Let's start with what this project is about:

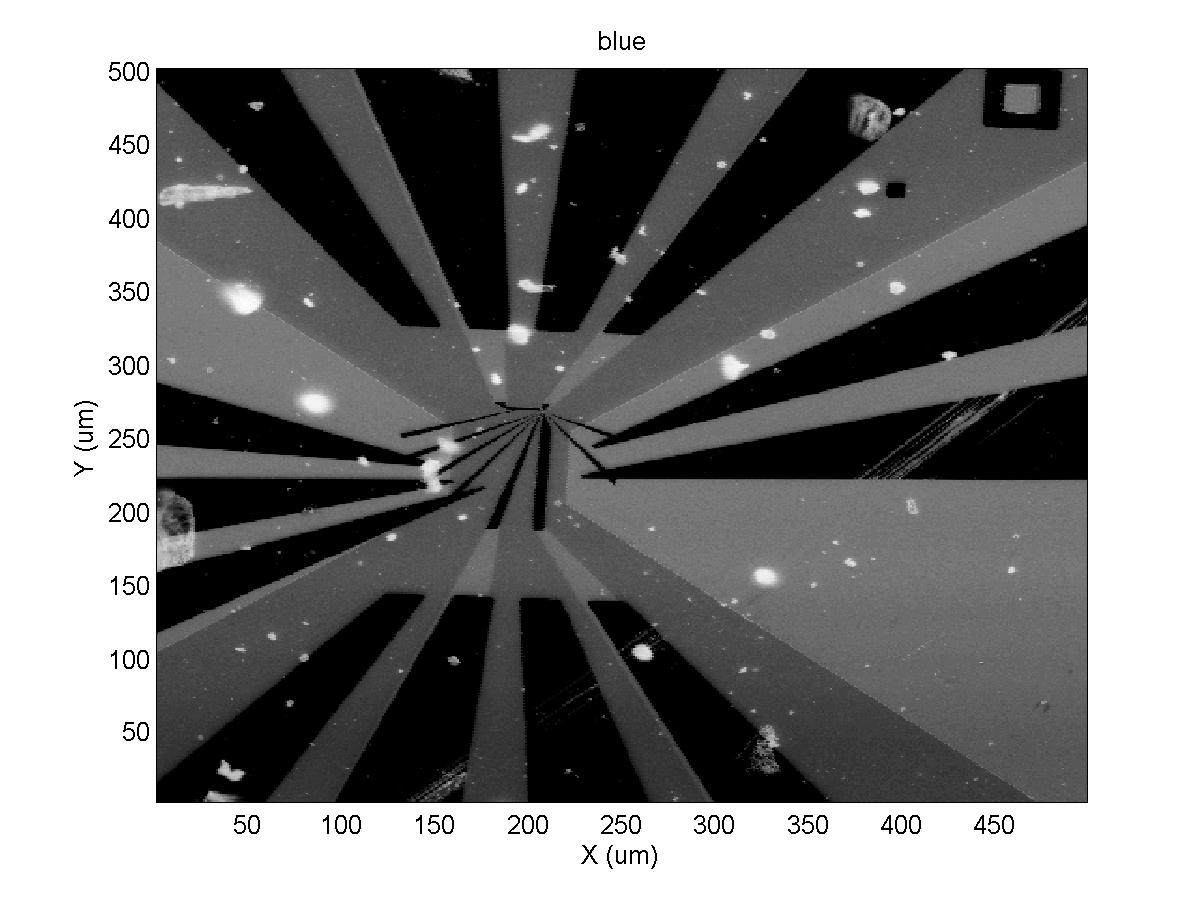

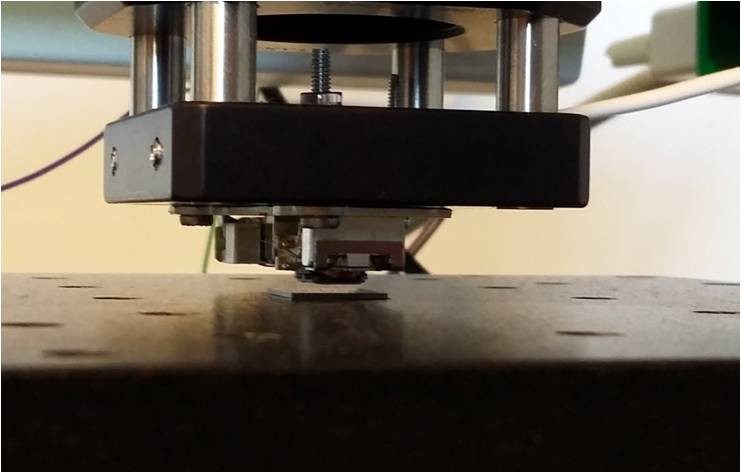

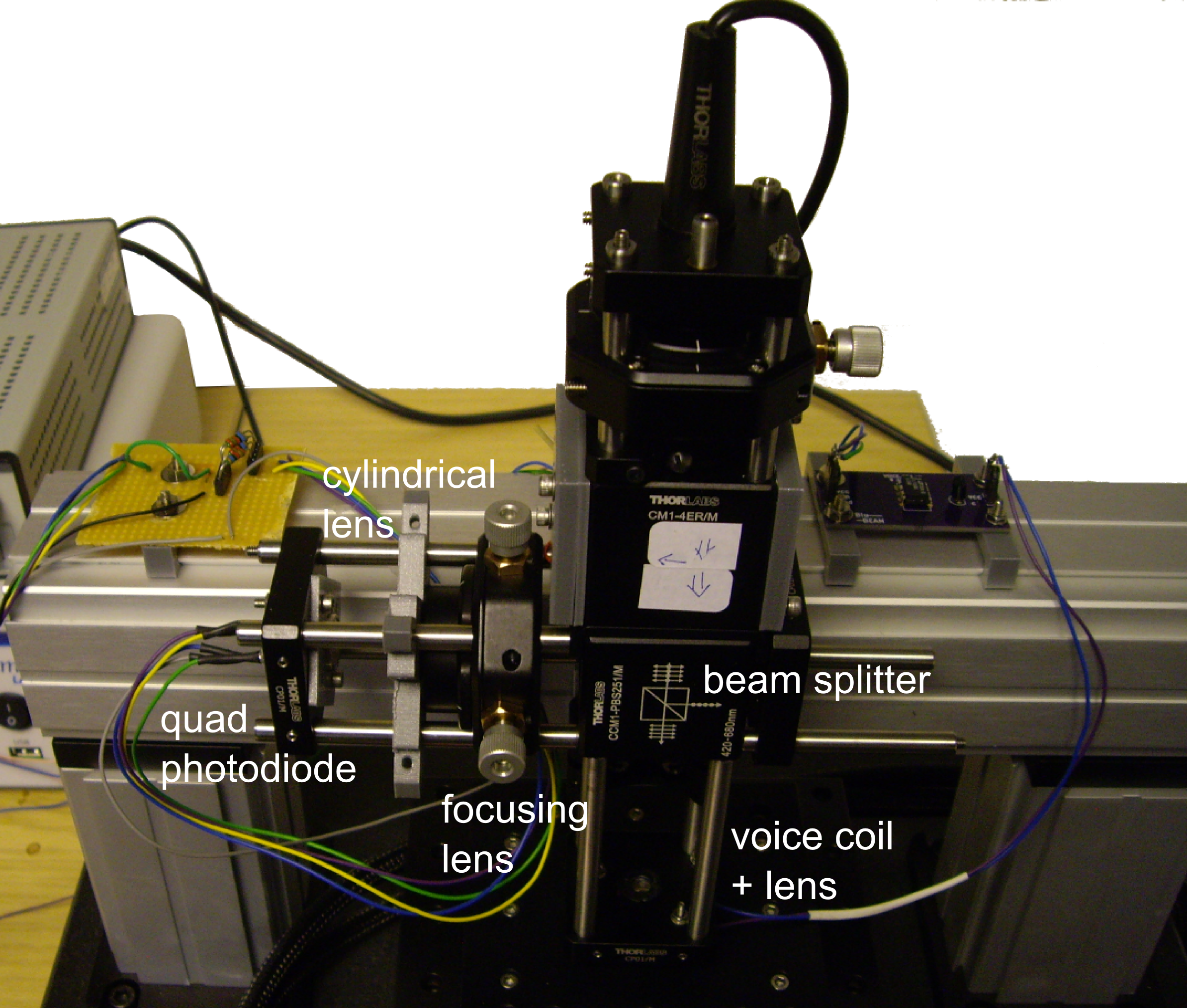

It's about imaging objects at the micrometer scale, using "off-the-shelf" components (quite literally sometimes off the things-I-took-apart-shelf) and a fair amount of reverse-engineering and hacking.

