Survey of results got so far:

PLA: little testing done, no noticeable effect found.

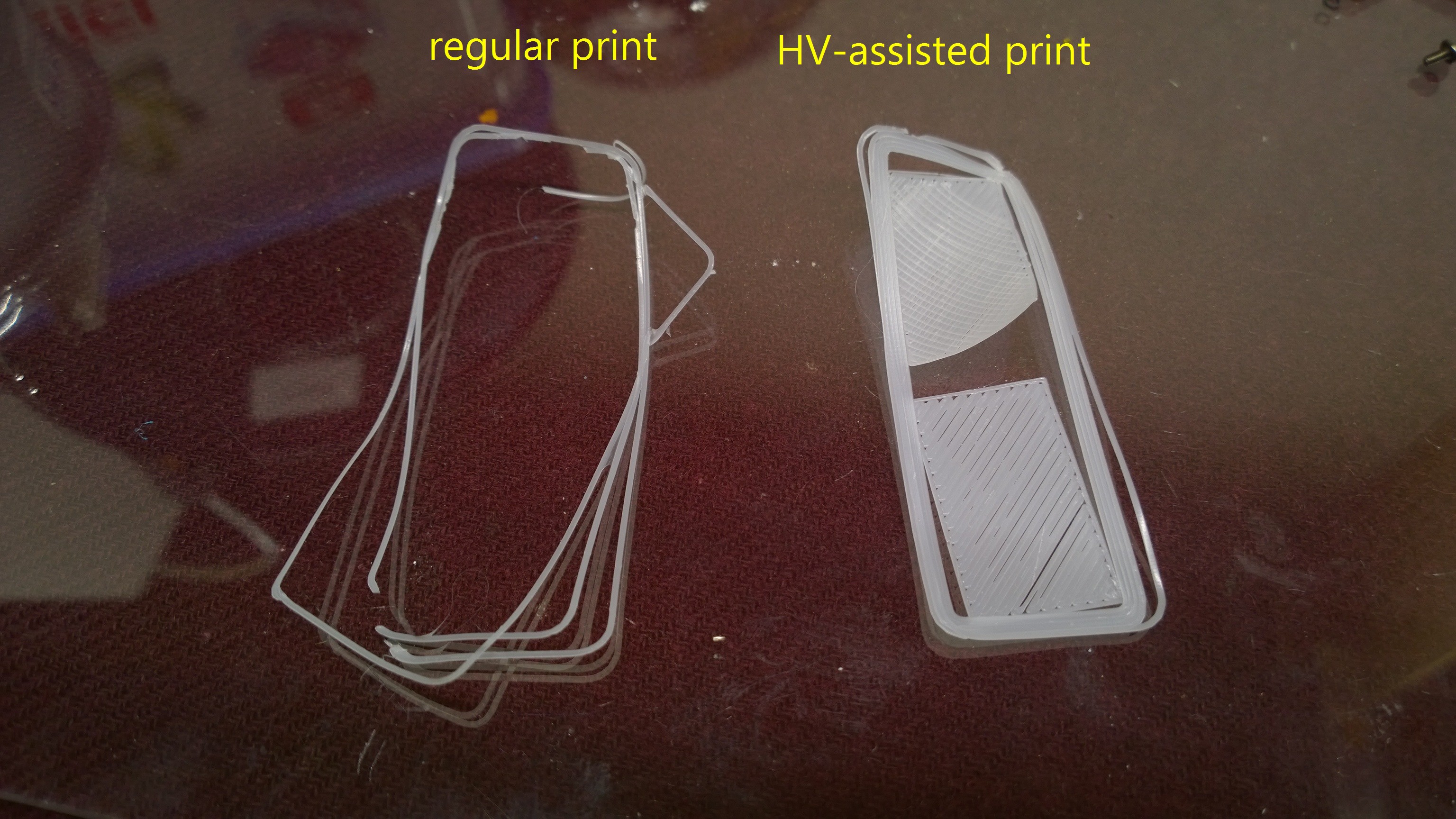

ABS: dramatic improvement. Apparently, high voltage is needed only for first print. The first print primes the surface, which makes further prints stick just as well with no voltage applied. Primary suspect is that arcing is at play here, not charges embedded in plastic.

