Human shoes are an utter disaster for lions. The single greatest idea for making human shoes fit lion paws came from

http://fellrnr.com/wiki/Modified_Nike_Free

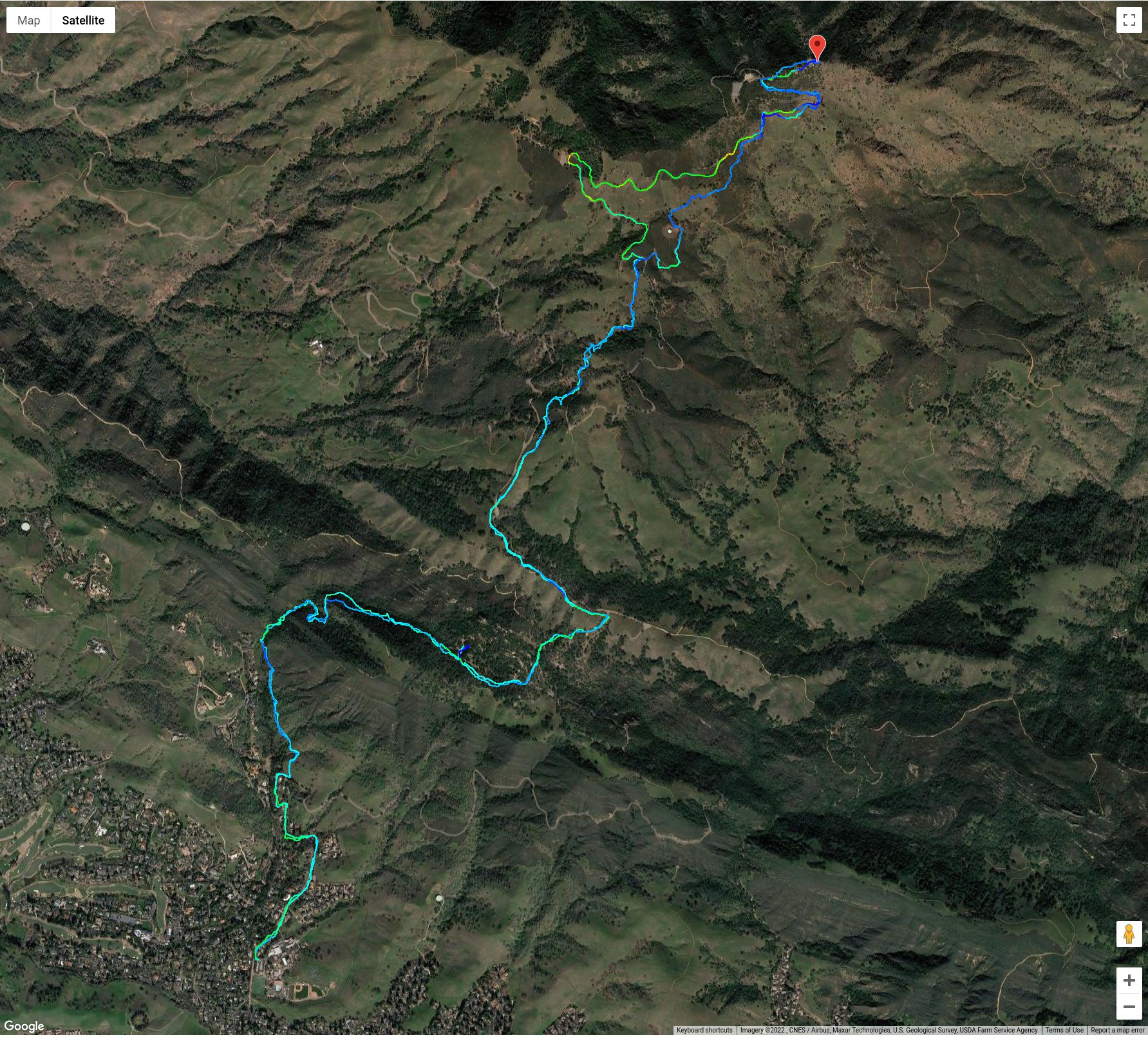

This is the only way we can run reasonable distances without blisters, pantar fasciitis, & black clawnails. Over the years, as lion fitness improved, distances & speeds increased, & even this has run into limitations. Barepaw running is unacceptable, because of the dog manure, human waste, & rocks. Humans are nasty animals.

