After getting into service screen I was little disappointed. I was looking for controller settings that I could take out from this menu but unfortunately settings are not quite obvious. Controller stated that nominal time for pump is 5400 seconds but settings were not specific enough to figure out what is cadence. I didn't know what is period time where pomp is not working at all. Moreover settings didn't provide any ability to configure circulation flow and thus I literally still don't know nothing about controller settings. Bummer.

I needed to observe controller in live operation. I mean not live in sense of having it connected to wastewater treatment plant but I needed to create fake environment where controller was proceeding as in deployment environment but in reality was observed by Arduino.

MonoBloc controller has current sensor to detect following failure conditions:

- Air pump not working

- In deployment scenario controller provides power socket outlet for air pump. User suppose to connect airpump to this socket and in case there is no power drain from socker alarm is rised.

- Valve not operational

- Similarly to air pump controller is able to detect no output current for valve operation

These are nice features that in fact provides justification for controller existence in deployment.

Anyhow, I connected current sense lines to Arduino PWM output in order to generate fake signals to controller so that controller would think that both circuits provides valid outputs. I found these pins by looking on pin voltages in condition when my hair dryer connected to outlet and powered. Using manual MonoBloc controller mode operation mode I also found two pins that corresponds with relays for valve and airpump power lines.

I wrote a simple Arduino sketch that reports changes on relays and powered up solution for whole 24h.

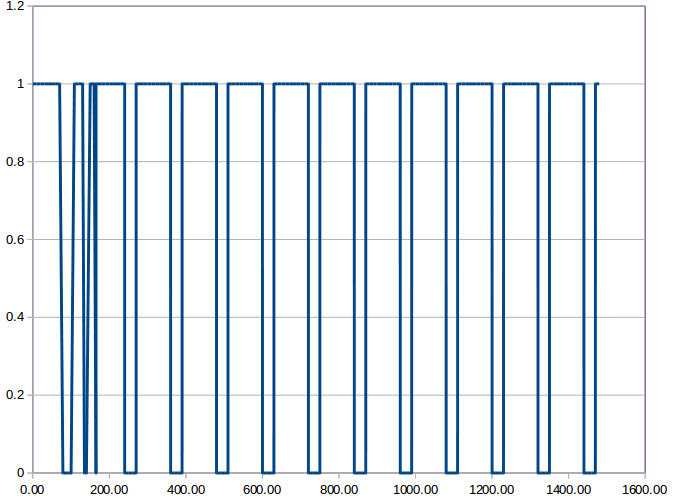

Here is output for air pump in normal operation mode:

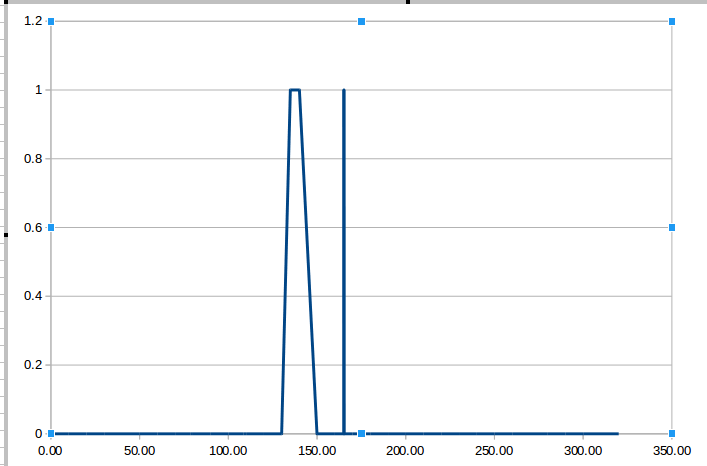

Here is output for valve (circulation):

X axis corresponds with time in minutes. Please refer to full data in files section.

Conclusion:

5400 seconds (1.5h) is time when pump is enabled. Cadence is 2 h). That makes air pump working for 1.5 hours and then controller allows 0.5 hours break. Valve is open only for 15 minutes per day. There is also 3 second spike on valve which I suppose is to check valve operational state. I didn't record RTC time precisely to say exactly when valve is opened. This happens close to midnight as test started around 8 PM.

Summary and next steps:

We got everything in place to create our own controller that exactly mimics what MonoBloc controller does. In next log I will provide Holiday settings for MonoBloc controller. After this I will present first controller that actually can drive wastewater treatment plan as described.

leszek-wojcik

leszek-wojcik

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.