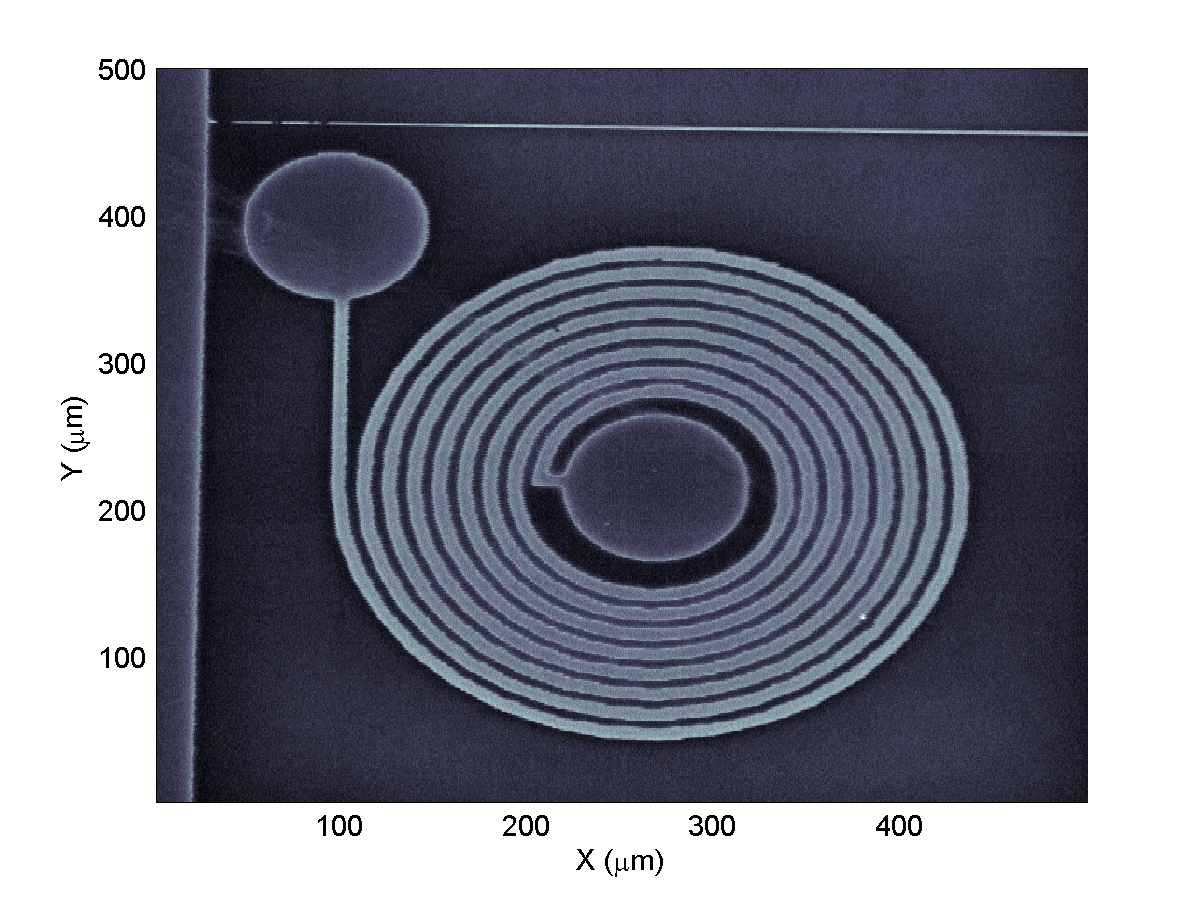

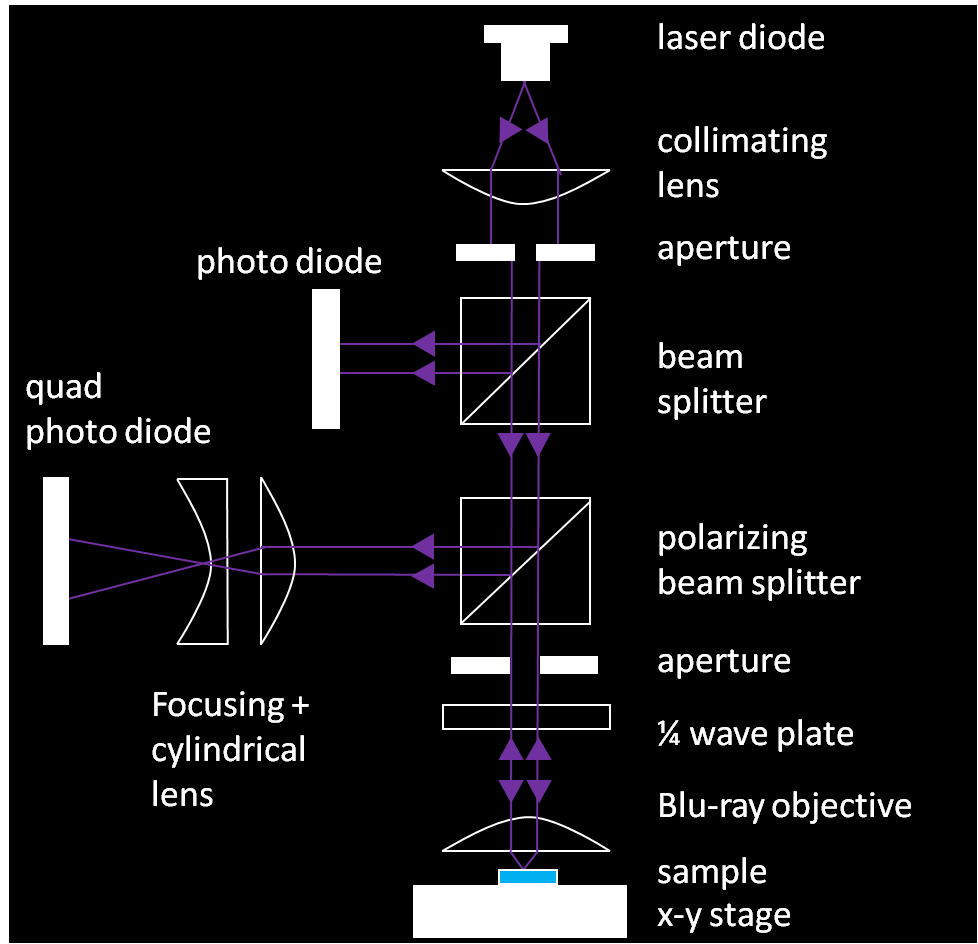

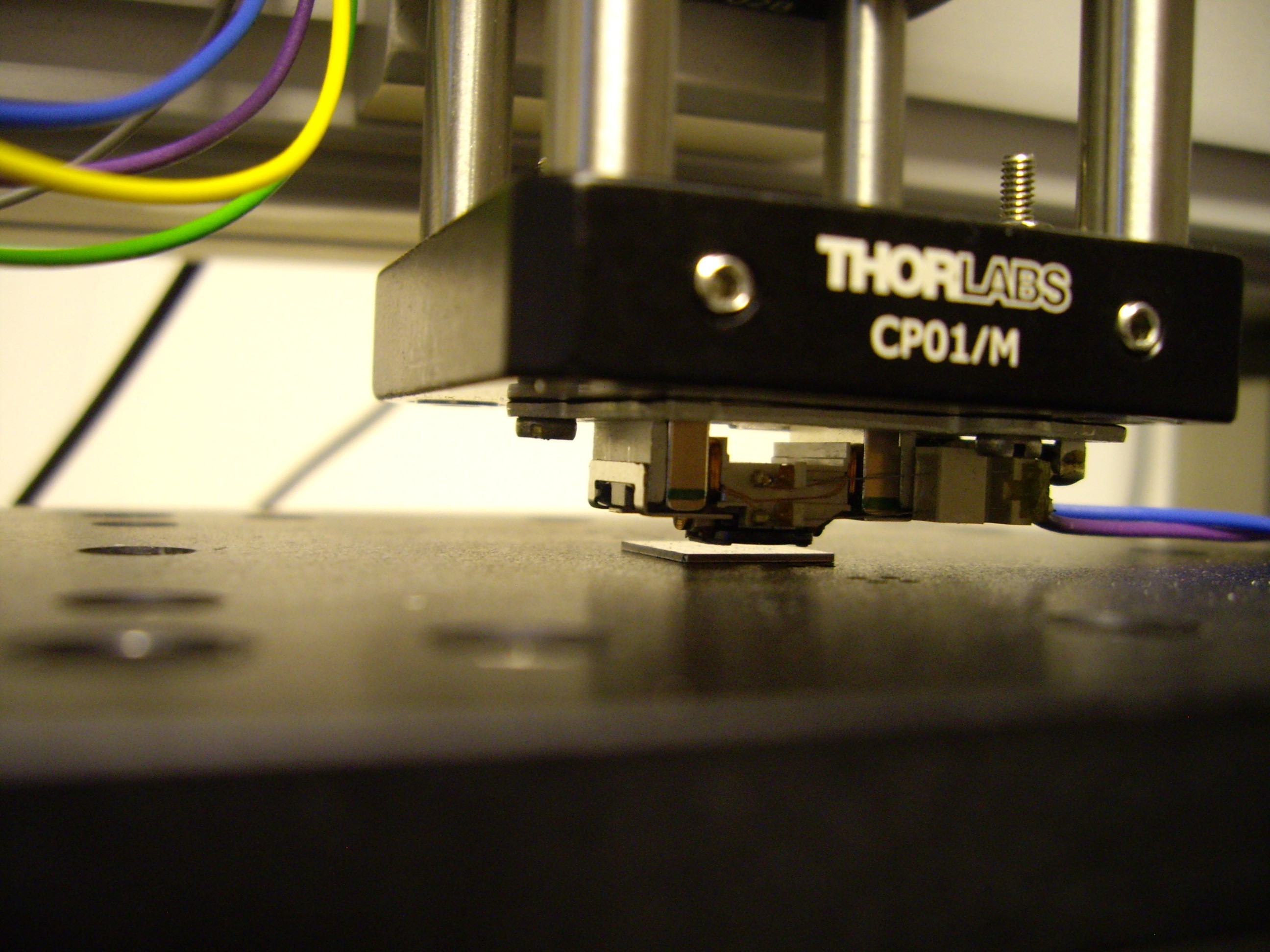

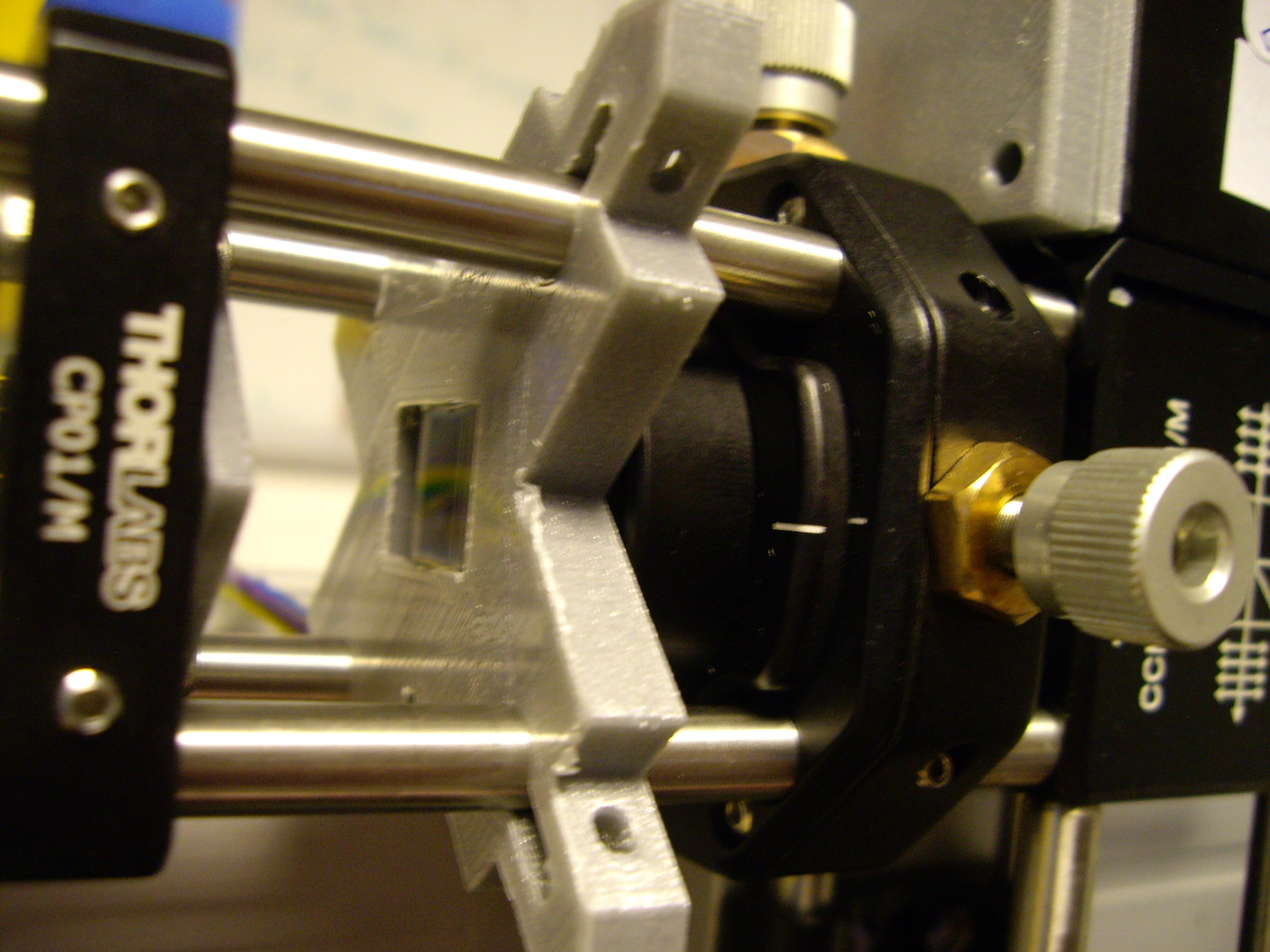

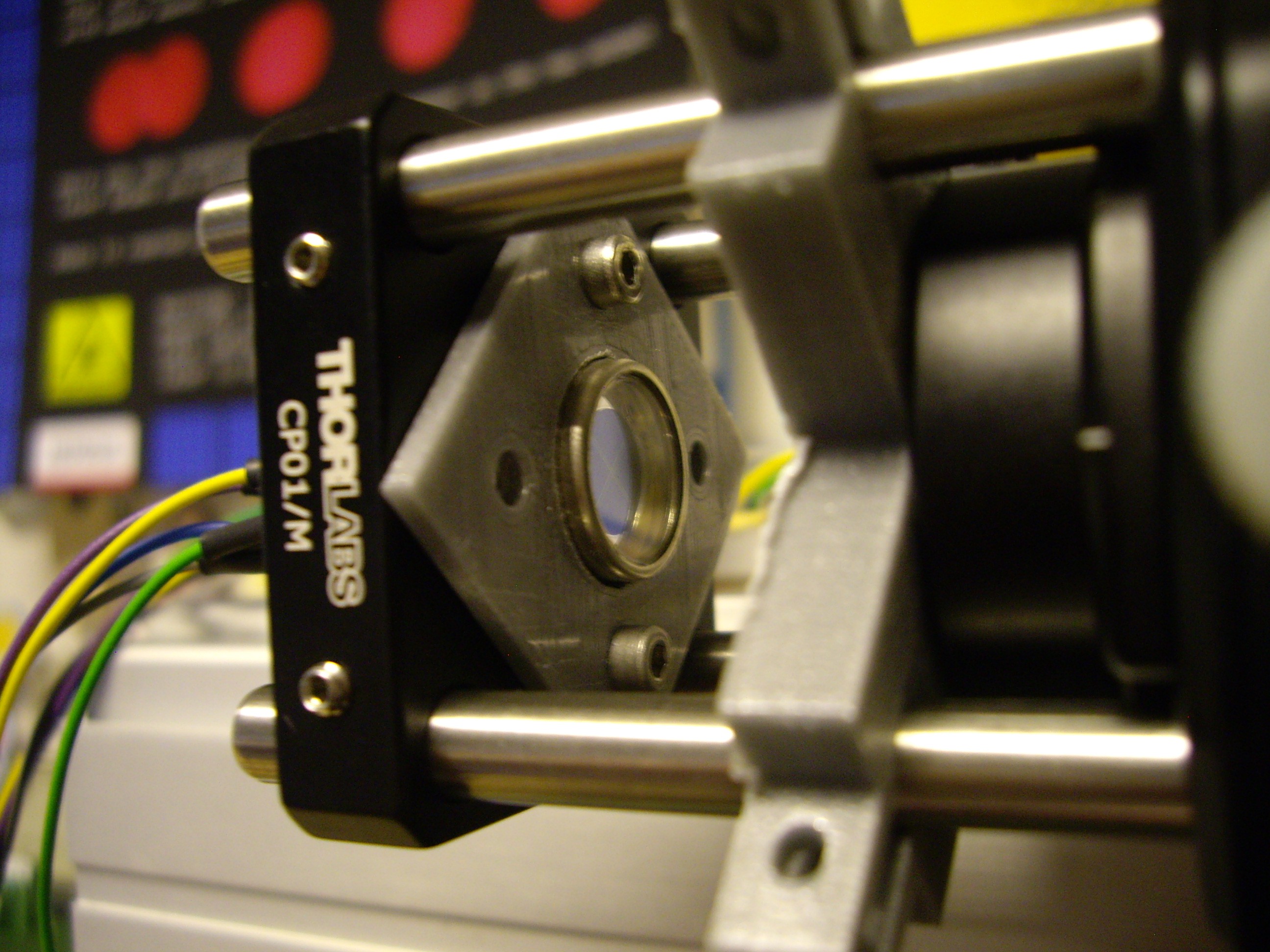

