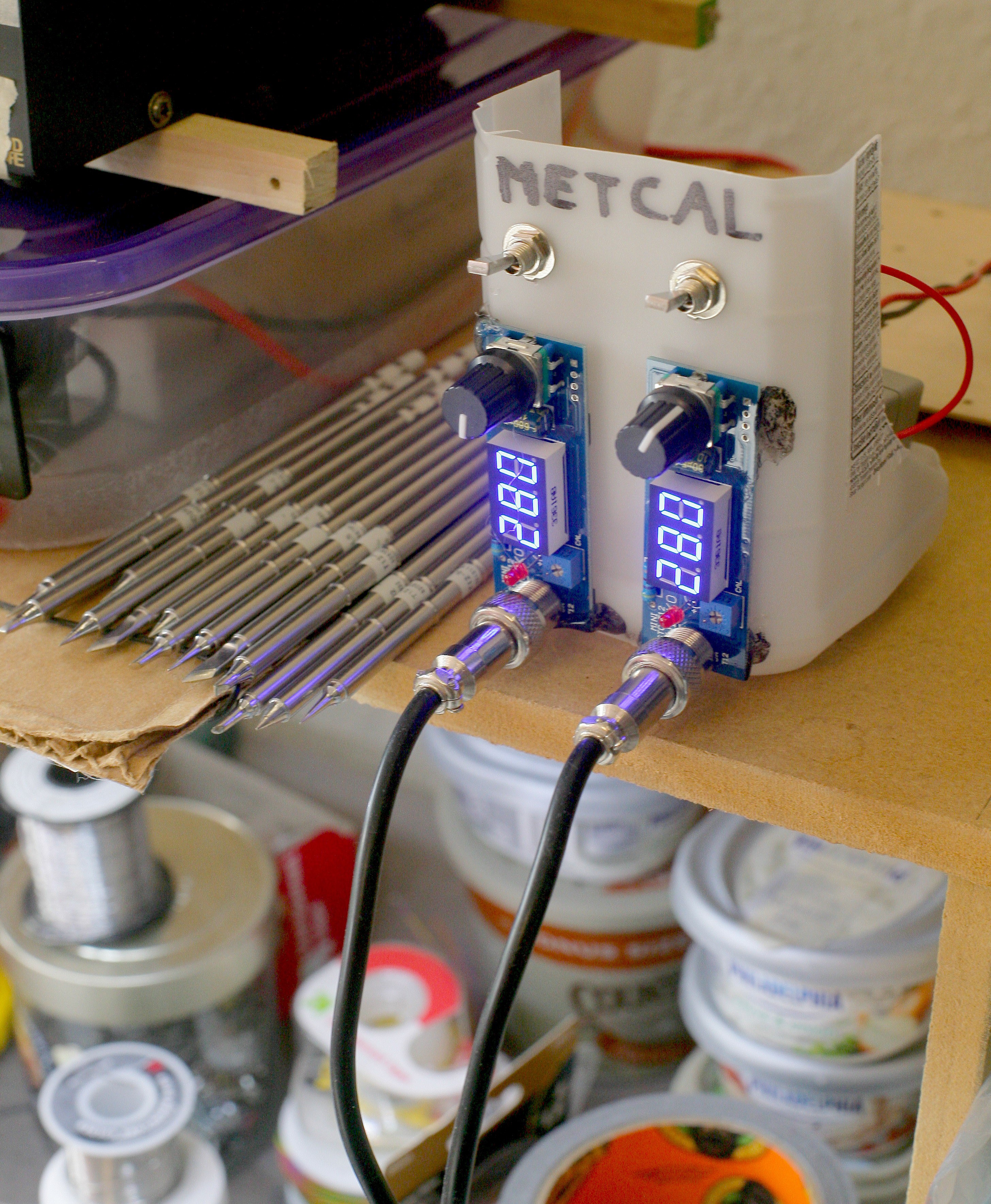

After having access to a Metcal MX5200 with the full 2 soldering pencils, the lion kingdom became aware of its limitations & advantages. The mane problems: changing temperature required changing tips & having the right tip. There wasn't enough room for 2 stands. Most of the time, only the copper wool in 1 stand would be used for cleaning while the other was behind a pile of cables. The connection to the base station was also constantly glitching out. The smartheat/curie point system is all but obsolete, nowadays.

It was luxurious having tips that fine. It was much easier to pick & place surface mount parts with 2 fine tips. It could heat ground planes effortlessly. The base station was a very compact way to power 2 tips. Unfortunately, it was a loaner.

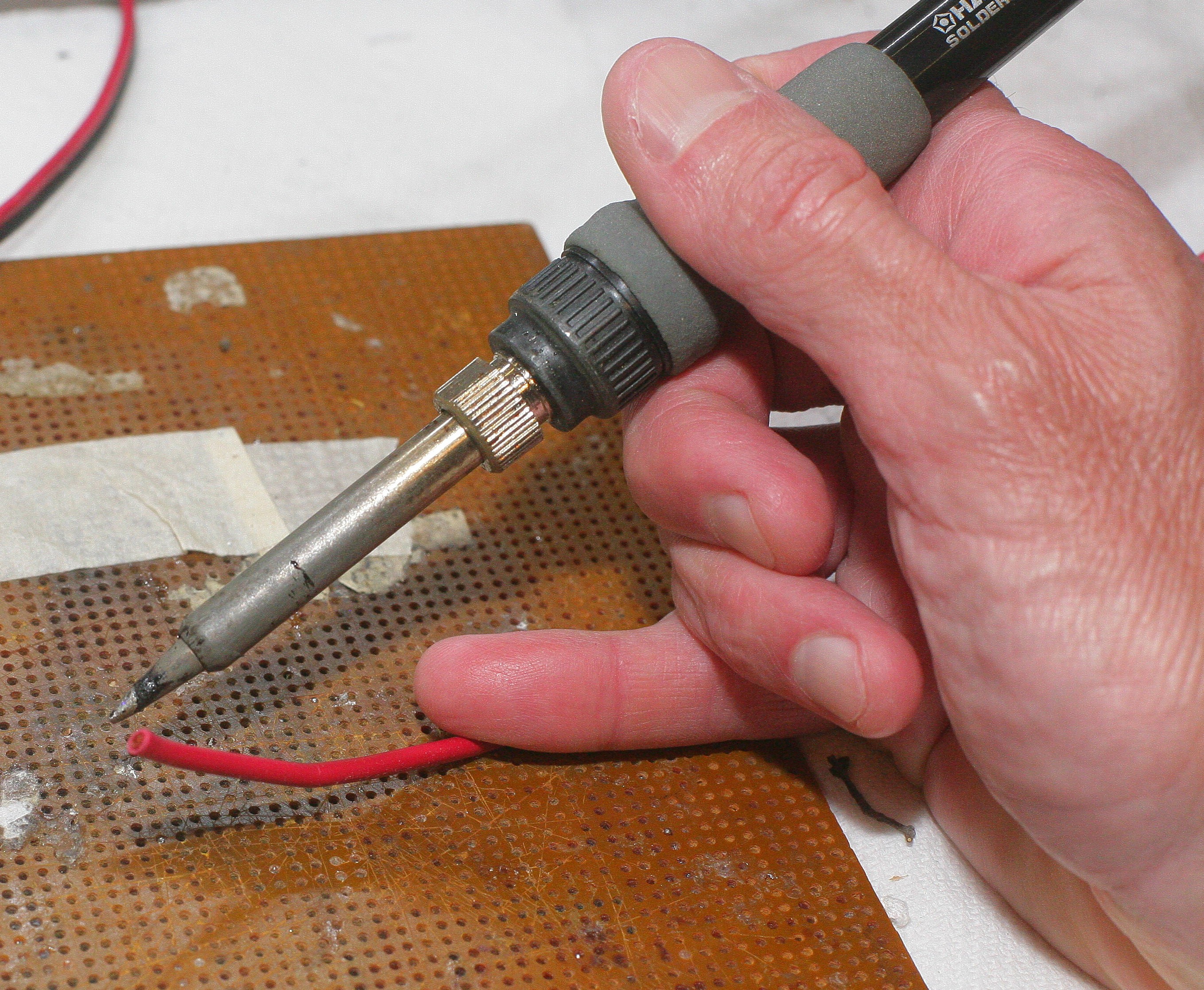

The lion kingdom's previous irons were the Hakko FX-888, Weller WES51, & for the 1st 15 years, the $8 Radio Shack iron. The Hakko FX-888 was the duck's guts in 2012, for soldering 0603's & bigger, but its mane problem was the lack of any tips for it as small as the Metcal. The finest tips were conical. These required turning up the heat to get the very end hot enough & risking burning up components.

