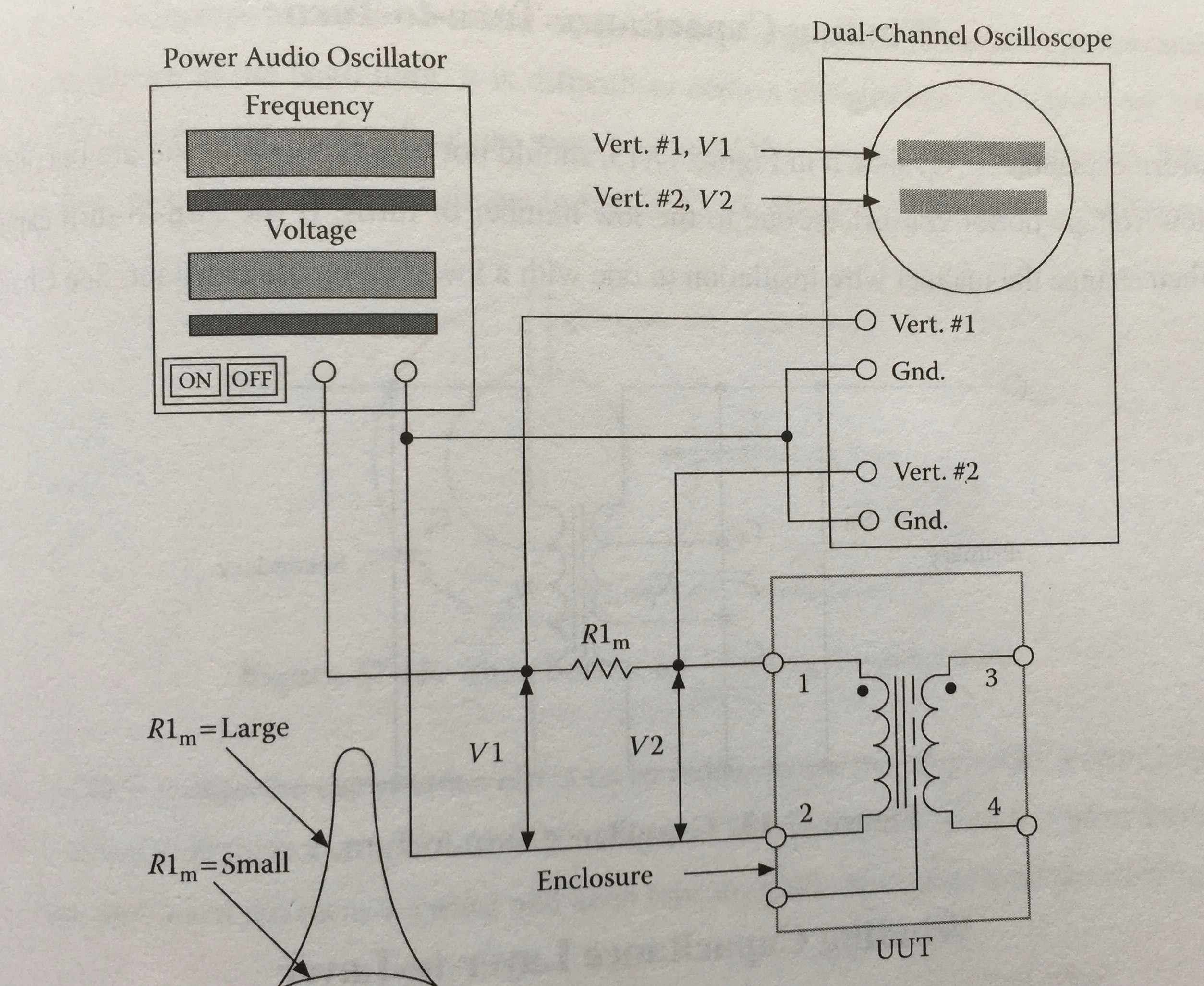

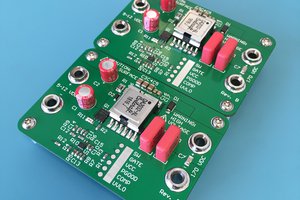

Specifications (as pictured)

