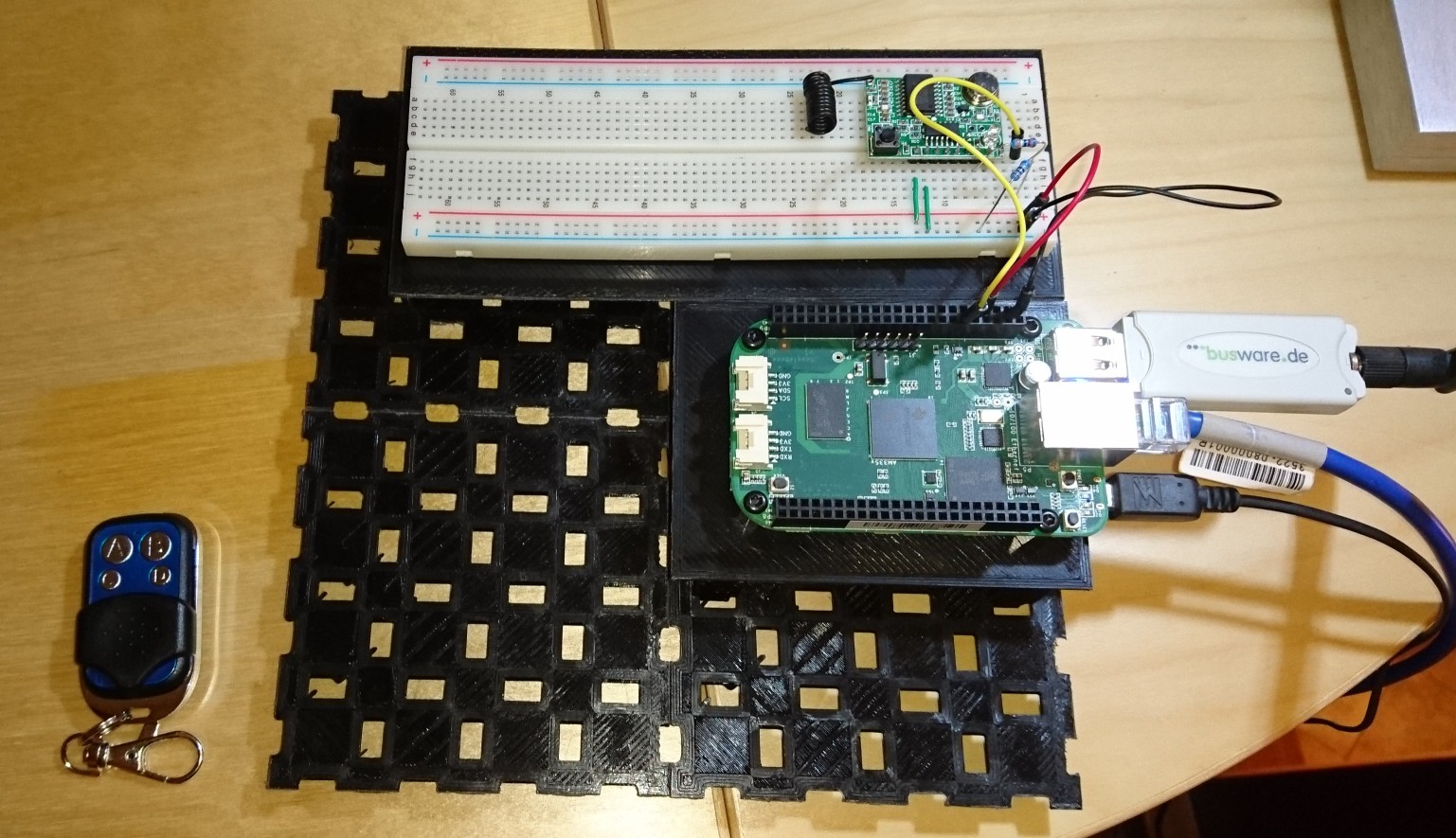

The project use 25x25mm mechanical grid. All of the modules/bases are contains multiple squares of this.