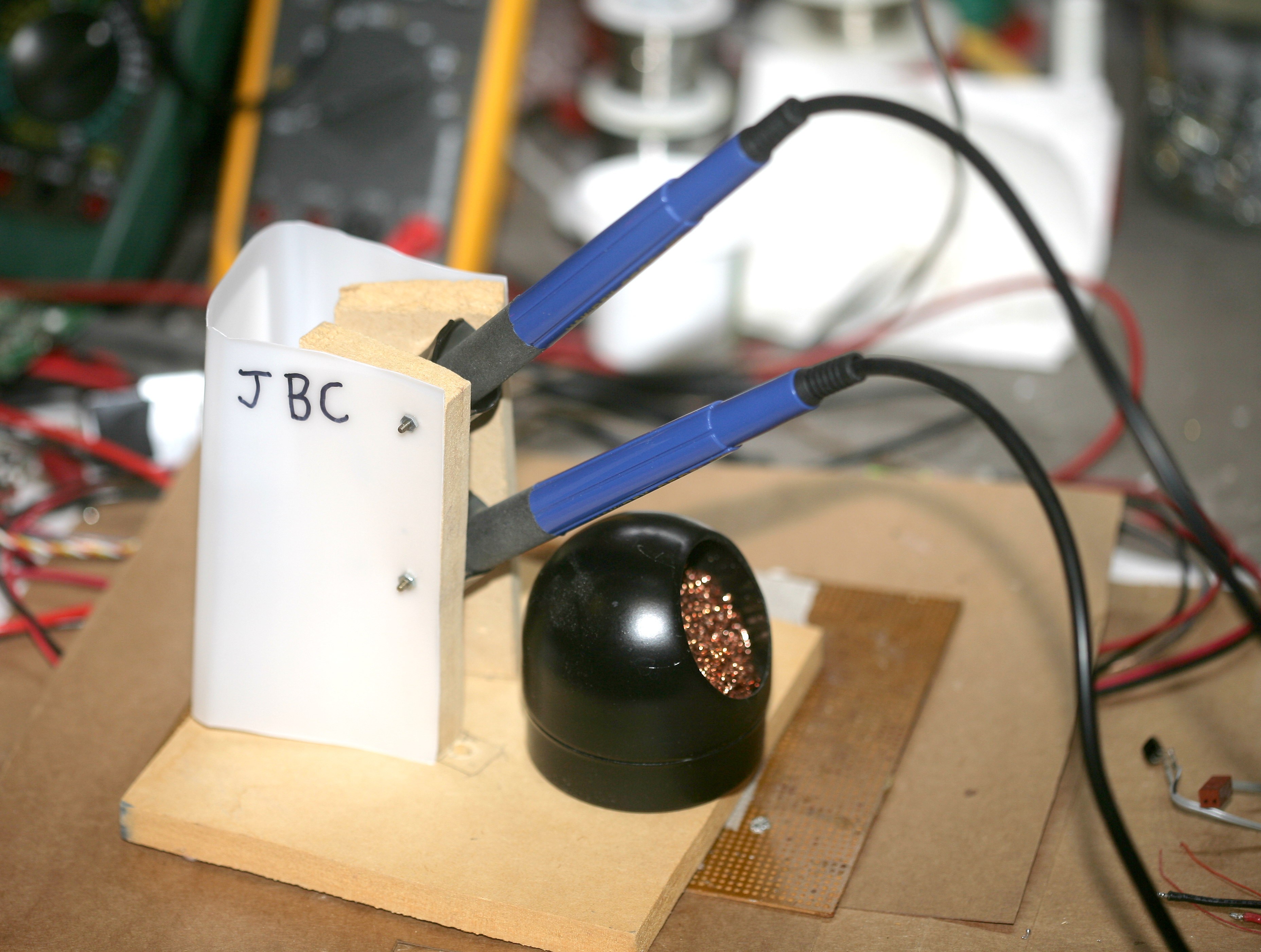

The quest for an affordable & modern alternative to the Metcal revealed this Jeri Ellsworth video showing 2 JBC stations.

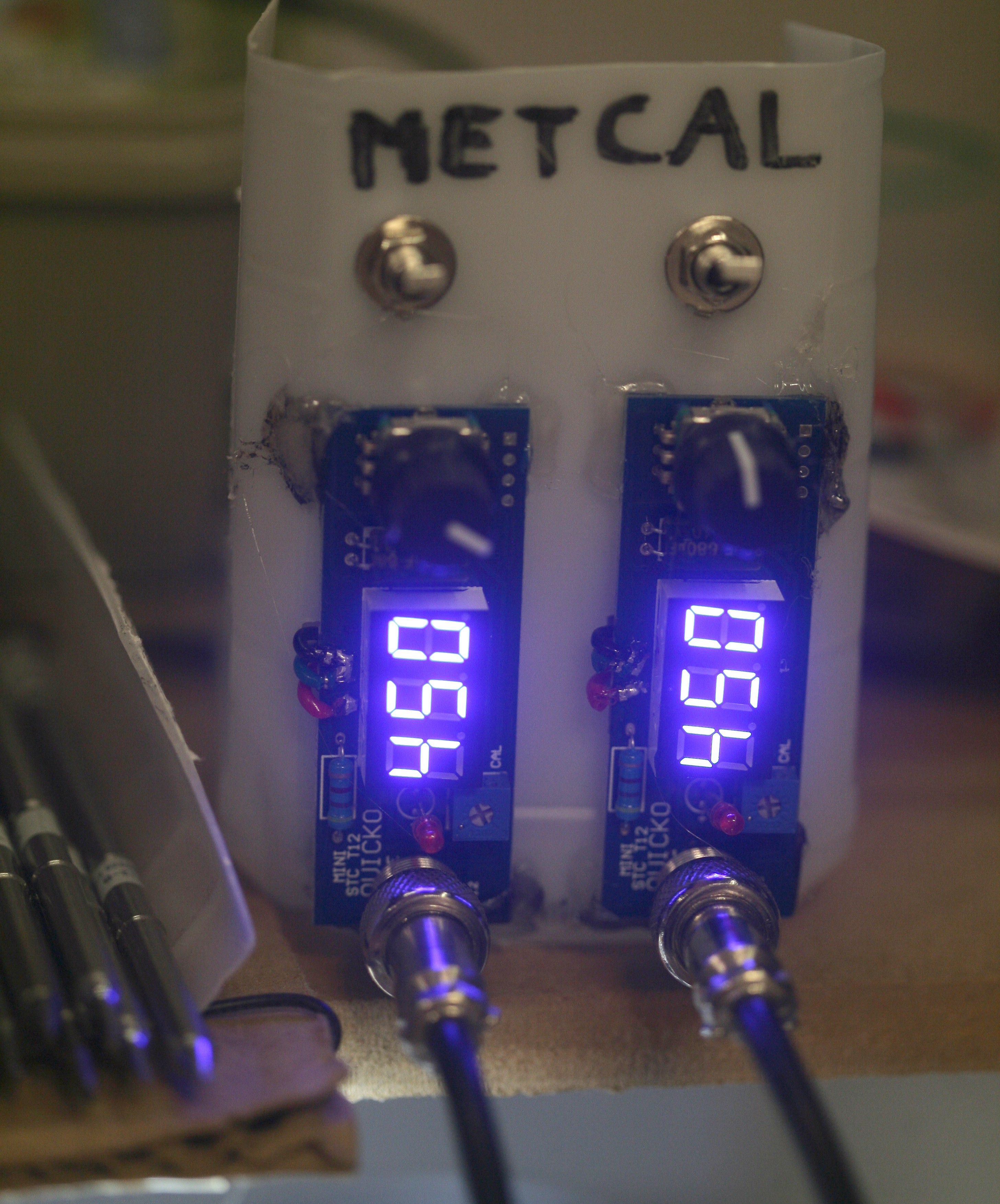

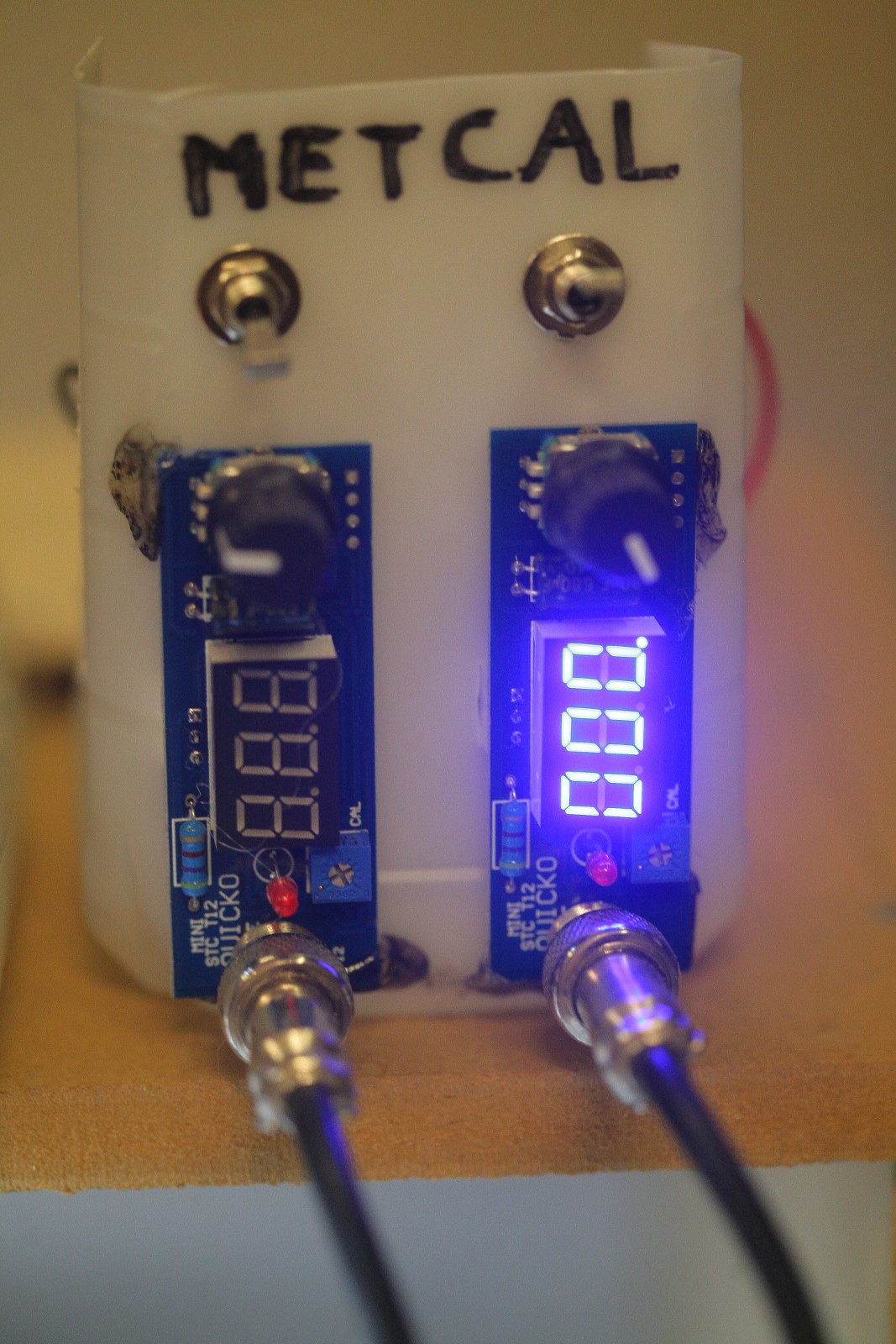

Dual JBC's were obviously a sign of someone who had arrived. That was what people were using for the newest components. The next step was figuring out what made a JBC better & trying to clone it in a smaller, dual iron package.