- Input voltage: 11-16 volts DC

- Operating temperature: -20C - +40C

- Maximum continuous input current: 45 amps

- Idle current: 420mA

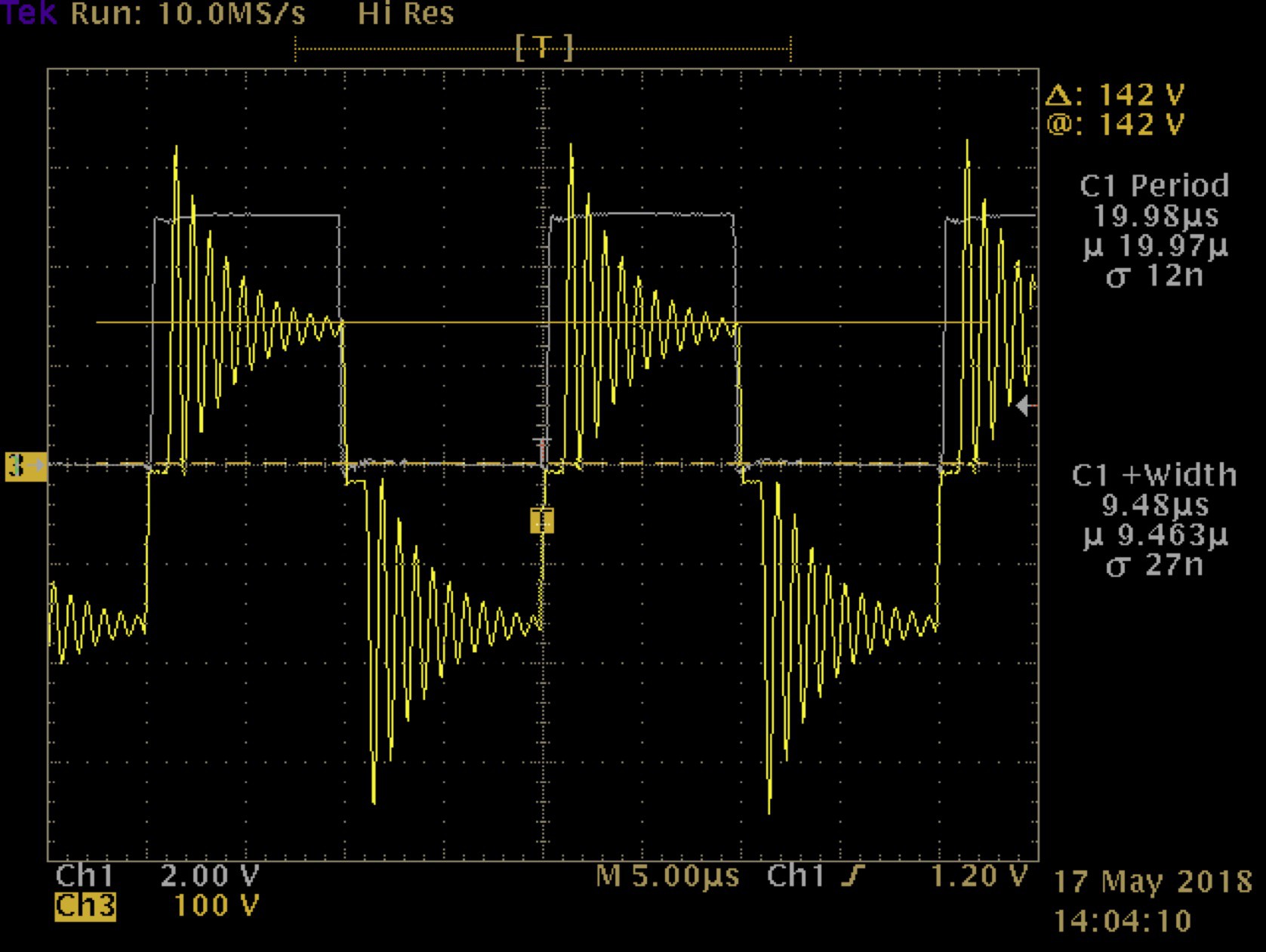

- Output voltage: 100-120 volts AC RMS (110V AC RMS nominal)

- Output frequency: 60Hz, +/- 0.5Hz

- Maximum output power: 400 VA

- Continuous output power: 350 VA

- Total Harmonic Distortion (THD): <5%

- Efficiency: 81%

- Galvanic isolation between DC input & AC output

- Protections:

- 60A input fuse

- Input under/over voltage

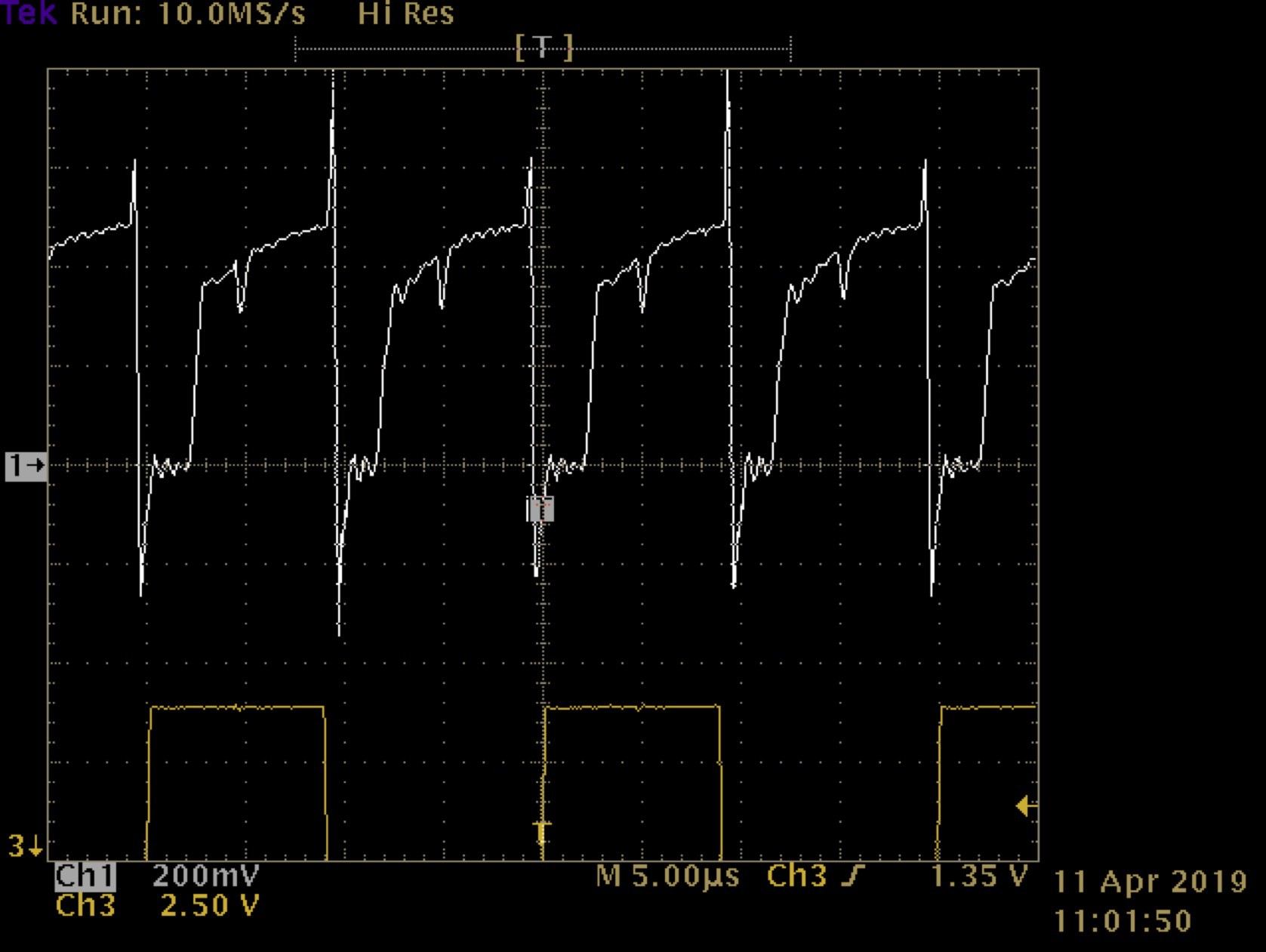

- Over-current / short

- Overload

- Overheat

- Dimensions: L=203mm (8"), W=144mm (5.7"), H=68mm (2.67")

- Weight: ~ 1.36kg (3lbs)

This project is done. If you do build it please read thru all the instructions first. I recommend that you build from the input section forward: power -> start -> controller -> inverter -> transformer & supplies -> sine.

CAUTION: high voltages, currents, and temperatures exist in this design.