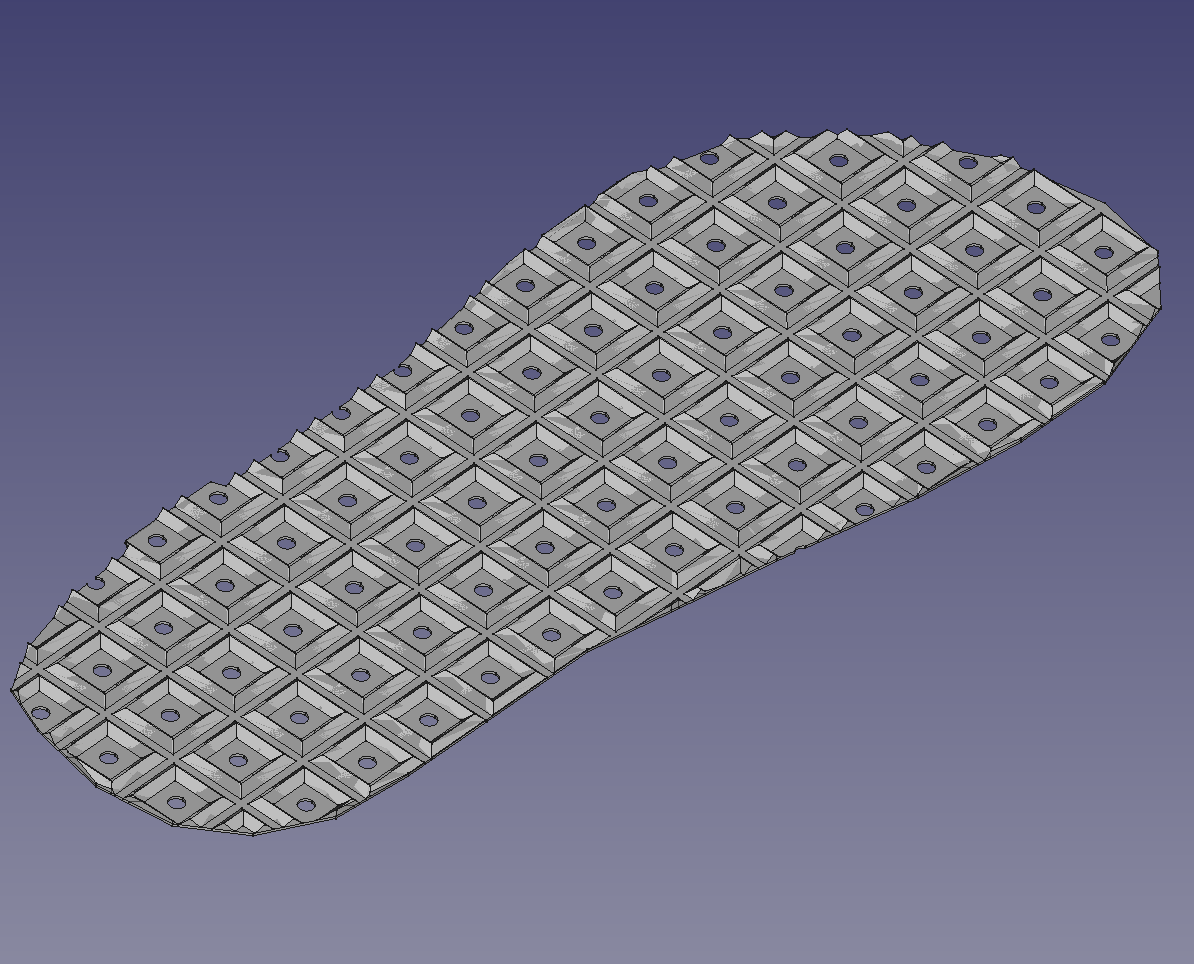

Another problem which has arisen is shoes are now being discontinued after only 1 production run. Like books, programming languages & blockbuster movies, they're sold more for publicity & thrown away. Finding another shoe which works as well as last year's blockbuster can take years, if ever. The only long term solution is making shoes from scratch, from easily obtainable materials.

After extreme blistering in a 19 hour race, lions experimented with slow quarter miles in $8 Walmart sandals. In the 19 hour race, shoes trapped sand & moisture from the beach track. If they just had more ventilation, the problems might have been avoided. Sandals could actually hit decent speeds, with a bit more upswing. It became clear the best chance lions have of reaching the next level is modified sandals. Sandals won't allow the maximum speeds, but they should allow the maximum distances.

Humans have since created

https://xeroshoes.com/

https://lunasandals.com/

extremely expensive versions of $8 Walmart sandals, with more straps. $40 for the Xeroshoes Genesis would be reasonable if it wasn't for another problem. The last pair of shoes wore down in only 3 months. Most of a lion's life is spent running on inner foam rather than rubber.