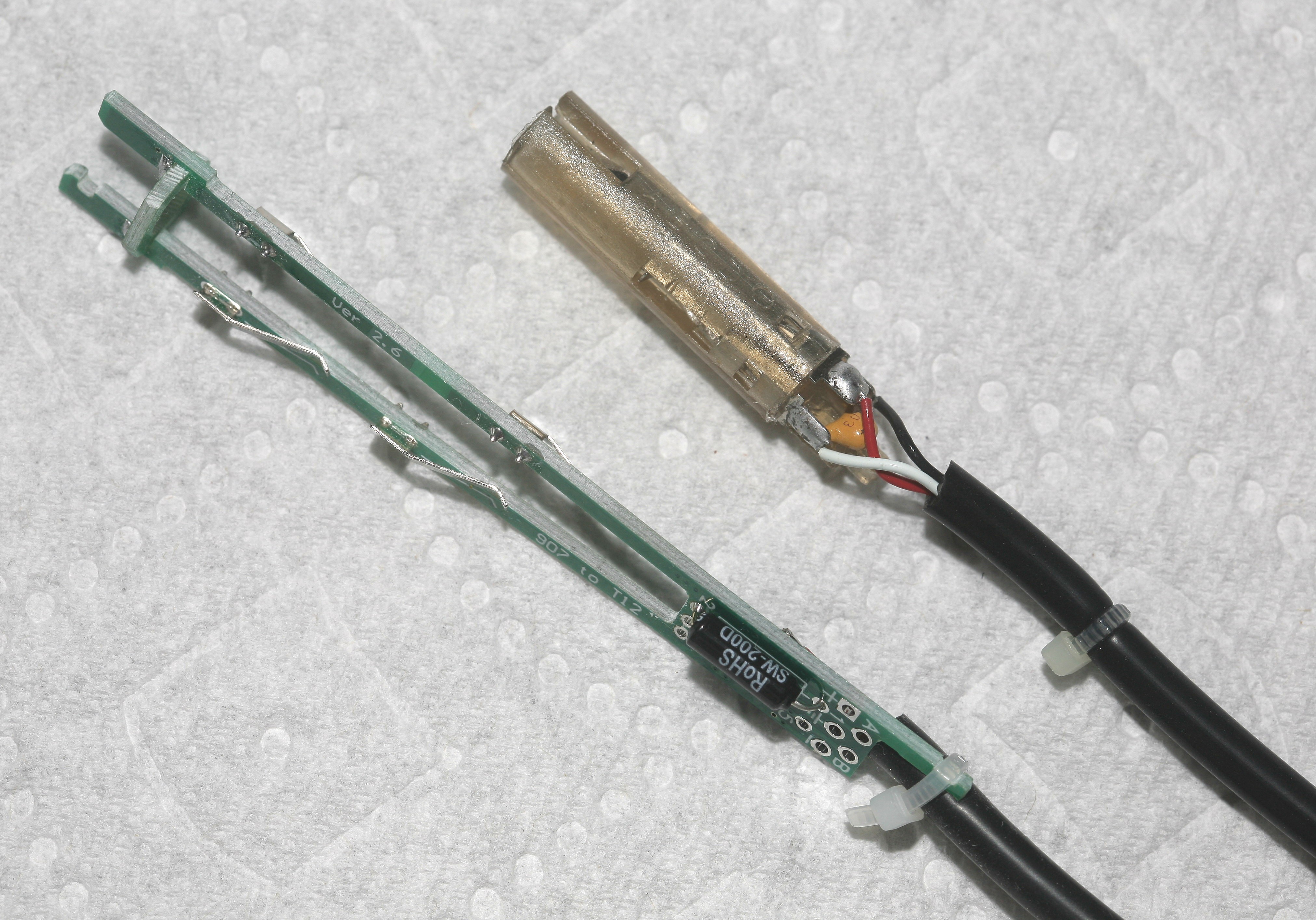

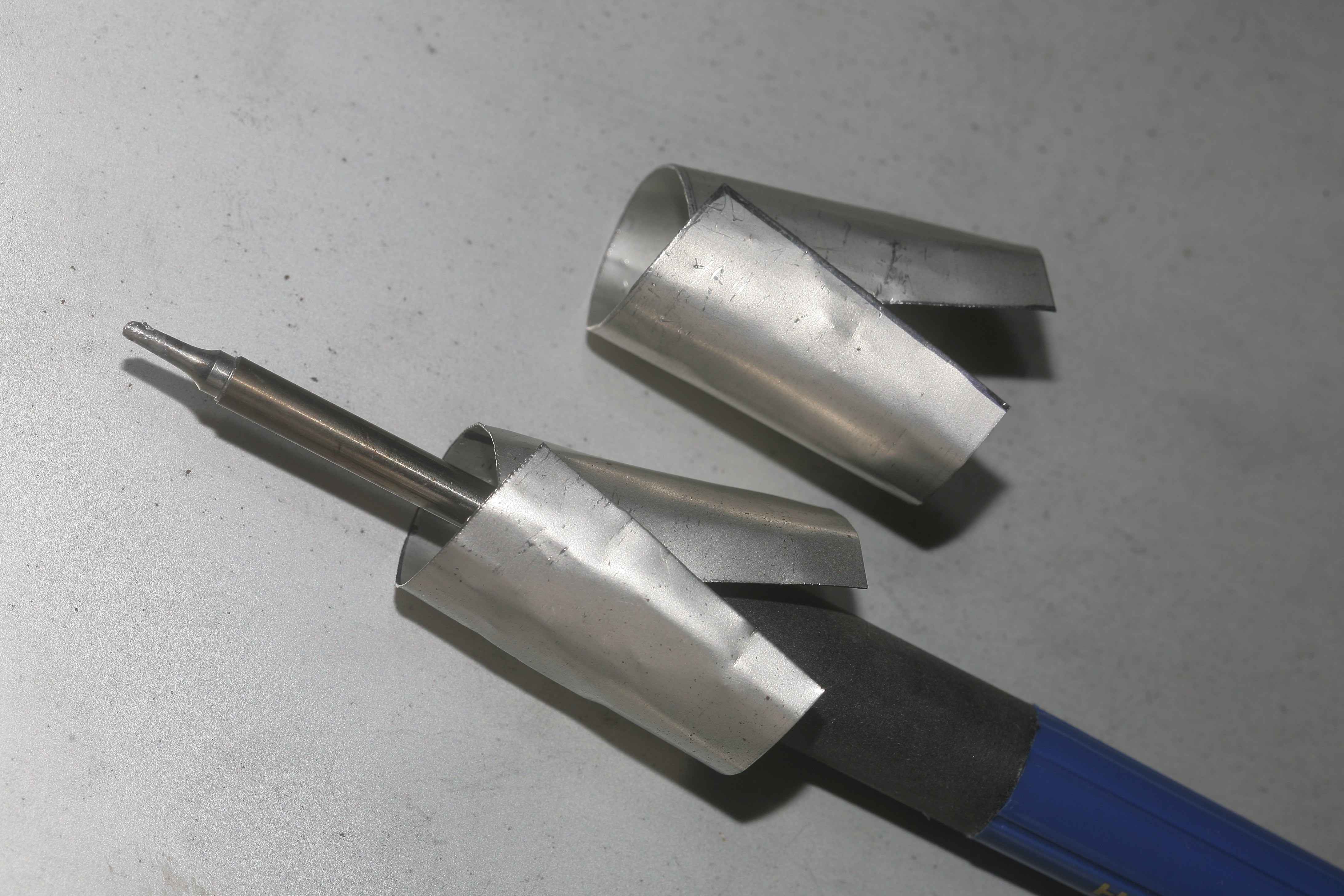

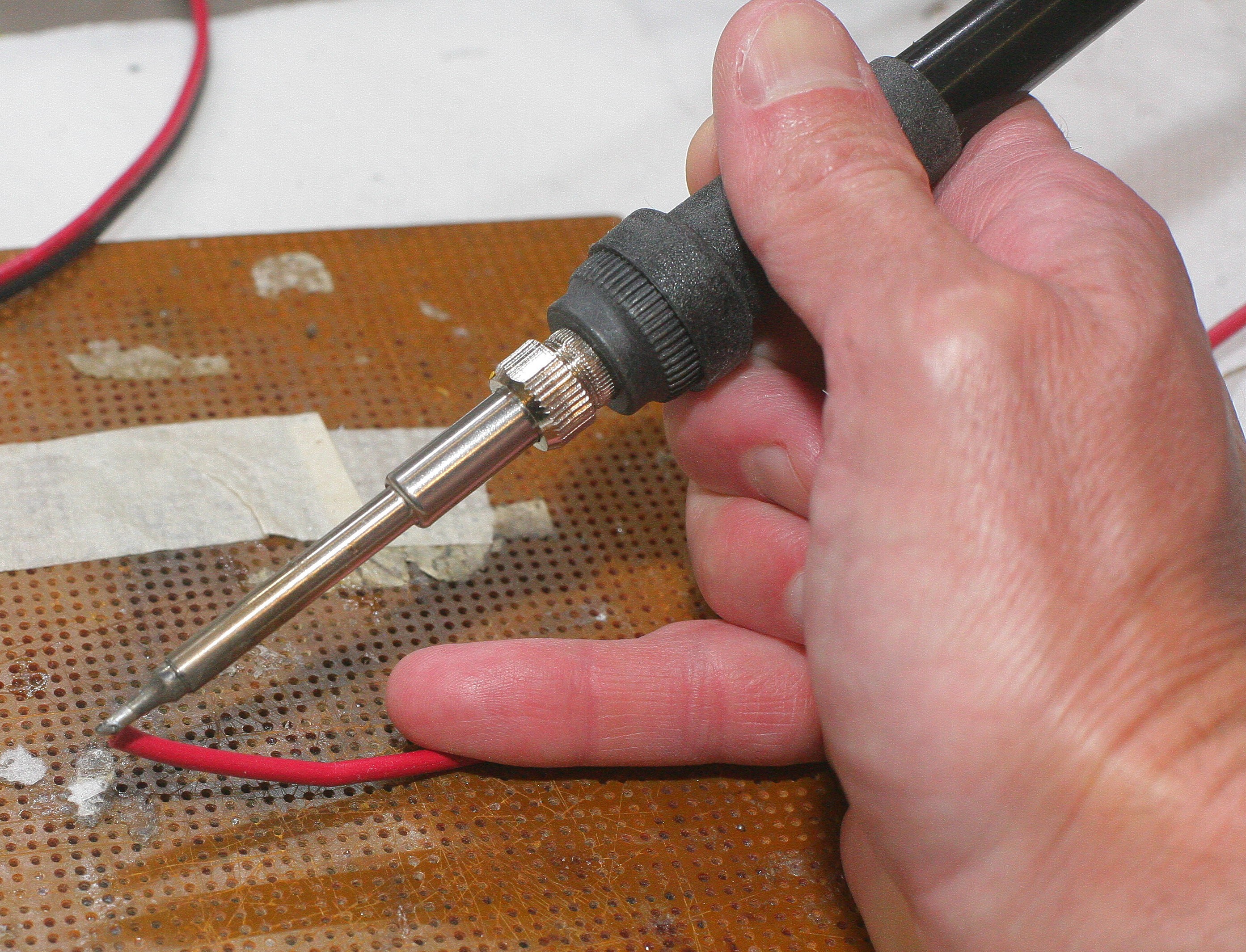

The thermal inertia of a very fine tip is too low to rely on a wide heater separation. To make the tip finer, the heater has to be closer to the end. The curie point was the original way of doing it, but better manufacturing has proven good enough to use active temperature control.