James Wilson

James Wilson

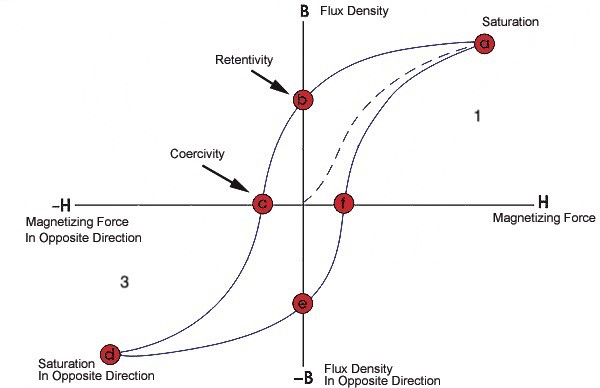

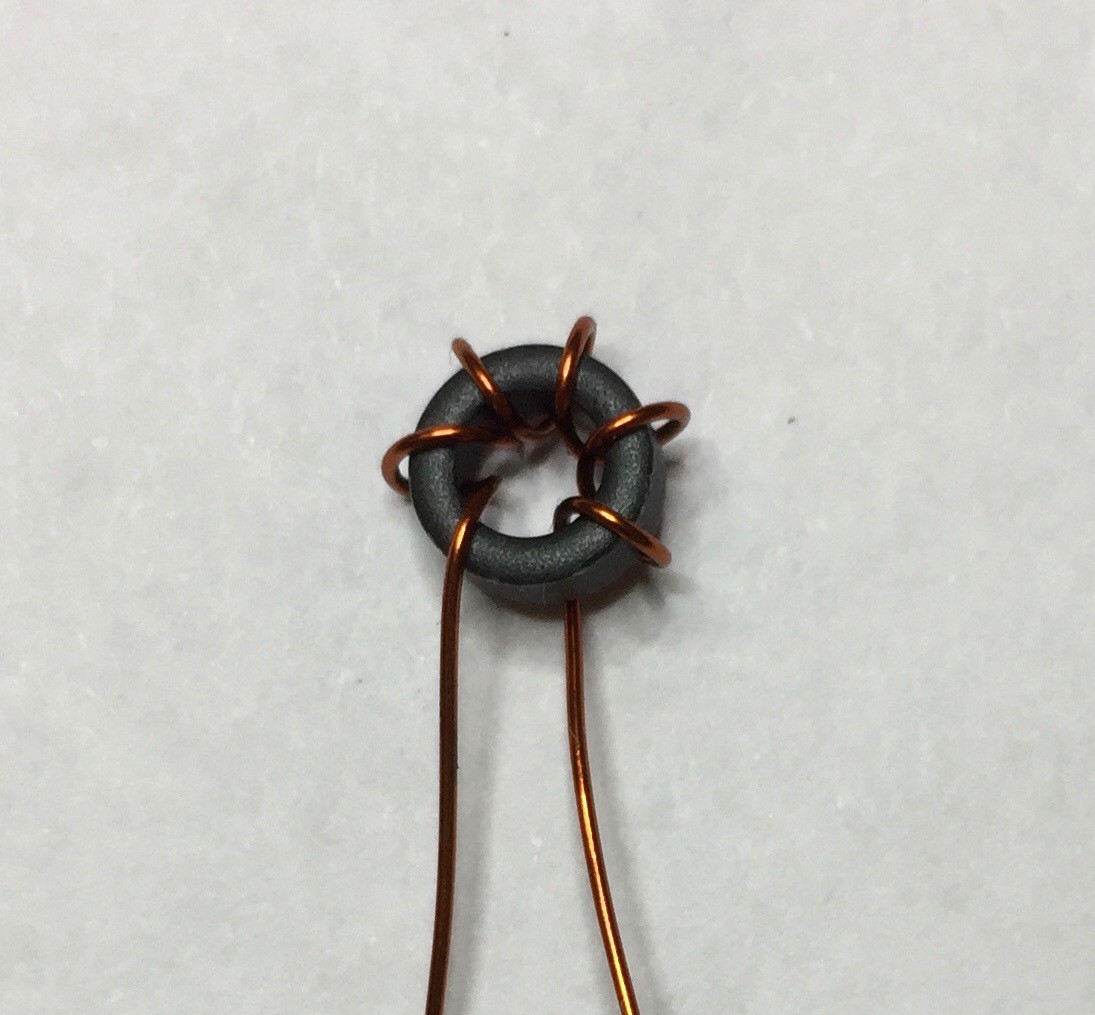

I had a DC blocking capacitor on the AC output in early prototypes but found it unnecessary. After that I didn't do much investigation on why but I suspect it's similar to the self-balancing effect you get with MOSFETs on the transformer bridge: an imbalance increases current on that leg of the bridge which raises junction temp, increasing their Rds(on), thereby reducing current. Somewhat ironic since the output inductors are designed as DC.

I haven't encountered problems running old-school gear. In fact, the cover photo with the TV has the audio running thru an early 90's Denon receiver/amp that uses a line transformer & linear supply.