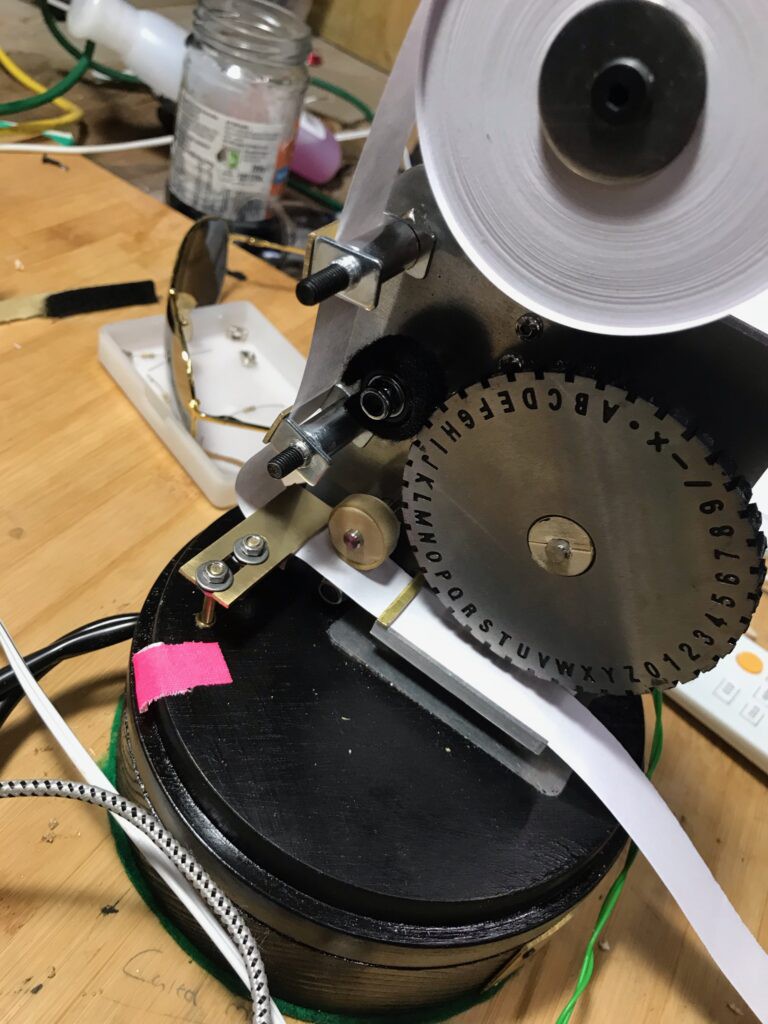

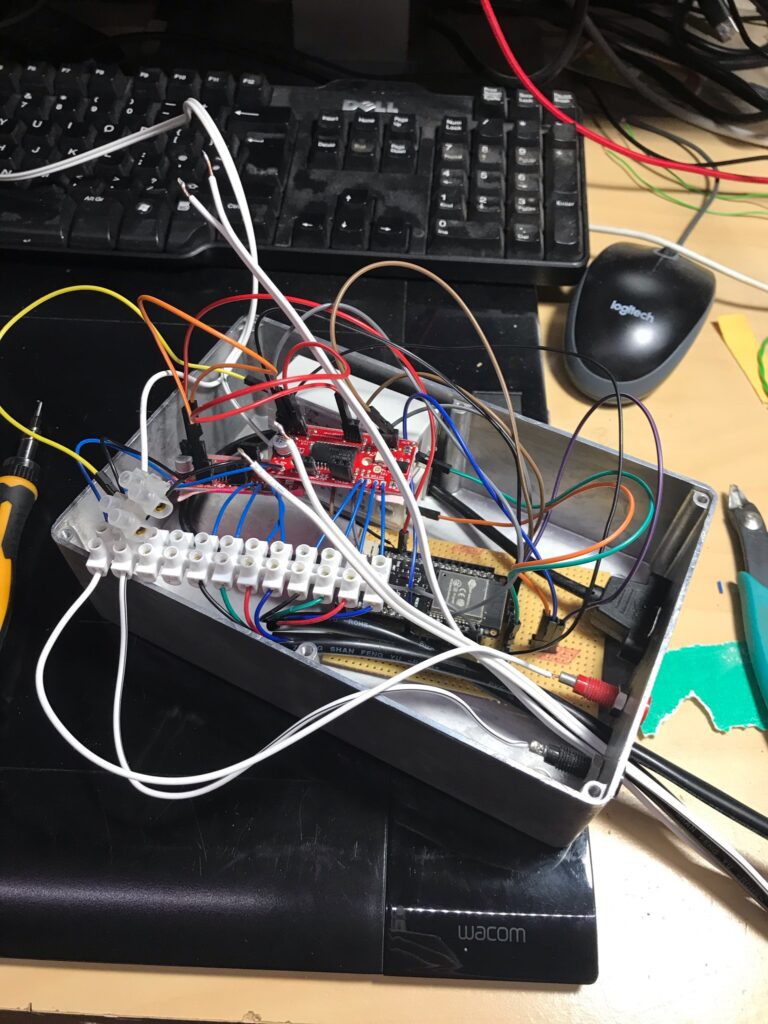