POM: helps, but not anywhere close to enough.

DeepSOIC

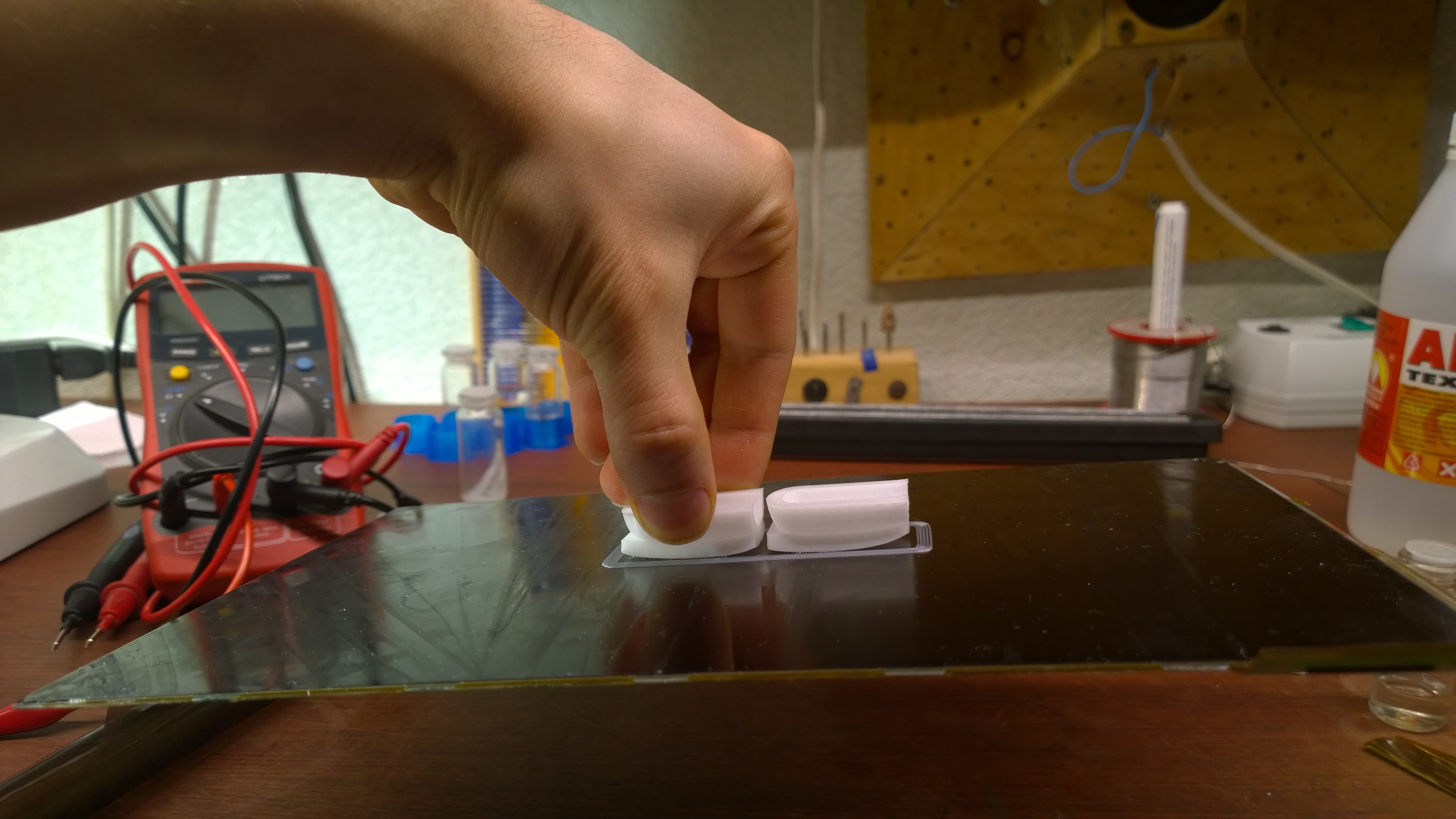

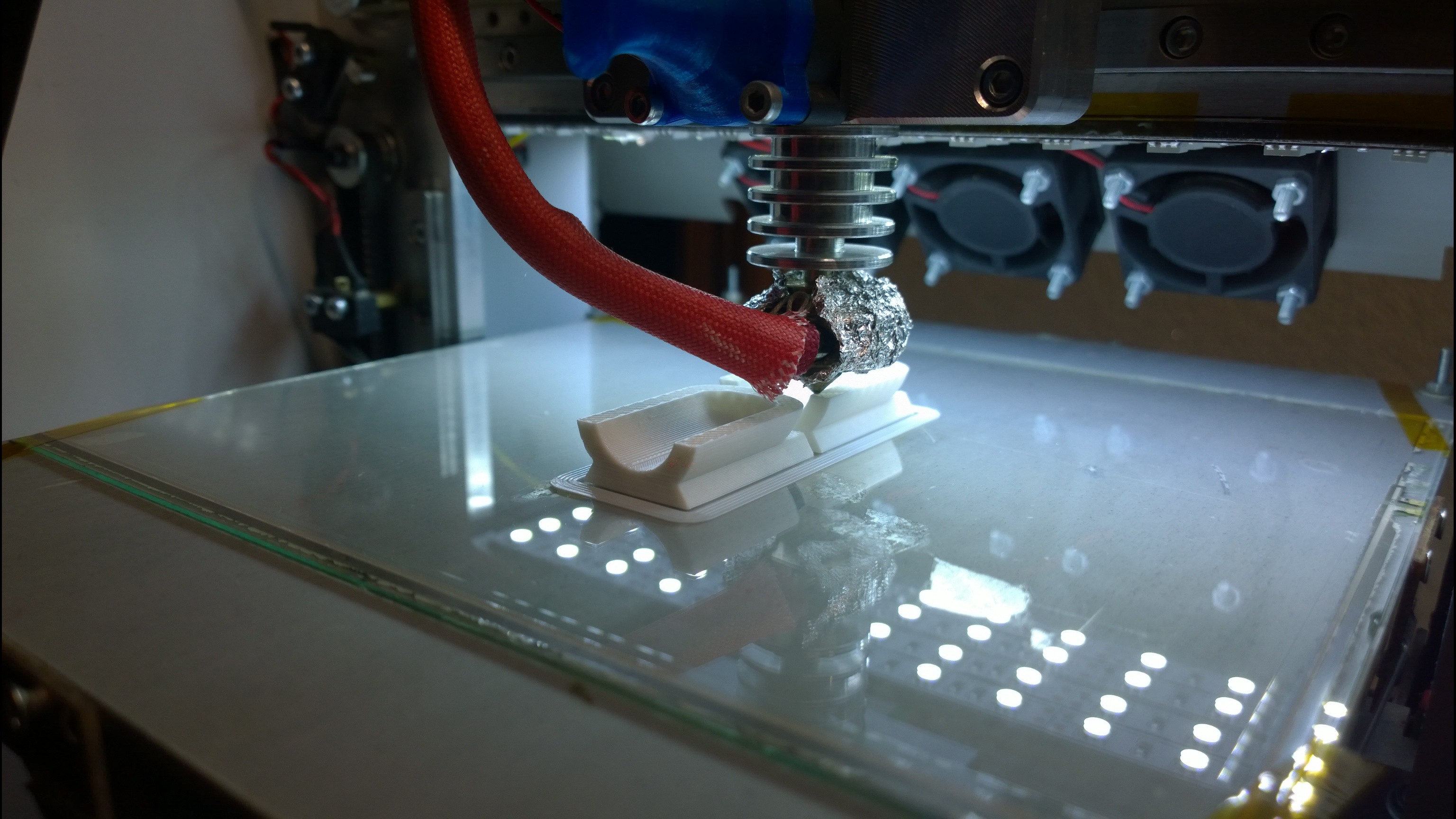

DeepSOIC This is an old LCD panel from a laptop. I ripped off the polarizer film (acetone helps doing it). The layer of glue that remained after peeling off the film is the surface I printed on.