The system has the following building blocks:

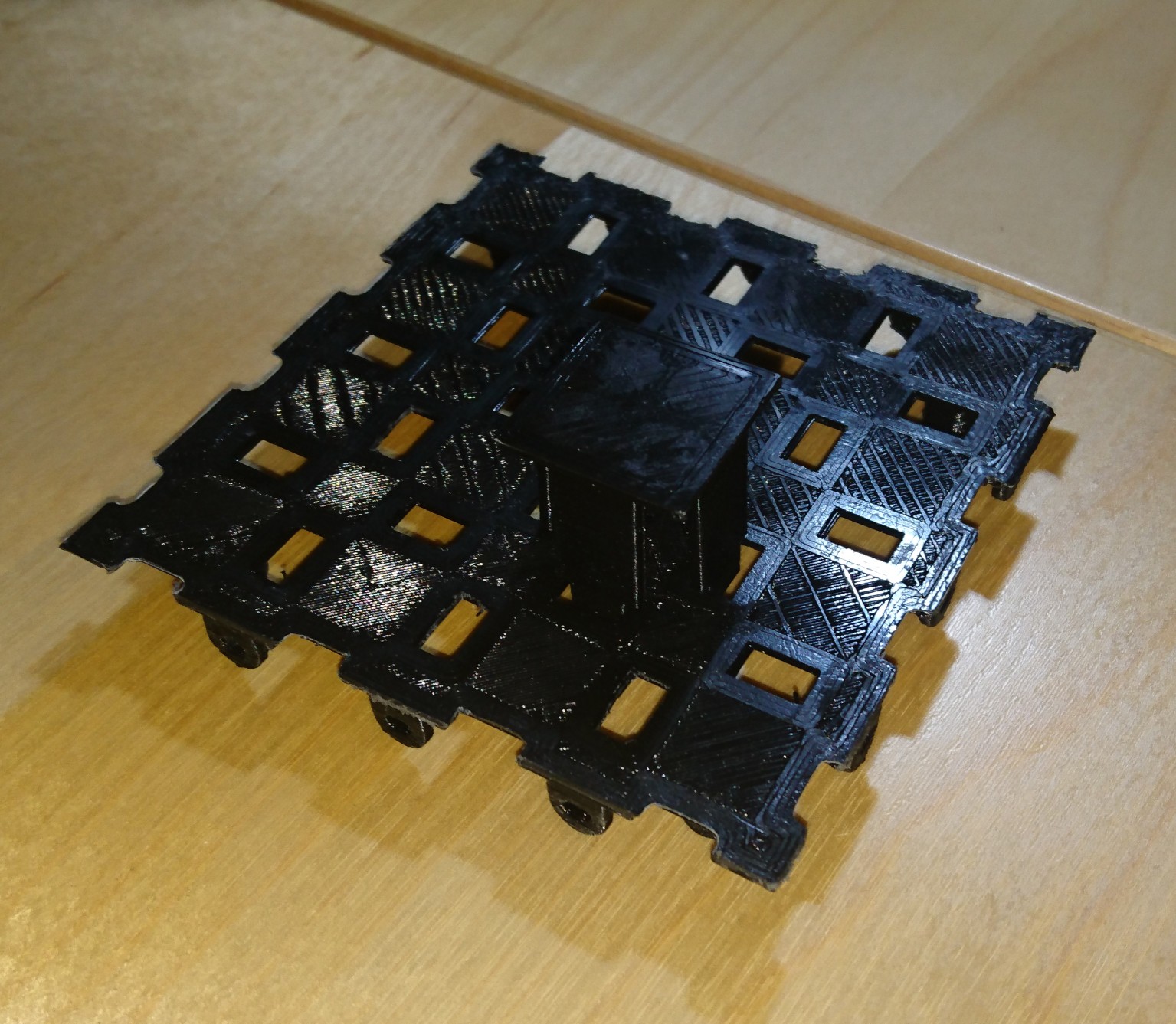

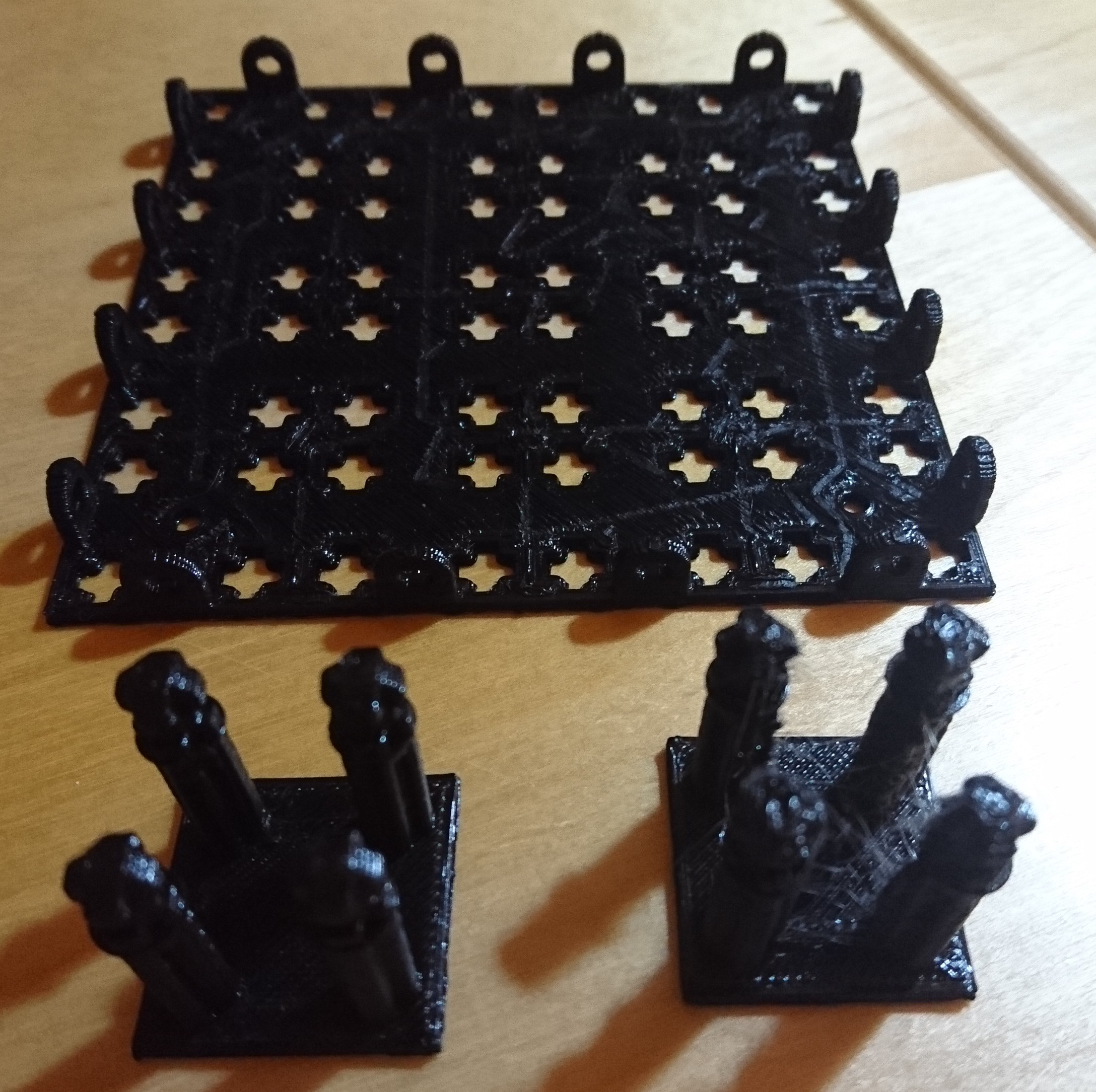

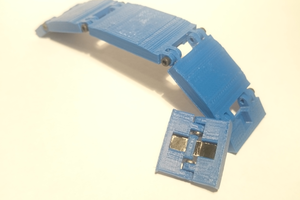

- Base plate. This is the main component, has cross shaped holes for holding the modules, and circular holes on the edges to screw modules together, and holes to mount the feet.