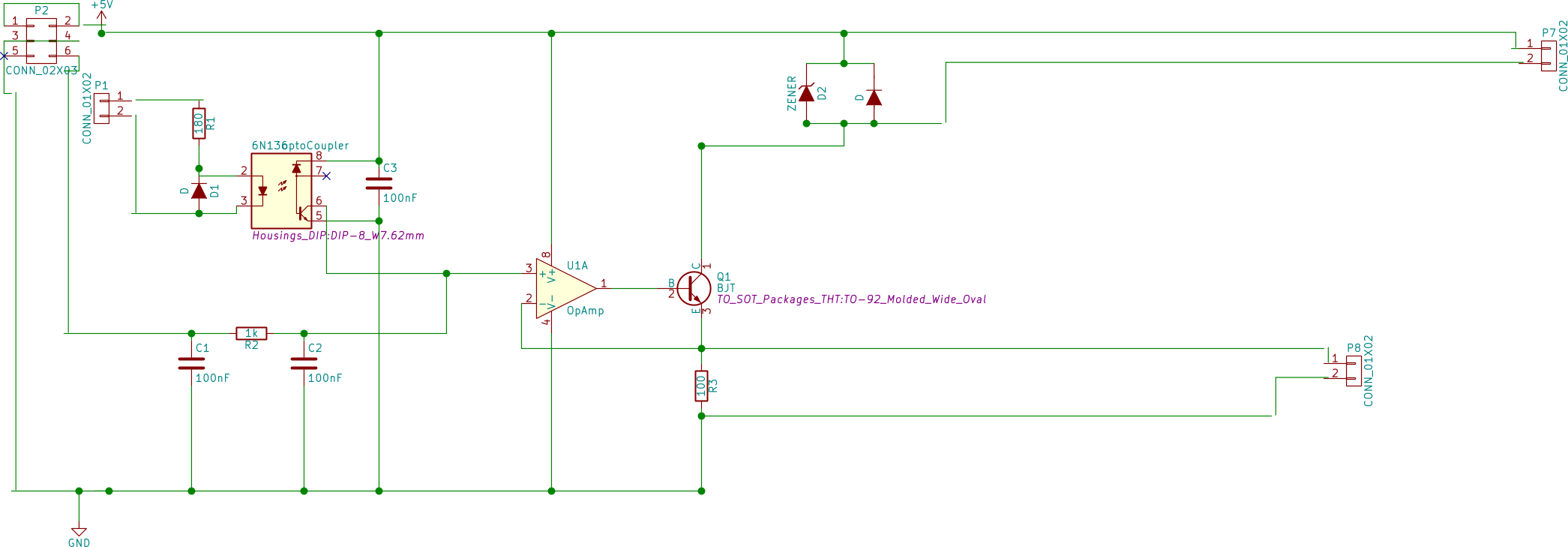

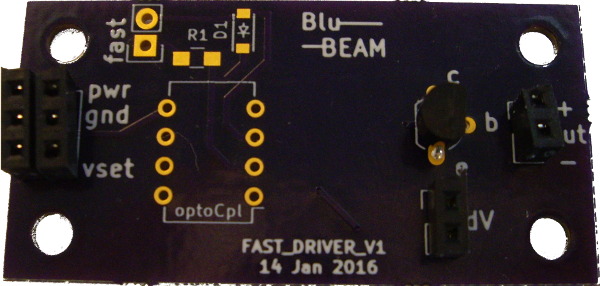

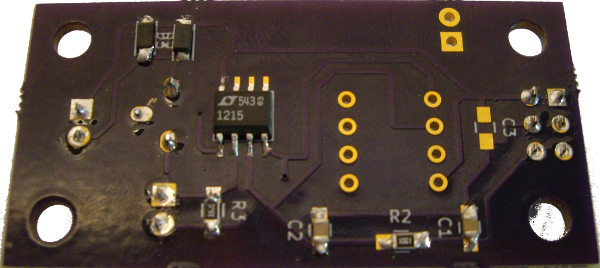

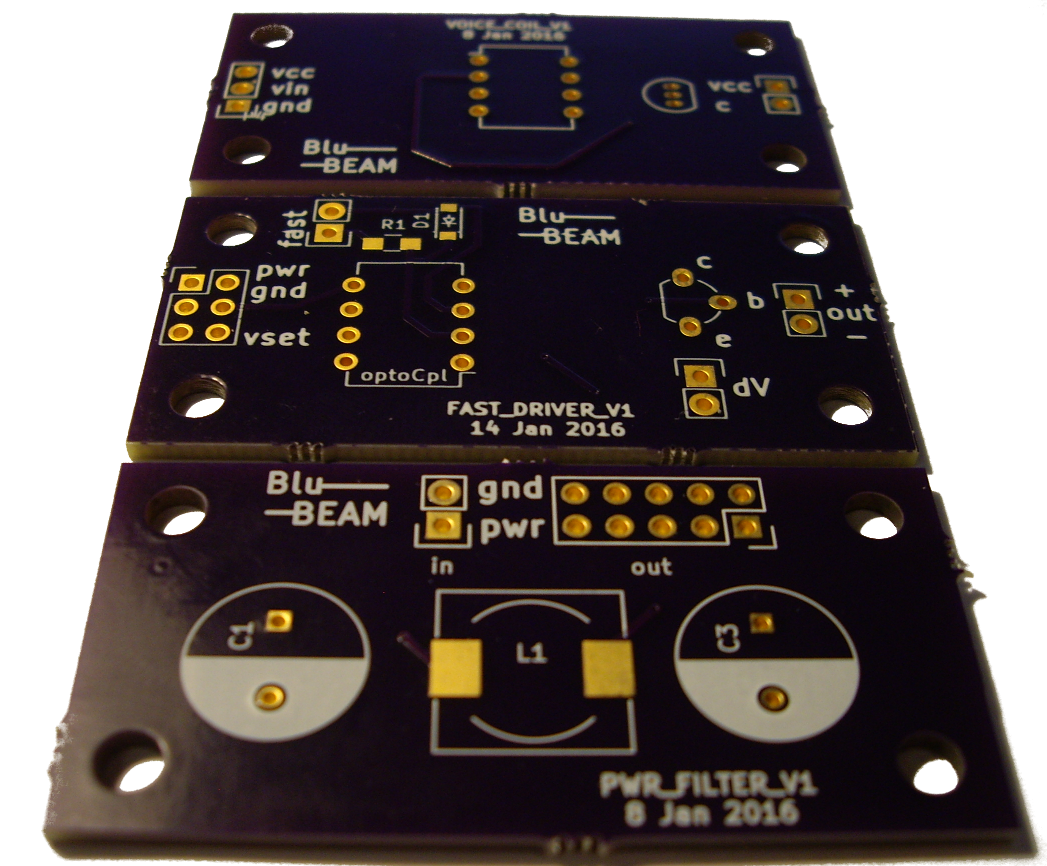

The heart of the microscope will be a Blu-Ray