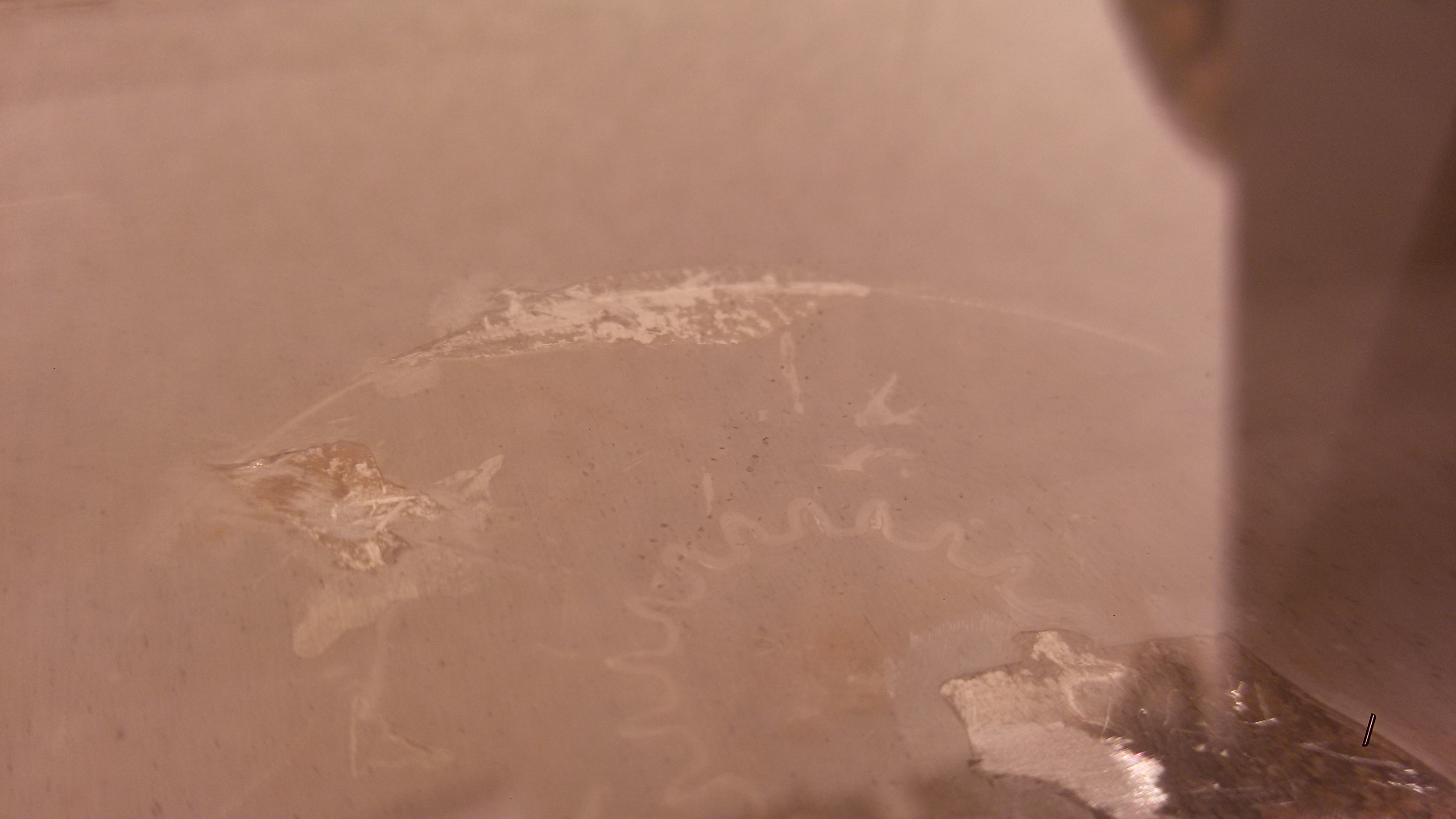

This is an old LCD panel from a laptop. I ripped off the polarizer film (acetone helps doing it). The layer of glue that remained after peeling off the film is the surface I printed on. This time, the deposited plastic remained stuck to glass for some 20 seconds or so. That was enough to print the first layer. But then it just curls up and I have to kill the printing.

