DIY oven for baking larger PCB boards

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Front_panel.stlSTL for front panelStandard Tesselated Geometry - 1.21 MB - 11/26/2019 at 18:27 |

|

|

ro_button.stlbuttons for front panelStandard Tesselated Geometry - 135.04 kB - 11/26/2019 at 18:27 |

|

|

rev_B_iBOM.zipdata for part placementx-zip-compressed - 64.80 kB - 11/26/2019 at 18:19 |

|

|

|

Portable Network Graphics (PNG) - 99.63 kB - 06/25/2019 at 19:12 |

|

|

|

Portable Network Graphics (PNG) - 71.58 kB - 06/25/2019 at 19:12 |

|

|

When I was thinking about new FW for my board and how people will or should work with it I realised that would not be bad has 2 more buttons (Menu and Back button) so I made new board revision.

Actually, I made 3 designs:

1) Design with CH340G UART chip (easy to solder), JST connectors

2) Design with CP2104 UART chip (easier to buy), JST connectors

3) Design with CP2104 UART chip, screw terminals (easier to connect peripherals)

From experience which I gain when I assembled previous boards (rev. B) I realized that micro USB connector is not strong enough and sometimes get loose, so I bought new USB-C connectors and all my new boards will have these. They are much more better.

Changes from rev. B -> rev.C :

- micro USB -> USB-C

- added Reset button (sometimes handy)

- added circuit to drive 5V fan to cool oven more quickly (I copy it from Reflow Master)

Sadly I did not know about error (see update from previous log) from rev. B so now I have about 15 of each these boards. I already made changes to my design so next batch of boards will be fixed.

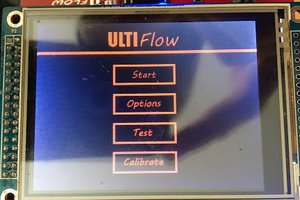

I also designed case so controller can be used outside of the oven. It can work in vertical (original) or horizontal mode. I spend few last weeks with development of newer version fo FW and here is small demo of it. This is still work in progress.

How you can see, there is still a lot of work and I´m now focusing on reflow profiles. I hope you like my progress.

When I complete my rebuild I had no time to test all parts of it and I recently found out that my speaker is not working. I also could not find original schematic from which I copied part for speaker and I was unable to make it work in any way, so I decide to make new revision.

This revision is completely same as first one, except buzzer instead of speaker and few diodes which were not needed.

Here as small test of it (sorry for bad video quality):

FW need a lot of work as for now, there is not much what it can do.

As i have some spare boards, I will probably try to sell them on Tindie, so if anyone is interested look there or send me a message.

Update 26/11/2019:

- I uploaded files for part placement for this revision

- I uploaded STL files for front cover & bottons

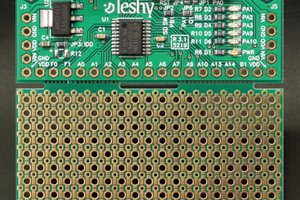

Here are pictures of this board:

I sold few of these boards and with help of Lukas Testo from Germany (I hope he don´t mind that I´m mentionign him) I realised that I have my cicruit for SSR wrong, at least wrong for SSR which need more than 3V to turn on. It is working for me with SSR in part list so I hope this is not such a big problem.

If somebody, who bought my board, have problem with it and can not drive SSR, please contact me and we will sort it out.

Rebuild of oven to reflow oven is finished.

Was it worth it? Definitely yes.

Main reason for this rebuild was big space as I need one for 23x23 cm PCBs (for my other project) but I can reflow also more small PCBs so it will be used quite often I guess. Because of limited capabilities of the FW (i time of writing this) and that I finished it few hours before i went for Christmas holidays I was able bake 2 boards. One small neopixel ring with 32 RGB diodes, just to test if reflow profile is OK and 1 big board which is those 23x23 cm and contain 144 WS2812B diodes. Both of them went really well and except one dead diode on that big board, they were reflowed really pretty. I would say that these boards are better reflowed than other board with same solder paste, which I baked in one Chinese reflow oven which I have at my work (similar to this one, but for 220V).

From price point it was also worth it. If I will compare it to similar oven which I have in my work, it´s really cheap. I did not count all parts, but I think the price for my conversion will be somewhere around $100 + I can change what ever I want on it (HW & SW).

Here is picture from baking my big board.

and here is board alive (thx to Luboš Moravec, which repaired that dead diode) :

I will work more on FW side so it can be used with more profiles. Right now will reflow just one profile and is missing any capabilities for menu and those Advanced features, which I mentioned few logs back.

I hope this project was interesting for you and if you have any question, pls just ask ;-) .

I gathered all parts, assembled PCB and I did buy new connectors for heater elements so I can start with final assembly.

Because oven should be mobile and independent, I designed power connector on PCB so I need something which will convert main power to 5V which I need for controller. After some thinking about what I can use and how can I attach it to main body, I decided that I will sacrifice one of my USB chargers for my phone. I cut it in half and soldered 2 wires on each side (main power & 5V). I attached PCB to printed front panel with M3x5 screws and SSR with M5x10 screws.

