Background

The initiation for this idea actually came way back in 2019, after competing in the 'Polypanels' 3D printing design competition. Polypanels were created by Devin Montes, of the 'Make Anything' Youtube channel fame, and the purpose of the competition was to creat custom 'Polypanels' as a sort of open source construction kit.

I took second place in the competition with my Beam Engine model. I had added some basic moving parts: gears, links, and shafts, to create the 3D printable model. Then the idea was seeded. To make a new construction kit, like Meccano, K'nex or Lego Technic, to be able to make custom mechanical creations limited only by your imagination and printing filament.

I personally was a K'nex kid. I made all sorts of strange mechanical things, but was frustrated by how limited the pieces were, try making a tank with a differential from K'nex (I did... with difficulty). I remember learning how a clock escapement worked, and then tried making one with K'nex... it worked... most of the time (pun intended). I wish I had that particular part or thing to make something, but I knew nothing of 3D printing back in 2010.

So now I have the perfect opportunity to make a construction kit how I want to. To be able to make any part I want, or use someone elses who had the same problem/idea. This is the essense of open source 3D printing, and many people are making their own construction kits, notably the awesome PrintABloks by The 3D Printing Professor, or the aforementioned Polypanels.

Development

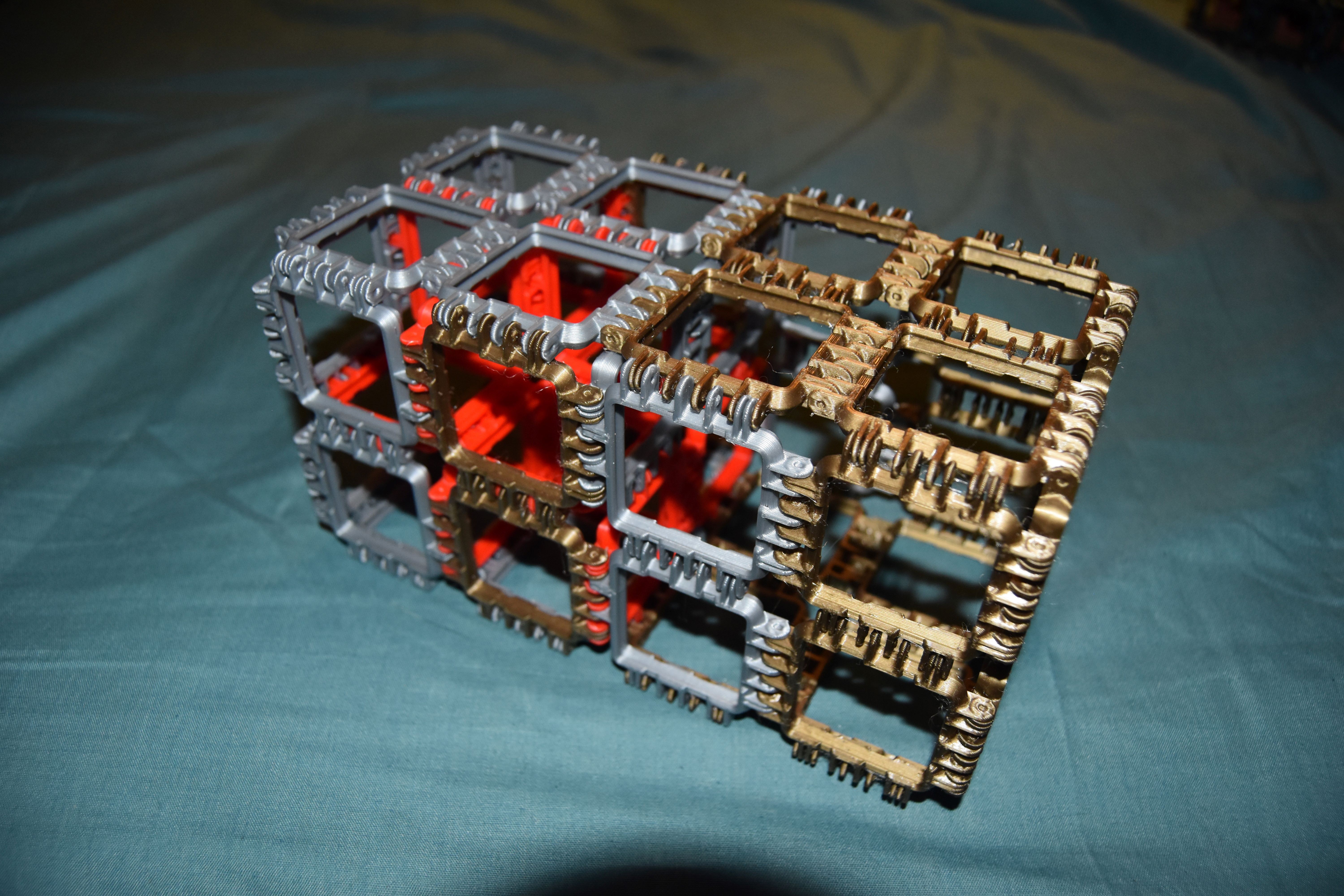

It has taken me over four years to develop this new type of panel, which is similar, but different to Polypanels. I could write a 5 page essay on just developing the panel, so I won't. You can see the previous iterations of panel on my MyMiniFactory page. Essentially the design has become progressively refined by reducing the number of different panels, reducing the complexity of the building techniques, and making the panel generally more robust and modular.

The final version of the panel is not yet published (along with many of the features shown here) but I will be publishing them soon over the next month or so. I plan to use the new 'Clubs' feature of the Printables 3D printing sharing site. Once I have created the 'Club', you will be able to support the ongoing development of Omnipanels with donations or a subscription. The subscription will give early access to the published parts, free access to comercial files (only some particular special designs files will be commercial, they will be generally optional interesting components which will not be functionally better than free models), and a poll to give direct stake in what parts I design next. I have so many ideas of things to make (I will never run out) and am open to suggestions on what parts people want; or you could just make it yourself!

Key Features and Components

For brevity, I will list the key features of the system, along with some images, more details for some things already designed can be found on the respective pages.