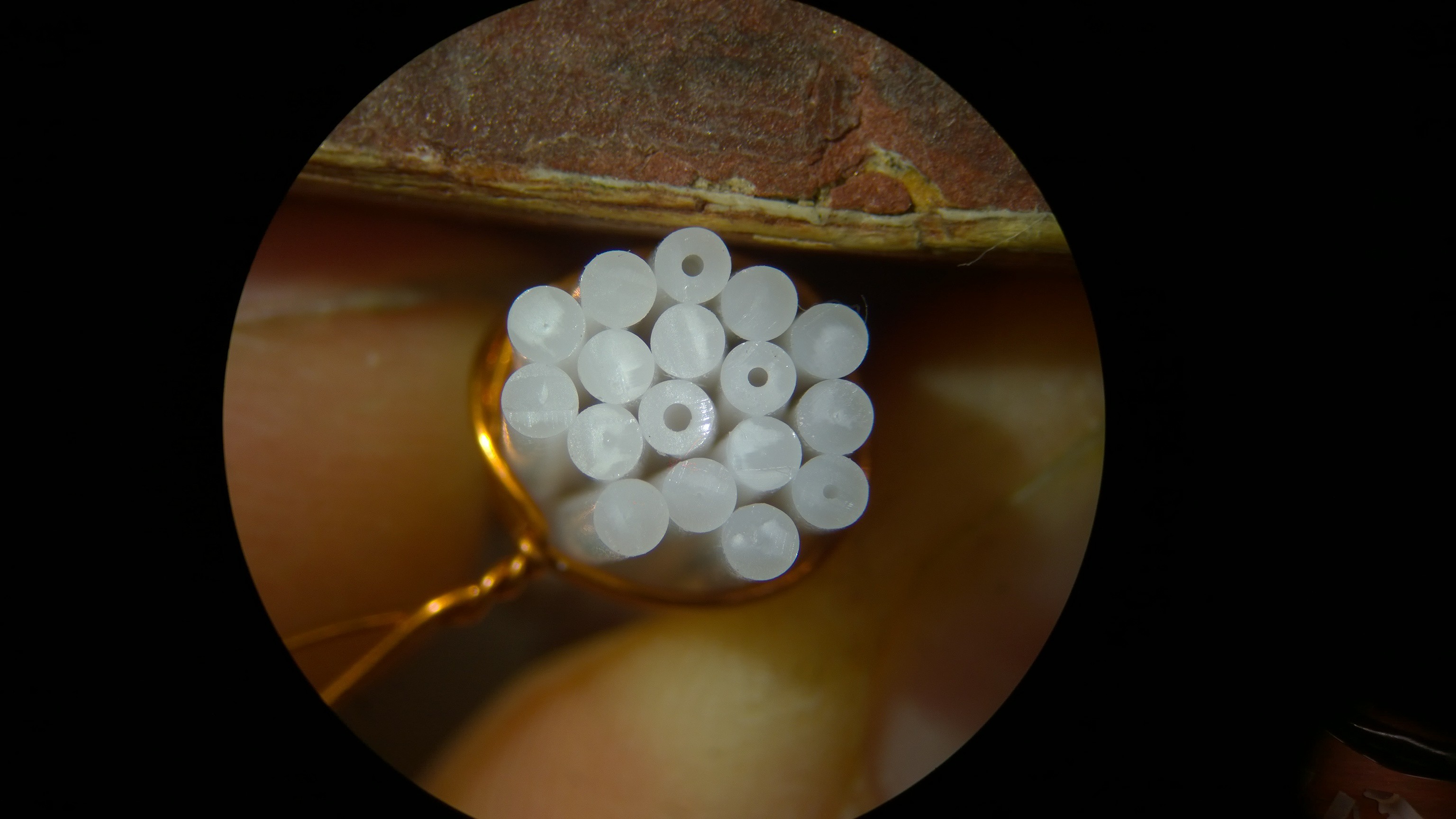

This time, the deposited plastic remained stuck to glass for some 20 seconds or so. That was enough to print the first layer. But then it just curls up and I have to kill the printing. It is tubular in some places. I don't expect it to print well in the first place, but the bubbles inside can futher turn my prints into a mess. It won't (hopefully) stop me from doing electrostatic adhesion experiment, nevertheless.

It is tubular in some places. I don't expect it to print well in the first place, but the bubbles inside can futher turn my prints into a mess. It won't (hopefully) stop me from doing electrostatic adhesion experiment, nevertheless.

Daren Schwenke

Daren Schwenke

nfk

nfk