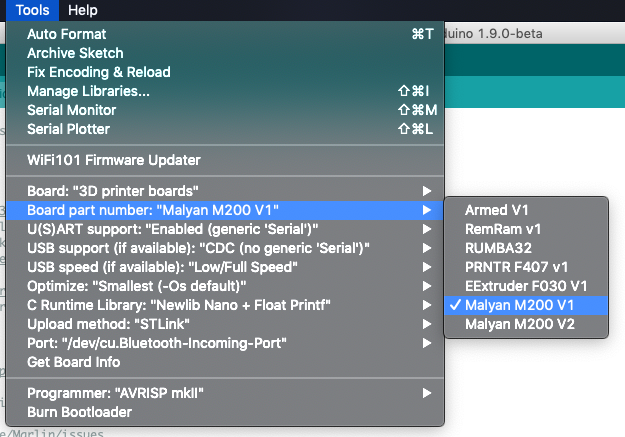

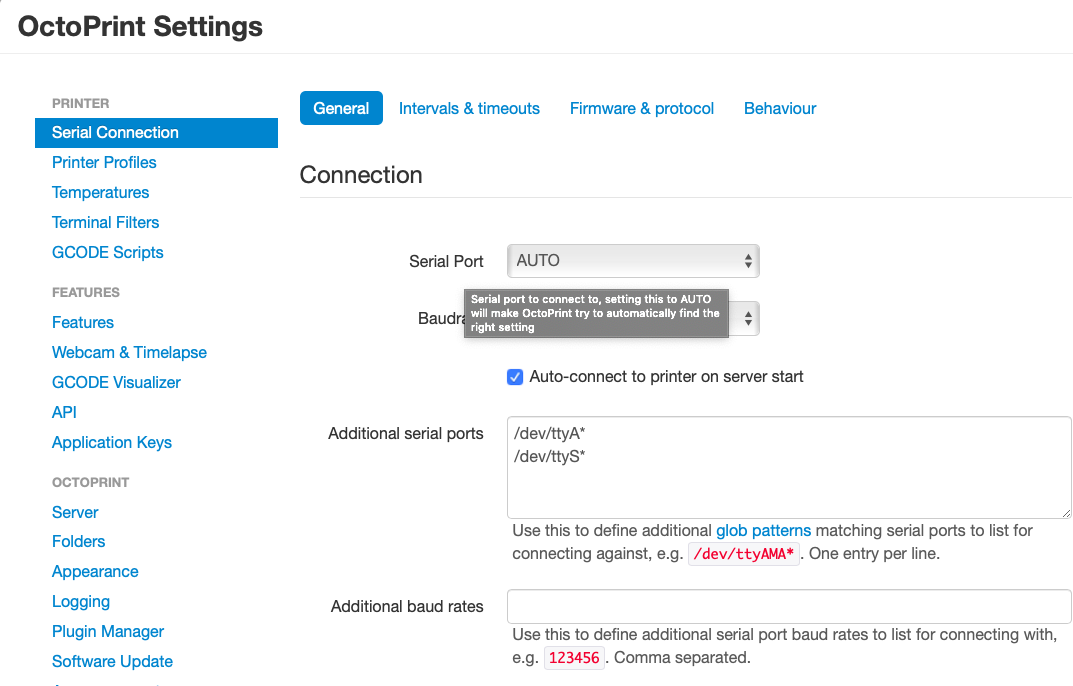

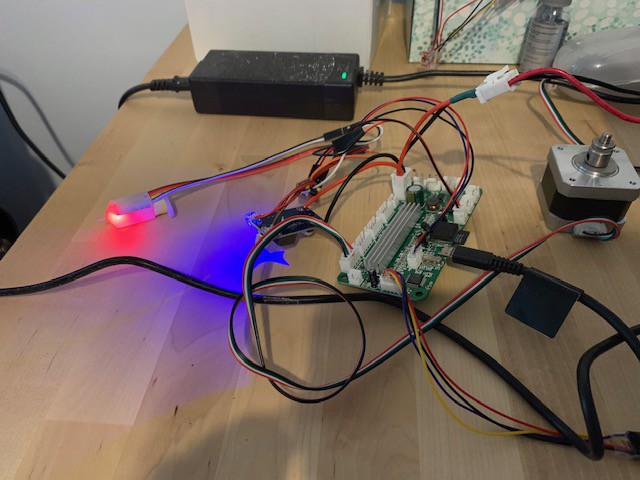

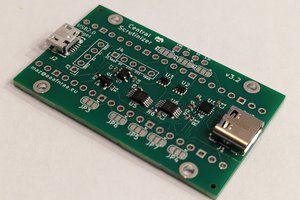

The MPMini/Malyan M200 V1, V2, and Pro (V3, for all purposes) run on an STM32Fxxyy processor using a firmware which is claimed to not be derived from Marlin (hook a serial monitor to the display port and make your own decisions whether or not that's true). These project logs follow my progress making Marlin 2.x run on this board across multiple hardware revisions/Arduino cores.

V1 and V2 work today if built with the Arduino IDE. V3 in theory works (it's the same processor as most V2s) though ABL doesn't work without EEPROM emulation. M300 support would most likely be a different project, but it feels like an extension of this one, so for now, I'm leaving it here.

J.C. Nelson

J.C. Nelson

TinLethax

TinLethax

charliex

charliex

Alex Brown

Alex Brown

I'd like to give your project a try some day for my "MP Select Mini V2" but it's not quite clear which Marlin version (git branch names are confusing - 1.1 or 2.0 or ... ?) or sources are to be used - are these the complete build instructions? https://github.com/xC0000005/Marlin/issues/1 Could you maybe reference these more prominently? What are current limitations in comparison to the stock firmware? Are there any updates on a open UI firmware that you mentioned? Unfortunately, the Facebook group (probably this: https://www.facebook.com/groups/1717306548519045/) is closed so I can't have a look. Thanks!

<hr/>

https://github.com/MarlinFirmware/Marlin/tree/bugfix-2.0.x/config/examples/Malyan/M200