- There are plenty of other conversions of toaster ovens on the internet. Links in the project logs, or search right here on Hackaday.

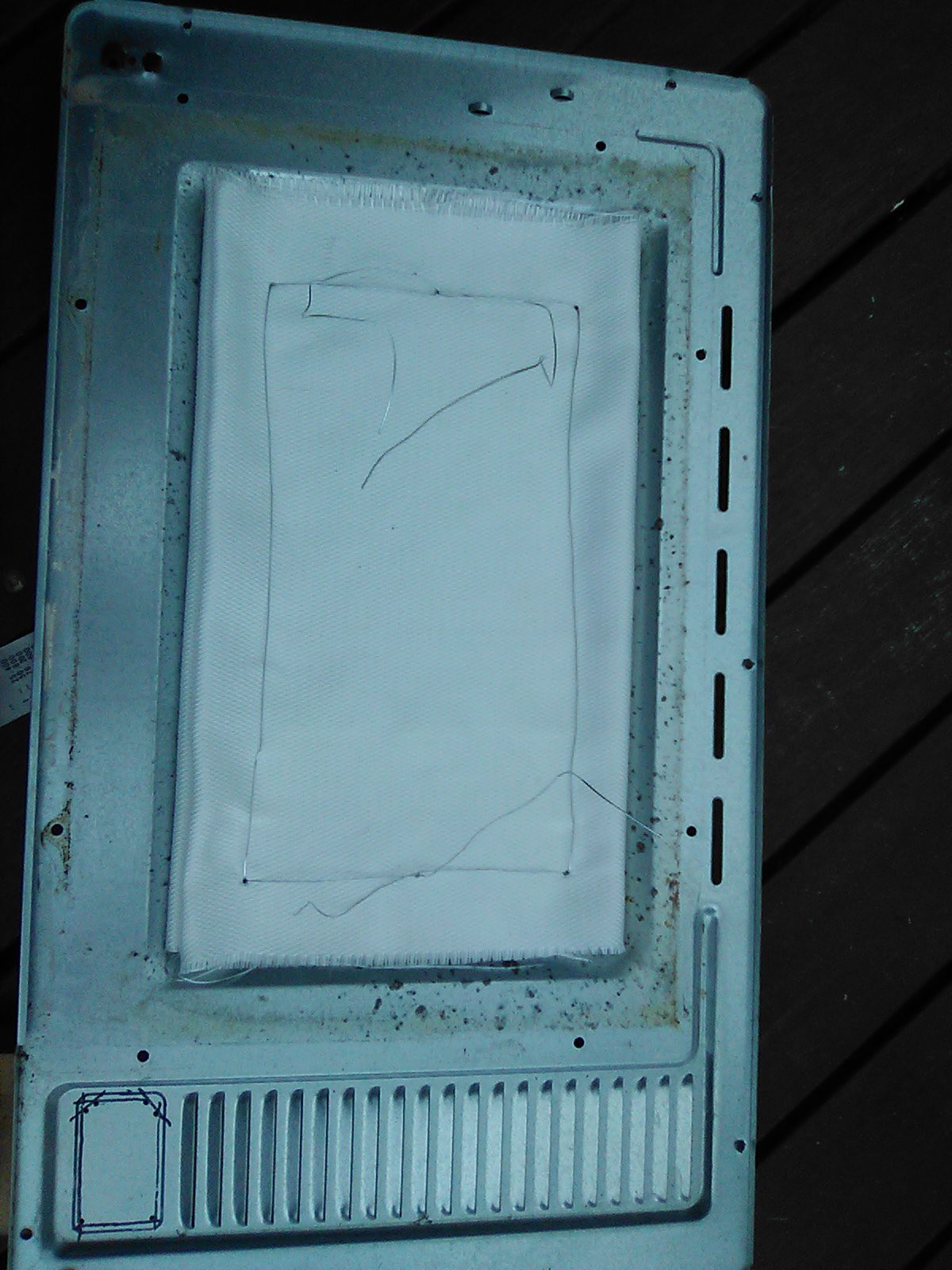

- I am using a Breville LOV560, which is a 28 litre oven rated at 1380-1650W. This is actually a bit underpowered for its size, but the price was right - 15AUD second-hand, compared to over 200 AUD new!

- Another option for a home reflow oven is the T-962, which is a purpose-built SMD reflow oven and can be found for about $200 USD on the usual auction sites. Unfortunately the T-962 has a reputation for some questionable aspects of its design which lead to it needing significant rework to make it useful and reliable. Therefore If I would have to spend time and money fixing the purpose-built device, I might as well roll my own. It will be educational and keep a big piece of electronic equipment out of e-waste.

- If you do have a T-962 and need to fix it, this Github link is a good place to start: https://github.com/UnifiedEngineering/T-962-improvements

Yet Another Reflow Oven

I found a cheap toaster oven. Let's try to turn it into something better than a T-962... and do it cheaper.

Jan

Jan

David

David

Matt Moses

Matt Moses