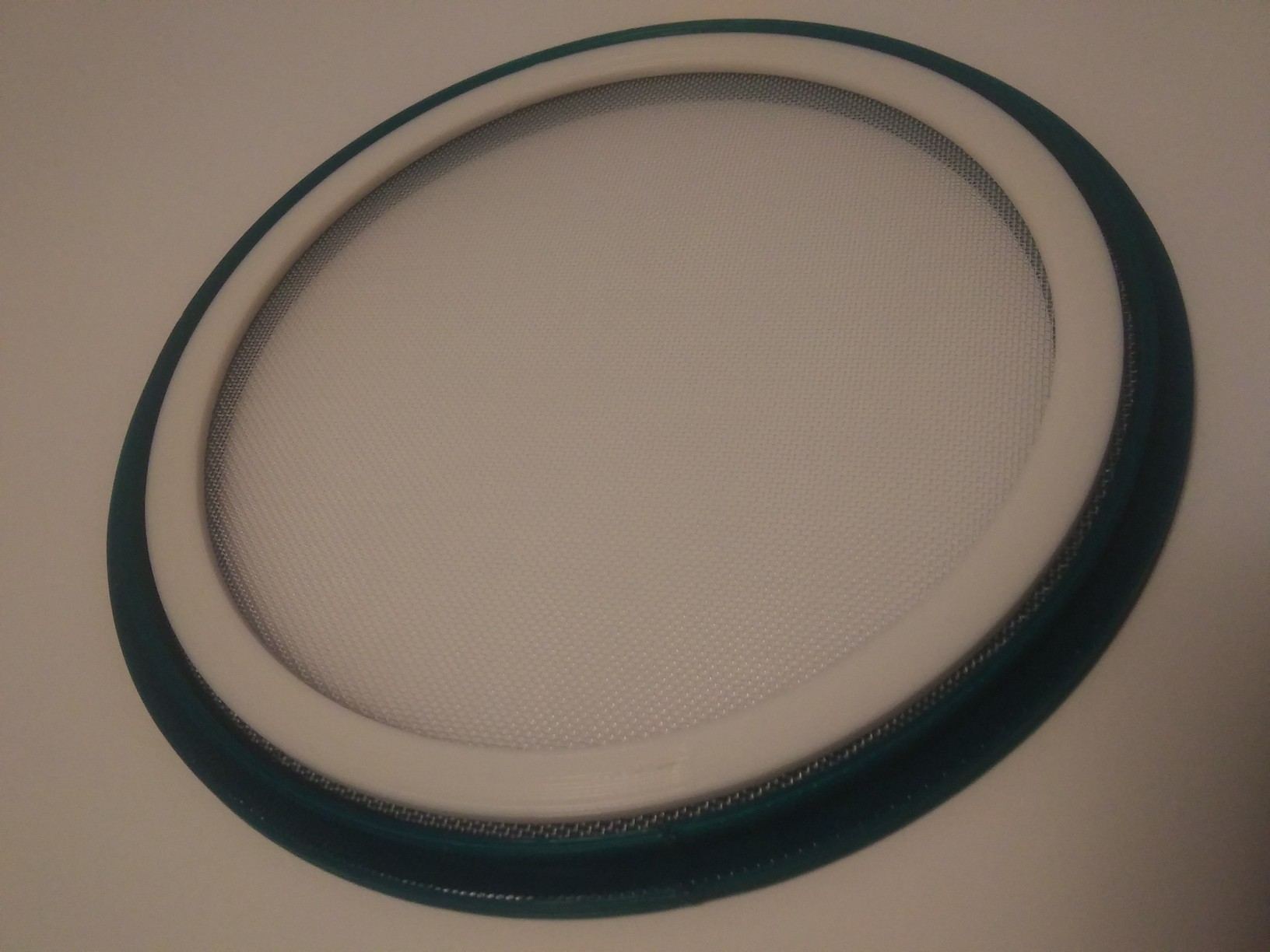

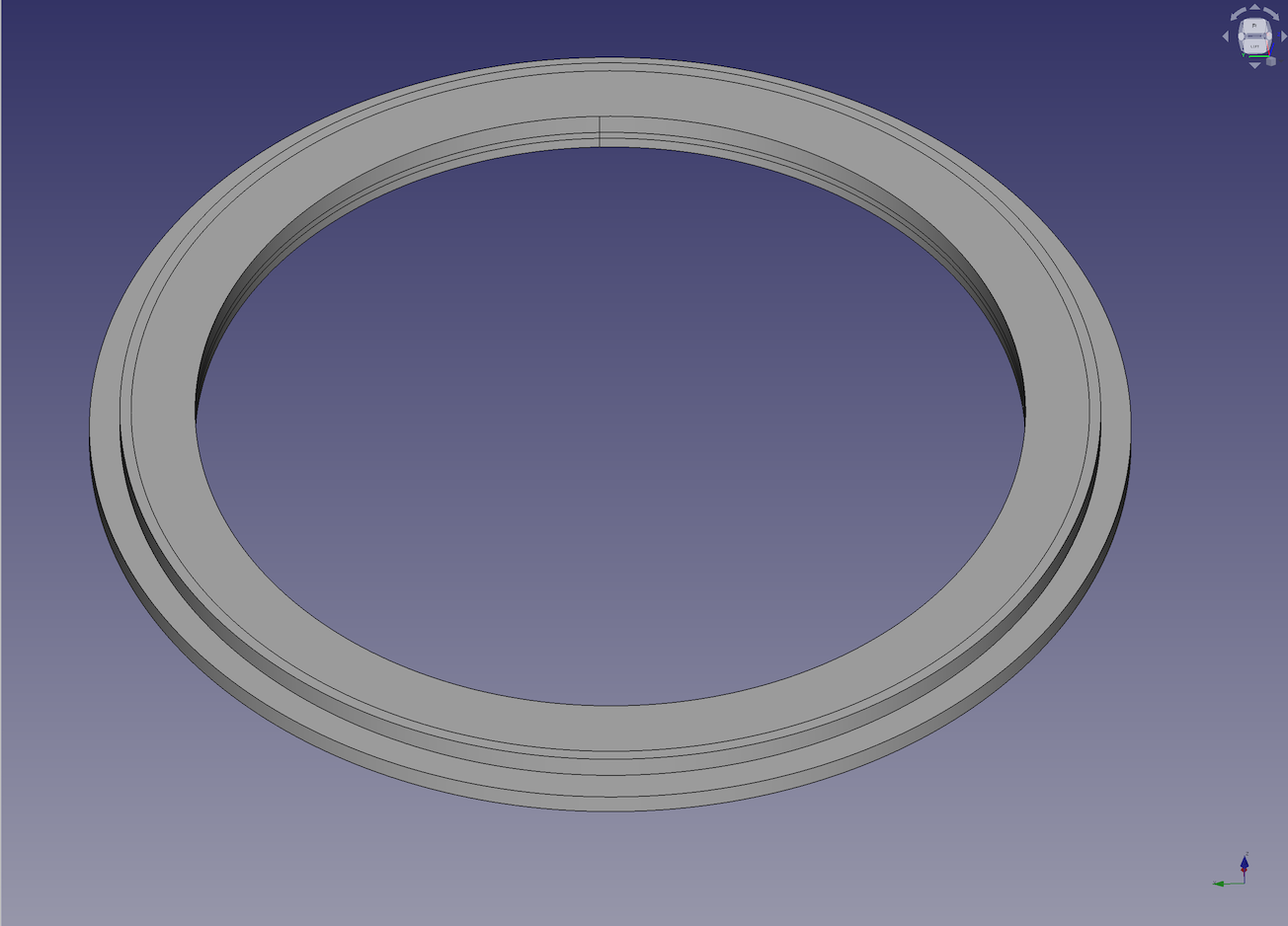

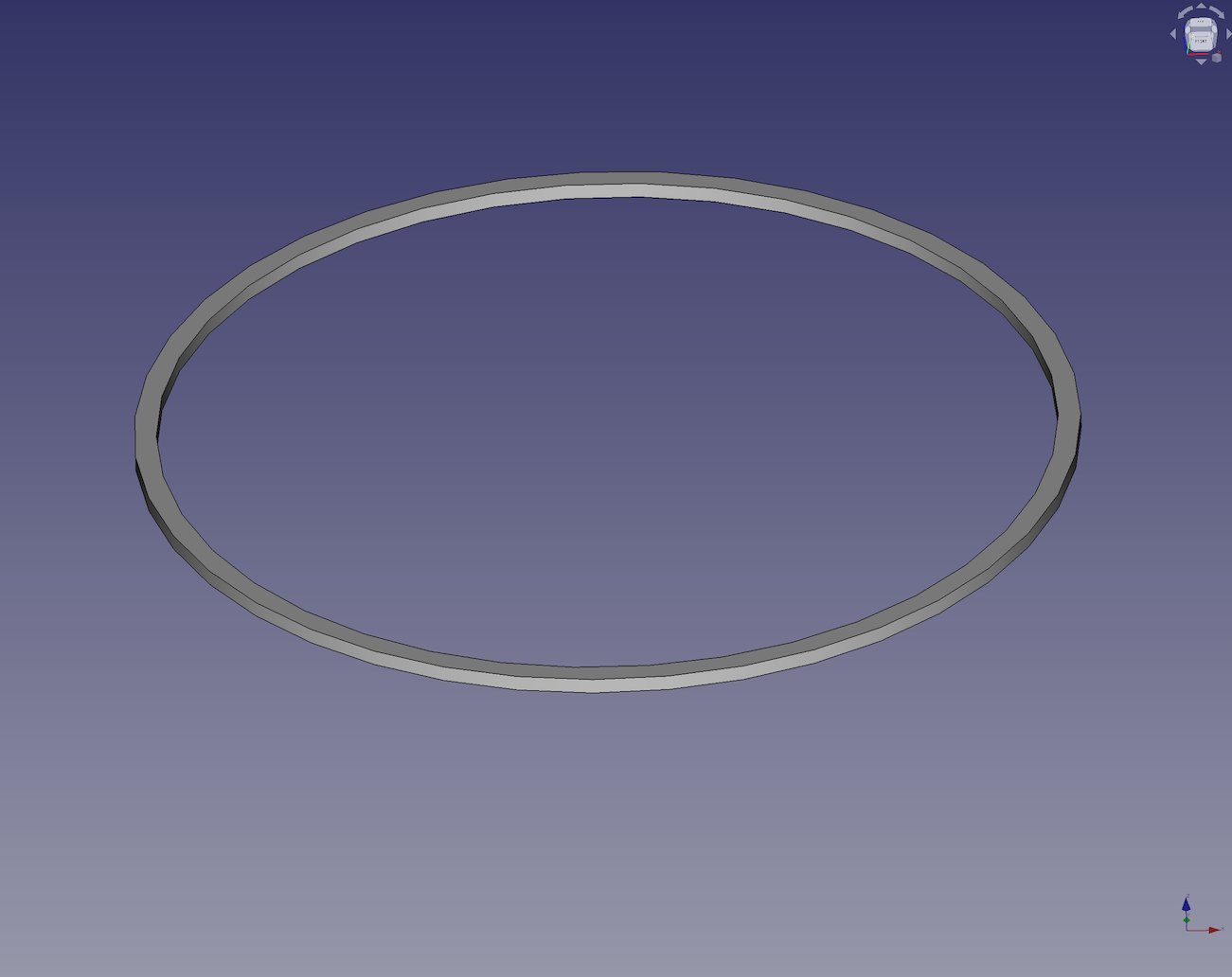

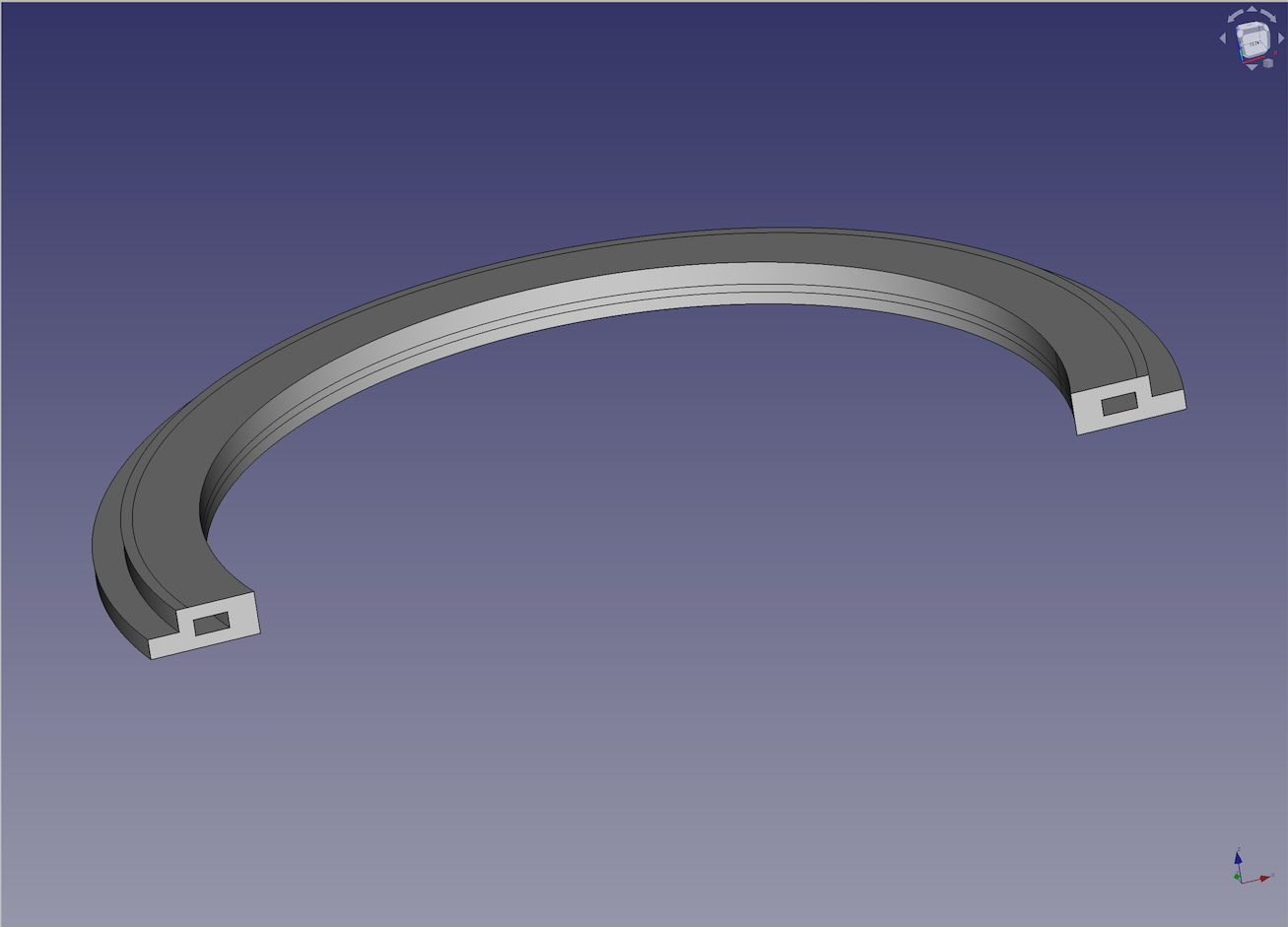

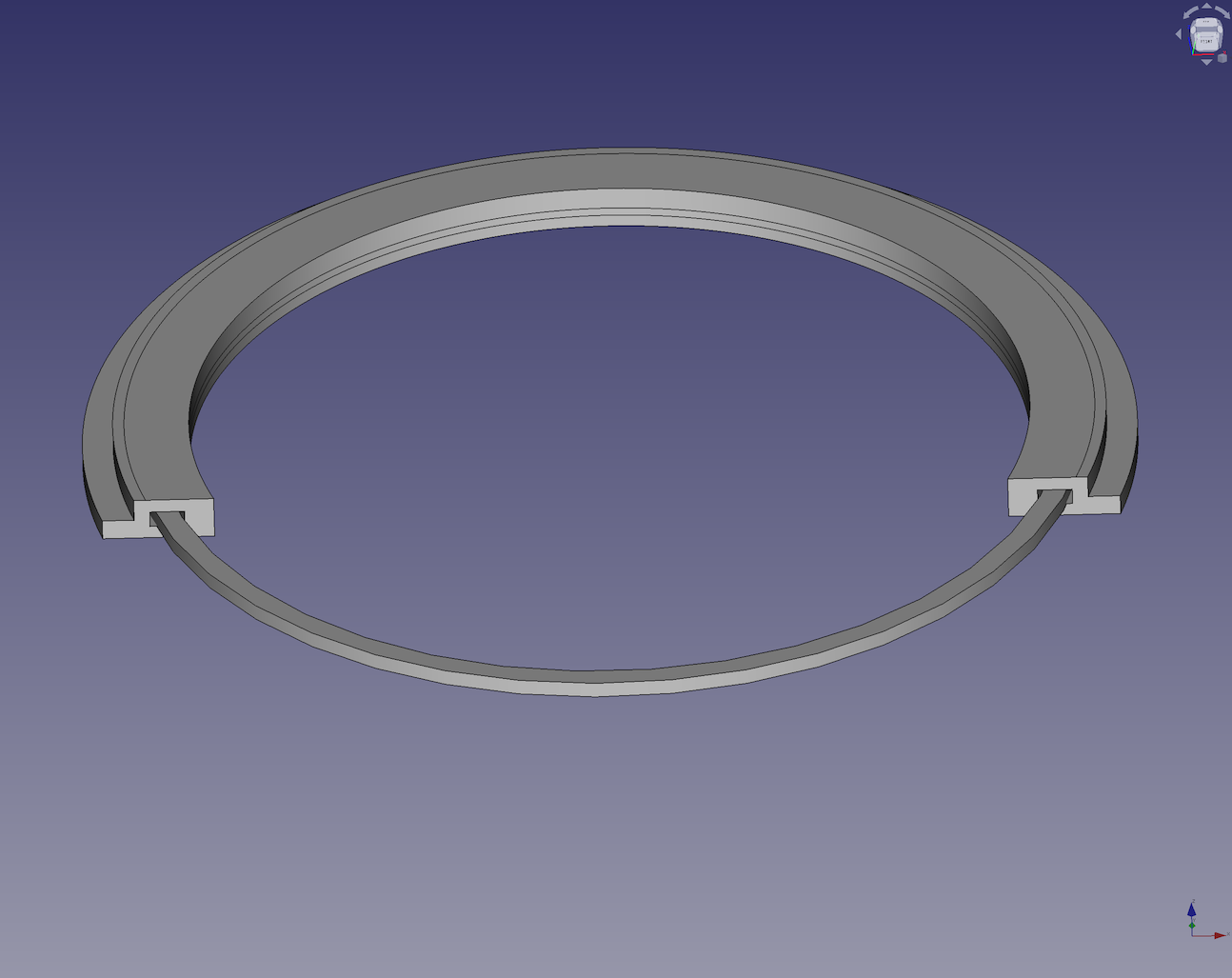

In order to produce a new product that I'll be getting out soon, I needed to have a fine mesh attached somehow to the 3D print, with the idea that the mesh will allow easy fluid flow, but retain certain size particles.

In this project, I'll show you how I was able to print a part that functions as if it was injection molded.

Zoé

Zoé

What i did for prints like this is to program a pause at the location where i wanted to have the mesh. Placed the mesh on the print and pushed it in the print with a soldering iron. This way the mesh is embedded in the previous layer flush and you also have the possibility to adjust the tension of the mesh while pushing it in with the iron. Then resume the print. The mesh wont move or cause problems on the following layer.