drive read head. It's an incredible piece of engineering, and the optical/electronic components that we need for our microscope are already in there. The challenge will be to get access to the components, to drive/read them at will, and to integrate the read head with a precision stage.

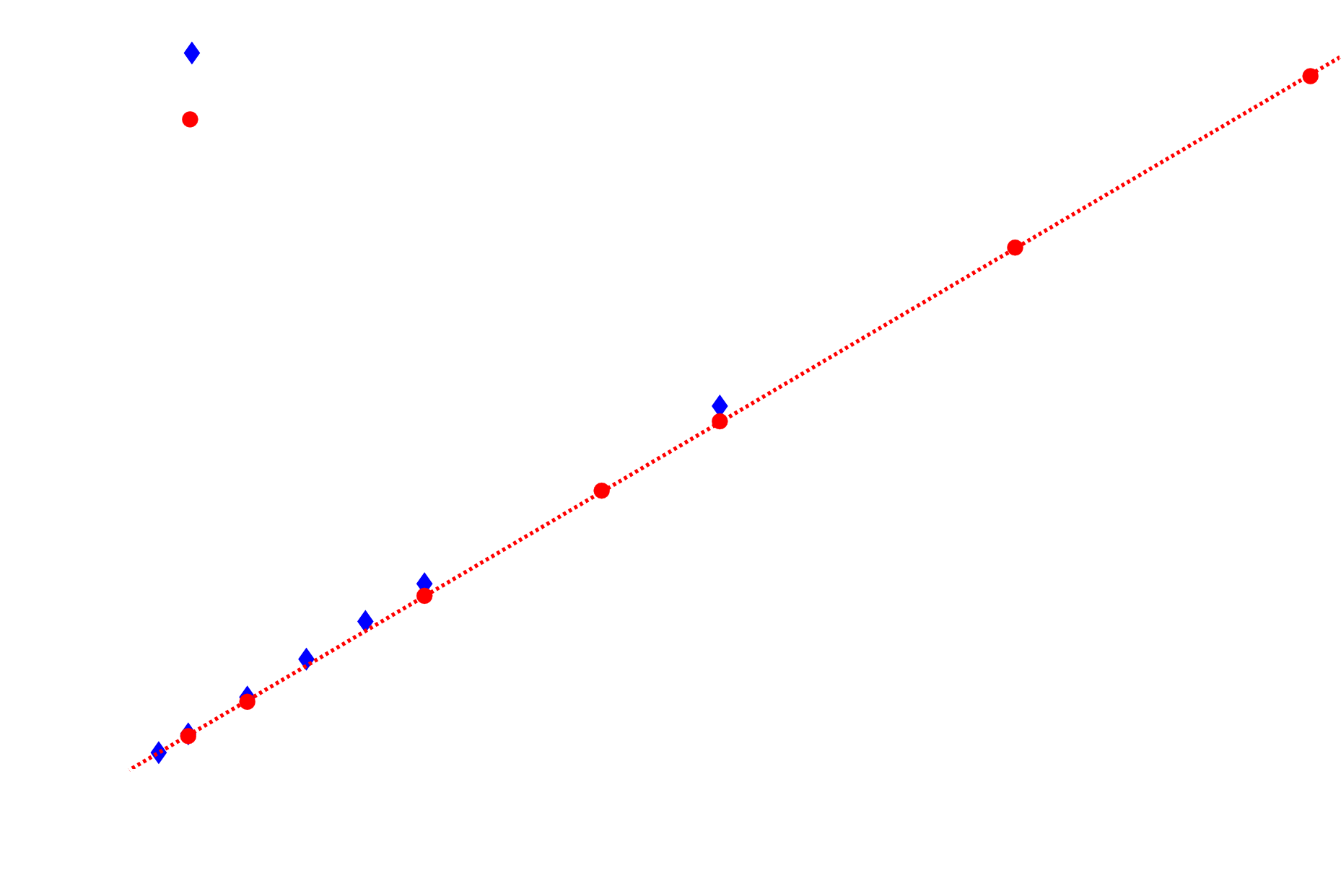

The scan area will initially be limited to 1mm in one direction and a few mm in the other.

