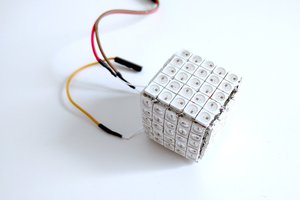

I've been working with the APA102 (SK922) on a couple of projects using off the reel chips from AliExpress. During prototyping I ran into the issue of trying to solder small wires on to the chips which would take up to 30 minutes per chip. So I started designing a breakout board to allow quick prototyping.

After I finished the board I saw the Flexible PCB contest I thought what I could make with a flexible PCB. This project came to mind!

The reason why I think this would work well as a flexible PCB is it would allow the StripOut Board to work the same way as a standard addressable RGB LED strips with more room to make it your own. Cut each one to its own length, chose just the right distance between the LEDs for your project then just added some double sided tape and stick them in place.

One of the main reason I started making my own breakout boards for the APA102 over the premade strips was so I can ensure the fit where I wanted them to in way I wanted them to so I could test out different arrangement quickly and cheaply. I hope these will allow me to do that!

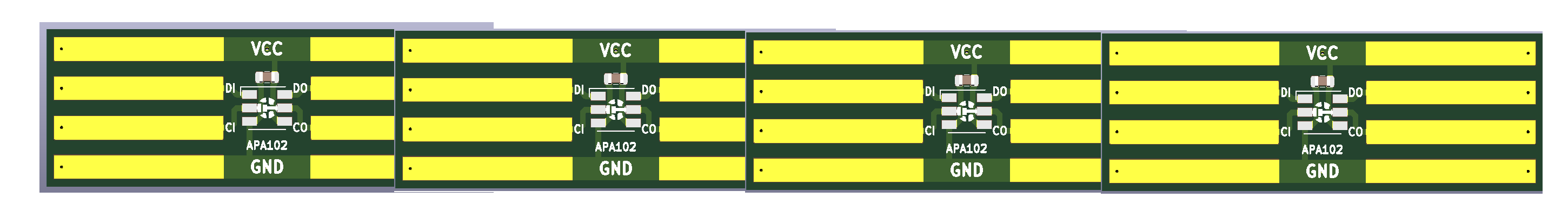

Below is an mspaint mock up who how it would work. Just solder them together, and you have a custom LED strip!