The Goog may actually embargo all but adsense paying commercial links, since it reveals no hacks. Of course, lions don't sew & don't want to be like the male humans who do sew.

http://www.diyfootwear.com/huarache-sandals/

A nugget of info escaped the Alphabet corporation's embargo.

https://www.youtube.com/results?search_query=Huarache+Sandals

Sandals & how to tie them. All these guys have pretty beat up feet & watching their videos conjure up foot odors. Something is a bit off when it's only being done by men. The dominant search result is https://www.youtube.com/channel/UCAq7JfGUobKA-pDDxVQ58Rw, but he's bald.

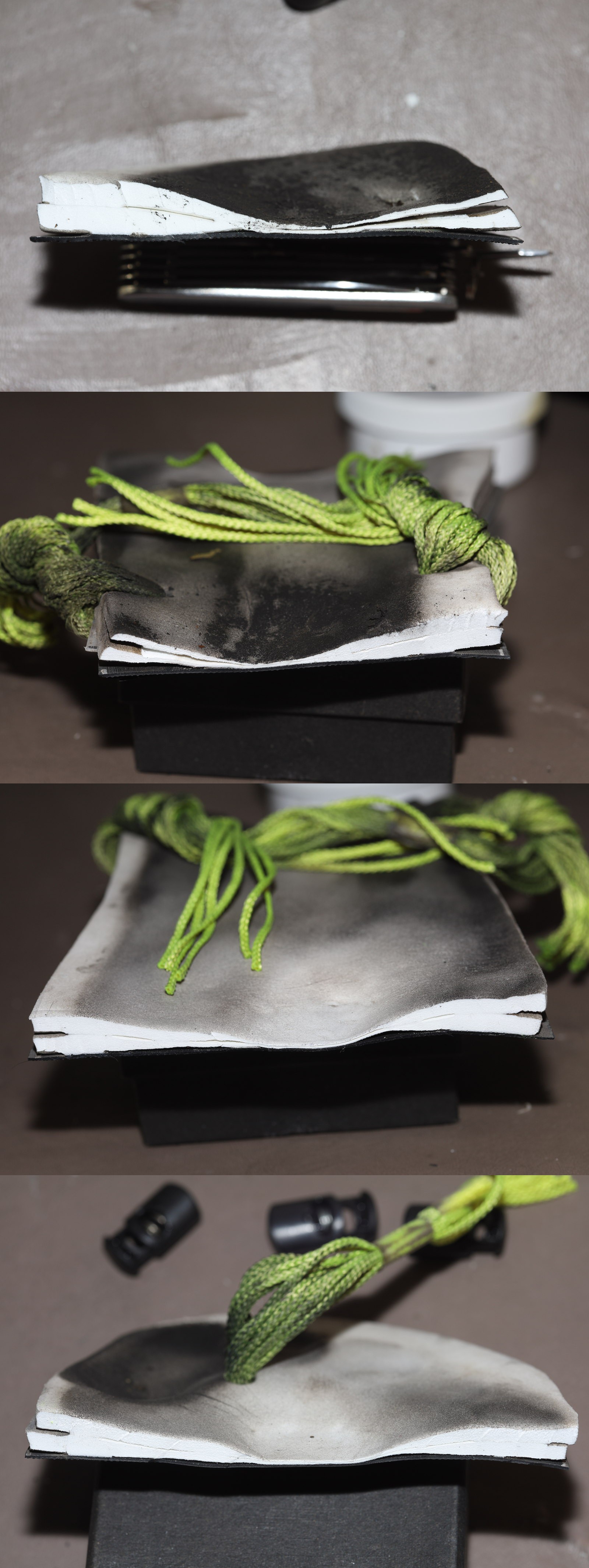

1st lion run in sandals

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Current bill of materials:

