Generally I have one project log per plane, indexed here for easy reference. As I'm often working on multiple at a time, the log dates may be out of order. (I use draft mode as I work, and publish when "done")

Background/Reference

- My background, interests

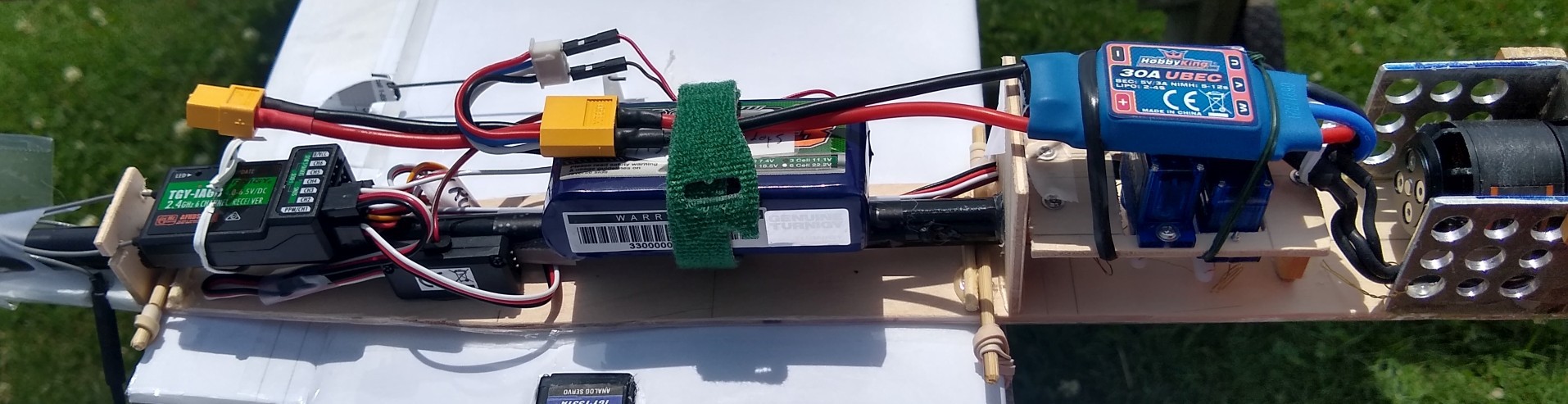

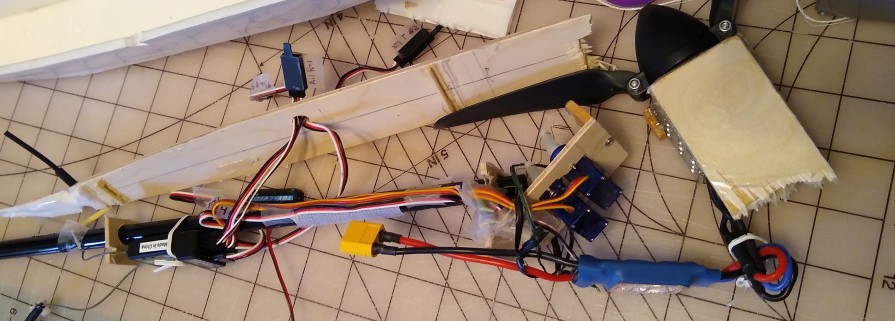

- Gear

- Techniques

- Hot wire foam cutter

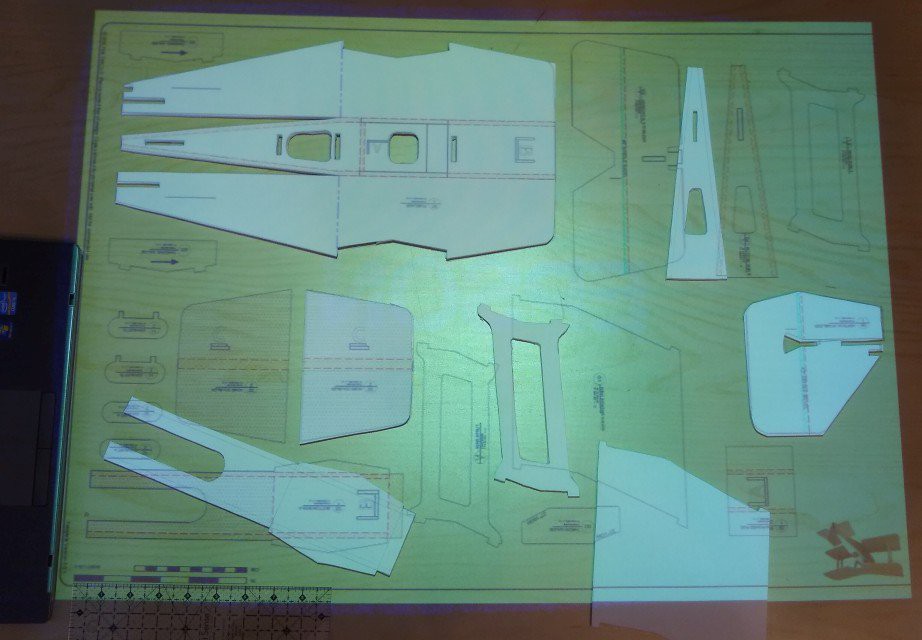

- Pattern/Plan Projector

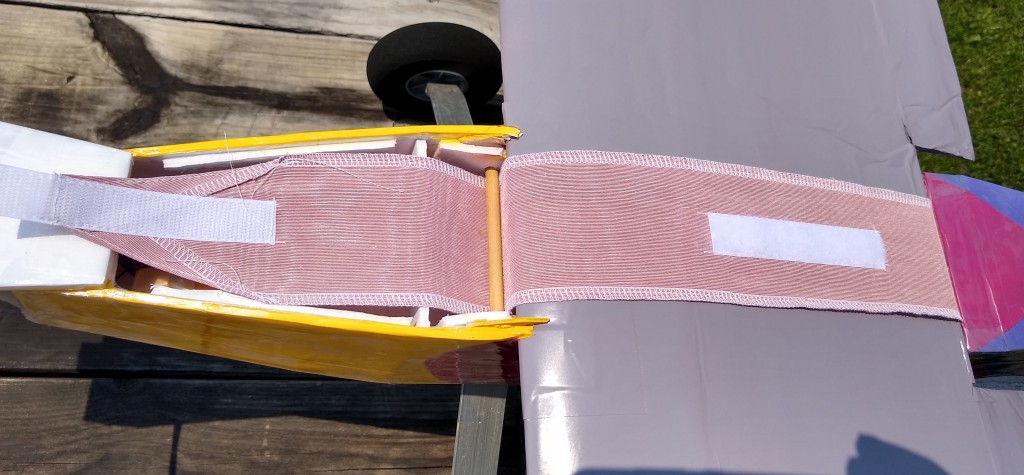

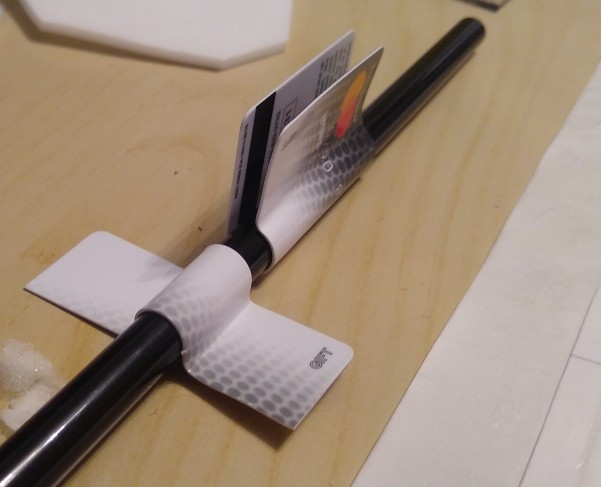

- Simple Wing Strap

- Wrap storage for piano wire and tubes

- Radiomaster TX16s to Flysky trainer cable (coming soon)

Planes

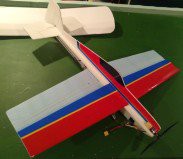

