The Rocket team is going to have a busy three weeks ahead of us; right now we're all doing our best to get our 1/2 scale ready to launch as soon as possible. This weekend a few members of the team and I are going to a night launch sponsored by ROCC, one of the local rocket clubs. Two of us are trying to get licenses so we can buy and launch higher powered rockets; joining the local club in one of the steps in doing that, so we're going to talk to them. One of my other team members has a few questions to ask them about rocketry in general. That same weekend we'll be co-sponsoring a movie night at Elon University to see if we can raise some publicity. We're hoping to have our 1/2 scale mostly finished by then so we can show it off. The weekend after that we're going to be presenting what we've been working on at a mini maker fair at one of the malls in Burlington. Then on the 28th I have to formally present our project to the kickbox staff (And whoever else shows up? They didn't give us many details). Hopefully by then we'll have launched the 1/2 scale, that's the plan anyway.

First, we are STILL troubleshooting the altimeter we built, and as it stands I don't see it being finished before my deadline to present. We still have two of our team working on it and they've been trying to consult with one of the professors here, but from what I hear it's a slow process. It's disappointing, but something we have to move past. To make up for our altimeter difficulties, I ordered a commercial altimeter that also does dual deployment and will work for our final rocket. We're currently trying to build some electronic bays for it so it will fit into our 1/3 scale rocket and our 1/2 scale rocket. It will be easy for it to fit in our 1/2 scale rocket because the rocket is very big compared to everything else we've been launching. Our 1/3 scale rocket- what we're planning to test it with- is another matter. In our 1/3 scale the e-bay will be competing for space with the parachute and it will be tricky to fit it in. We're going to end up cutting the body tube 1/3 of the way down from the nose cone and adding in another section with the e-bay in it so it will fit. The shape of the e-bay will also be different from the traditional ones to save space- it's simple but a little difficult to explain so I'll post a picture of it once we get it printed. We also printed out a new motor mount for the 1/3 scale. We used a different plastic that melts at a higher temperature this time because our old one melted slightly and fused with the rocket motor.

