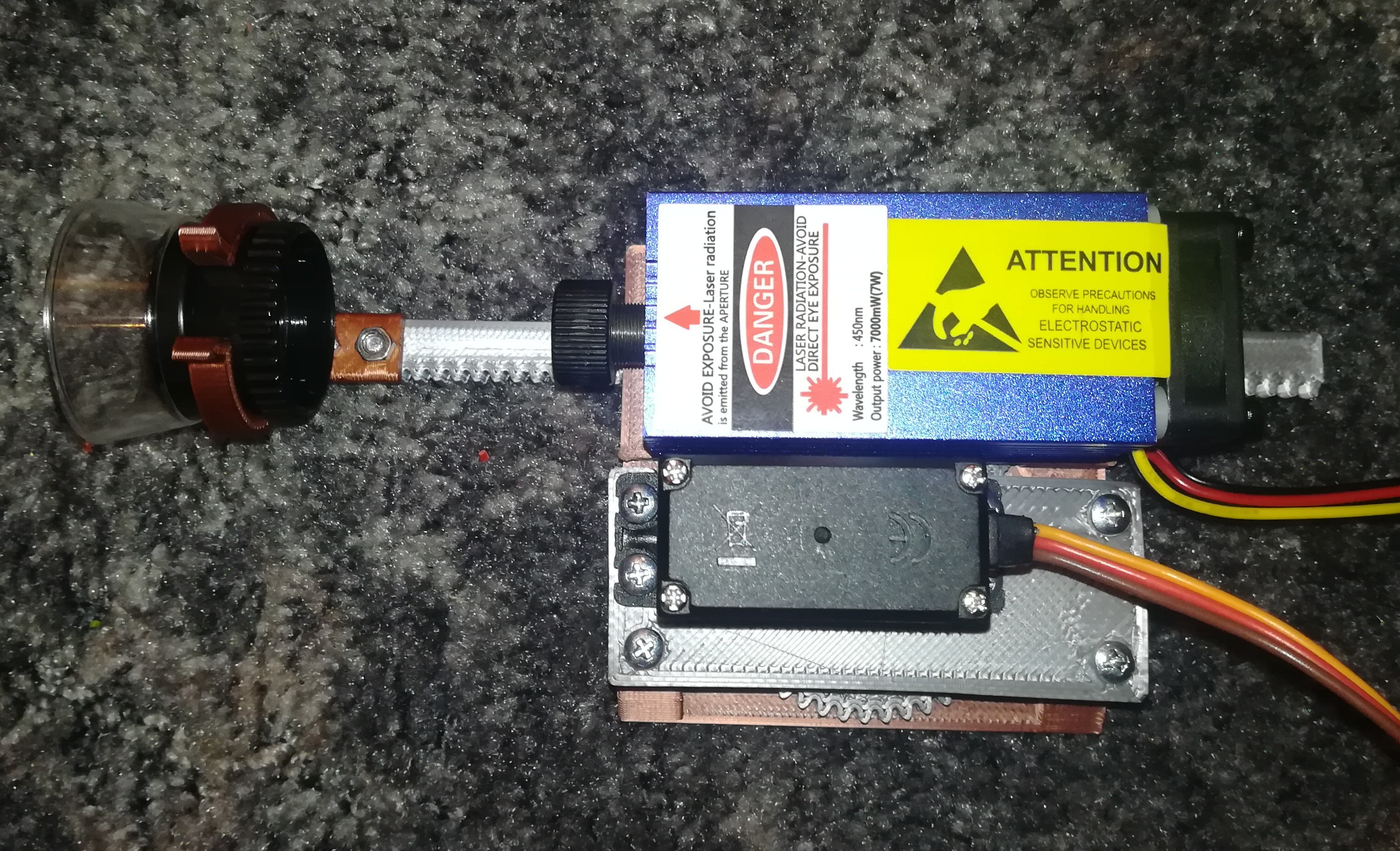

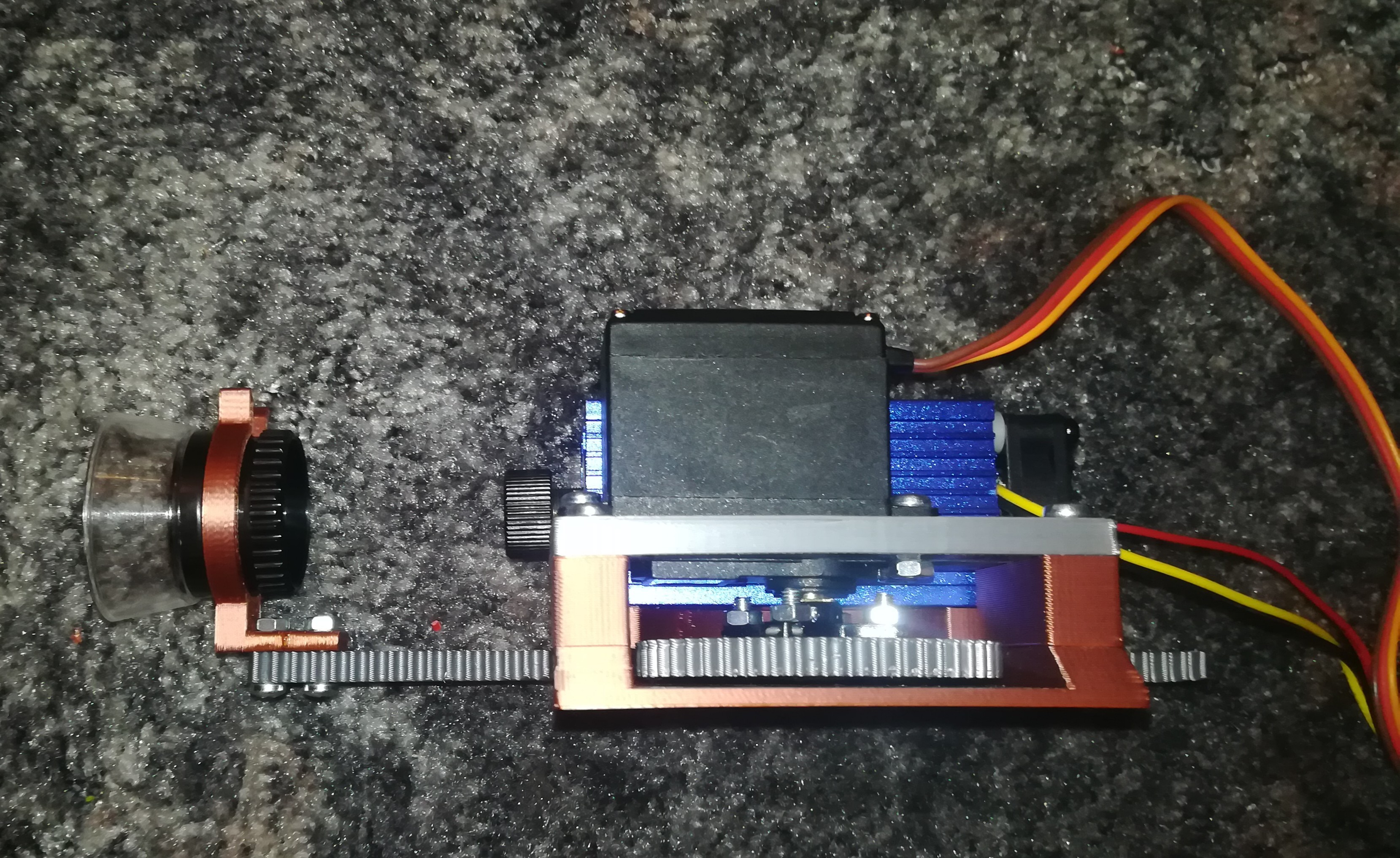

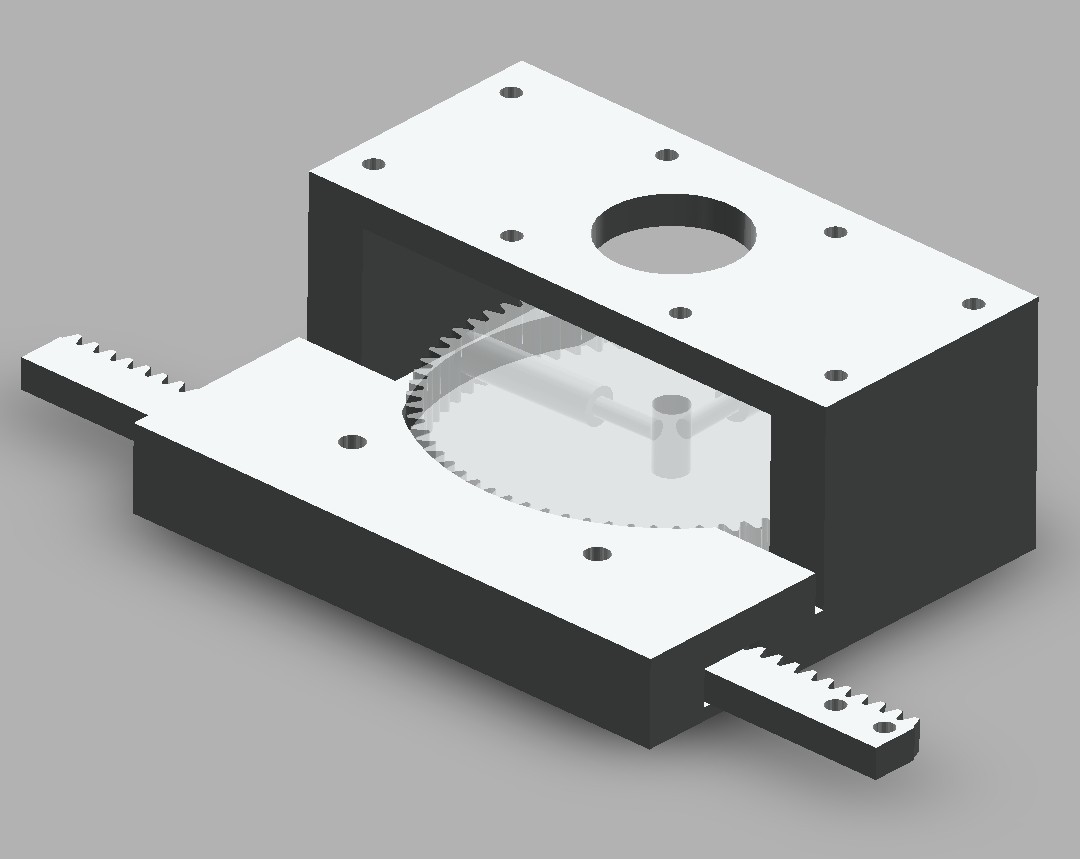

I spent the whole week designing, building and testing an autofocus unit.

This one has a MG966R servo motor which turned out to have a far too inaccurate positioning ability for an autofocus.

I also designed one for a NEMA 17 stepper motor, which I was about to build...

But I couldn't use my 3D printers at the time (because of noise and sleeping family members) and so I did some other testing.

I tested the prism cube with the 7W laser and was actually able to burn some wood with it. But through the cube almost the whole power of the laser gets wasted, so that the engraving speed has to be very low to work with it.

The second thing I've tested was how the distance from the workpiece to the galvo affects engraving.

I tested engraving at the farthest position and focused the laser as good as possible, but couldn't get any good results. The results were terrible and to get at least some burned lines the speed had to be very slow.

Next I tested a position closer to the galvos at which a max working area of 150*150mm was possible and the results were great even at 750mm/min.

That it just works by reducing the distance means not only that I wasted a whole week for building an autofocus, but it also means that the machine can be kept simple while working just fine at low distances.

I also added pins for RX and TX to the galvo converters, which should be for sending the autofocus their current position, but now they can be used for another task which would need a serial connection.

I will look further for a dichroic mirror to give the laser a red dot, but that will be the only upgrade (for now).

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.