The ERB is a design project at Hampshire College. Based on ideas conceived with members of the Timothy Harkness Fund for Invention, this project is intended to explore the possible benefits of ultra-lightweight EVs in the field of rescue technology.

Firstly, this bike is designed to be light and liftable so that first response personnel can get it over large obstacles in the woods.

Second, the bike is designed to be powerful and torquey. That's easy, it's electric.

Third, the bike should be completely waterproof. Water proofing electronics isn't that bad, I could even make them submersible because unlike internal combustion engines, they don't need air. This means that the ERB should be capable of ridding through large puddles or even underwater through shallow rivers.

Fourth, the ERB should produce no sparks or sources of ignition. This is easy, the motor is brushless so it makes no sparks. As long as the battery wires aren't disconnected during use, the ERB is not a source of ignition like a gas engine motorcycle would be. That means that the ERB can be used in flammable conditions like ridding through a factory with a gas leak. I don't know if you'd want to do that, but it's good to have options.

Adam Curtis

Adam Curtis

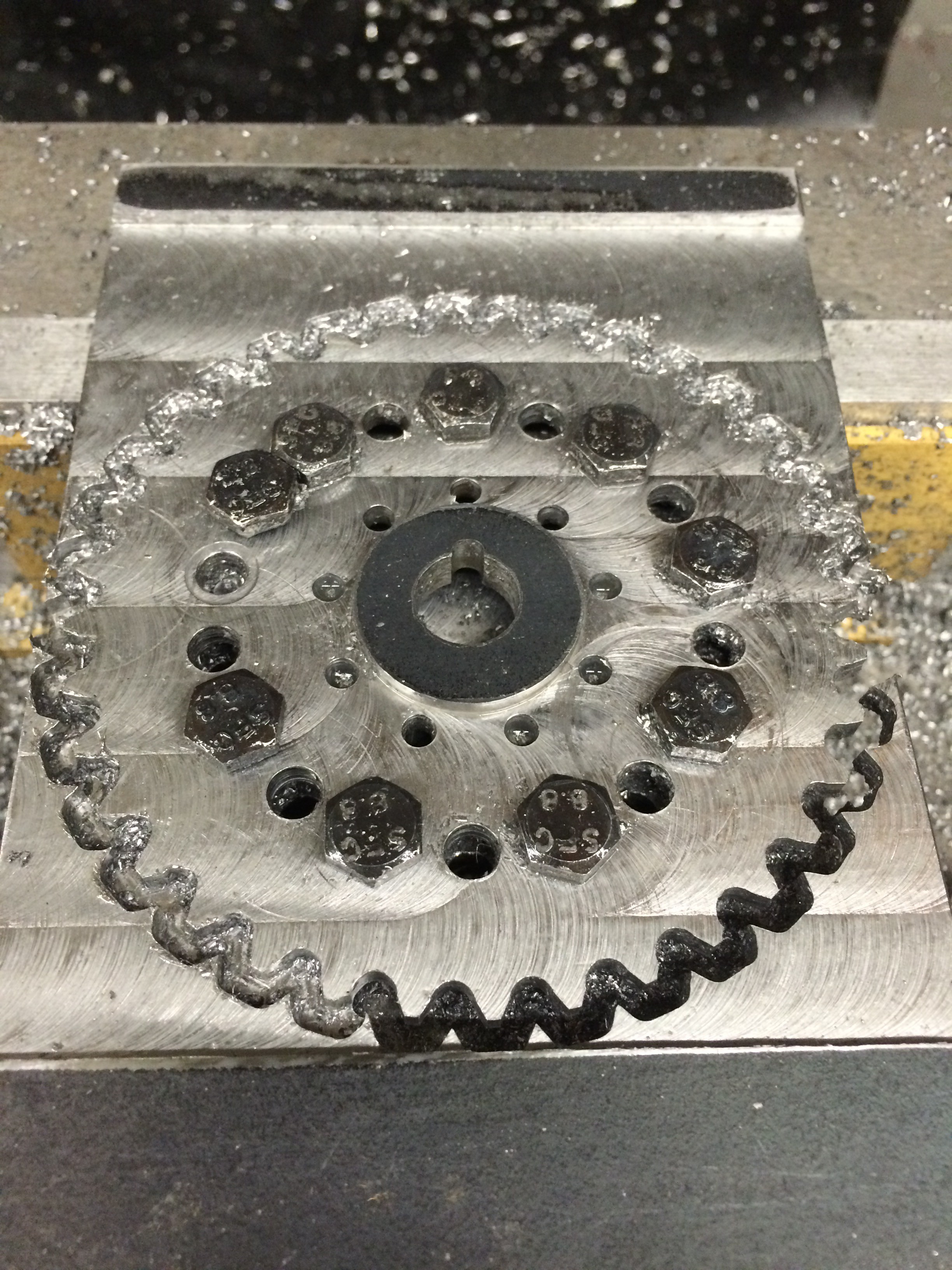

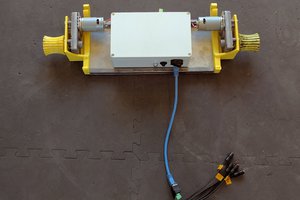

The original Lightning Rods kit. Looks nice... but when it moves the flaws are immediately apparent. Neither the plastic pulley nor the steel cog were concentric.

The original Lightning Rods kit. Looks nice... but when it moves the flaws are immediately apparent. Neither the plastic pulley nor the steel cog were concentric.

Quinn

Quinn

Mike Turvey

Mike Turvey

(Just a thought Adam...Since your rescue vehicle overlaps with the "Emergency Communications Universe" that hams are big on, I hope you'll consider participating in the noon hackaday chat tomorrow about keeping Amateur Radio relevant, many new hams are "off-roader" types.--KK6VDR extra class ham and C.E.R.T. trained)