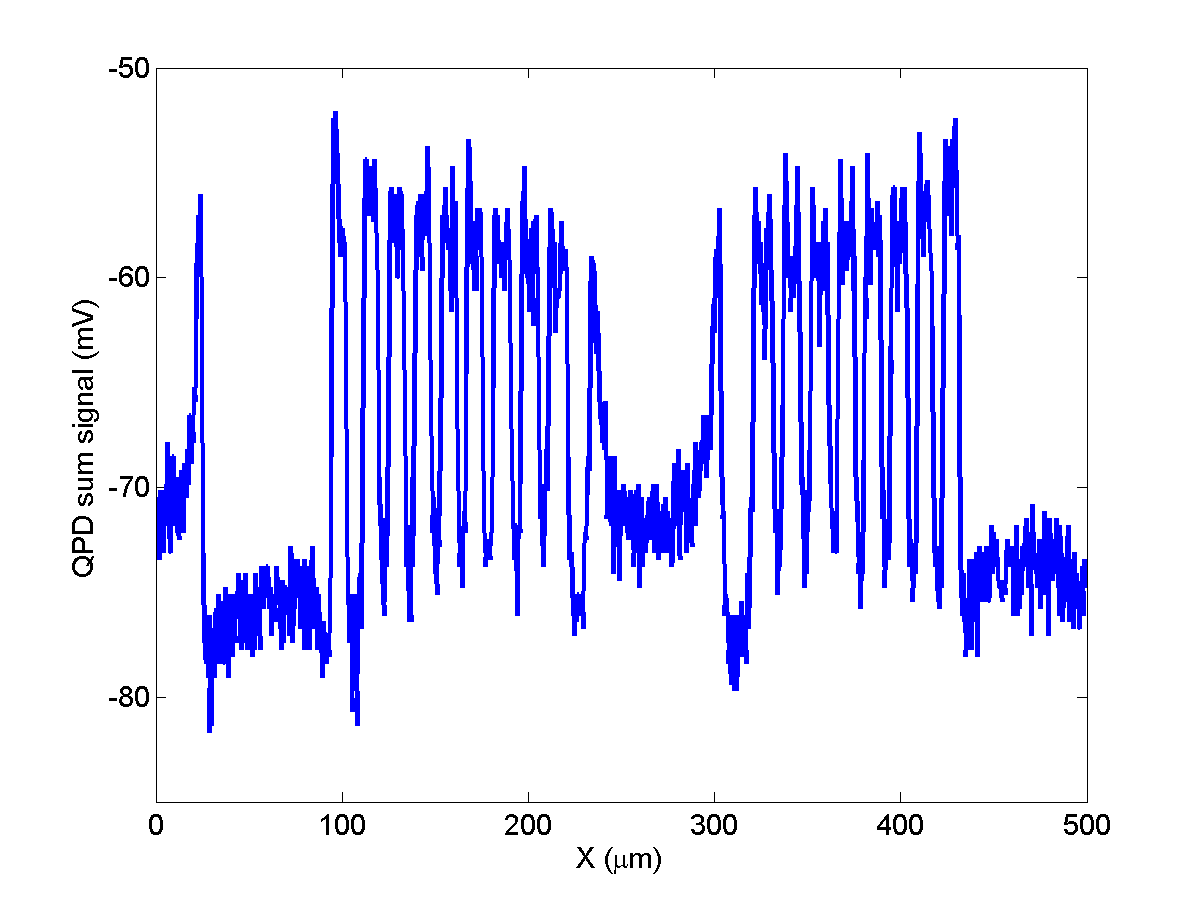

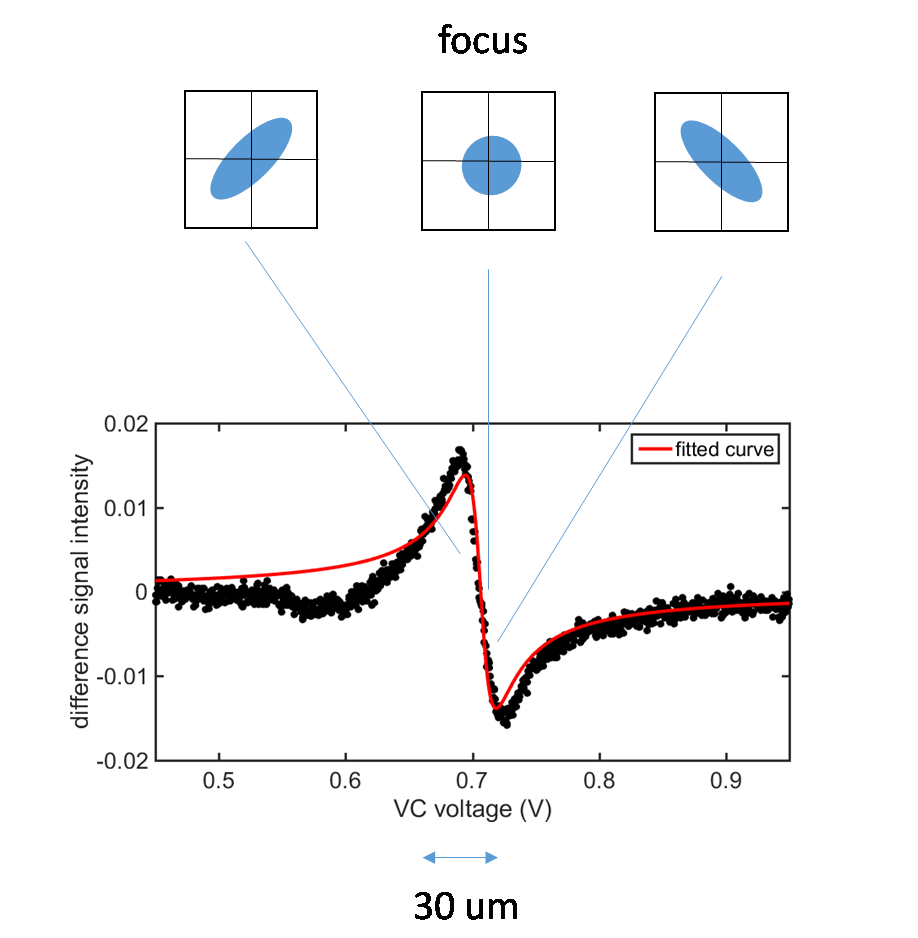

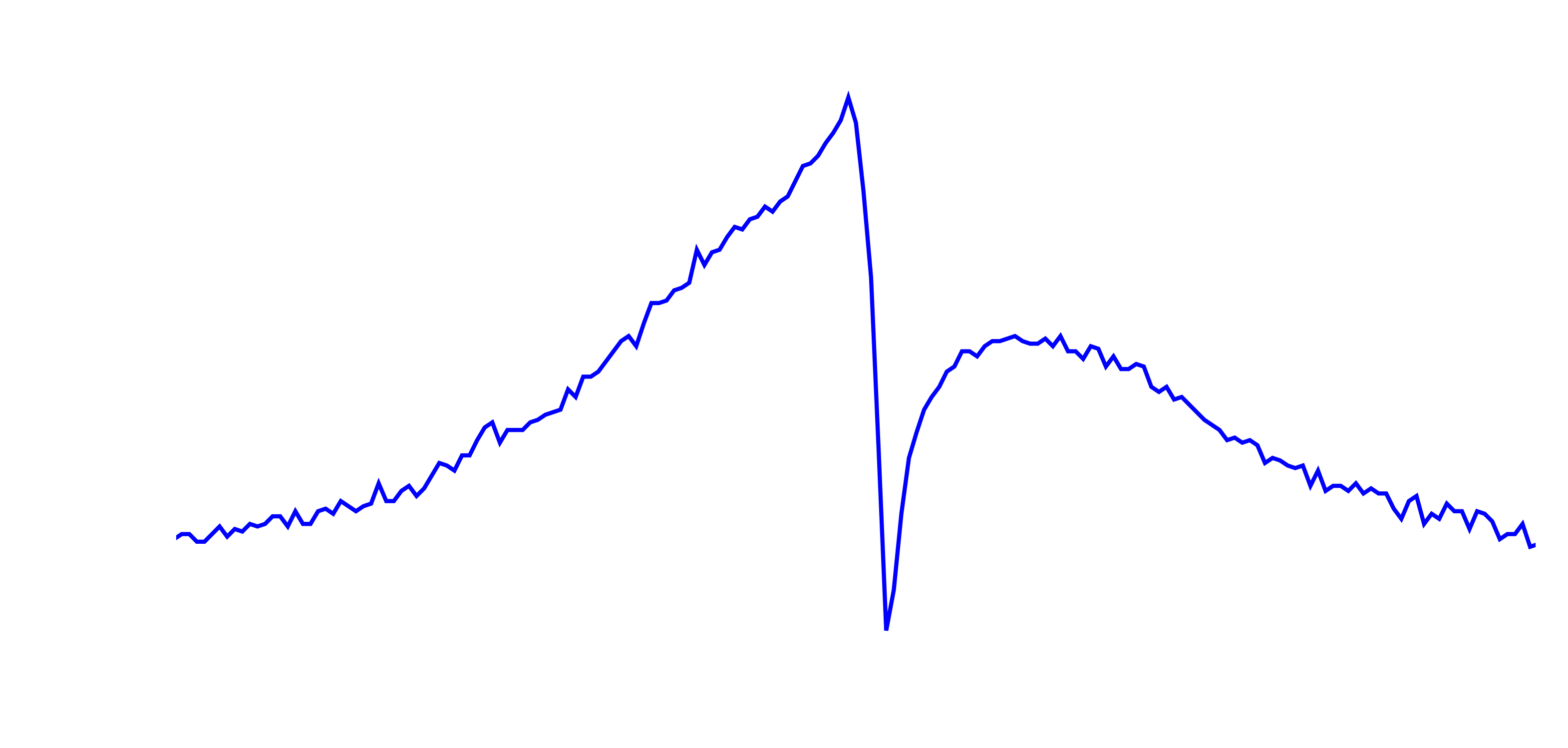

For focusing we will use the quad-photodiode built into the read head.