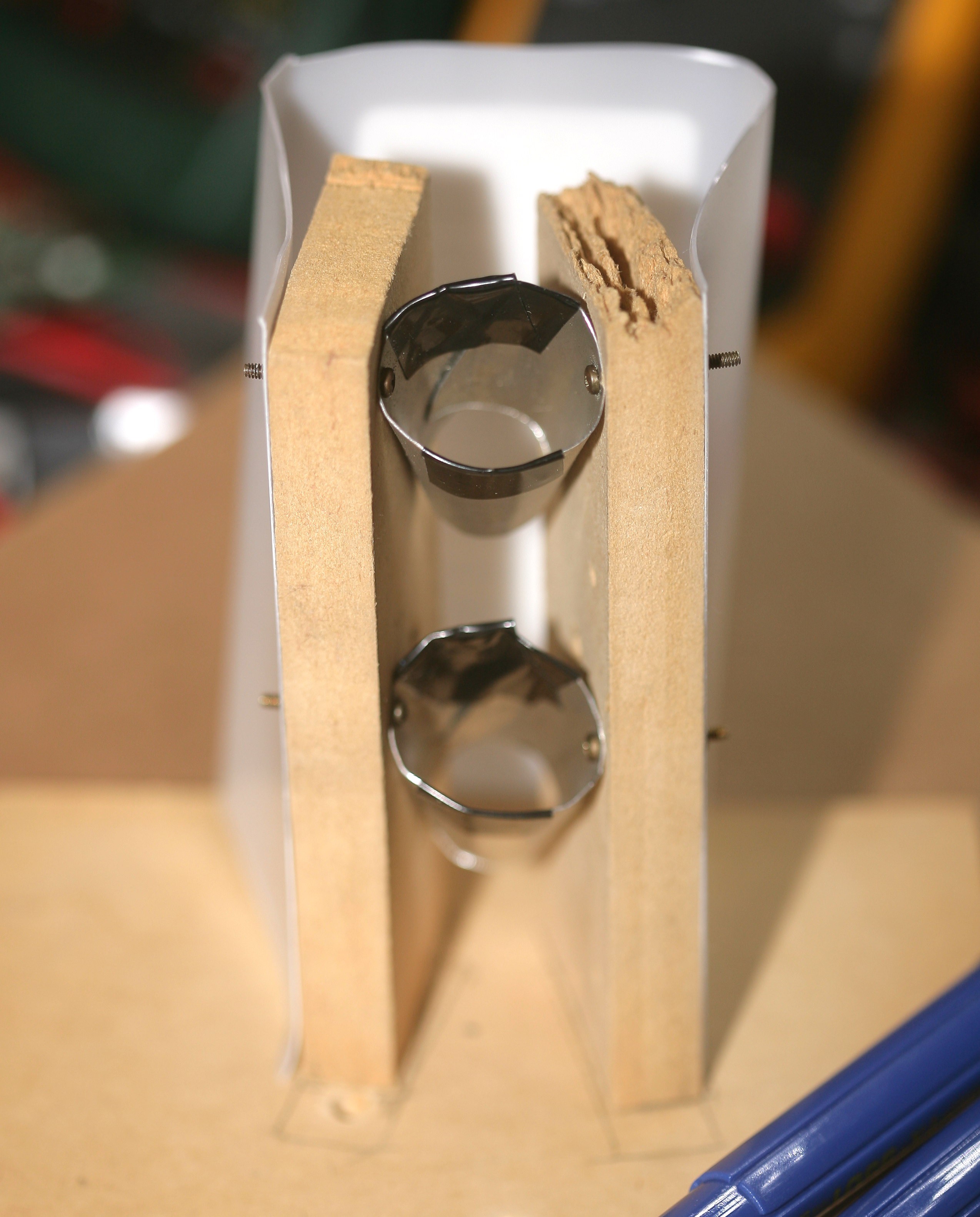

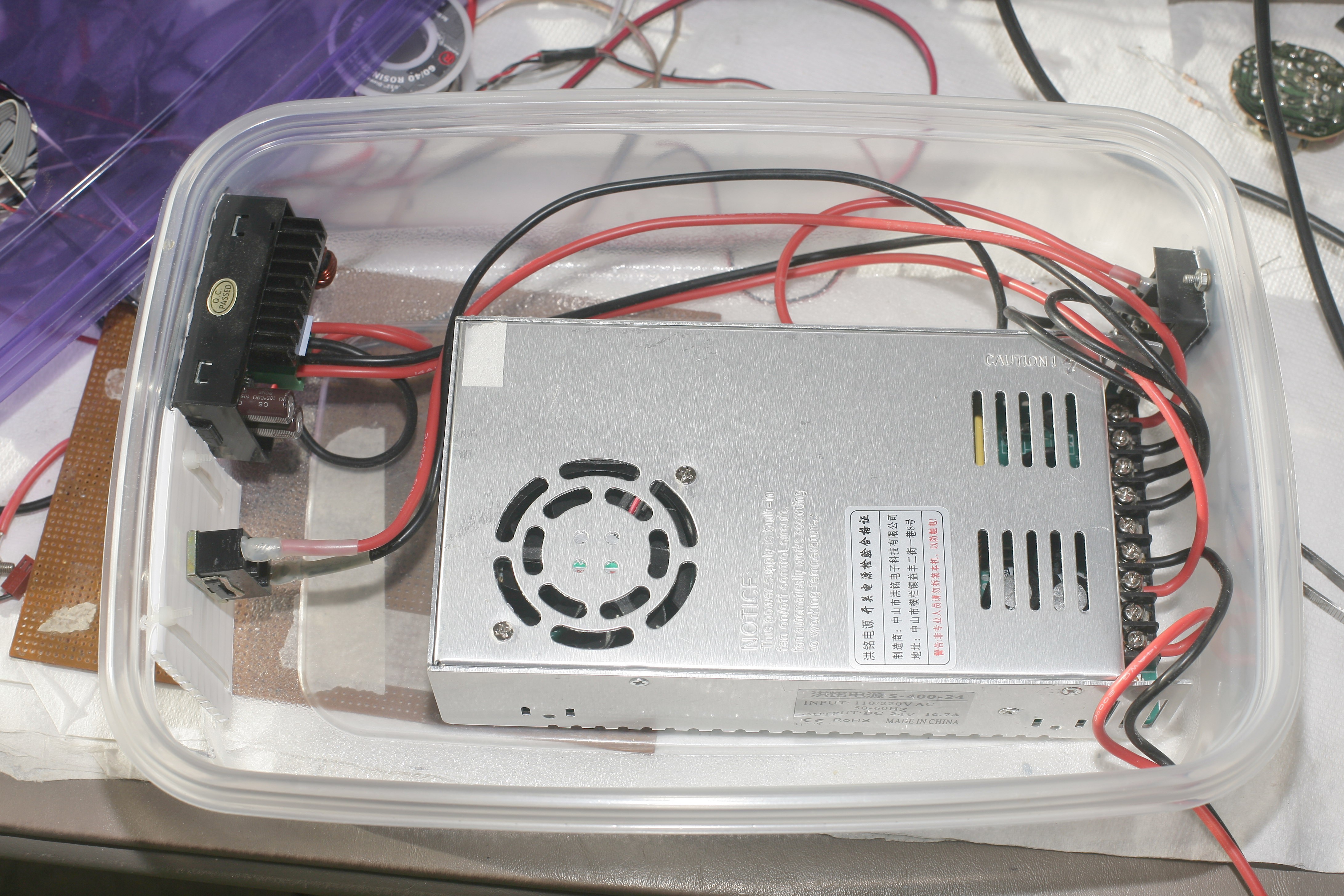

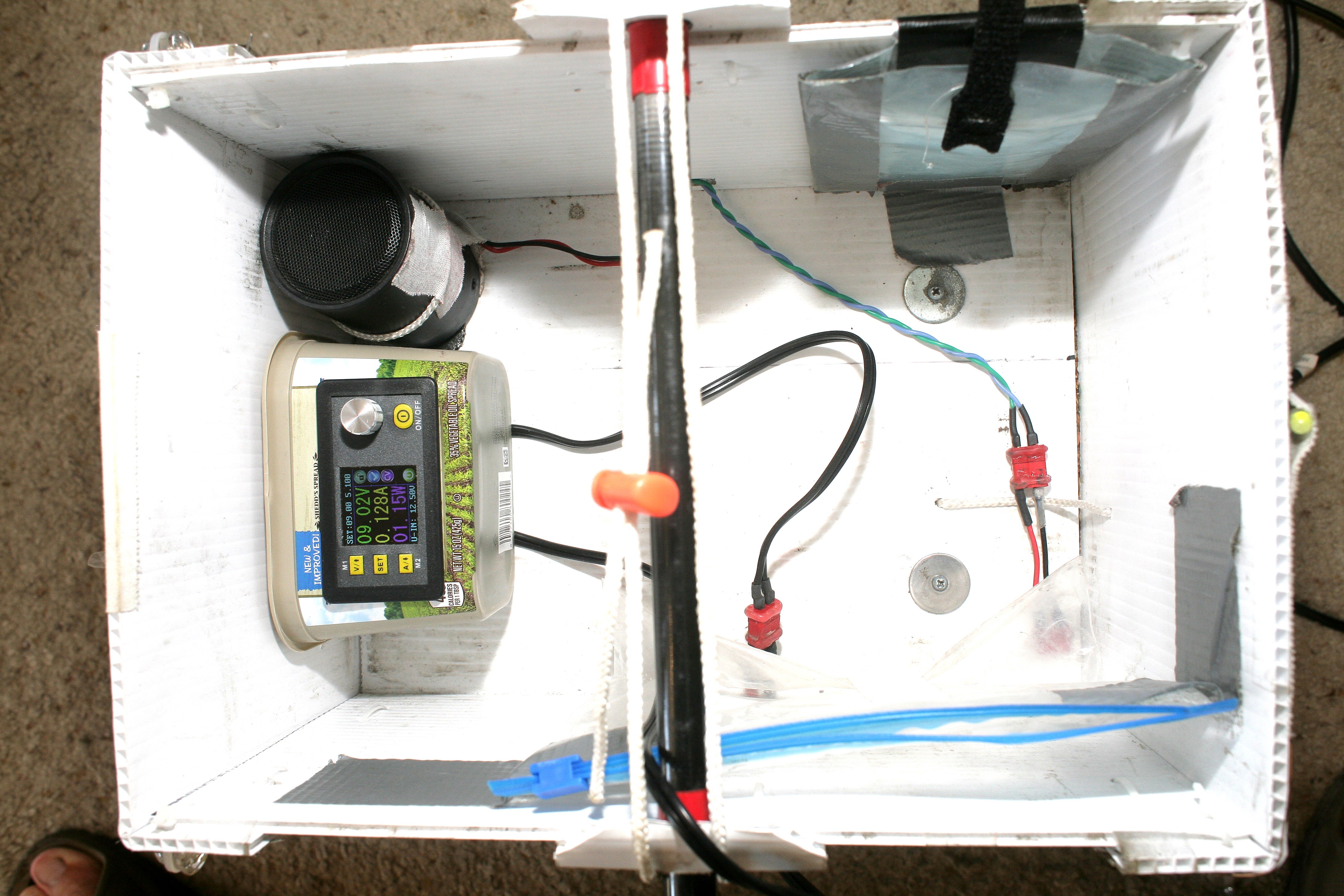

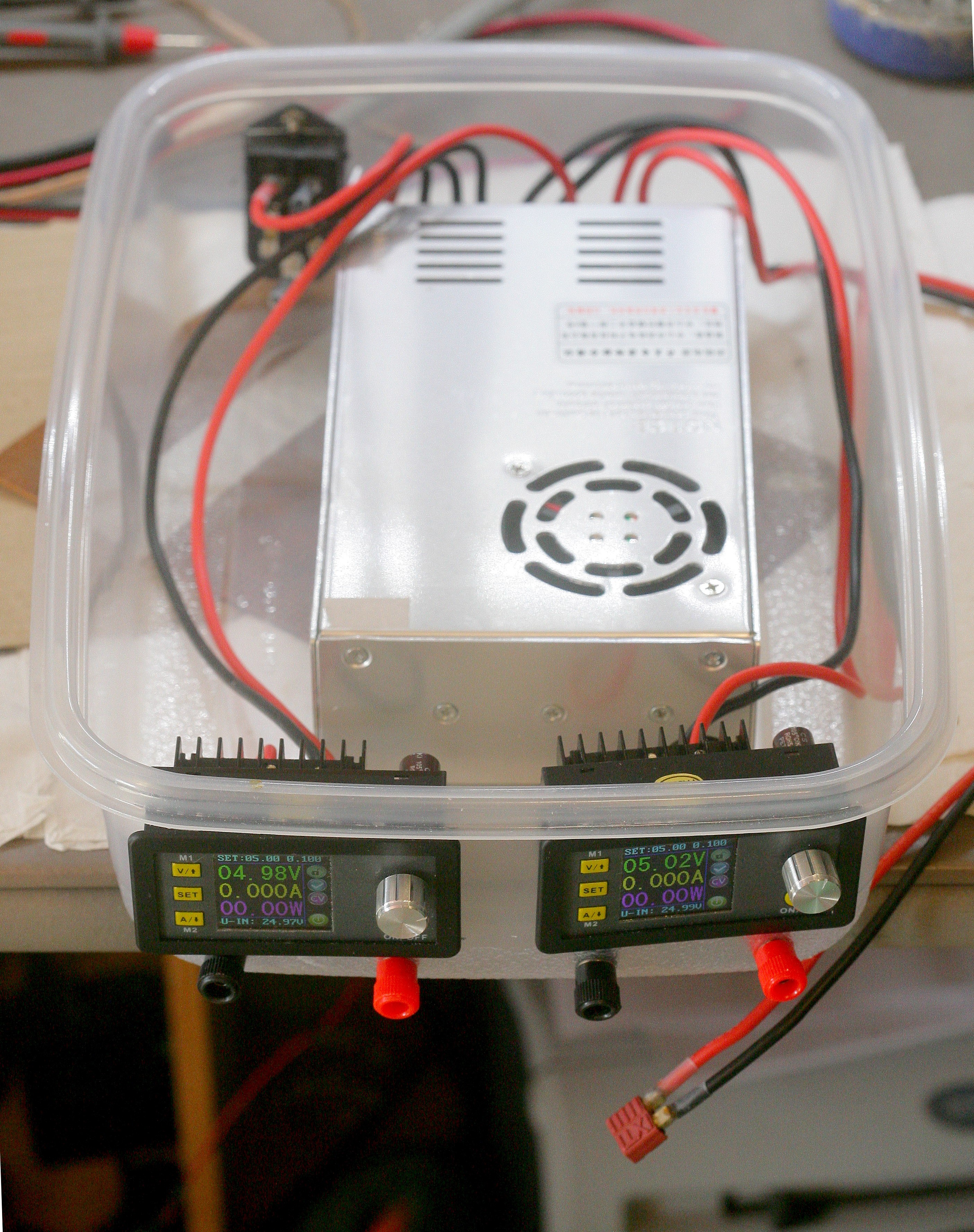

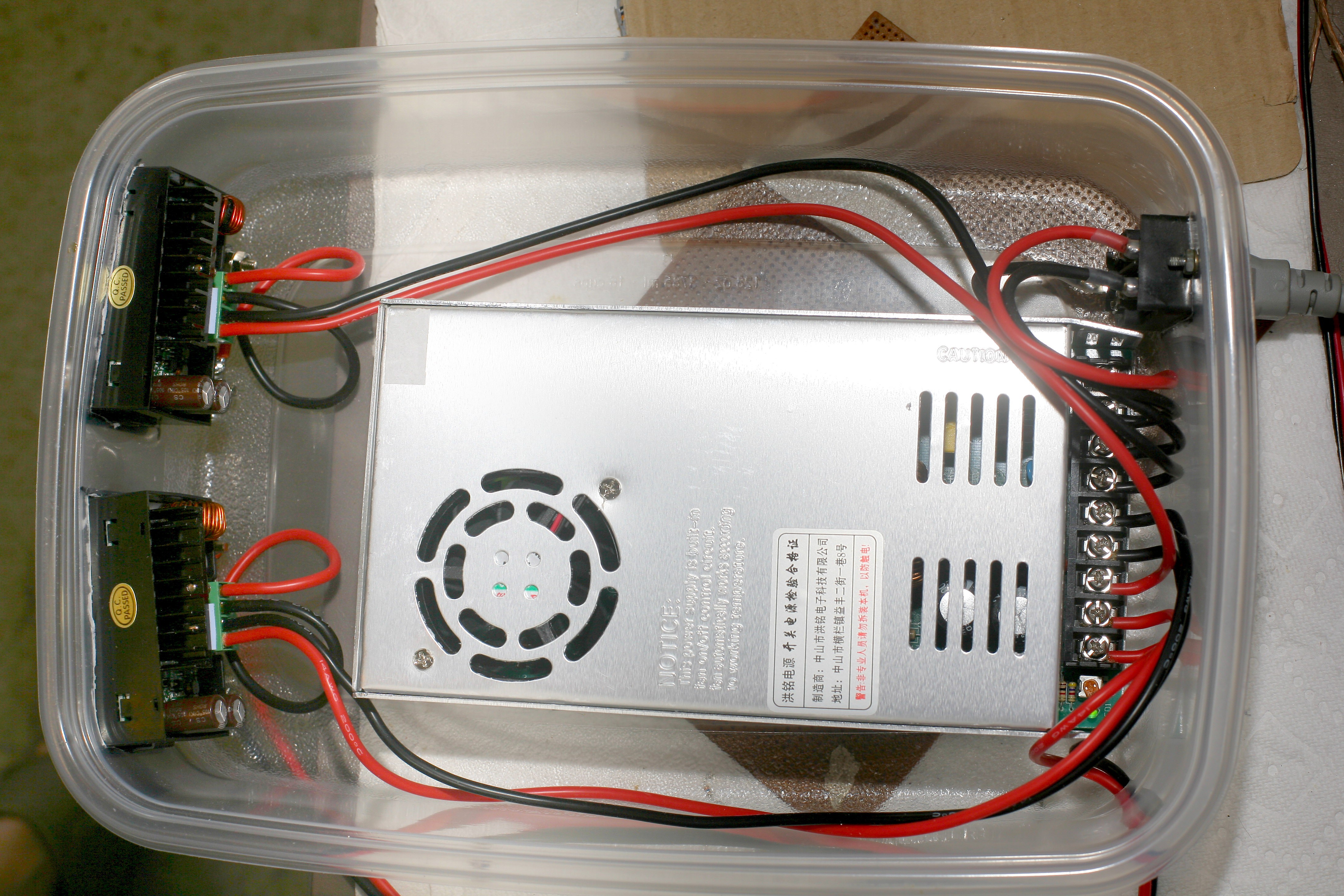

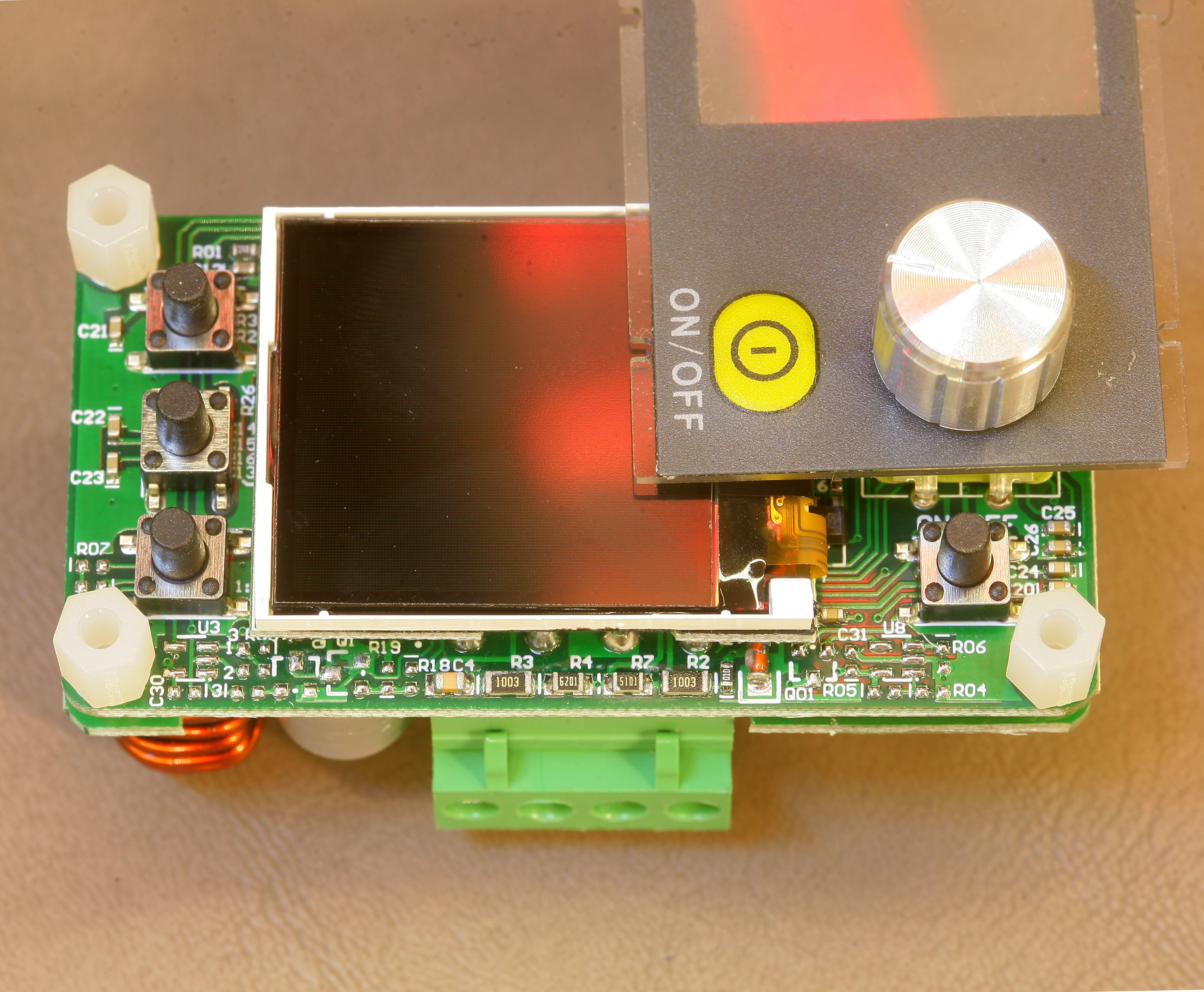

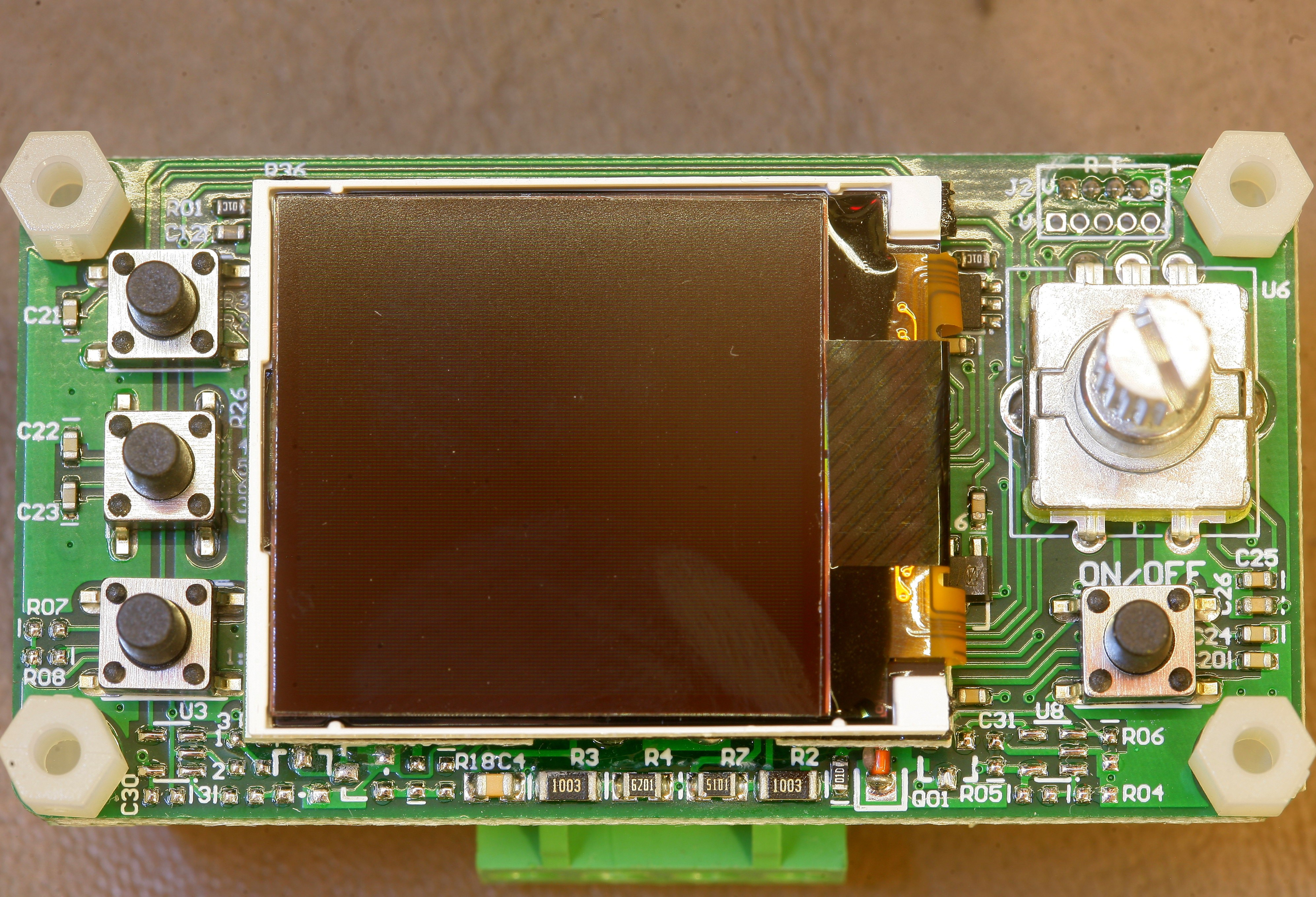

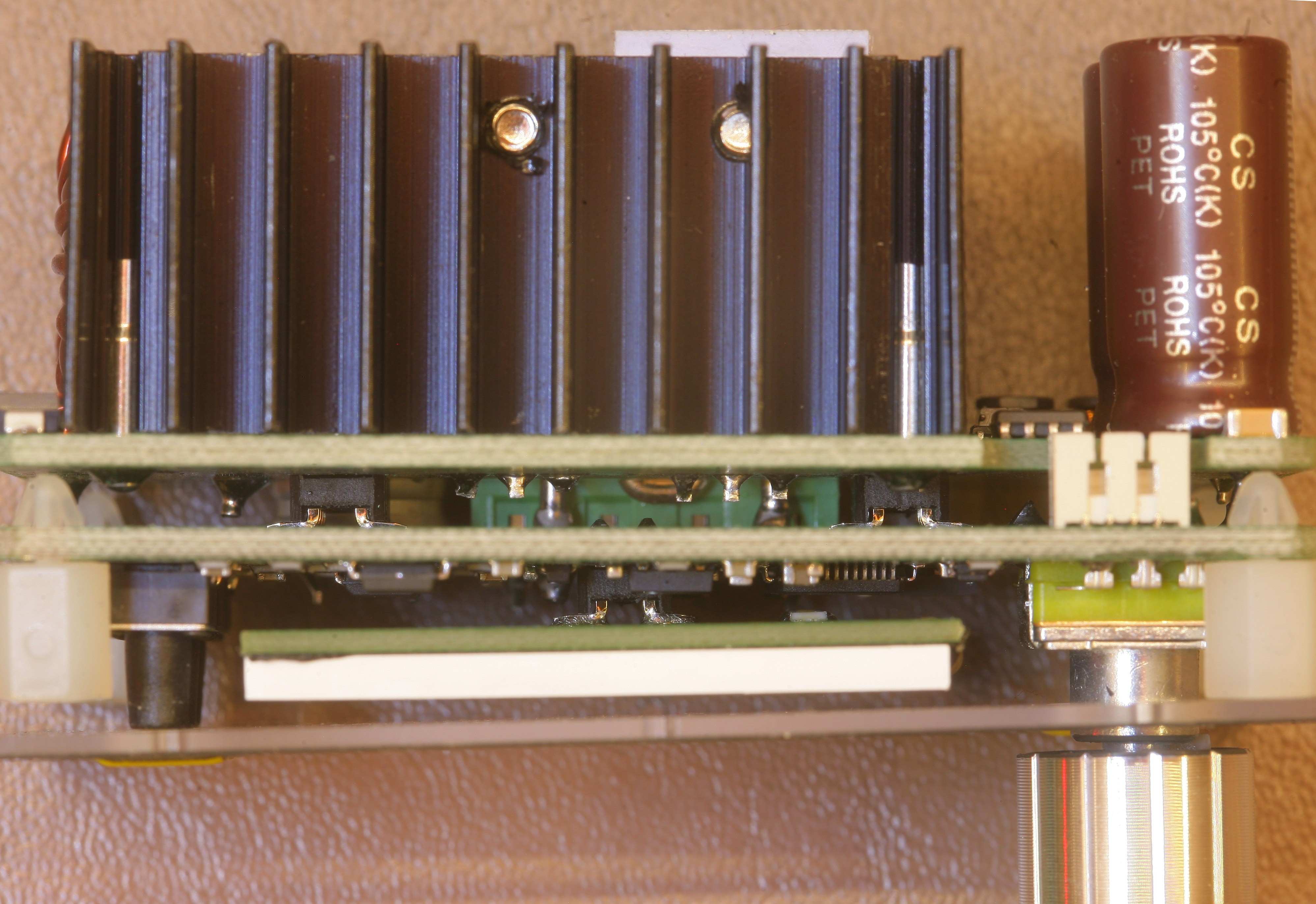

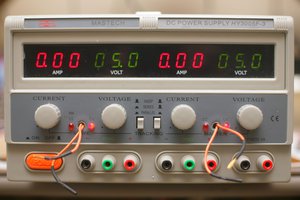

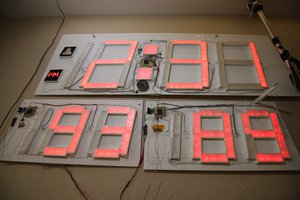

The lion kingdom really needs a single controller feeding 2 tips & a single stand for holding 2 tips with 1 copper cleaner. There's no commercial solution at any price. The idea of making