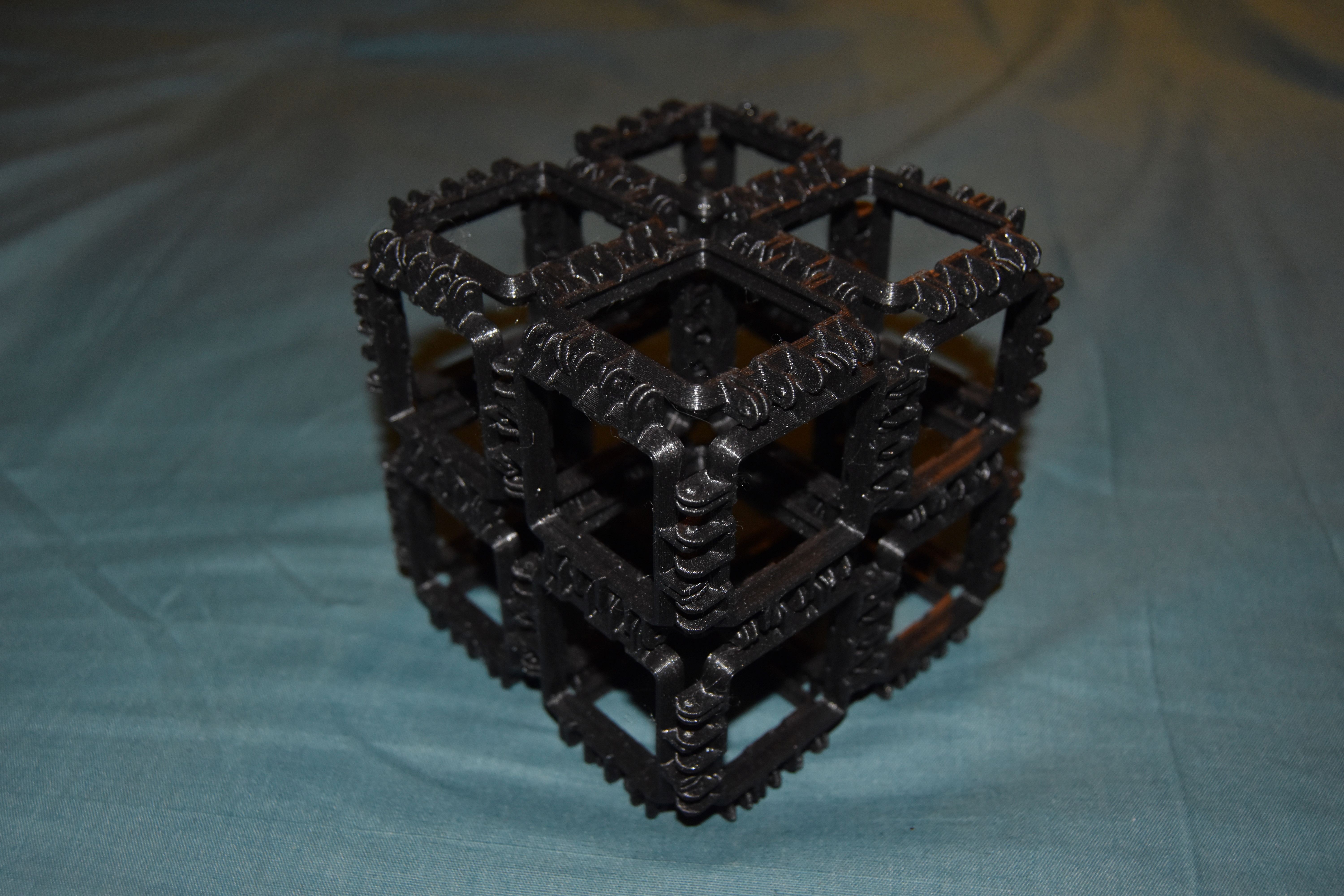