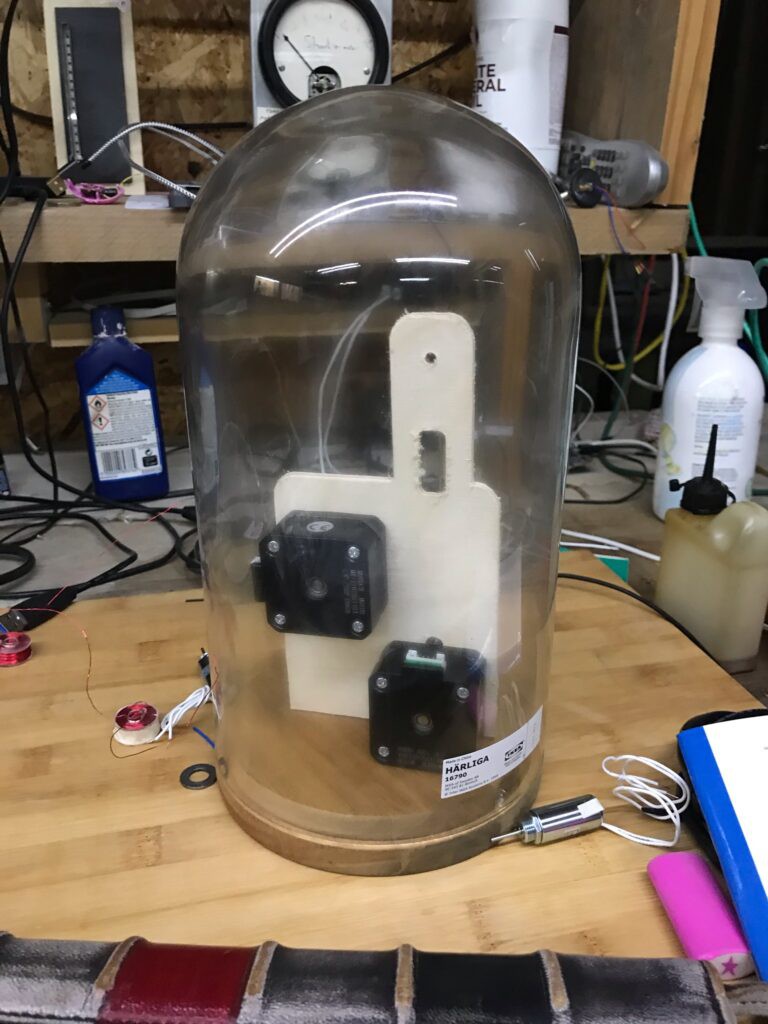

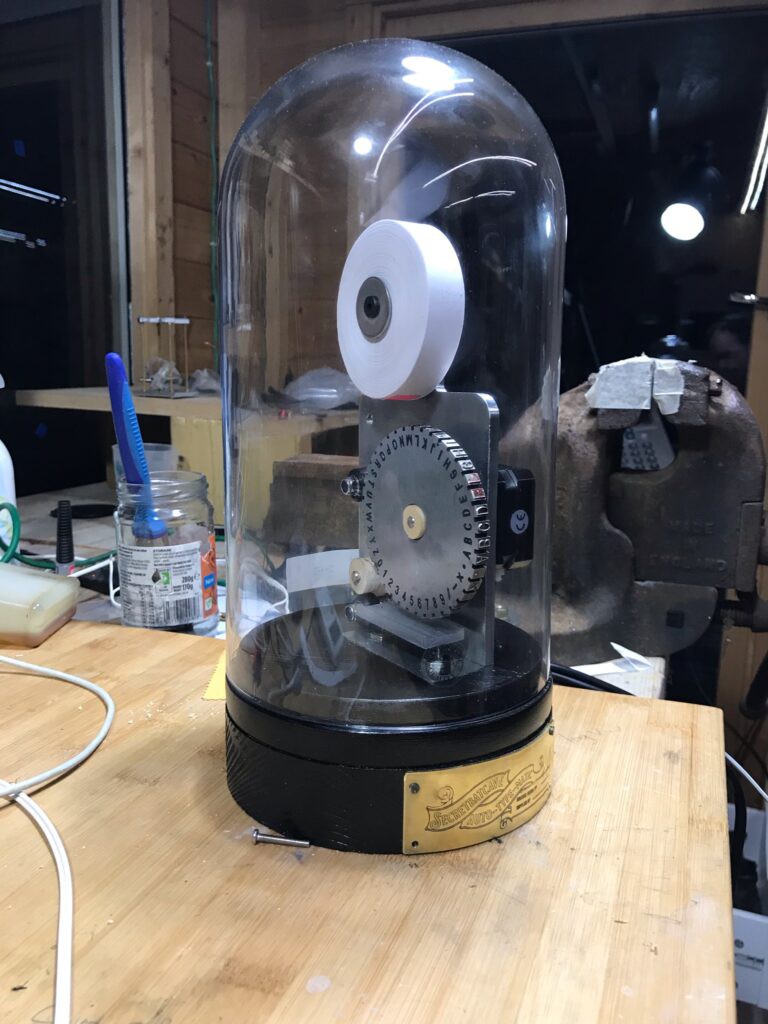

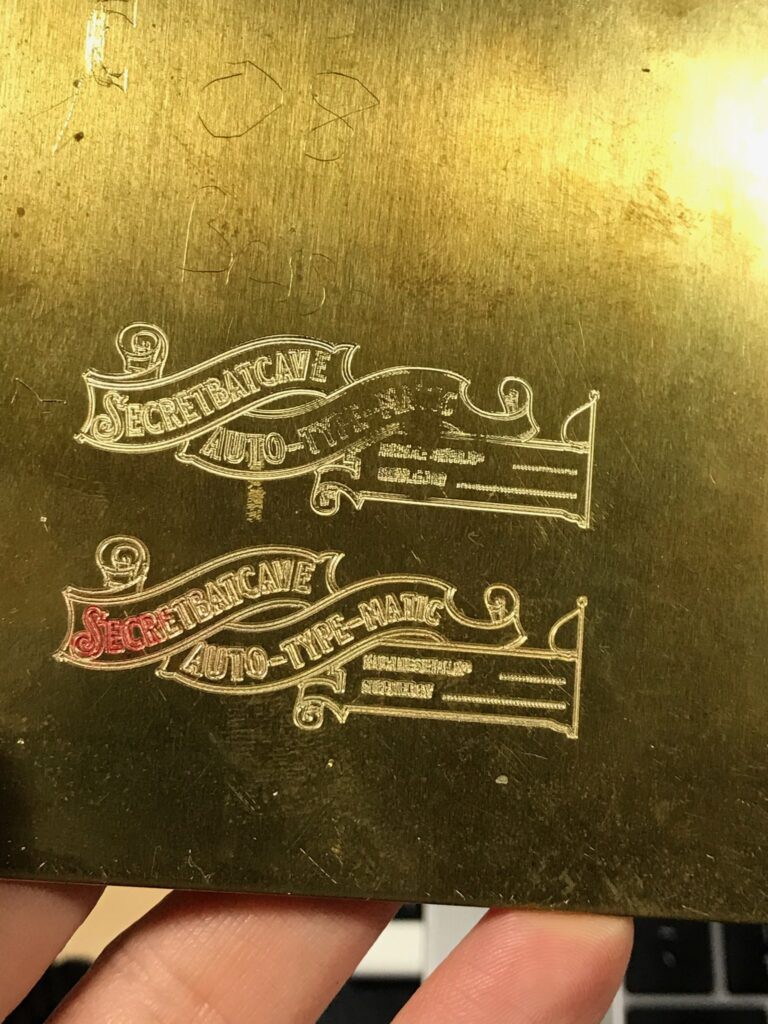