- Locking plate. The locking plate is almost identical to the base plate, but mounted upside-down, has larger, oval holes at the places of the feet, allowing to slide a bit. When you slide it, it will lock the mounting pin of the modules in it's place

- Feet. It has an additional role. Keep the Base plate and the locking plate together.

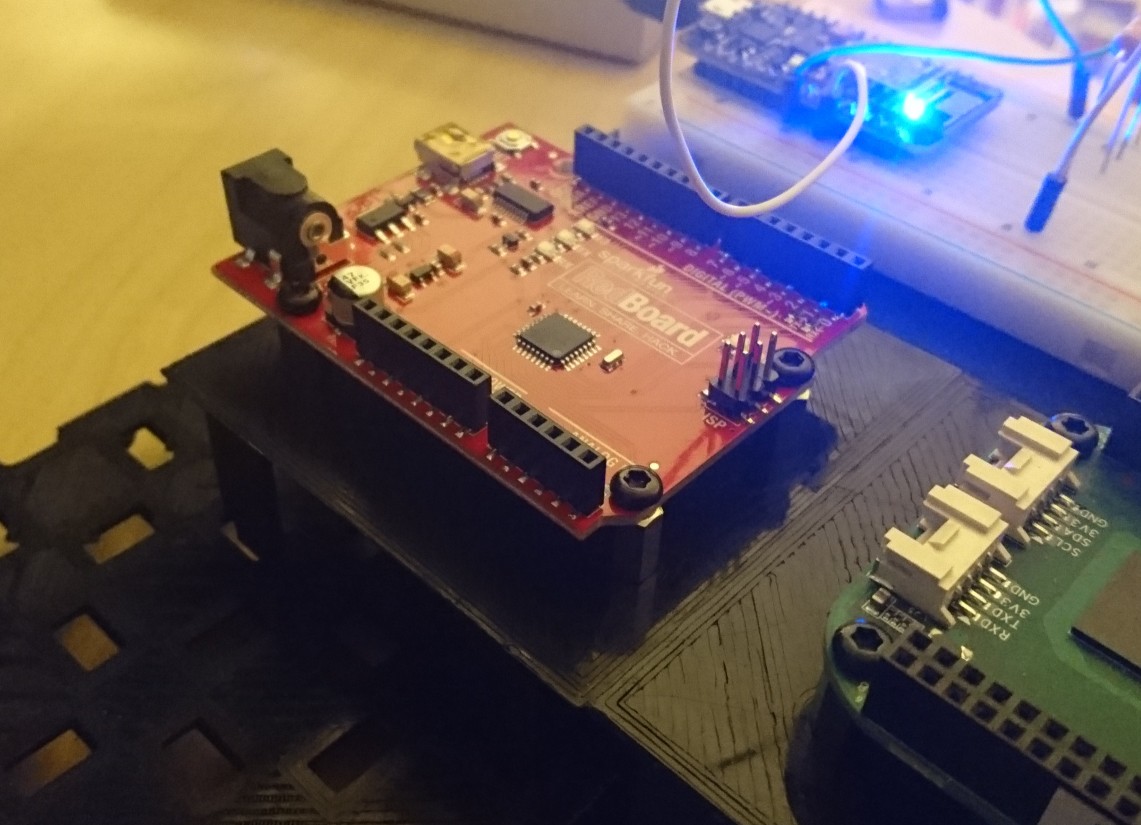

- Modules. The modules has cross shaped mounting pins on the corners, for locking into the base plate.

All of the components has parametric SCAD design files, so it easily customizable.

I plan to design several modules in the near future:

- Rpi mount

- BBB mount - done

- Arduino mount

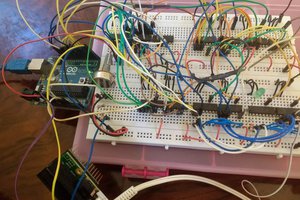

- BreadBoard mount (expandable also) - done, partially

- Banana socket mount

- Grove module mount, probably parametrized

- Little bits mount

- etc.

SUF

SUF

mulcmu

mulcmu

novirium

novirium

Chris Hamilton

Chris Hamilton

Matt Bradshaw

Matt Bradshaw

Great idea!