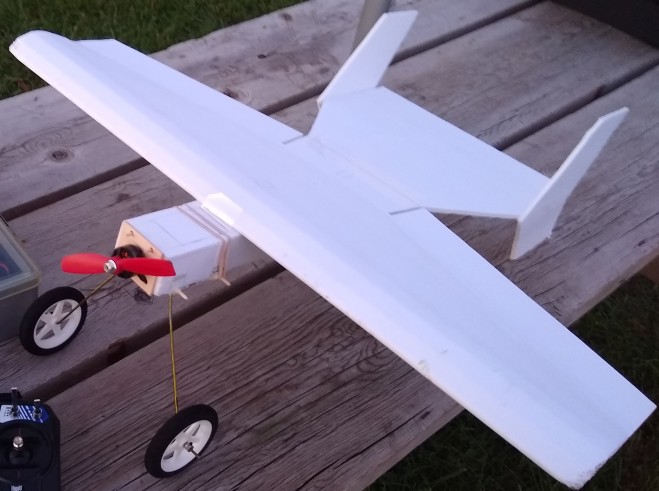

| Sapphire/Ruby (Flitetest Simple Cub) |  |

| Pearl (Flitetest Simple Soarer) |  |

| Connie (Flitetest Sparrow) |  |

| Lapis ( Flitetest Bloody Wonder) |  |

| Garnet (Flitetest Mighty Mini SE-5) | (Construction paused) |

| Rose (Flitetest Stortch) (Flight video included) |  |

| Sadie (Custom 3-D) |  |

| Opal (Full custom performance/glider) |  |

| Kiki (Graupner glider) Custom transport case (coming soon) |  |

| Rainbow Quartz (Custom Ultrastik) (coming soon) | |

| Nephrite (Custom DLG) (In construction) | |

| Peridot (Flitetest simple scout) (coming soon) | |

| Lion (Full custom high speed sport) (In planning) |

Quinn

Quinn

Will F.

Will F.

zakqwy

zakqwy