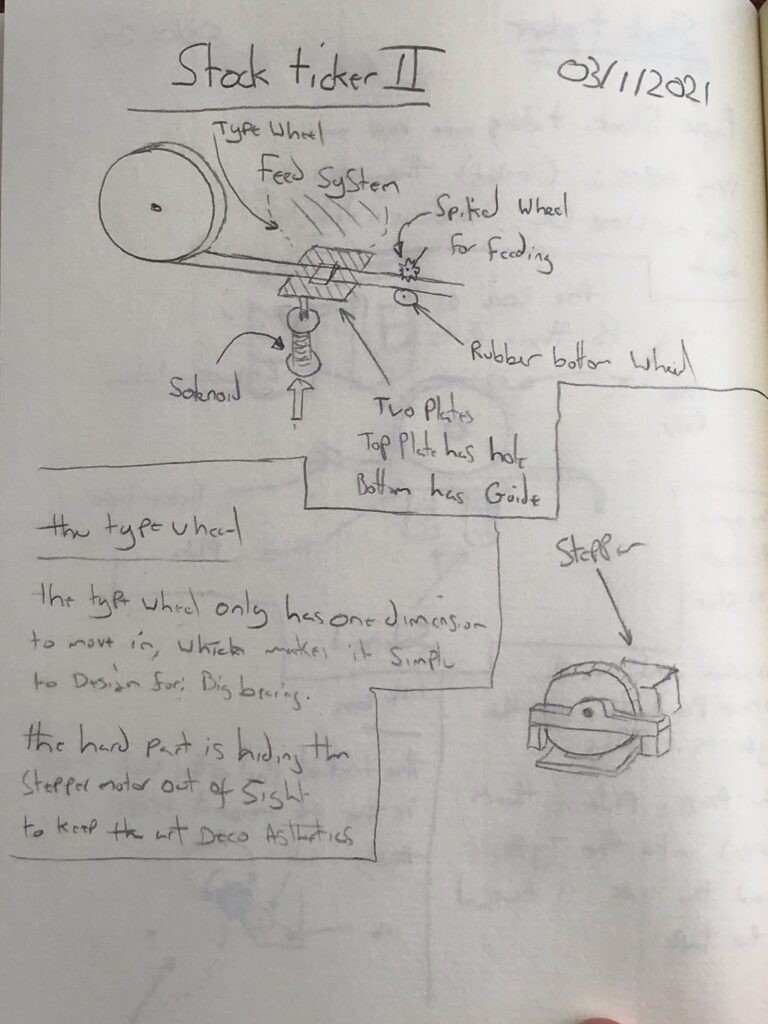

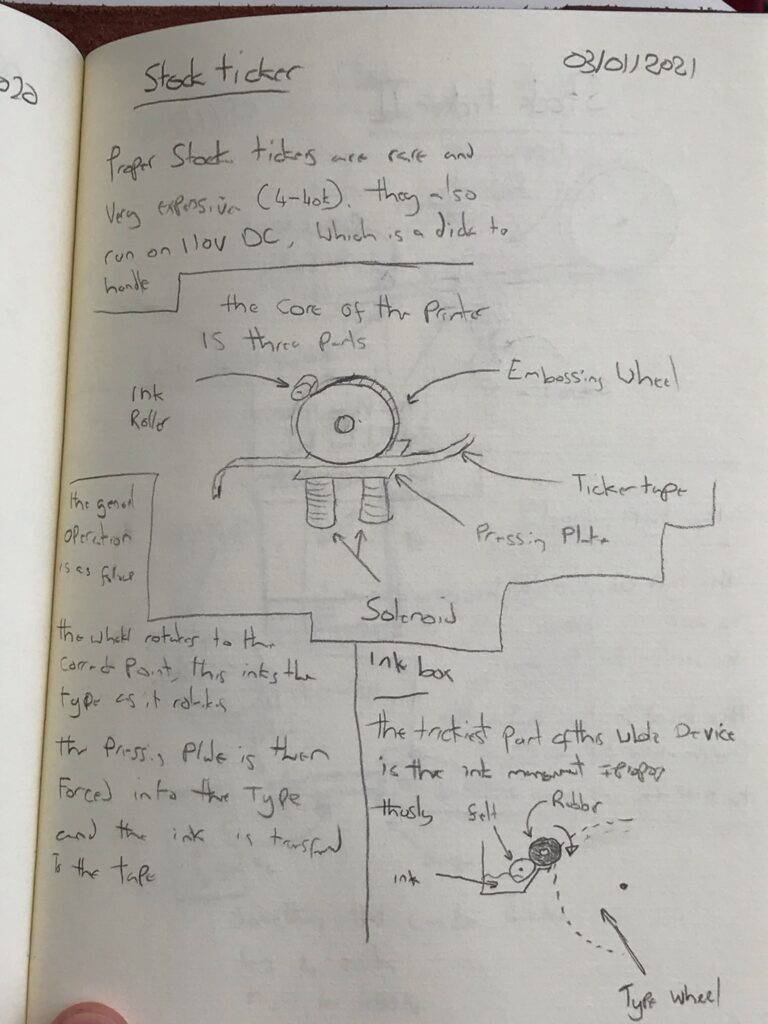

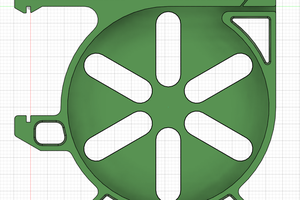

This project was a passion project. I really wanted to craft something that could look 1890s-1930s without looking steam punk. I also wanted it to be vague functional