your own soldering station didn't exist 7 years ago when the FX-888 arrived. It only seems to have appeared in the last 3 years.

The Hakko FX-951 is the cheaper version of the JBC & uses T-12/T-15 tips. It has an impossible user interface. They have a thermocouple in series with the heater. The thermocouple makes a voltage when the heater is off, which is proportional to the temperature difference between the copper leads & the heating element. It's heated by 24V AC.

Cold junction compensation:

https://www.maximintegrated.com/en/app-notes/index.mvp/id/4026

They're basically measuring the temperature where the copper connects to the thermocouple with yet another thermister & using a table that factors in the copper temperature. The trick is a thermocouple only senses difference between the copper & the alloys while a thermister senses absolute temperature. This is not actually used anywhere but internet comments. Assuming the copper temperature is 72F has proven good enough.

Chinese pinout diagram:

https://www.eevblog.com/forum/reviews/hakko-t12-pinout/

It's quite clear that the internet doesn't really know what the pins do. They all just copy the same wiring diagram from China.

Universal solder controller with typical voltages & wiring patterns for the various tips, but no functional description:

http://dangerousprototypes.com/forum/viewtopic.php?f=56&t=7218

This is incredibly overcomplicated, but it shows how recently it wasn't trivial to make your own soldering station.

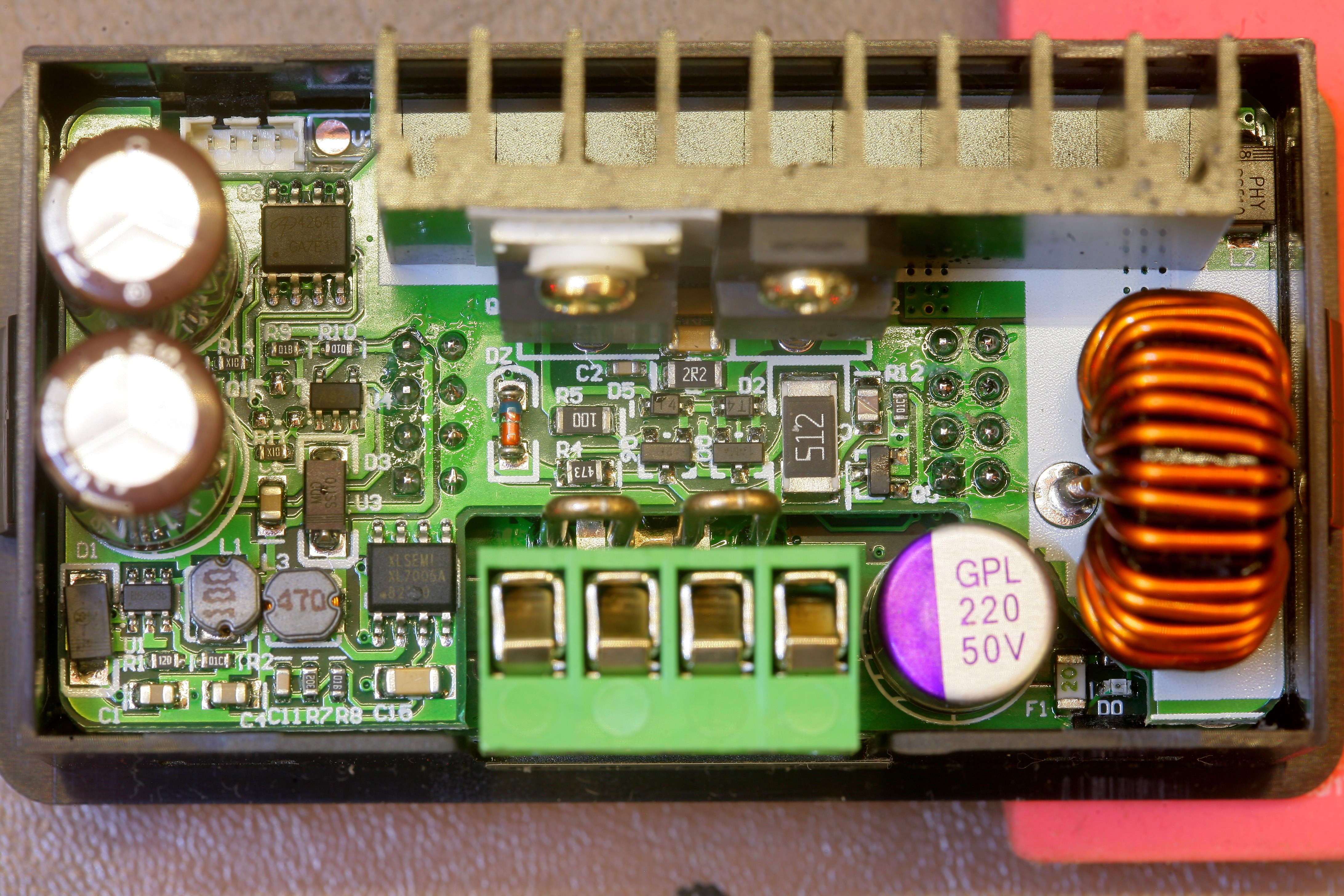

Teardown:

Analog circuit for reading the thermocouple & powering the heater:

The mane problem is getting the op-amp to handle the 24V when the heater is on. There's also a current flowing out of the op-amp input, which affects the voltage reading if a large current limiting...