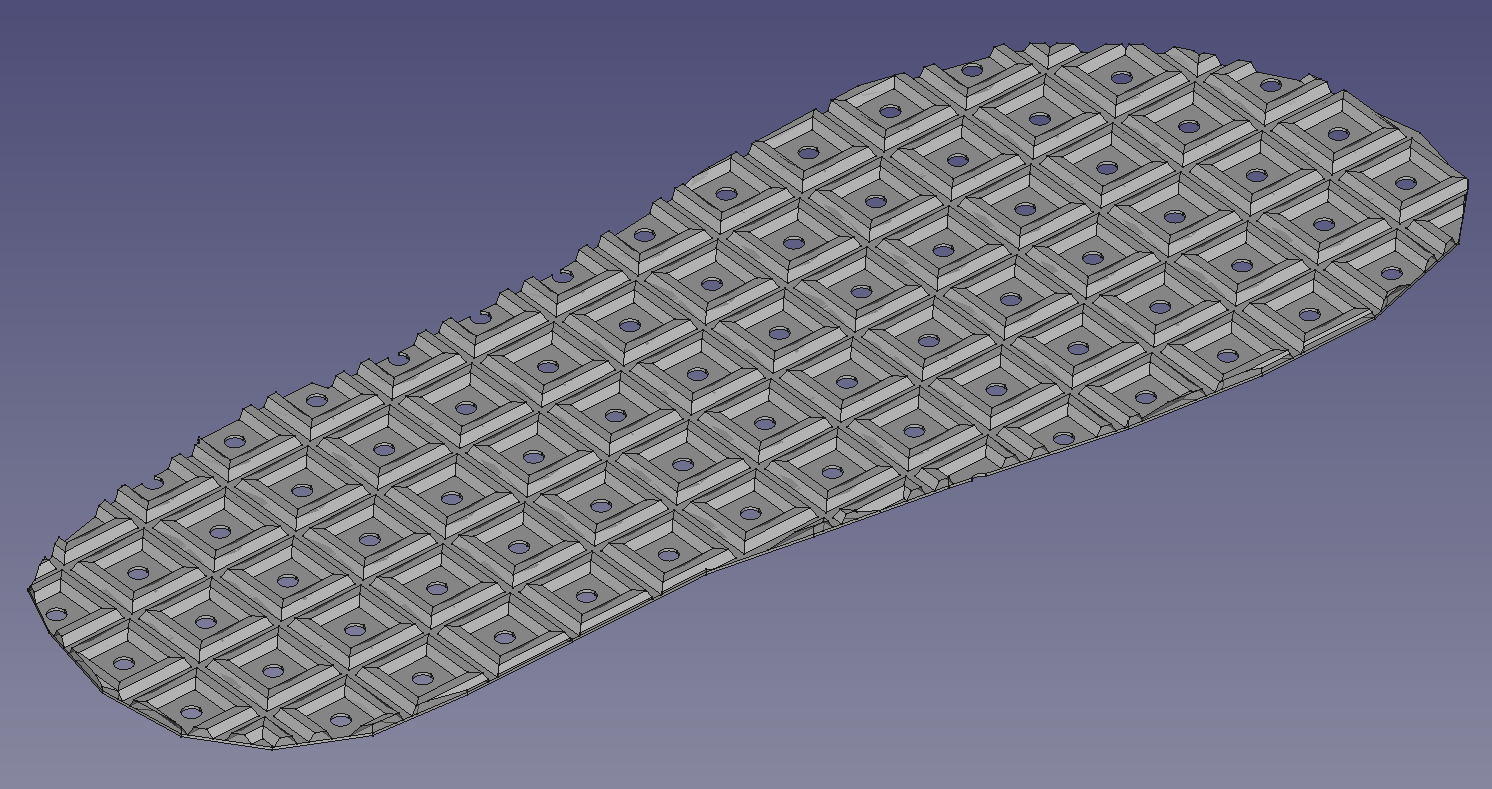

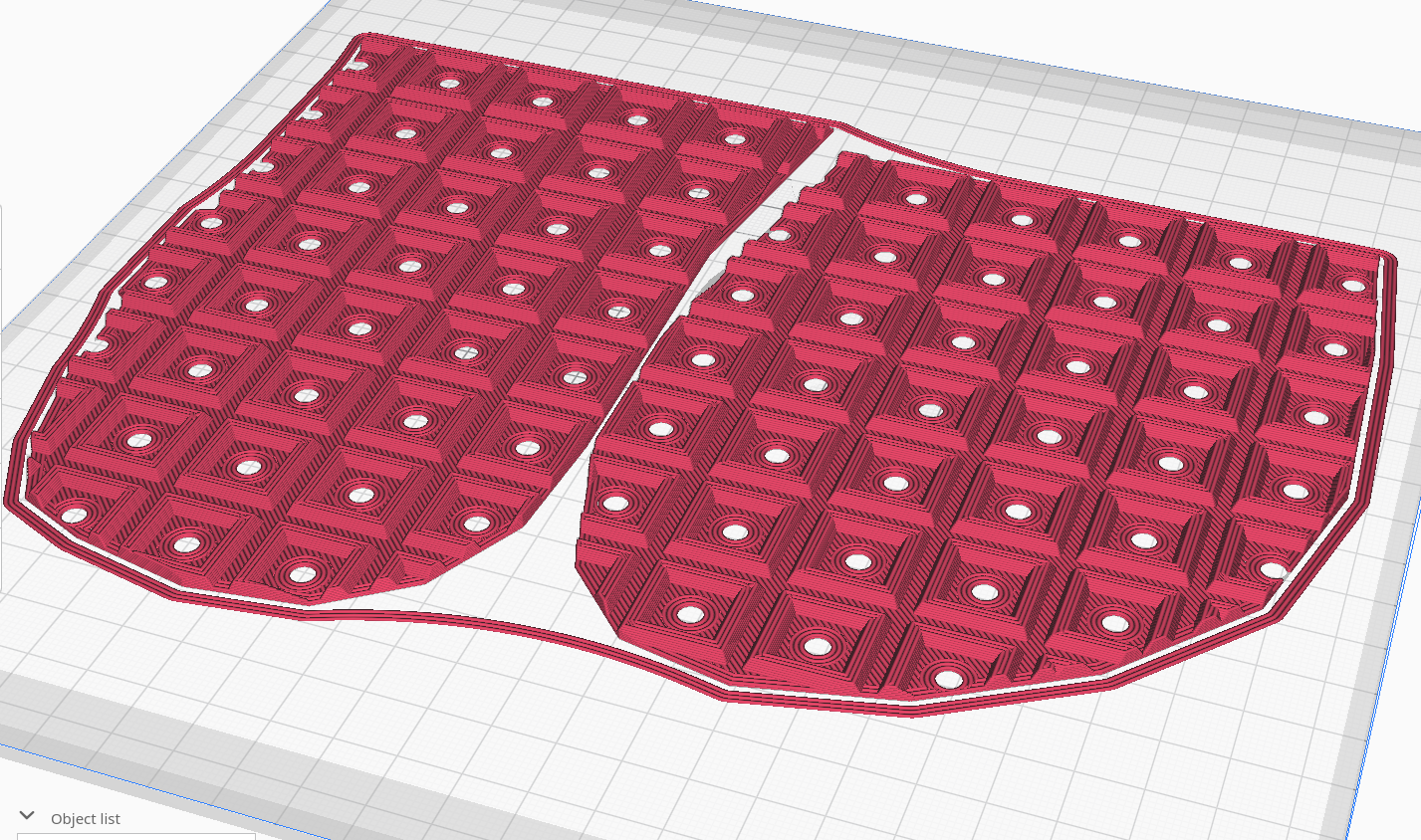

1mm Vibram soling sheet for the bottom, adhered with E6000:

https://www.amazon.com/gp/product/B00FE459NA/

https://www.amazon.com/Vibram-Tania-Protective-Sheet-Style/dp/B00I3LW9K2/

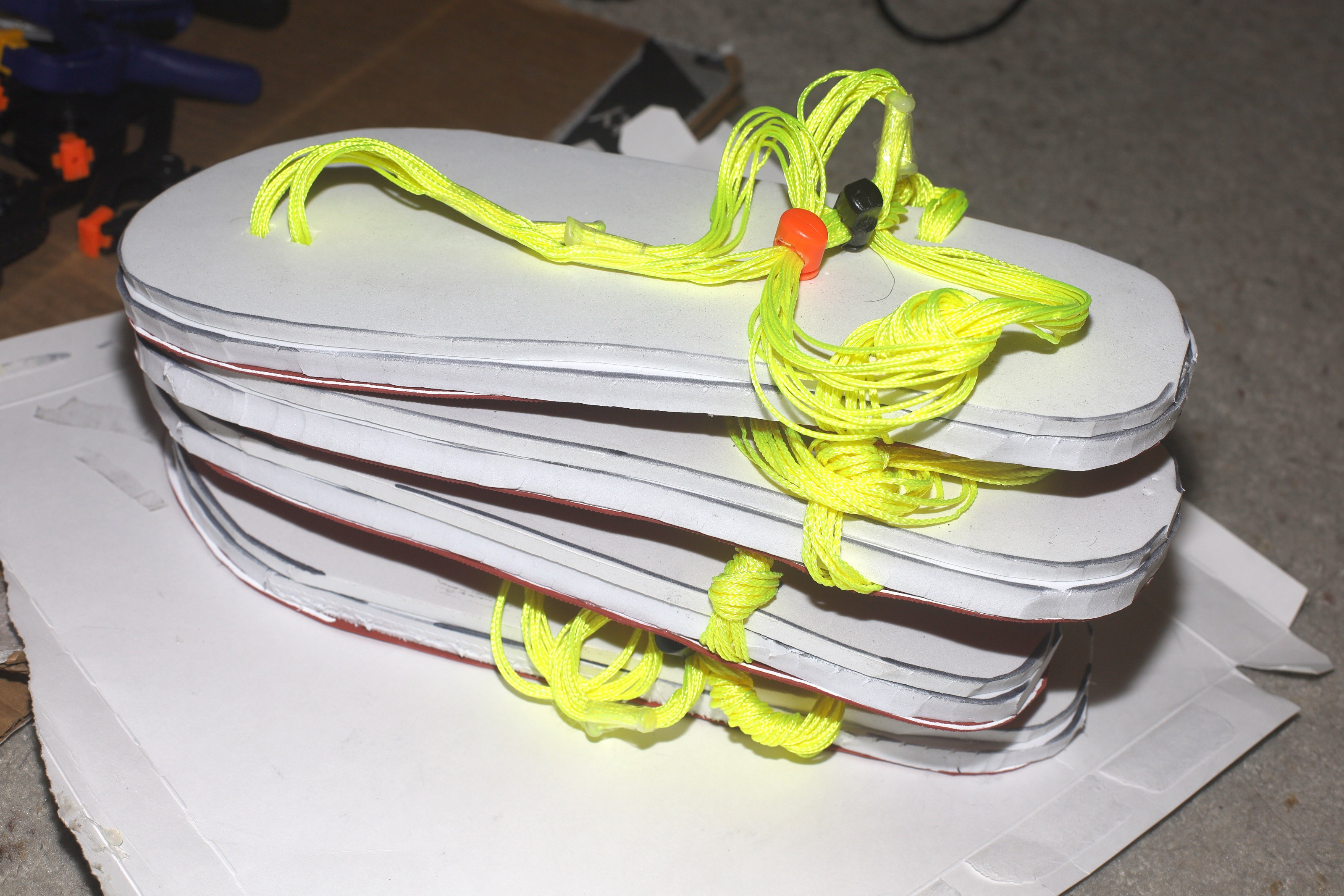

For the top, 2x6mm white EVA layers tacked by E6000

https://www.amazon.com/Bulk-Buy-Darice-1199-20-10-Pack/dp/B0033M2FBY/

or 10mm EVA combined with a 6mm EVA to get 16mm

https://www.amazon.com/gp/product/B082KH2CMJ/

Maybe a top layer of fake leather to improve traction in rain.

