The gear reductions blend the domains of Tetrinsic and Tetoroidiv together, and since the gears themselves are likely to be mounted on Tetrinsic, I'm writing the log here.

I started looking into it because I thought "If I could get 2x the reduction, I could use the 1-pole-pair solution. with a 40mm rotor".

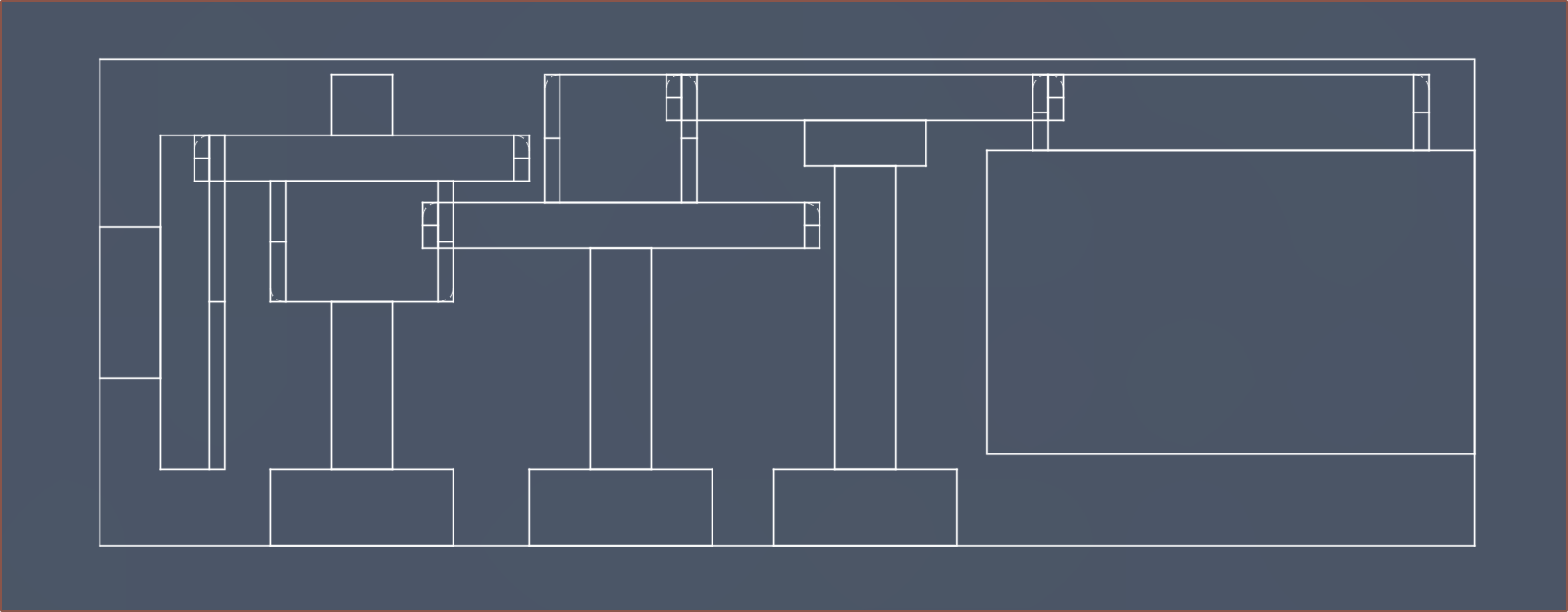

So after going through Pinion Parts Store on AliExpress, this is the compact solution I landed on after about an hour:

Then I started sketching the other gearing strategy planned to be used with a 58mm rotor. It was then that I realised that I just assumed "smaller number over bigger number" for the gearing calculation, and that the gearing ratio wasn't 2.6 : 1, it was 0.78 : 1! This was me when I put the new calculation into the Excel spreadsheet and saw the wattage numbers of motors such as Toroid-58mm and the 1656:

So I already weakened after that realisation, but the "Instant Damage" potion that took me down to "half-a-heart" (speaking in Minecraft terms) was when I then looked at my gearing strategy again and realised it's all backwards! I had created a 1-to-16 torque destroyer!

It took me over 12 hours to recover from that emotional damage yesterday.

Knowing that all the 50mm+ motors I had found now weren't going to fit, I went looking around. Most of the motors I found in the sub-40mm range all used 2mm shafts, and I can use a C202A for that.

