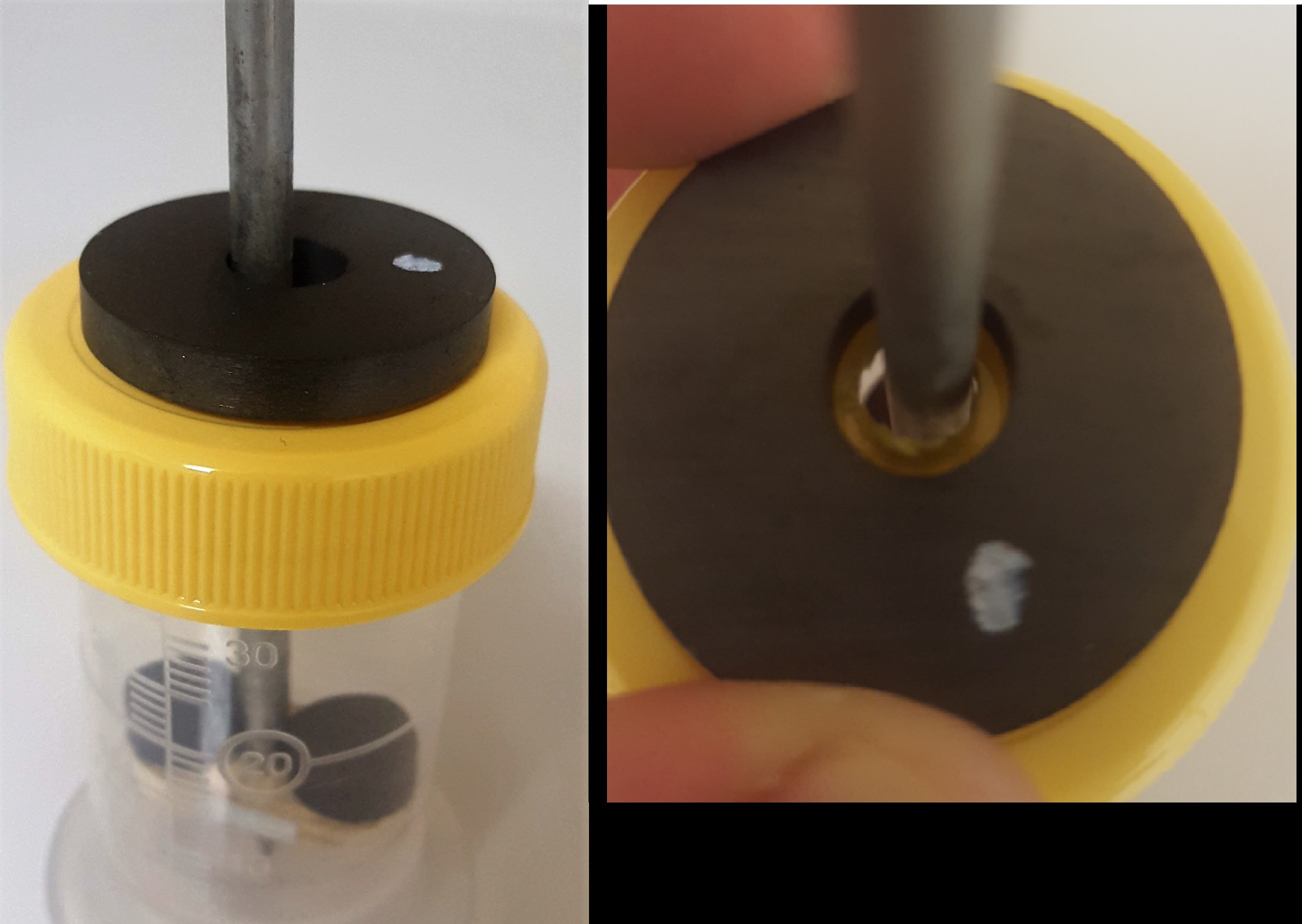

So I finally built something! It's just a crude device to test the magnetic bearing idea. Doesn't work very well, but was useful to guide the design further.

It all goes together in the little plastic bottle. Needle bearing works well on the concave bottle bottom, but would spin much better I think if it was against glass and not plastic. And if I made the tip sharper. The main problem is the magnet sucks the axle over too forcefully when it's stationary, so the axle rubs against the yellow cap's hole too much. I was just using my fingers to spin it so far, and was never able to get it going fast enough to even see if the magnetic bearing thing would work.

What that means for the pump is that we would either need a decent mechanical bearing (i.e., not just a plastic ring) small enough to hold the axle away from the magnet, but large enough to allow the axle to spin freely when it get's up to speed enough for the passive magnetic effects to kick in. Part of the point of the magnetic thing though was to reduce complexity and avoid having to source special bearings, and worry about the grease in high vacuum.

Another option I discovered though while messing around with it is to simply hold a magnet about 1/8 of an inch above the top end of the axle. It keeps the axle upright without touching it, and allowed me to get it going very fast just by blowing on the lower horizontal bar (I was just holding the axle outside of the bottle this time, holding the magnet above. Any old magnet would work for that, it wouldn't have to be a ring magnet or anything.

A second option would be to make a "active" passive bearing, by using a solenoid coil instead. Then it could be turned off until the axle got up to speed. But that requires power to get inside the chamber somehow, whether through pass throughs or more coils.

A third option would be a combination. A permanent magnet, with a coil around it that cancels out the magnetic field of the magnet until the axle got up to speed. Then the coil could be turned off, power removed, and the chamber cover set in place. That sounds complicated to me though.

I'm thinking the first option (magnet held above the axle) is going to be the best.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Consider ceramic ball bearings. They are ... well.. a bit expensive, but obtainable.

I'm not sure if they can run without grease, but I guess they can.

Are you sure? yes | no