After cutting stuff, I often see evidence of dust getting up to the top of the works...

...which I suppose indicates dust escaping entirely. For various reasons that wouldn't be great even I wasn't doing this inside the living space of my home.

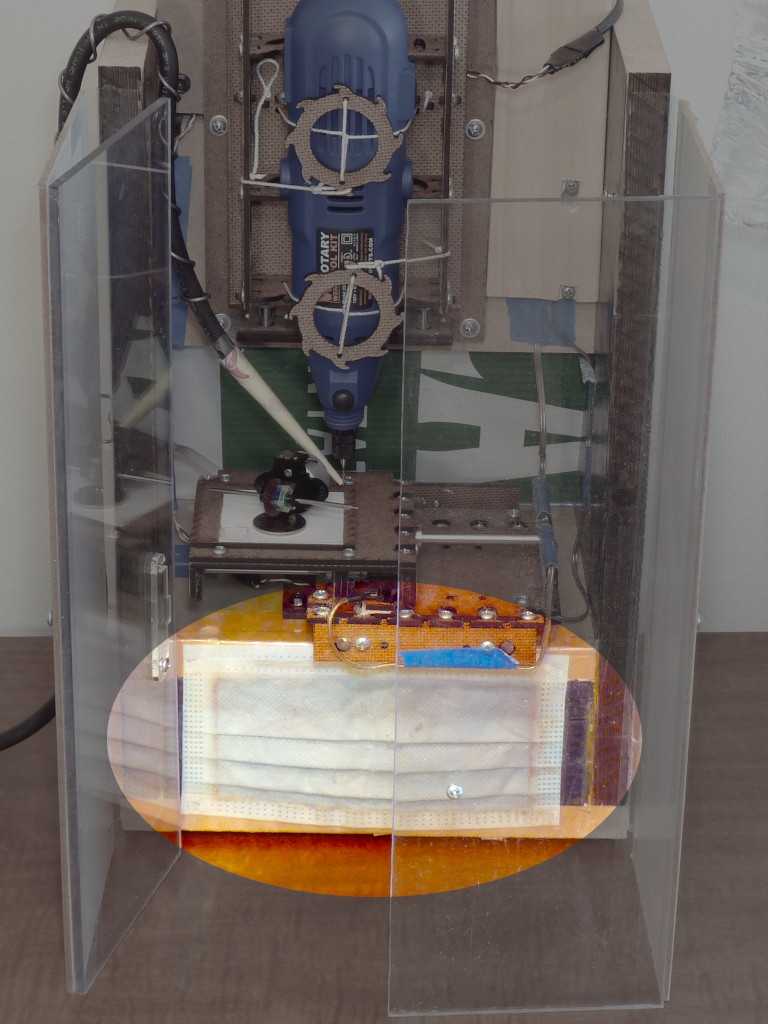

In the first semi-enclosed frame I knocked together, sucking air down into the enclosure and thru a filter worked well:

Sticking a vacuum hose into the same space would probably work too -- to the extent that a given vacuum's filtration works -- but I'm going with running a vac briefly to clean up vs. continuously while operating (and I can use a cordless hand vac).

Sticking a vacuum hose into the same space would probably work too -- to the extent that a given vacuum's filtration works -- but I'm going with running a vac briefly to clean up vs. continuously while operating (and I can use a cordless hand vac).