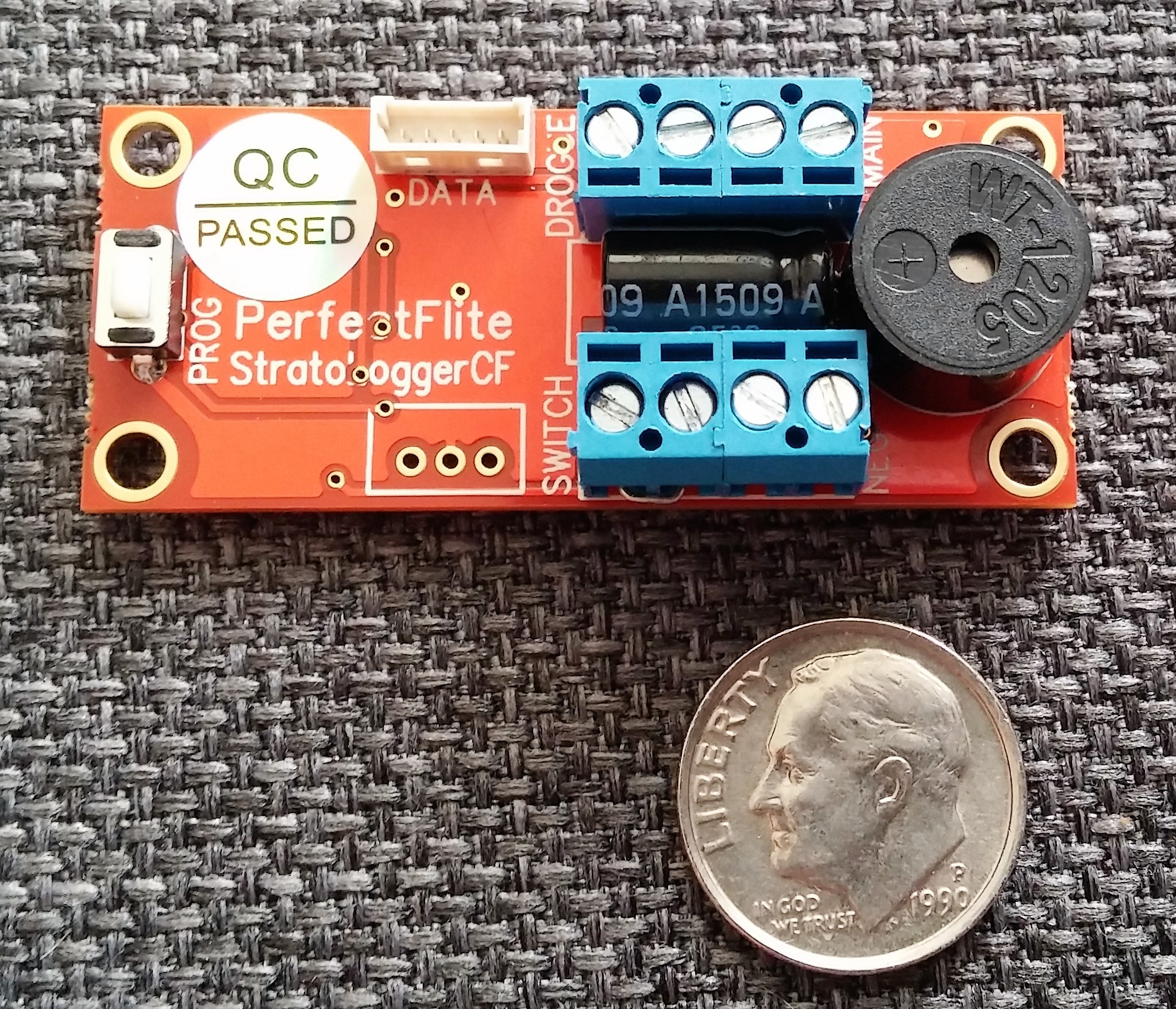

Here's a picture of the altimeter I bought- it's a good price for what you get, and instead of having a display it communicates the altitude by beeping. I compared it to a dime for size.

One of our members also wanted to fit a go-pro camera into our 1/2 scale so he could get some cool videos of the launch. One of the cameras will fit into the nosecone and will be looking out (we'll cut out a small window for the lense, and fit some clear plastic over it). We'll also probably put another camera in the rocket later with a little para-scope-type-thing sticking out from the lens so it can get a shot looking down. Since cameras are technically a flight recording device, I decided to include them in the project because we're having to do some creative things to fit them in. One of my team members wants to maybe put them both in the rocket at the same time, but I don't really think that's going to work because it's not as it the cameras are weightless.

Here's a picture of the cylinder that we 3D printed to hold the camera. The nose cone will fit over it.

Speaking of the nosecone, when we printed it the head of the printer got bumped somehow and our nosecone got printed slightly off, so we had to cut it in two today and reattach it properly. After that I had to sand the inside slightly because it doesn't fit perfectly over the cylinder for the camera. Nothing we print ever seems to fit perfectly like it should because of the different plastics that are used (it's only about a millimeter off, but it's still a pain). You'd think our team member who designs the stuff for 3D printing would have realized this by now, but I guess not. It's not really his fault, and it's not like the rest of us have learned to use the 3D software yet (it's on the to-do list). Anyhow, the nosecone is fixed now, and at this point we're just squabbling over what color to paint the rocket.

Here's my very artsy picture of the inside of our nosecone. It was printed with transparent plastic, so it looks pretty cool.

Here's a picture of our nosecone before we fixed it; you might see how it could be a problem like it was.

The last thing to get past for the 1/2 scale will be the motor itself. It will be a G motor, and unfortunately it seems that those have extremely expensive shipping ($30 hazmat shipping). We have enough money in our budget to buy it though, and the motors themselves aren't that expensive (less than the shipping actually), and once we have a reloadable casing for it, buying the motors will be less expensive. We also have to print the motor mount for the rocket, but that should be an easy scale up of our last mount.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.