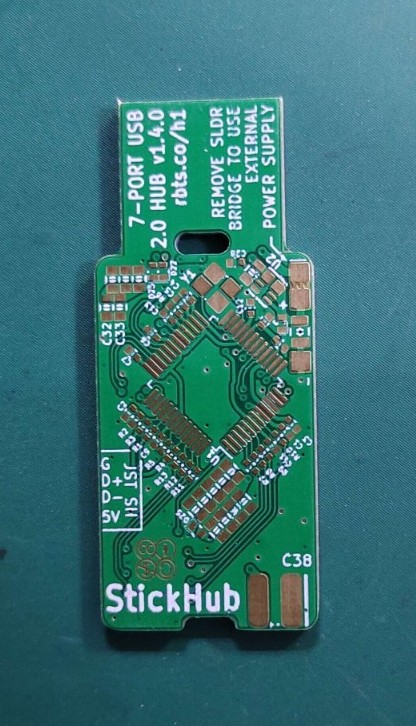

Features & Specifications

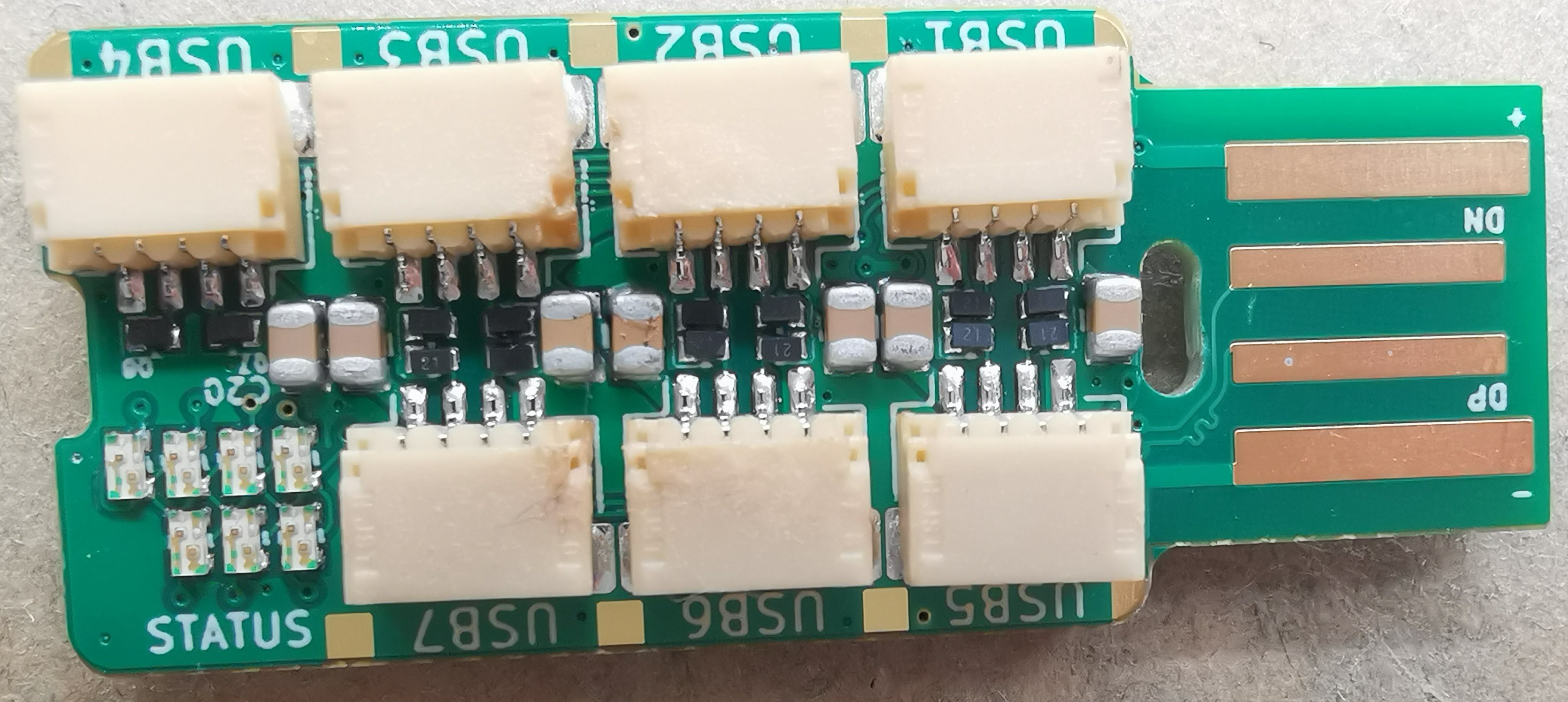

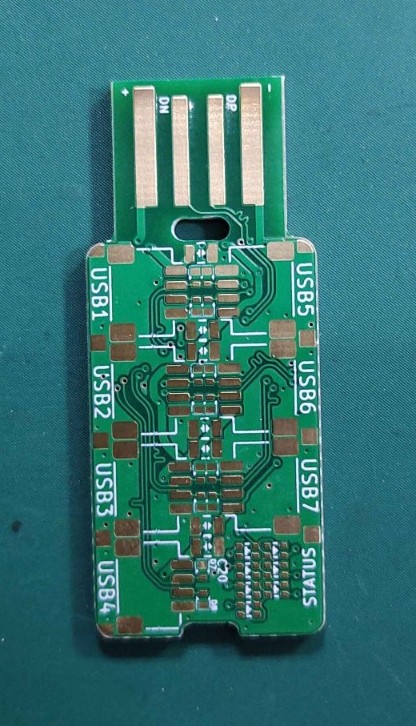

- One upstream port (plug) communicating at HS (480Mbit/s) or FS (12Mbit/s)7 downstream ports with 'Multiple transaction translators (MTT)' for HS, FS or LS (1Mbit/s) speed per device.