More detail on all of this will follow in the project logs, as and when we achieve them.

andreas.betz

andreas.betz

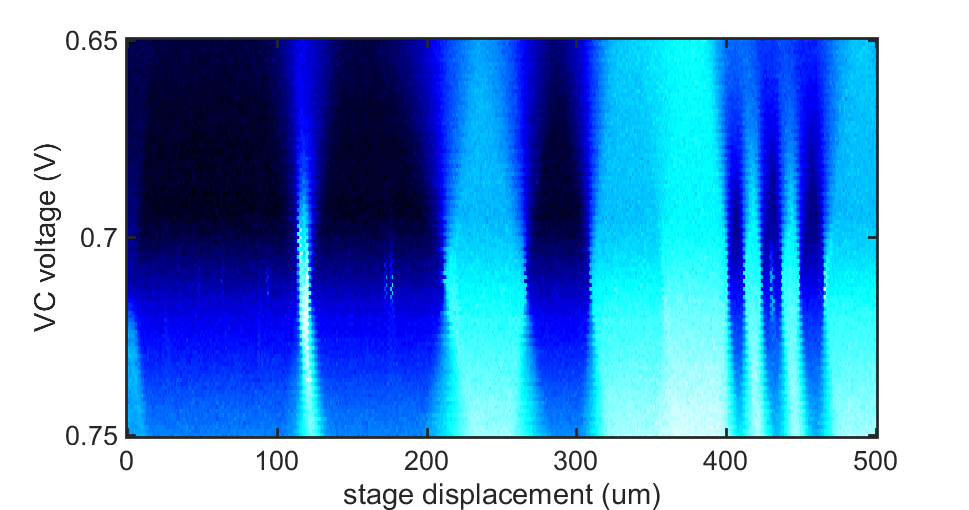

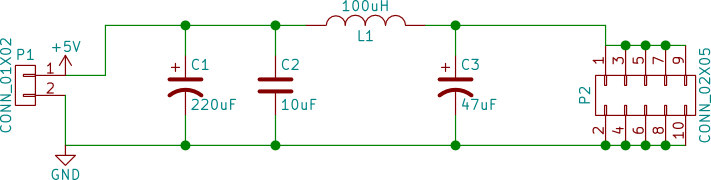

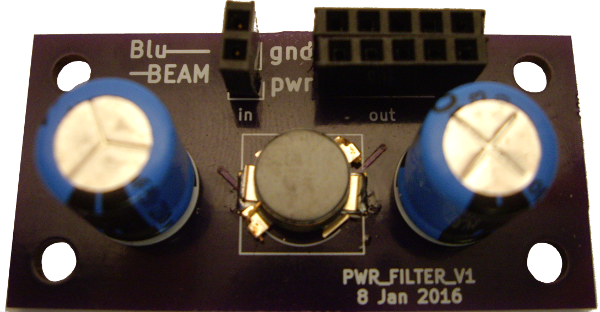

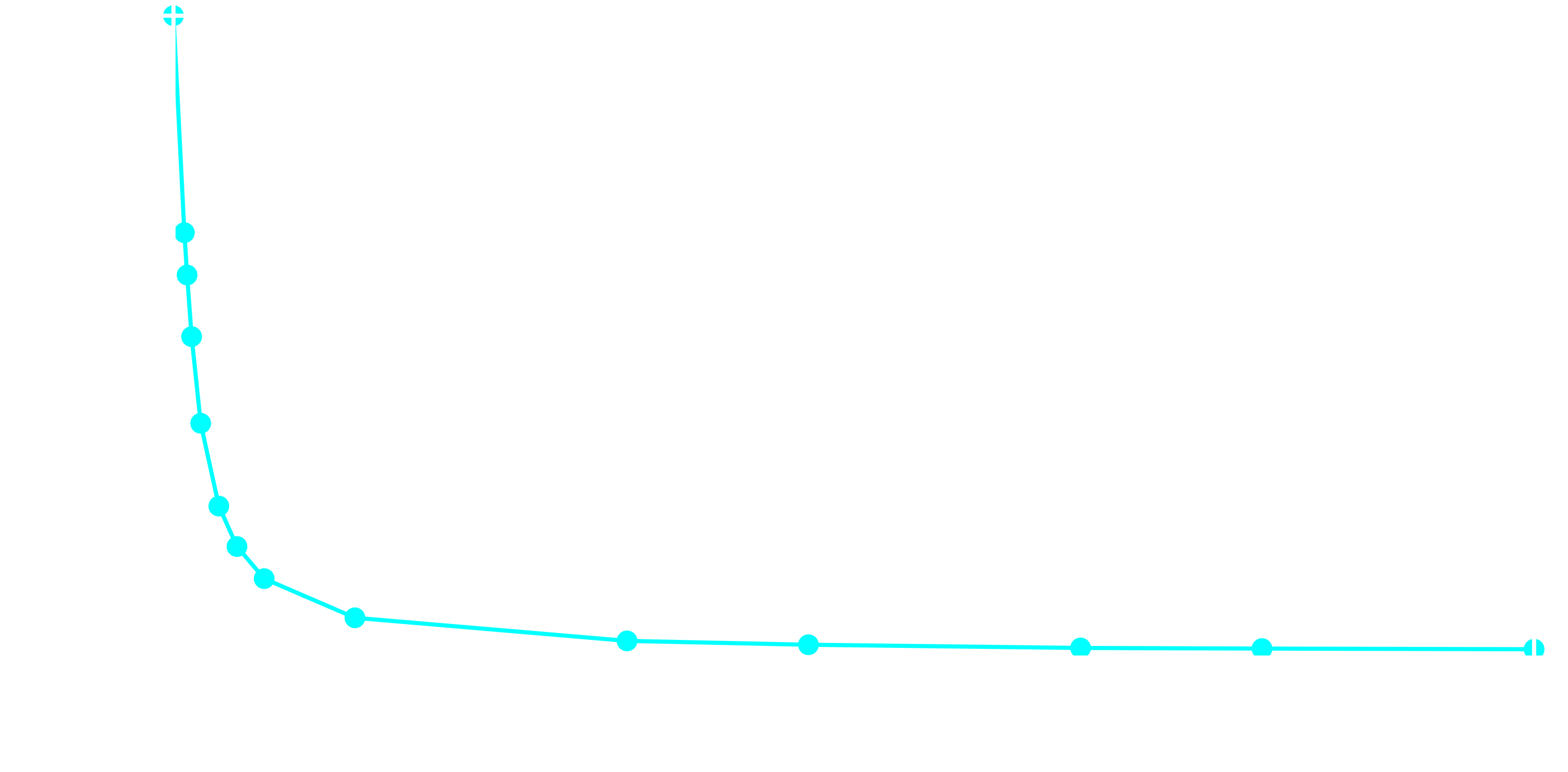

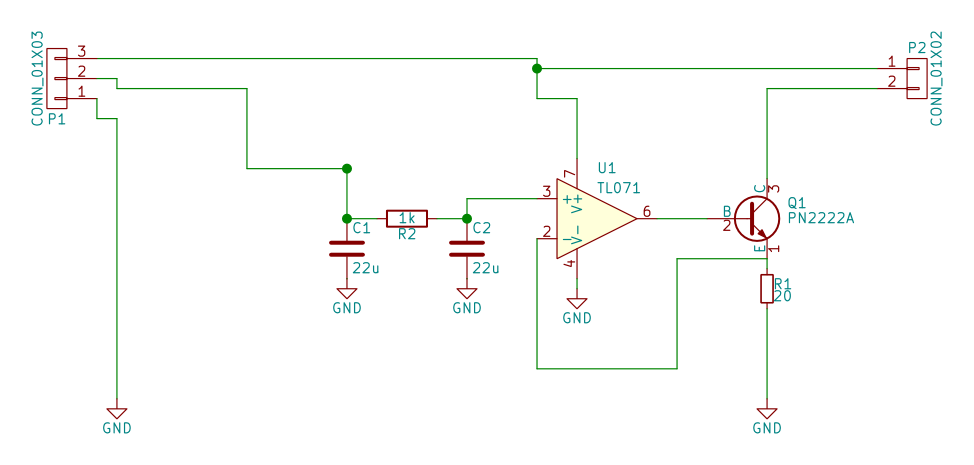

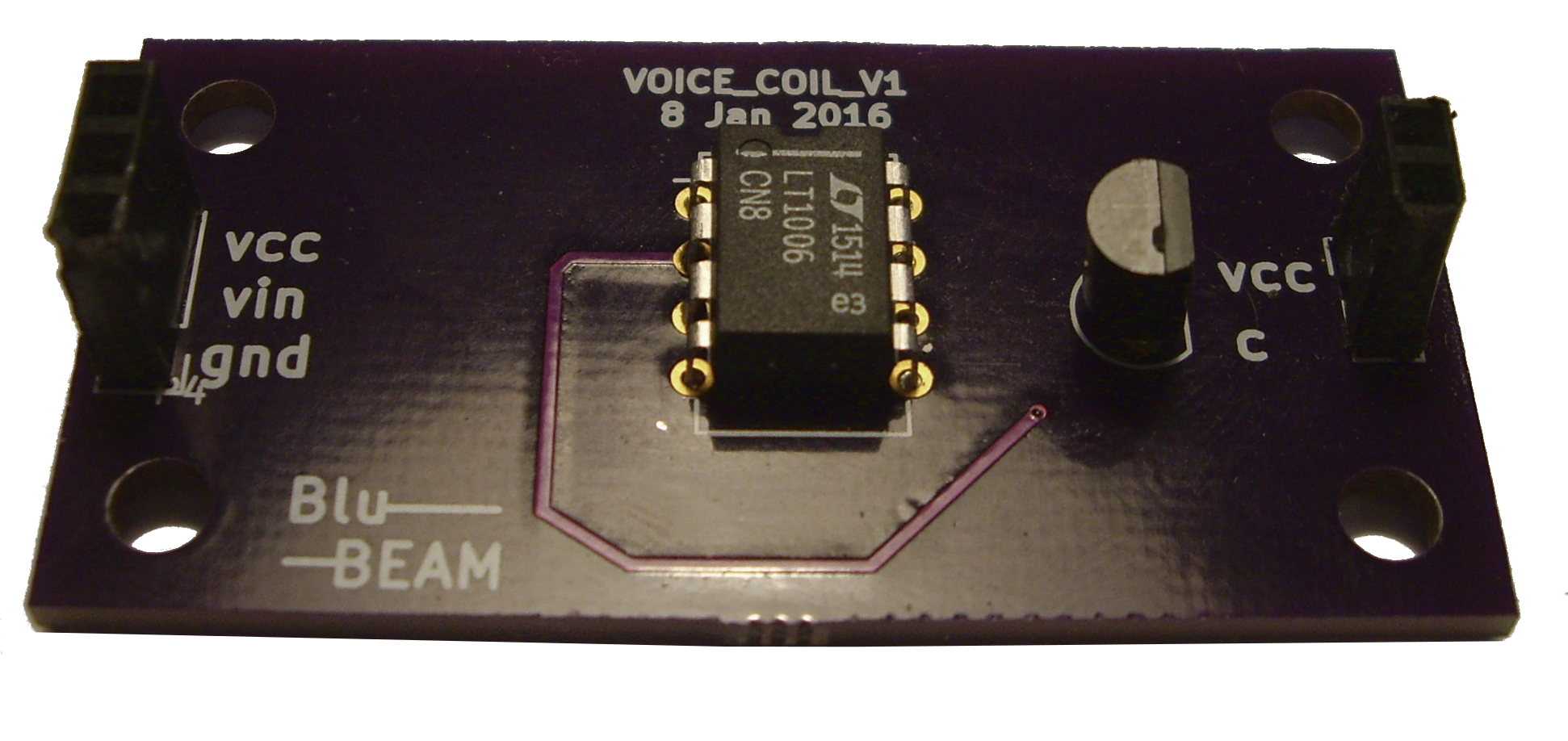

