Overview of parts:

- All products will connect to a mesh network

- All products will be able to be controlled via app software anywhere in the world

- All products will be compatible to be used with google home etc.

- All products will have a unique part number so no number will be the same

- All products will have a reset button

The final design was composed of 5 boards:

- The mainboard which used an Arduino board

- The Wi-Fi boards

- The power board (SMPS)

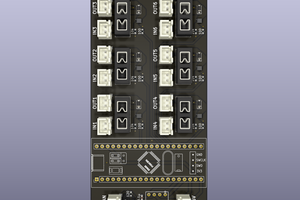

- The LED boards

- The Triac PCB

The final prototype was successfully made and tested. As was expected, it could be used for dimming light loads from LED to incandescent up to 500w from 0 to 100%. It could be controlled or scheduled by an app or manual control push on push off or push and hold to dim up or down. The use was also able to group lights, set timers, etc. with the app.

The product could also be used to control other devices remotely like a 2-way non-wired control, or a dimming fan base up to 500w, etc.

Our Challenge:

After the design, we had to go into the prototype and mass production phase of the PCB. At this point, we were looking for a company that would give us a high-quality product and with good speed. We contacted several companies.

Finally, we chose NextPCB because they have strong and fast communications and they were able to deliver the product with high quality and considerable speed. The first ORDER is FREE from NextPCB. We decided to choose NextPCB for the mass production of 20K Products.

You can see how to place an order on NextPCB as we experienced.

fr.shirvan

fr.shirvan

hesam.moshiri

hesam.moshiri

UGRT

UGRT

Jon

Jon

Tyler Ward (Scorpia)

Tyler Ward (Scorpia)