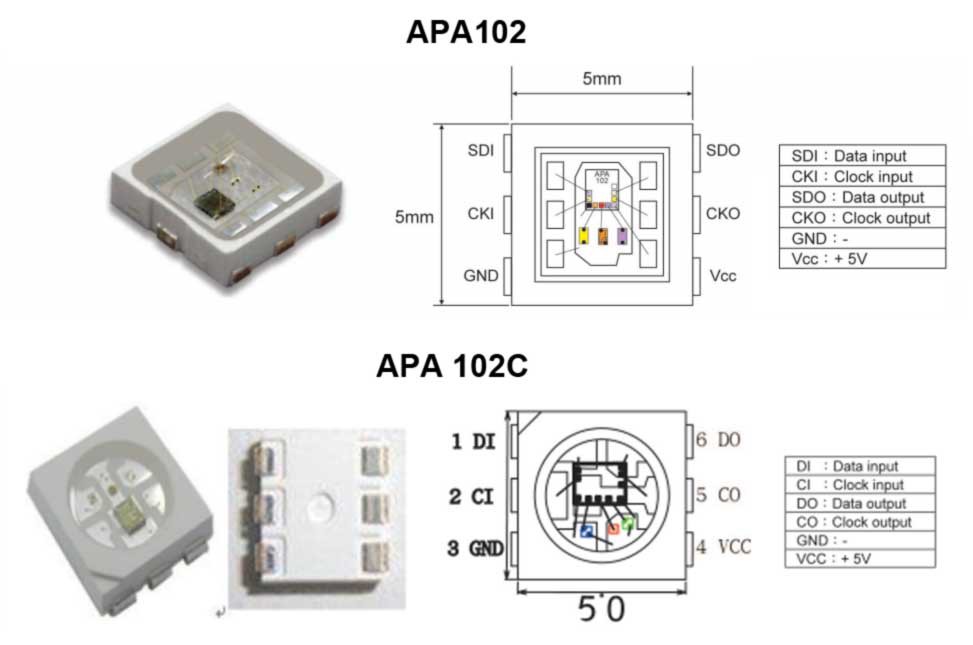

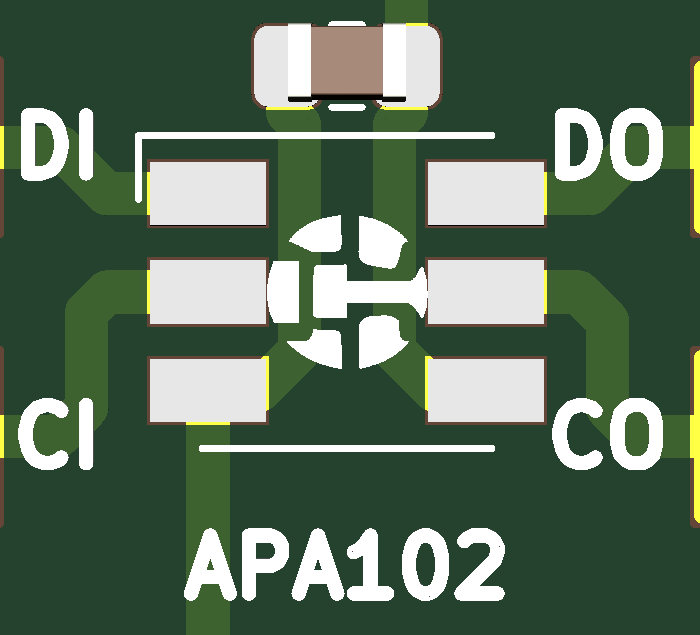

An issue I wanted to solve with my StripOut Board is the issue with ensuring you are soldering the LED the right way up. An adressable LED like the APA102 has 6 pins, 3 on one side for data in, clock in and ground. The other side has data out, clock out and VCC. I've always had issues remember which way it should go.

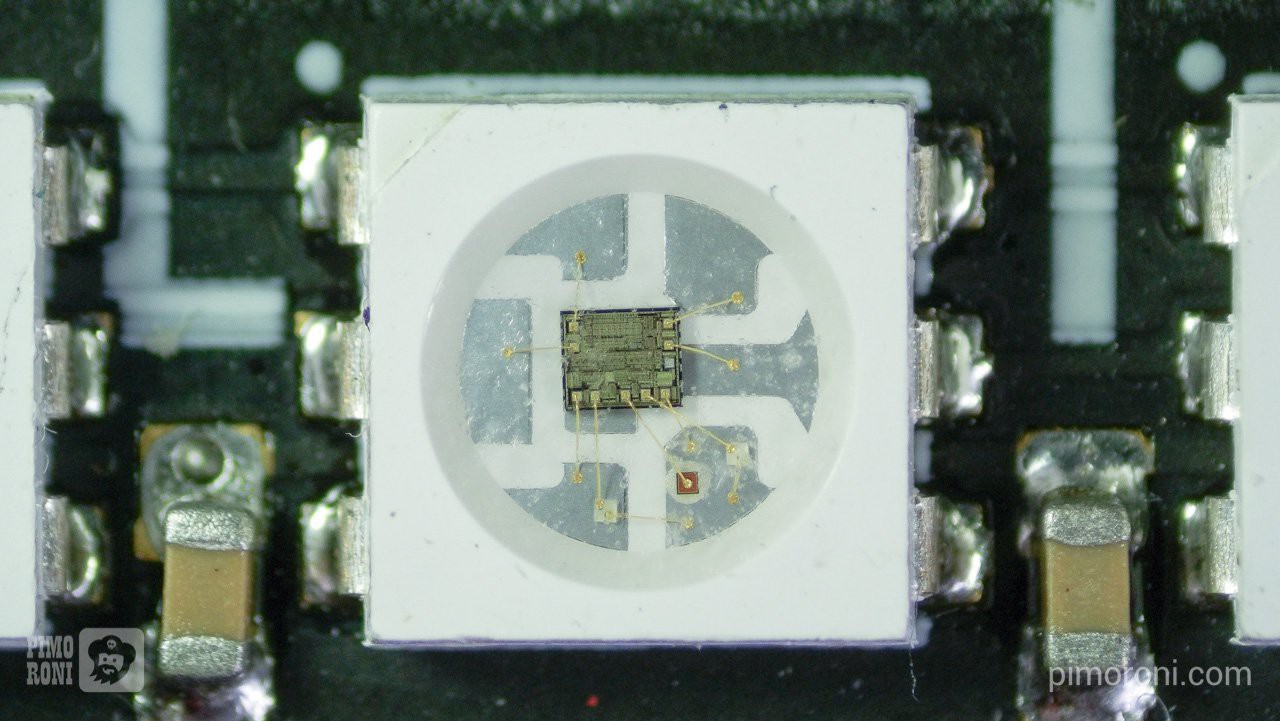

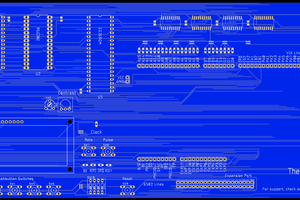

The data sheet shown above shows that you need to look at the dies orientation or the triangle top corner to see which way round it should go. On my PCB I thought I would add the triangle so it was clear which way round was right. However the layout of the die and bond wires look super cool so I wanted to try add an image them to the PCB. So I looked up so high definition picture of the die, seen below, and started tracing.

Then after spending around 3 hours trying to work out how to get the image into KiCAD I found this cool website that did just what I wanted.

Now you just have to look at the die and you can ensure its soldered on the right way up. Also it looks pretty cool. Way better than a triangle.

deʃhipu

deʃhipu

Josh Kittle

Josh Kittle

P

P