Read more » lion mclionhead

lion mclionhead

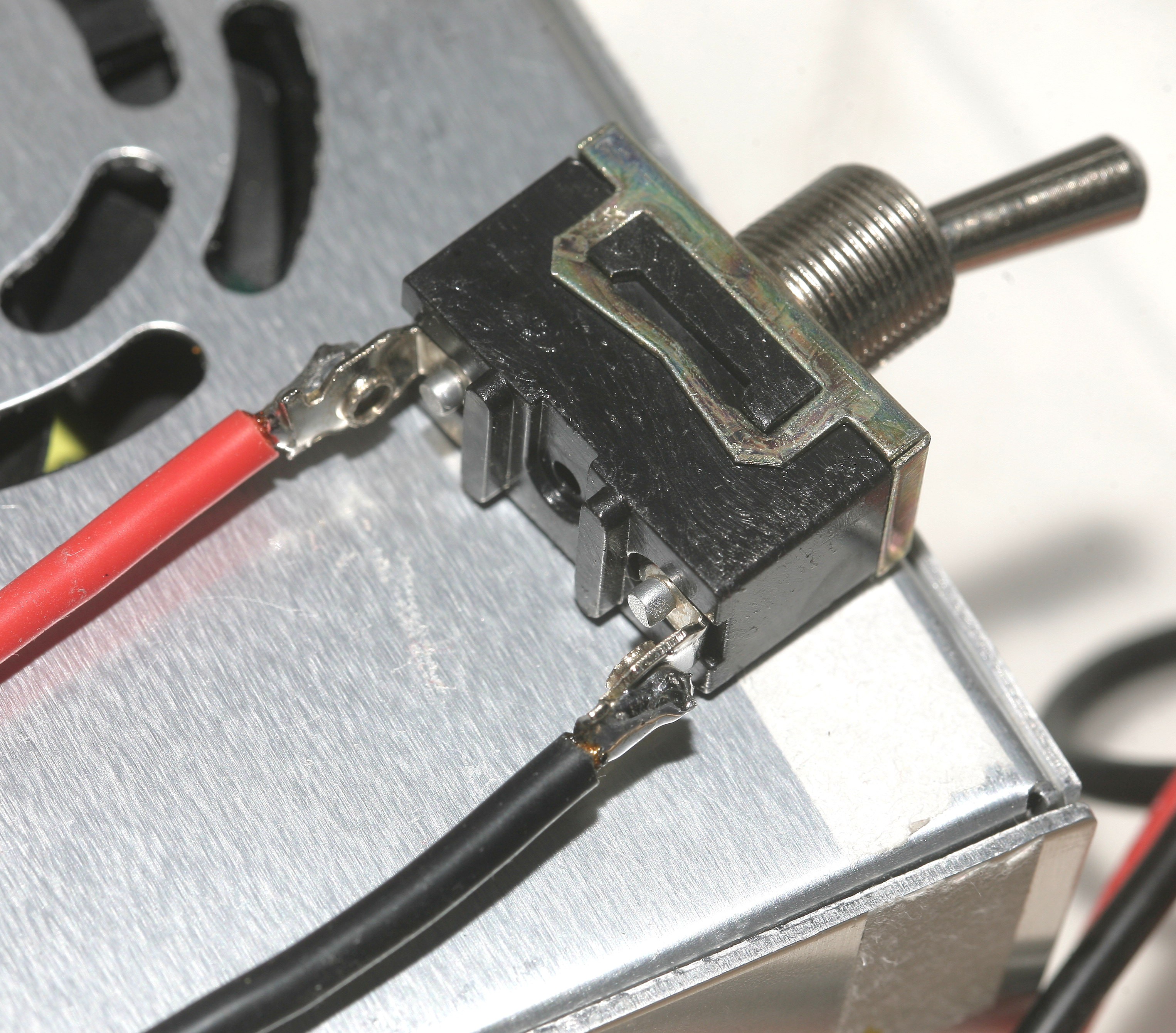

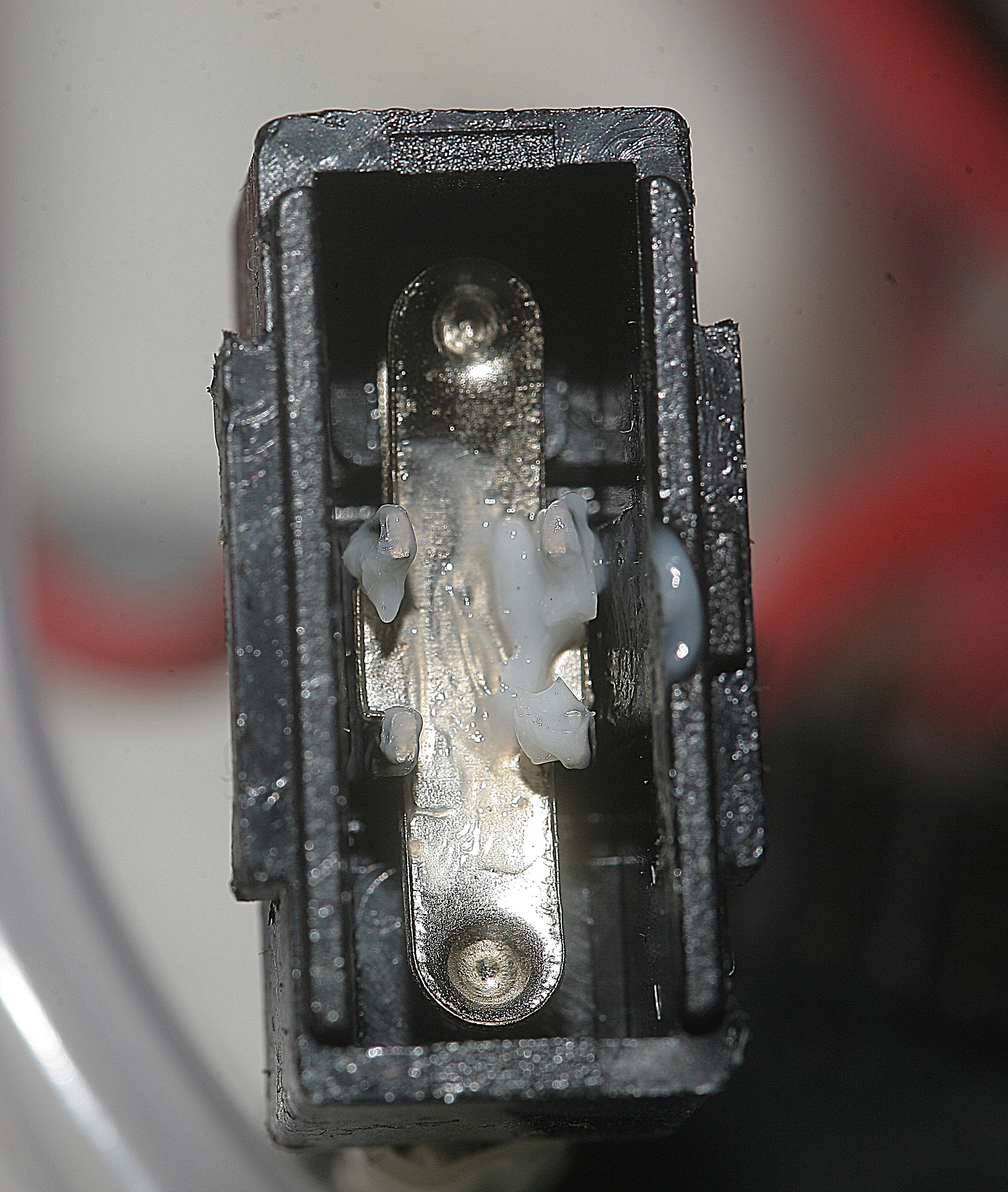

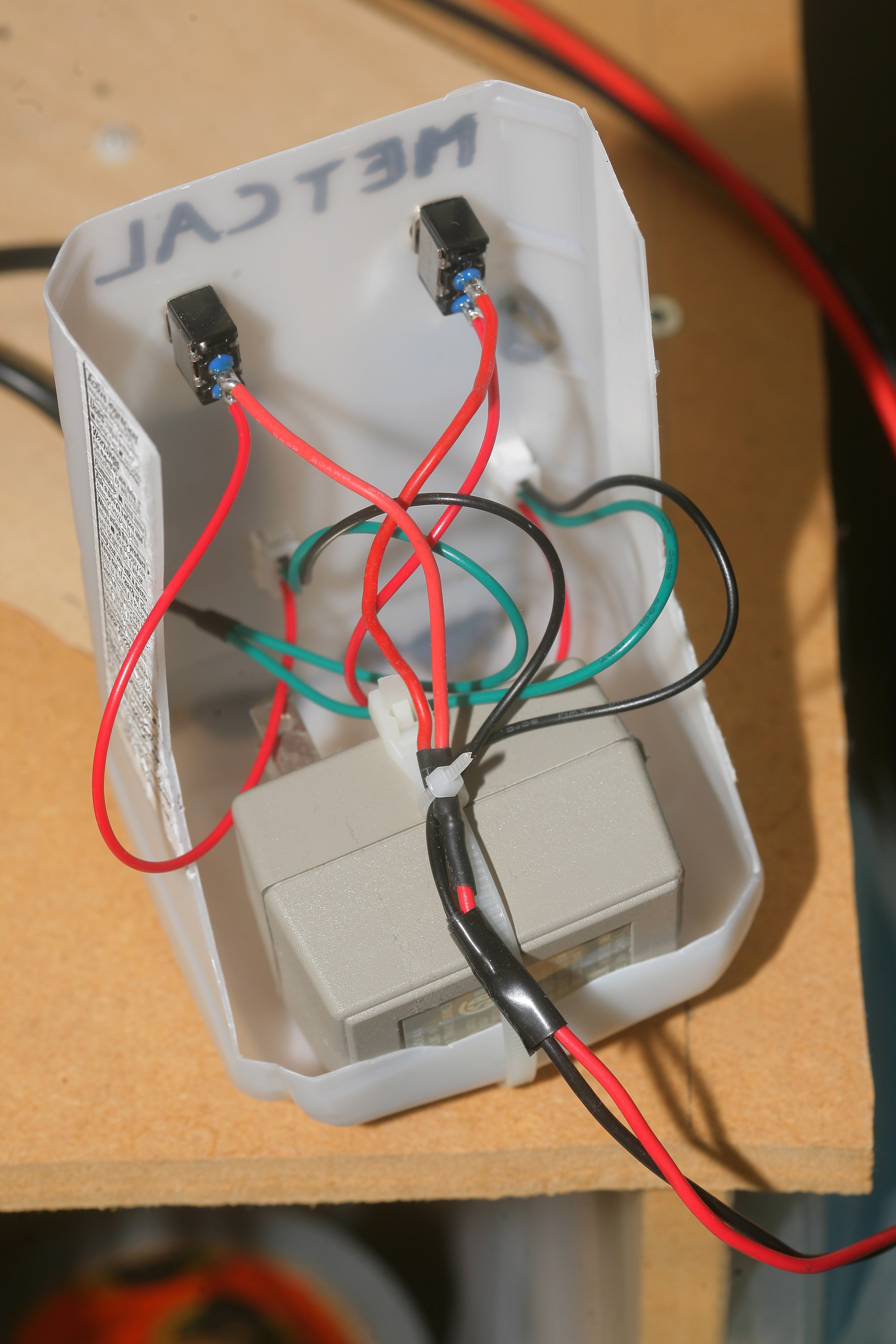

The switches were mashed in.

The switches were mashed in.

TheGrim

TheGrim

Dave_ Z.

Dave_ Z.

However,what do you think about Unisolder 5.2 ?

http://tiny.cc/56o14y