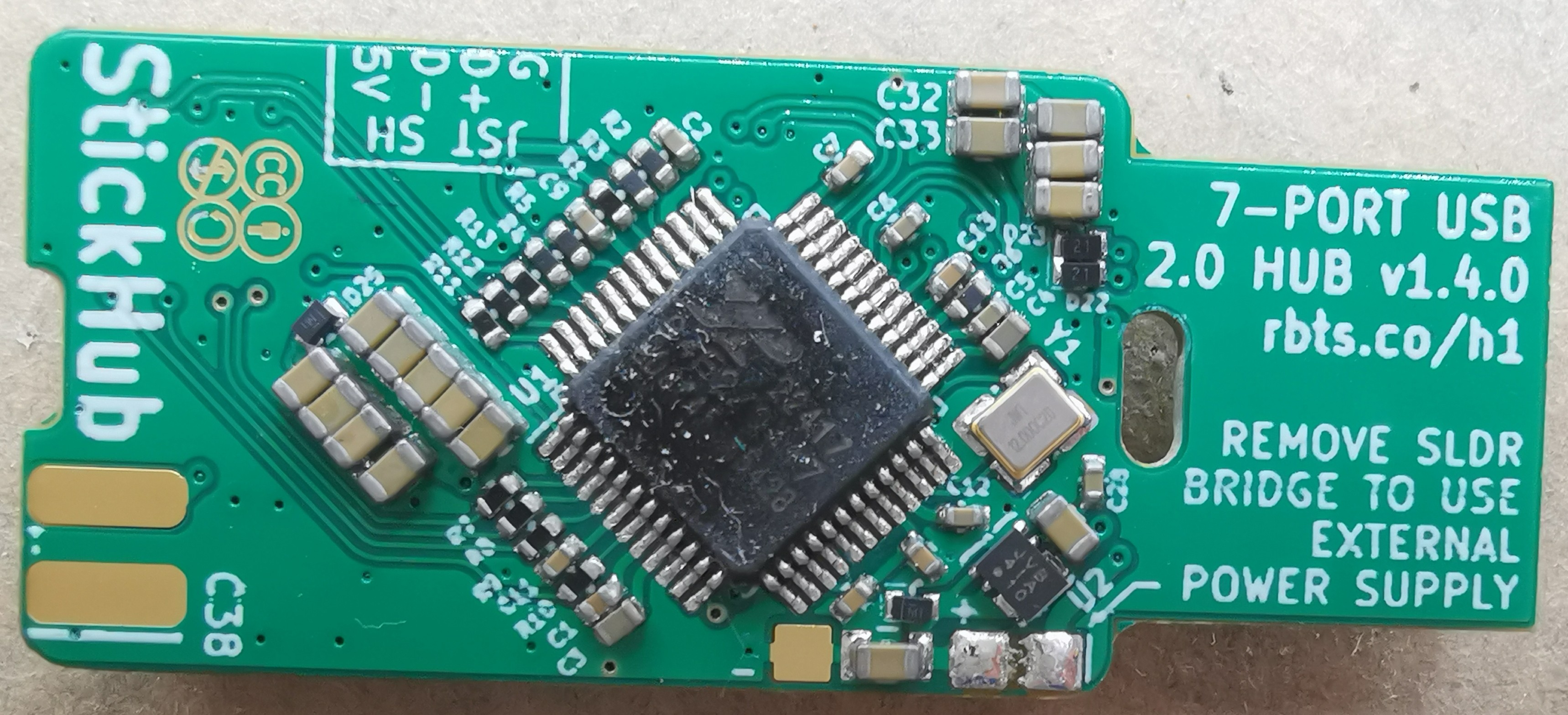

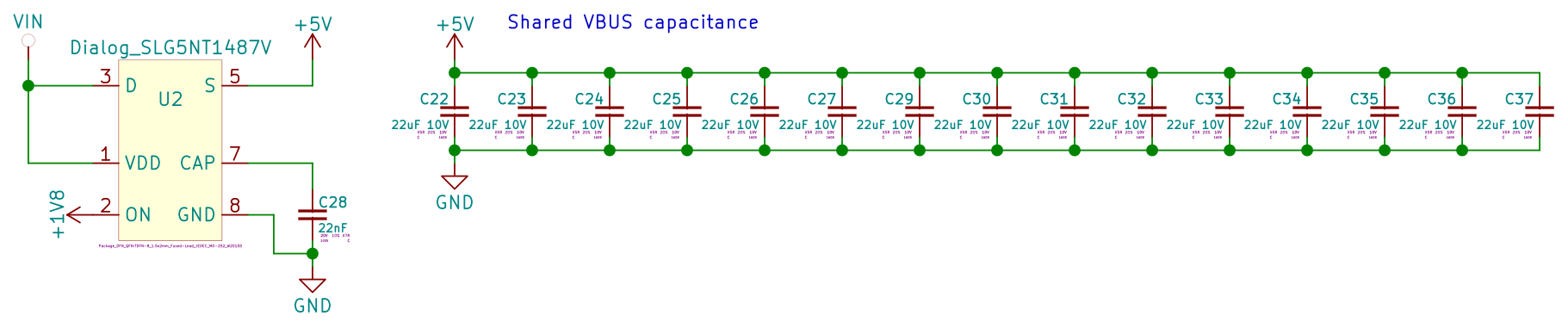

- Full ESD protection: A TVS per data line, a TVS for Vin, a TVS for +5V, and a 2012 capacitor per power line

- Short circuit protection: The Dialog IC will prevent short circuits from doing damage, switching faster than a polyfuse.