Connected power from USB charger, connected SSR to PCB and connected main power to one side of SSR and other side of the SSR which transfer power to heat elements when SSR is in ON state. Screwed front panel to main body with 6 screwes, attached USB charger to main body with double sided tape and drilled hole in wall of heating chamber for thermocoupler.

Here is final picture:

After I tested that everything works, I attached cover of the main body.

Oven is really not complicated. It´s just few parts, main body, some insulation and cover which is hold by few screws on the bottom of the oven. 4 pcs are in rubber feets and 2-3 are screwed to main body through cover. When you take down cover, you will see this:

There are 3 control parts: temperature control on top (70 - 230°C), heater selection (off, bottom, top, both), timer (on, off, 0 - 60 minutes). Main power goes to timer and if this is setup to ON or some time, power will go to temp control and after that goes to heater selection. If is everything setup, current flows to positive lead of heaters (negative are connected to ground directly).

Front panel of the oven was held by 6 screws, so when I unsrew them, I got part which can be easily replaceable. I measured all distances between holes for screwes, measured height & width & deep of the front panel and fire up Autodesk Fusion 360. As I also exported my PCB board to Fusion 360 and downloaded SSR from Grabcad, I could imported both of them to the assembly and use them as reference for holes and mounting points. Here is visualization of new fron panel:

I printed on piece from PLA on Prusa MK2 (I have to swap color to white, as I did not have enough silver), which I have at my work and tested it how it fits and I was surprised how good was the result.

I was not satisfied with buttons and hole for USB cable so I made them bigger and printed front panel again. Also I changed height of the stand offs for SSR, as I was not sure if I will need to add heat sink to it, so I prepared some space for it. I also printed some buttons from same material.

Now I have all parts which I need and I can do assembly with new front panel.

In my previous build of reflow oven, I used very simple controller based on Atmega328. Here is picture of my board, which I designed for this purpose.

Board was based on schematic of Reflow Oven Controller Shield (Arduino Compatible), but I wanted it like complete board so I implemented MCU on it. It was not perfect, but it worked. On top of this board was 16x2 LCD (JP1) and board from Adafruit with thermocoupler (MAX31855) was plugged to the SV2 header. SSR was hidden on side of the oven. Usaga was very easy, one button controlled start or stop of the heating profile. This was years back, when I just start playing with Arduino.

This oven controller is based on very popular ESP32 controller and I build it to have this Basic features:

In future I would like to also have Advanced features such as:

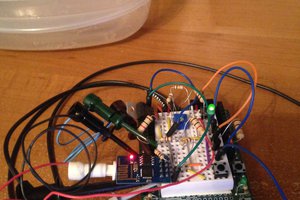

When I was waiting for arrival of my oven, I designed this board in Autodek Eagle.

I used ESP32 WROVER chip, as I also use them in other projects. Well known CH340G is used for programming & UART communication. For temperature reading I used MAX31856 because it can read multiple types of thermocoupler´s. TFT has ILI9341 driver.

Board are in production, so I can look at what´s inside of oven :).

As I build reflow oven in the past, I roughly knew what I will looking for, but to be sure, I did small research on the Internet.

I looked on some similar projects here and on other places and I confirmed to myself that I will need some oven with infrared heaters. They heat up quite quickly which is key feature which I needed. Also I did not want to spend too much money with first buy, as I did´t know if the oven which I choosed will be the right one.

I looked online what I can get cheap and fast to ship, as I had bit of time till Christmas. I was looking for some oven with at least 2 infrared heaters (top & bottom), inner space larger than 23 cm and good for hacking. After while, i founded this beauty (image is property of Lidl-shop.cz) :

. With 2 heaters at top & bottom, space for 26 cm pizza and price about 40 euro (cca $45) was the exact oven which I was looking for. There was no description about infrared heaters, but I saw some mentioning about it somewhere else, so I risk it and make order for it. I received oven in about 5 days and I tested it right away after receive it. I used multimeter with thermocouple, which I just put in the oven and closed the door. There was very small gap in the door, but nothing to worry about in first test. I knew, that heaters have to go up to 150°C in about (max) 90 seconds so if this will be ok, oven will be usable. I turn on top & bottom heaters, set up maximum temperature (230°C) and setup timer to 10 minutes. I did not keep record how fast oven heated up, but temperature rise up quickly enough to confirm that this oven can be used. I keep it on for while and I saw maximum temperature at about 270°C, so component which was reading temperature has a small offset.

My choice was right and now is time to make something which will be controlling the heating elements :) .

Create an account to leave a comment. Already have an account? Log In.

>> I have few spare PCBs

Is this for the Rev A pcbs or the newer ones.

Hi Miroslav Zuzelka are you willing to share your files? please pm me on jorgmuskens@gmail.com

Hi, sorry but no at this moment. If you are interested, I have few spare PCBs ;).

Nice project! any idea when the code/files will be available?

Become a member to follow this project and never miss any updates

fruchti

fruchti

NuclearPhoenix

NuclearPhoenix

zacnotes

zacnotes

What size of oven are you using? I am discussing getting your controller and maybe a larger convection oven, but I am unsure if that is advisable or not.