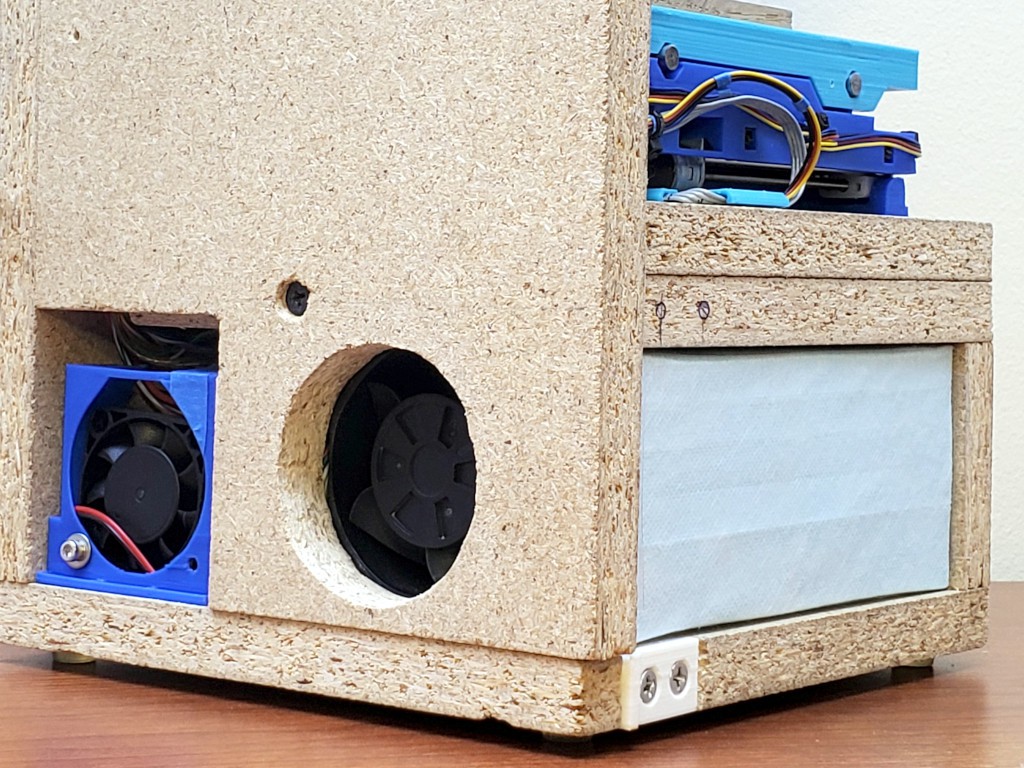

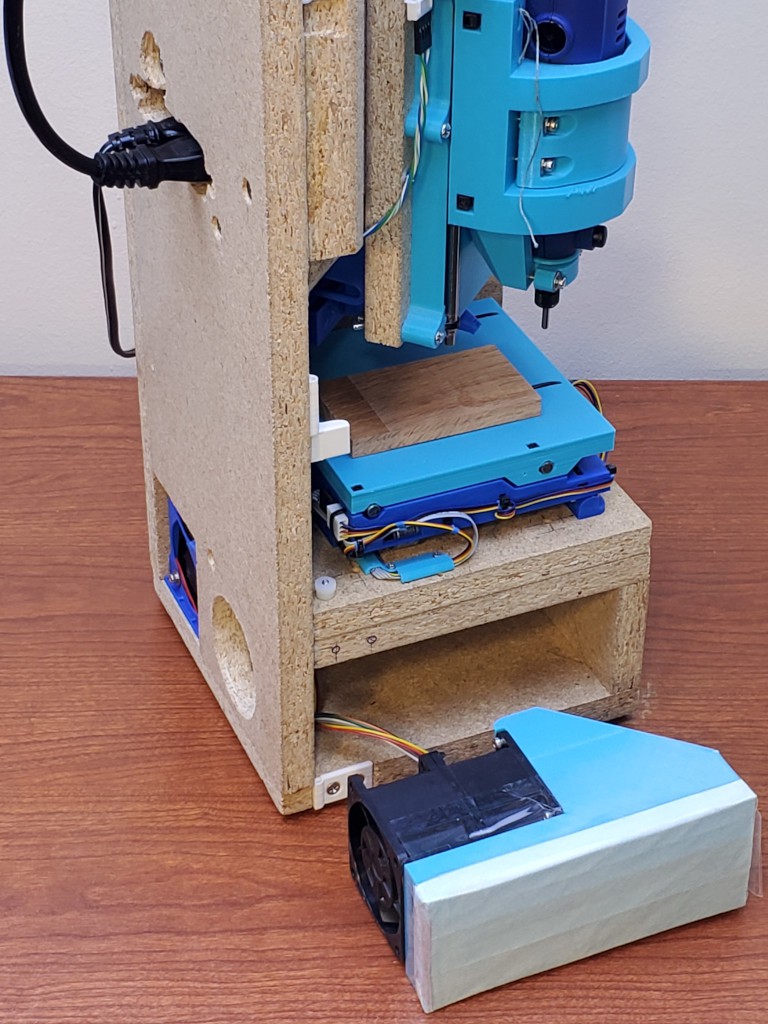

That was good then, then I bumbled into building a new box. The new (i.e. current Apr 2024) box includes space for fan+filter, the fan, and fan power switched by the "coolant" signal. But no filter or exhaust opening.