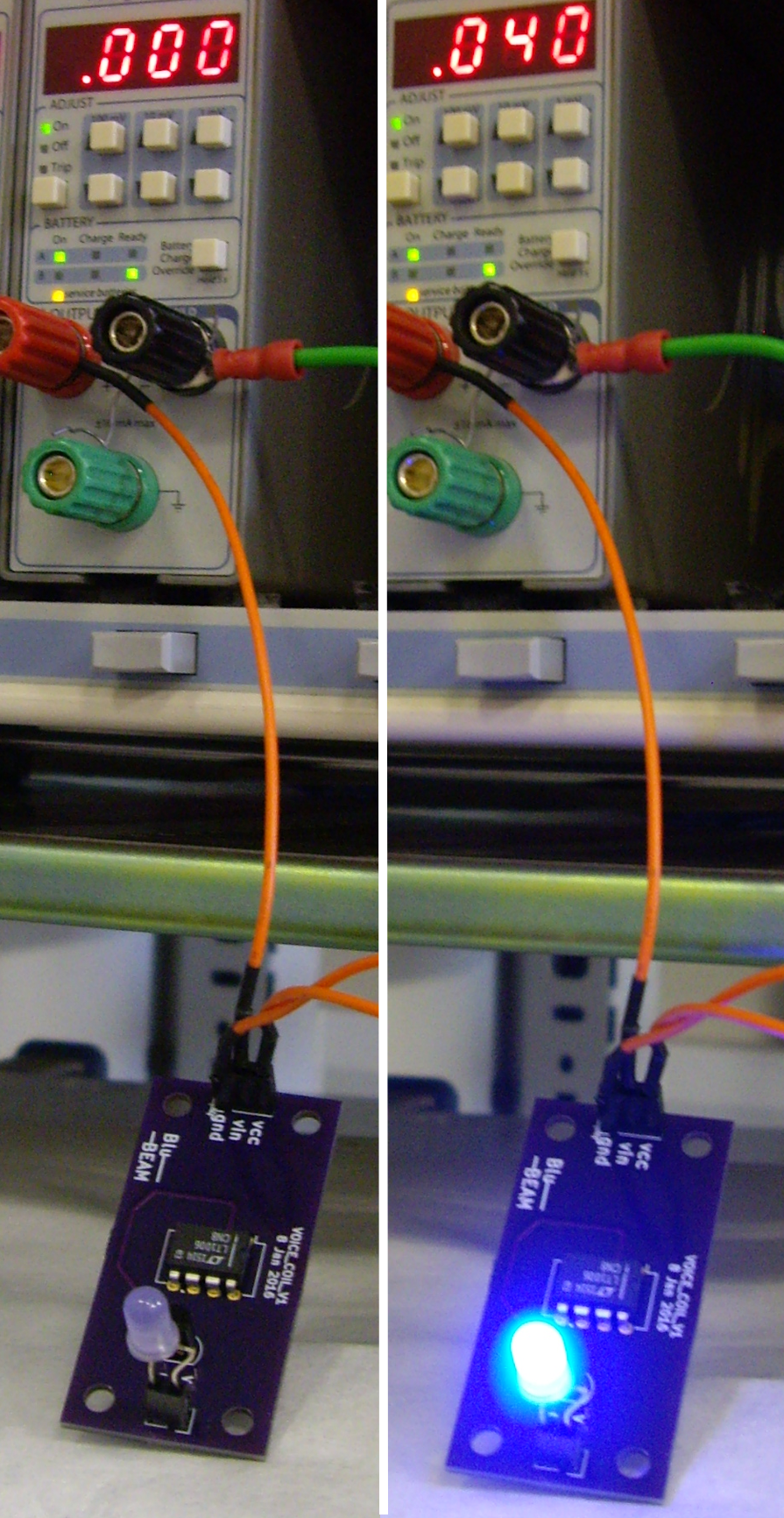

It allows us to have a dynamic focus range of several mm, paired with μm precision, all controlled by an DC voltage input to the

It allows us to have a dynamic focus range of several mm, paired with μm precision, all controlled by an DC voltage input to the

Cool! maybe you can also check my hacking: https://www.youtube.com/watch?v=5bqujaldaCQ