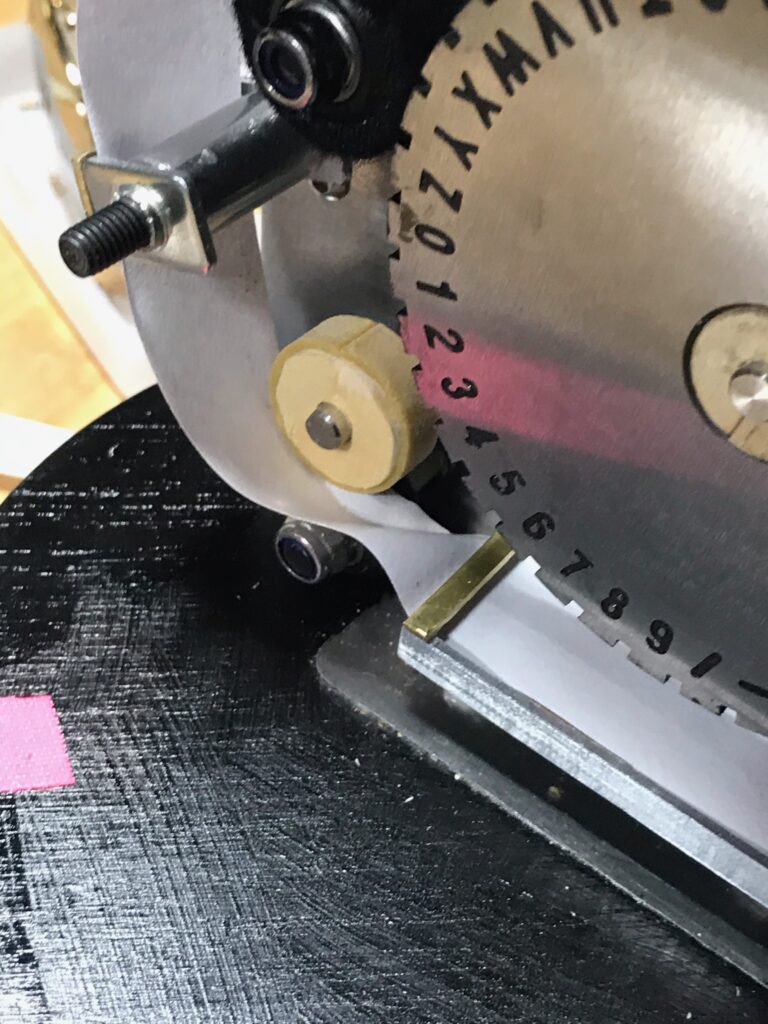

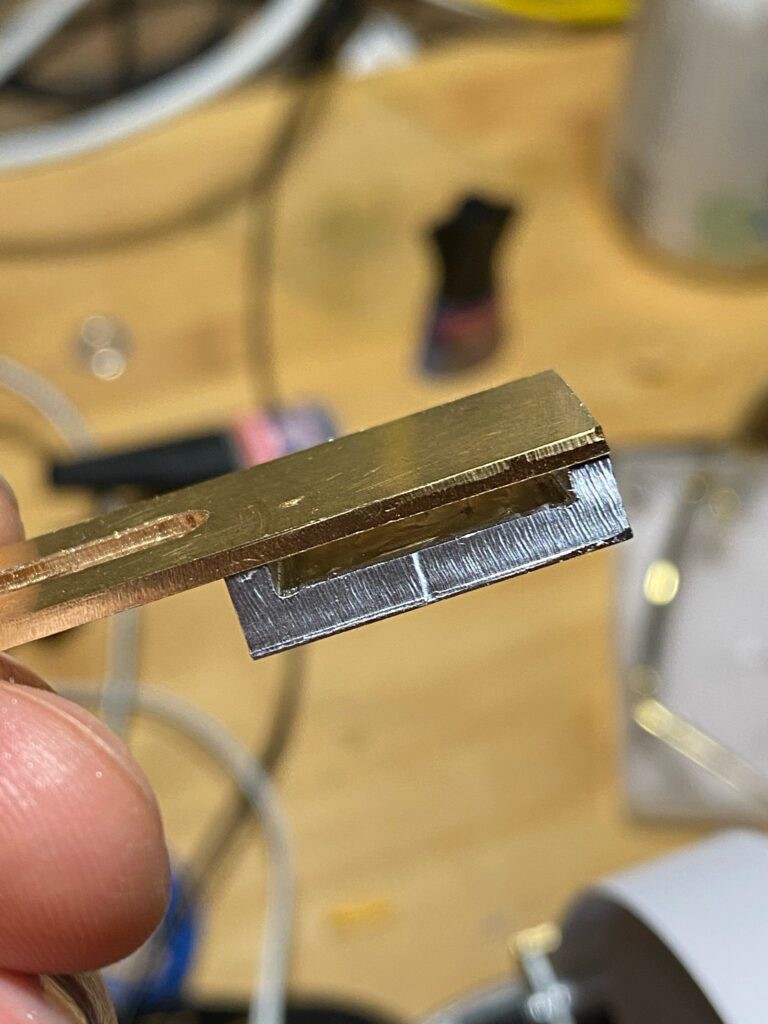

I wanted something that looks like the ticker machine in the simpsons, but was able to be a bit more functional. Here is the (mostly) finished printer in action:

secretbatcave

secretbatcave

dbtayl

dbtayl

Douglas Miller

Douglas Miller

Matthew Reeves

Matthew Reeves

The Stock Average calculator calculates the average value of the stock when you repeatedly buy the same stock. A stock calculator provides a way to create the cost basis for all the stock. This is very important to understand and calculate the average value you pay for the shares of the stock and see eye to eye. This will help you to analyze that you are getting the accurate opportunity cost for purchasing the stock at its recent price; you can say that again. https://stockaveragecalculator.org/averaging-in-the-stock-market/