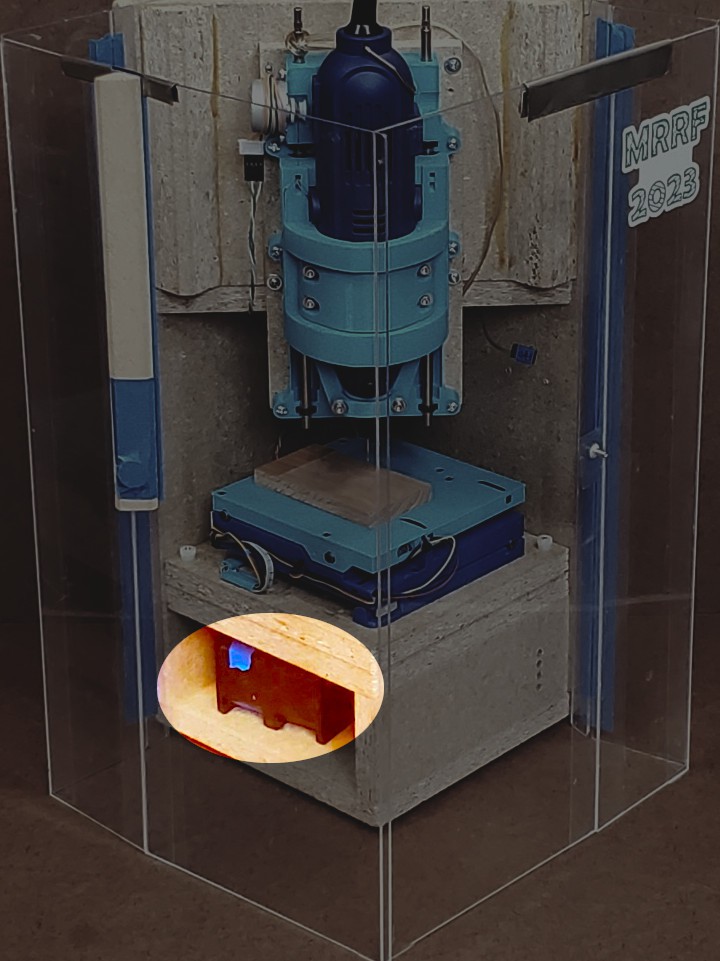

Lots of photos over the last ~year have shown this thing rattling around loose in that space:

... and sometimes in the accompanying text I've mumbled about that vent thing that's going to work great just as soon as I get it done.

Now at last ... it is done!

Only took most of a year.

The idea is to keep dust from floating up out of the enclosure, or filtering out through various gaps, by sucking a sufficient flow of air in, mostly down through the open top.

I could just stick a vacuum hose through the back of the box. But that wouldn't advance the all-in-one idea of this project.

Some of the meanest stuff to spread around would be fine wood dust <citation needed>. Appropriately rated surgical masks <US rating - where did I note that already?> which purportedly can catch >98% of the mean stuff have become much more readily accessible post pandemic. And the planar filters occupy ~no volume. That's great. But they're not very free-flowing, and I want to pull lots of air through one. That's less great. Qualitatively, I figured pulling much air through one of those would require pulling much pressure drop behind the filter i.e. pushing much pressure gain across the fan. At a useful flow rate. That means a) power and b) coupling power to air with suitable pressure/flow characteristics.

A mean fan

After proving the function of the idea with a pair of mean fans that very much did not fit inside the box, a search for sufficient meanness in a sufficiently small package lead to discovery of "6076"-type integrated counter-rotating fan pairs. While often packaged as quite costly "server" fans (originally developed as such?), they can be had for less from less institutional sources. The one I got is a 12V 3A unit, which seems typical for the type. It does the job. It is not quiet. Random sellers sometimes advertise them as "violent". In free air it's kind of like a ̶l̶i̶g̶h̶t̶airsaber: projecting a tight forceful beam that stays tight and forceful for about a sabre-length. Fun. But I digress.

(further digression: The search for a small mean fan started with the idea of looking for a fan with a stator. That lead to learning about high shear mixing and why those little stick blenders aren't necessarily a joke.)

The 60mm dimension of a 6076 fan conveniently fit in the first enclosure, which was a happy accident. Less accidental in the current enclosure.

Nevermind the janky blue thing on the left -- that's the Grbl sled (controller, stepper drivers, Bluetooth, buttons & blinkenlights, &c.) and it needs a do-over.

I probably could have comparison shopped all the hardware stores for a hole saw, gone back for the winner, got home, and made a hole in the time I burned making the hole for the fan exhaust.

This fan is by far the largest DC load in the box, so it drives power supply selection. It's switched by the "coolant" signal.

The next evolution I have in mind is to make some mechanical filter grip to make changing filters easier. And to make that grip thing hold pleats for more surface area.

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.