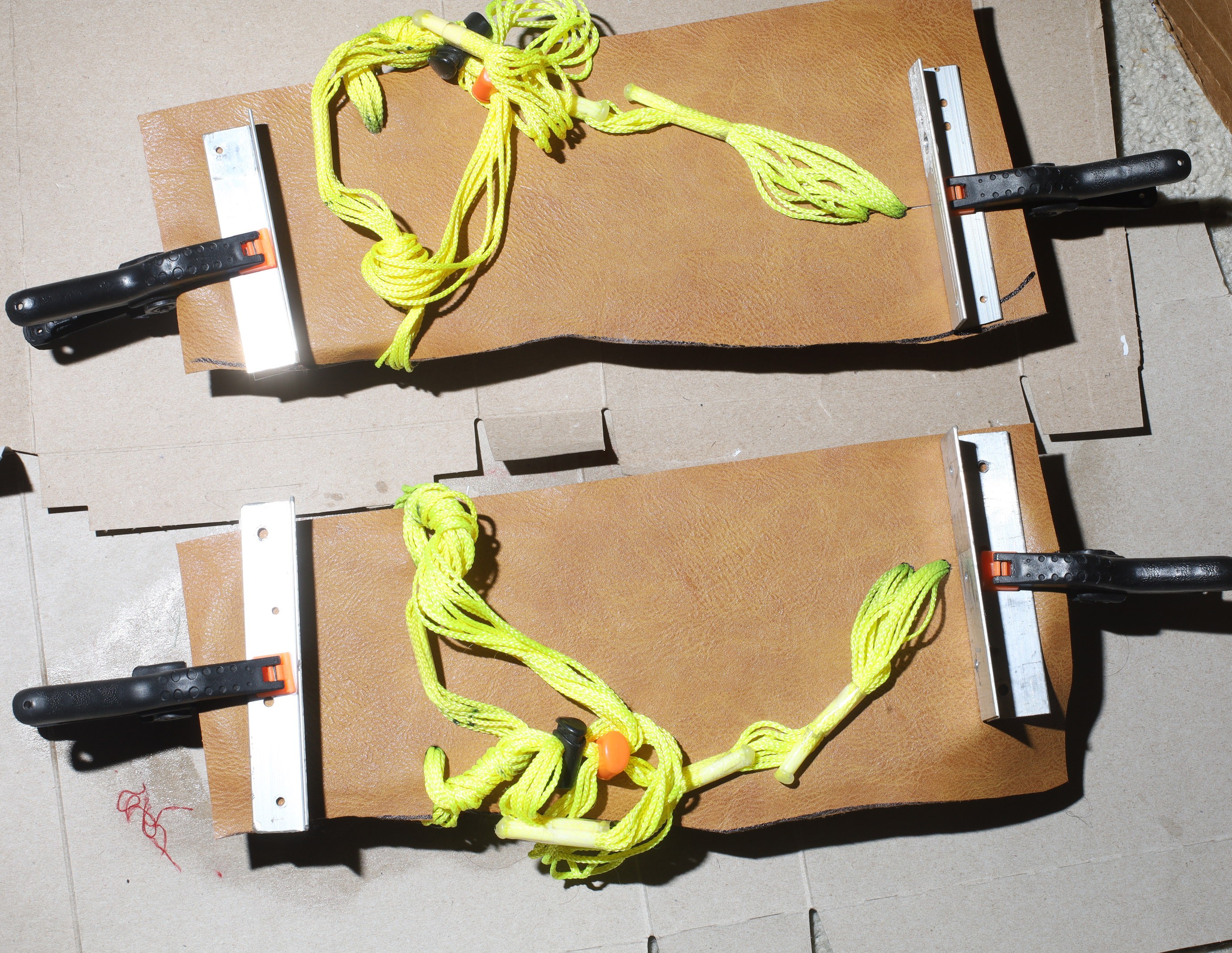

#18 yellow nylon mason line for the heel strap & toe strap.

White string is a different material that degrades over time, so yellow has been the only useful string.

E-6000 adhesive.

Hot glue.