- Inrush management: The Dialog IC also prevents the downstream port capacitors from overloading the host when powering up the board

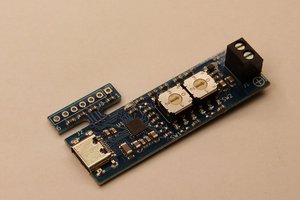

- A status LED for each downstream port

- JST SH 1.0mm connectors for the downstream ports

- Solder pads for using an external 5V power supply

- Solder pads to increase downstream capacitance

- A slot and groove for retention or housings

- 16.5mm wide, 40mm long (31mm inserted), and 6.5mm thick

- Very low power consumption: 0.6mA suspend - 167mA with 7 HS devices

- Open hardware: Schematics and design files included

Hub IC datasheet: https://www.maxlinear.com/ds/xr22417.pdf

Background

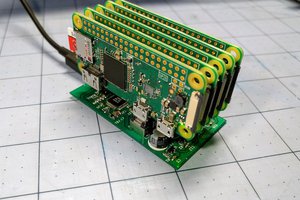

More and more modules used in robotics, machinery and product prototyping have native USB capabilities. Often of the USB 2.0 FS kind, as most MCUs won't need extra hardware for signalling. Your average dev board supports up to 4 USB devices, plug in some cameras and you'll have no other option than to use a hub for those Arduino, Teensy, STM32 or similar modules. Or a GPS. Or any fancy motor controllers... You get the point.

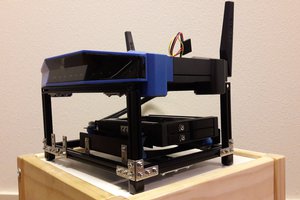

Thus came the idea to create a hub that would be a great addition to any robotics toolbox. It would need to be very small to fit drones or small service robots. ESD protection to allow some rough handling would also be great. Being a 'known quantity' / open design as final goal.

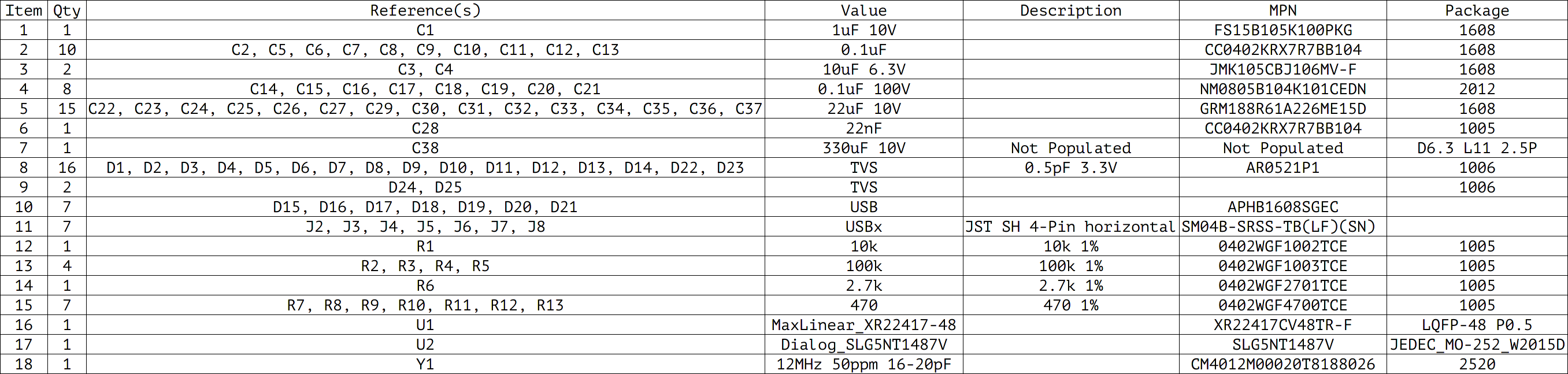

Parts used

Above parts are currently all in stock in Mouser and LCSC.

rbtsco

rbtsco

Patrick

Patrick

MagicWolfi

MagicWolfi

ajlitt

ajlitt

Stanislas Bertrand

Stanislas Bertrand

rbtsco: Greetings from Argentina. I came across your project on StickHub - The Space Friendly 7-Port USB 2 Hub, my query is the following, can this same project be done, but instead of being 2.0 it can be done as 3.0? It is to make this same design but for data transfer.