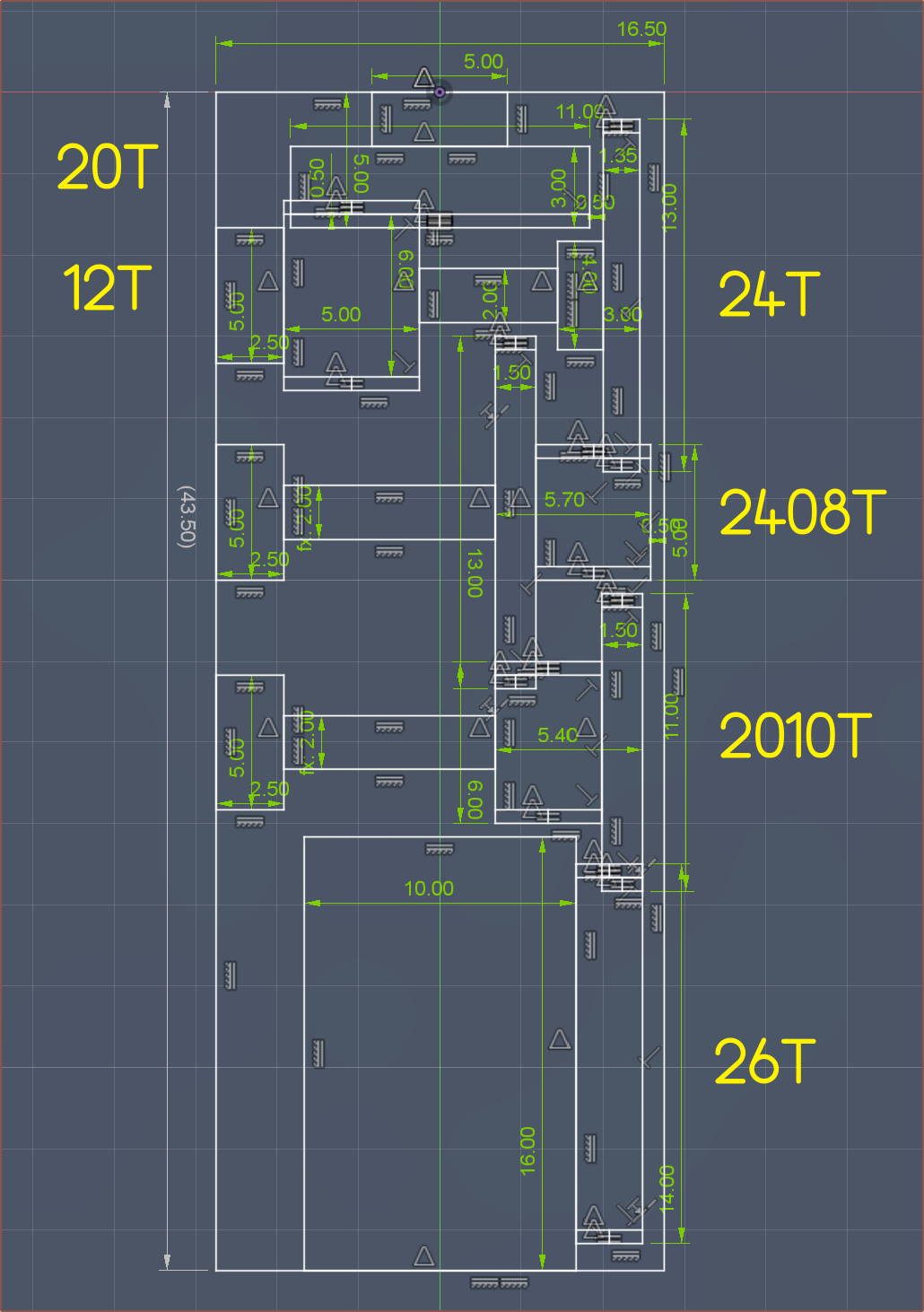

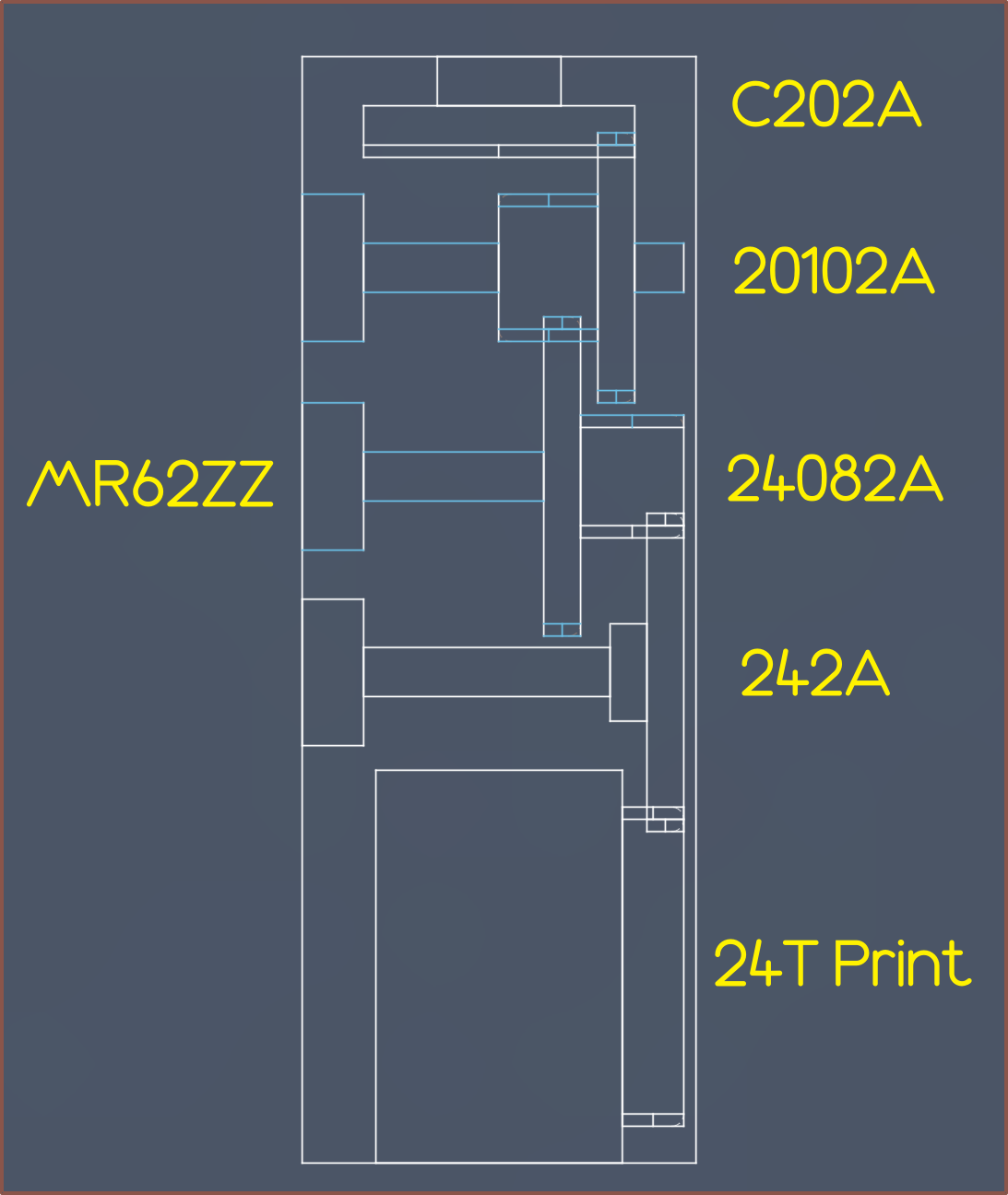

Today, I've converged on the following 16mm-wide solution, providing a reduction of 7.2 : 1:

I've also learned how to read the names. 2A means "2mm shaft, tight". Then it's just listing one or both teeth counts. For example "24082A" means "24 teeth connected to 8 teeth. Tight fit on 2mm shaft.". "C" stands for "crown".

Additionally, the idea is to potentially use the same bearings inside Tetoroidiv, as well as omit the crown gear and connect the motor directly to 20102A for the thumb Tetrinsics.

The height of the gearing is defined by the largest gear, so that's why there are many with the same 24 teeth. The length of the gearing could be shortened slightly by using 18102A -> 22082A -> 222A -> 22 teeth print.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.