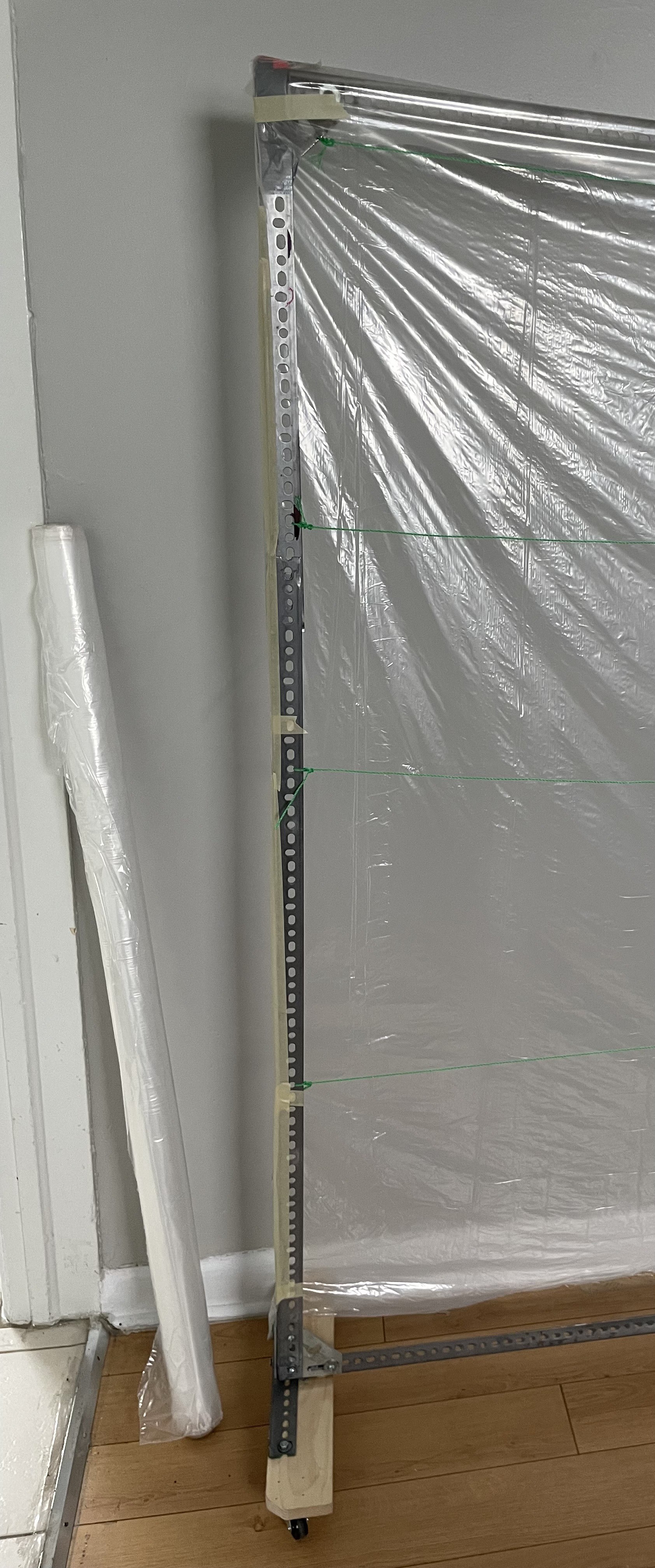

To make the 6’ verticals, a 2’ segment was bolted to a 4’ segment with two bolts, with a hand-width of overlap.

The pine board was cut in half to provide two wheel carriages each 18” long, and the outer corners of each were cut off and filed.

The laptop sits on its own small table, also on casters, that was purchased at a used office furniture store. A folding metal chair purchased at Value Village (a thrift store) with a generous stack of cushions on it completes the studio. The cushions are held down with a bungee cord. To let in plenty of light, the east and west windows are covered only in faux-rice-paper vinyl films, which also filter out ultraviolet. (See background photo.) By the way, faux rice paper film also makes a great surface layer for a DIY mouse pad (matte side up), with which this aside is being written.