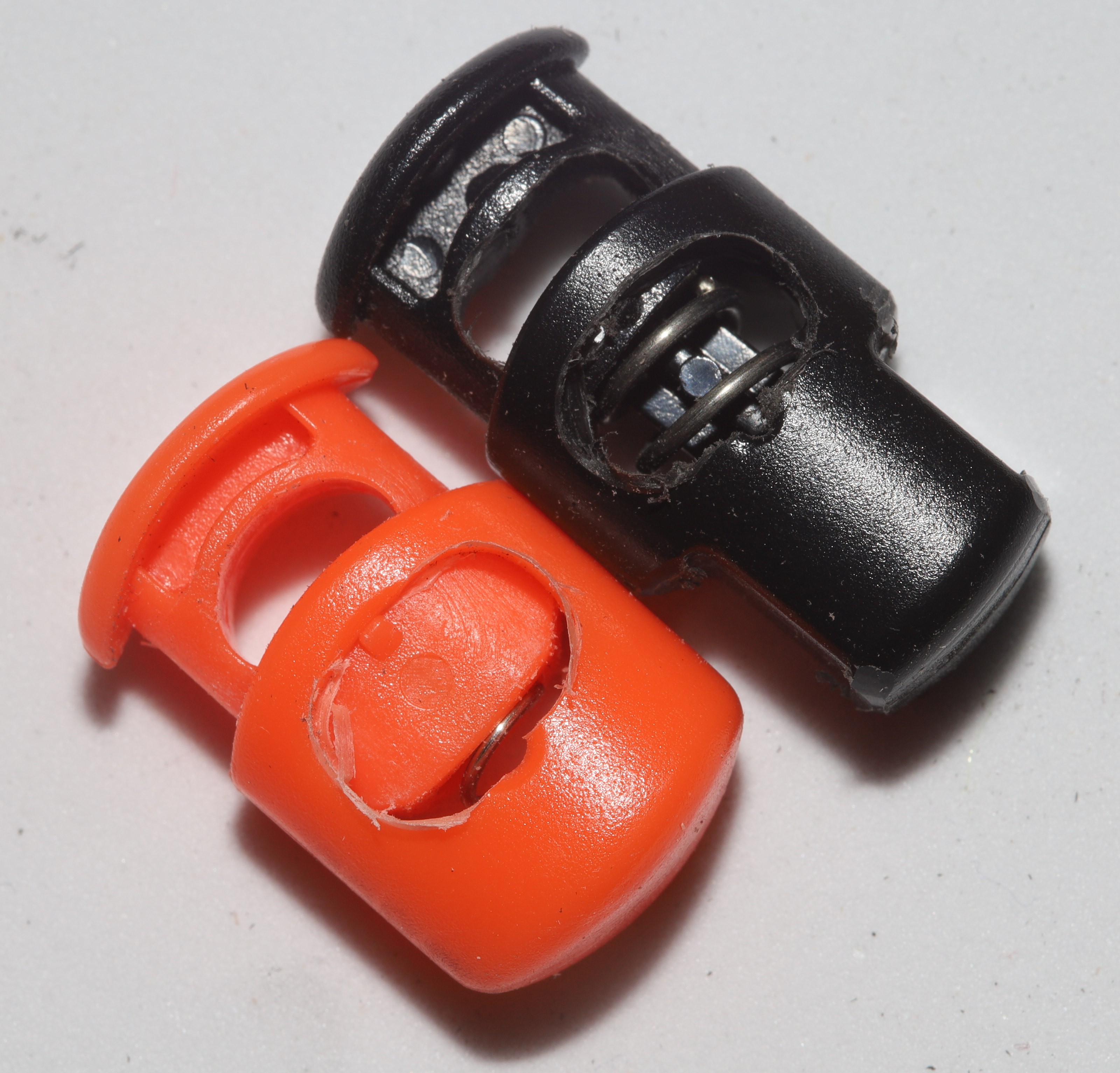

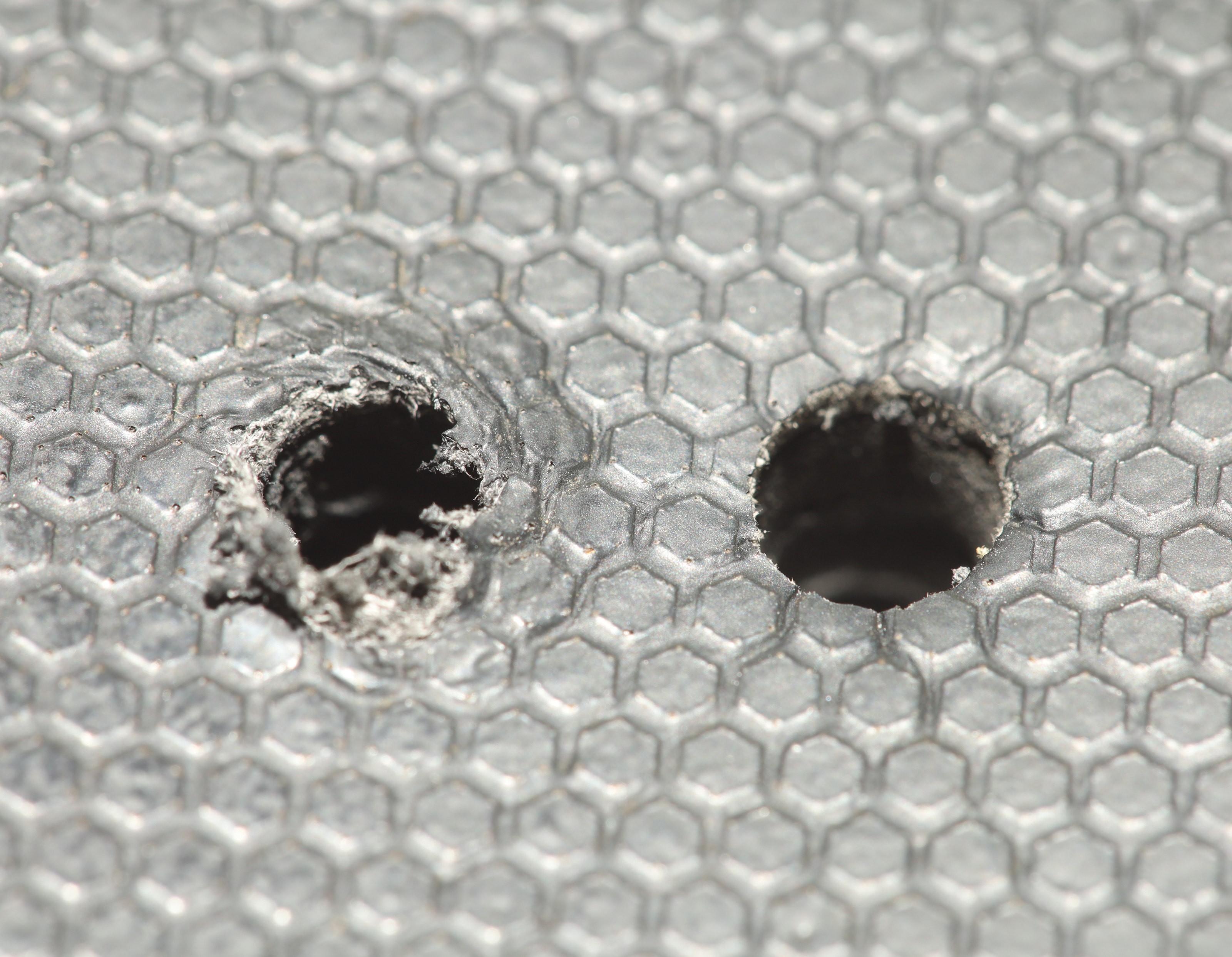

Cord fasteners with 8.25mm or bigger holes.

https://www.amazon.com/Haiker-Plastic-Toggle-Spring-Single/dp/B01JWJ911S

A polypropylene alcohol bottle turns into plastic reinforcement pieces.

-----------------------------------------------------------------------------------------------------

Assembly:

The toe strap uses a bundle of 8 x #18 string, 19" long.

The heel strap uses a bundle of 10 x #18 string,...

Read more » lion mclionhead

lion mclionhead