What ever you'd like to build, CNC machines make your job much easier. Most instructions in building a CNC machine start with:

"Take your CNC router to build the parts needed to make a CNC..."

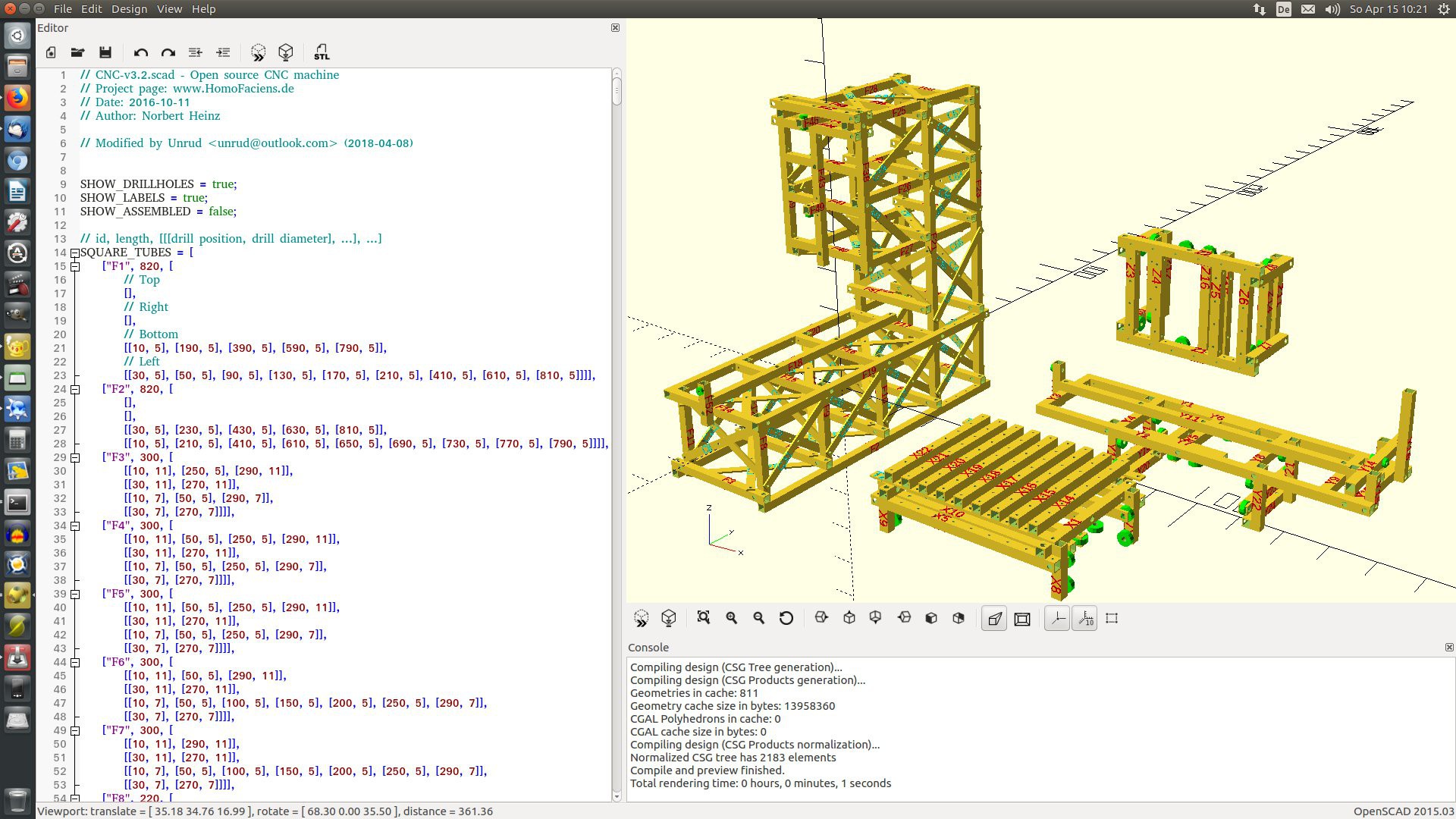

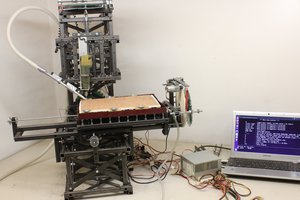

To get out of this chicken-egg dilemma, I am creating CNC machines using basic tools and commonly available materials. The precision I get with my current constructions is in the range of one tenth of a millimetre, which is sufficient for most applications.

In improving the design my aim is to get even better results. Latest idea is making my CNC router carve lenses. To get that I must add more axes and motors to polish the lens surface.

Norbert Heinz

Norbert Heinz

Thomas

Thomas

Andy Lee

Andy Lee

Paul McClay

Paul McClay