During the final tightening of the bolts, I fine-tuned the structure to get everything nice and right-angled. During this process, I found it helpful to tie the frame to the computer table to keep it upright. The holes for the centerline carriage bolts on the wheel carriages were made after fine-tuning.

To support the clothesline co-use, I waterproofed the frame by adding a double thickness of polyethylene sheeting, and taped it on.

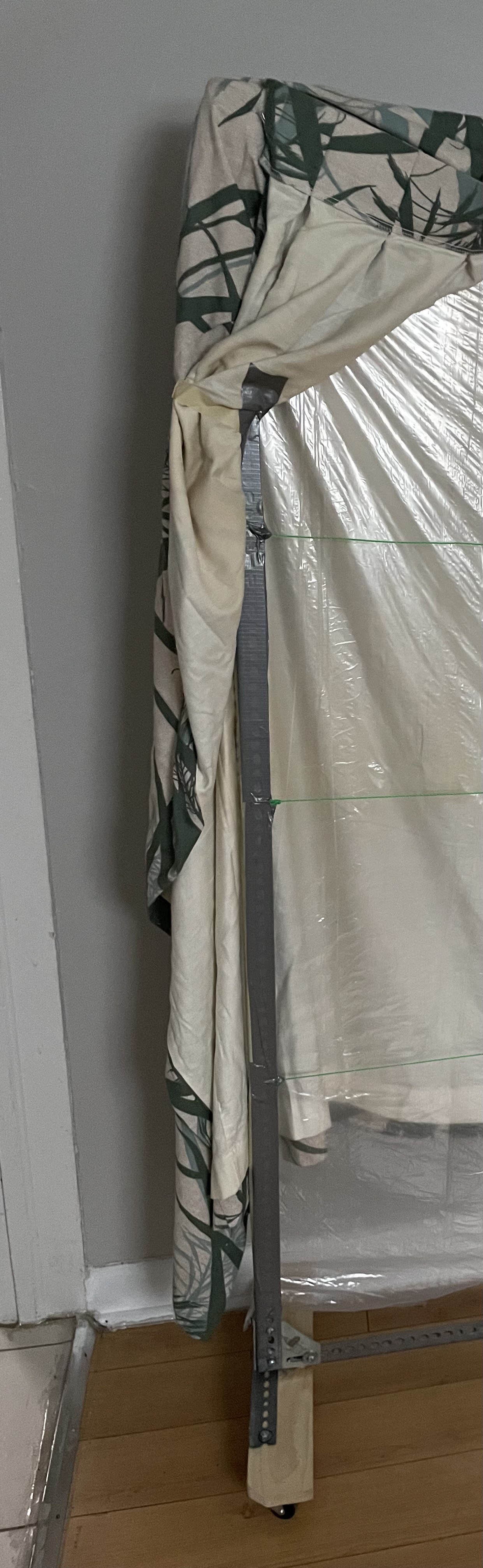

I then added polypropylene cords and coated any steel in danger of getting wet with duct tape. I used curtain hangers to pin up the corners of the curtain in back. Finally, I put a small rug with a waterproof backing under the project to catch any drips.

Here is the project in rear view with a mattress topper from Walmart fastened under the curtain to provide some acoustic separation between the Zoom meeting and the rest of the household. The topper was fastened with small plastic clips from Dollar Store and three small C-clamps along the top, screws down.

There are now 2 mattress toppers on the backdrop, mounted with the flat sides together and the corrugated sides facing out.

Further improvements in sound control were obtained by placing a double layer of mattress topper 2' wide (i.e., one topper folded lengthwise) on the ceiling where it was snugged up to the wall over the window and extended 18” to either side of the window, and on a portion of a bulkhead on my ceiling that probably contains air returning to the furnace. For this I used telescoping stick-up sticks, each made from a six-foot and a four-foot, half-inch diameter dowel rod, held together with two 3/8-7/8" hose clamps and with a rubber foot (Everbilt 1000 100 248 91310) on each end to prevent skidding.

David Matthew Mooney

David Matthew Mooney

Quinn Silverleaf

Quinn Silverleaf

Steve Dearden

Steve Dearden

Bharbour

Bharbour

Tinkers Projects

Tinkers Projects