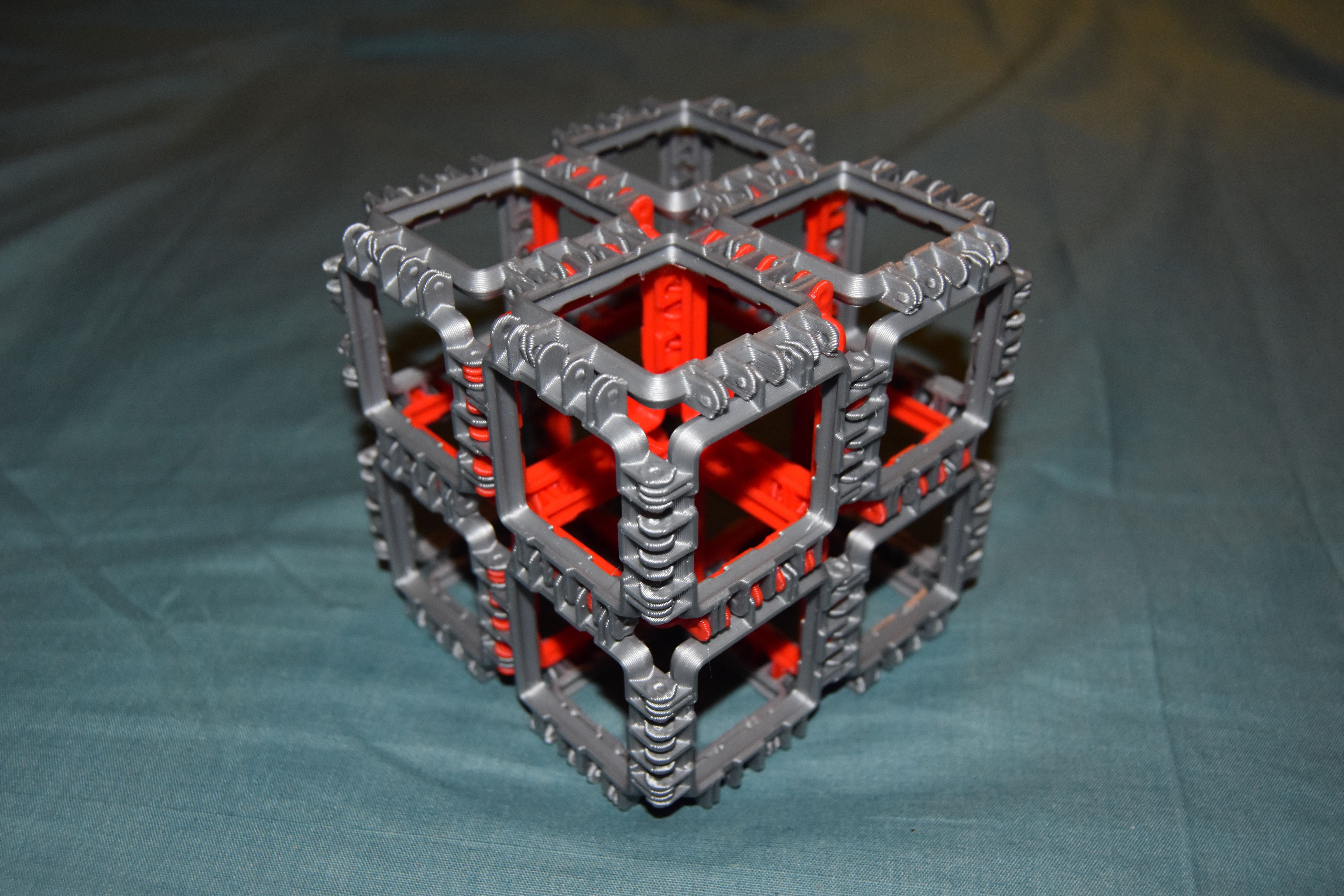

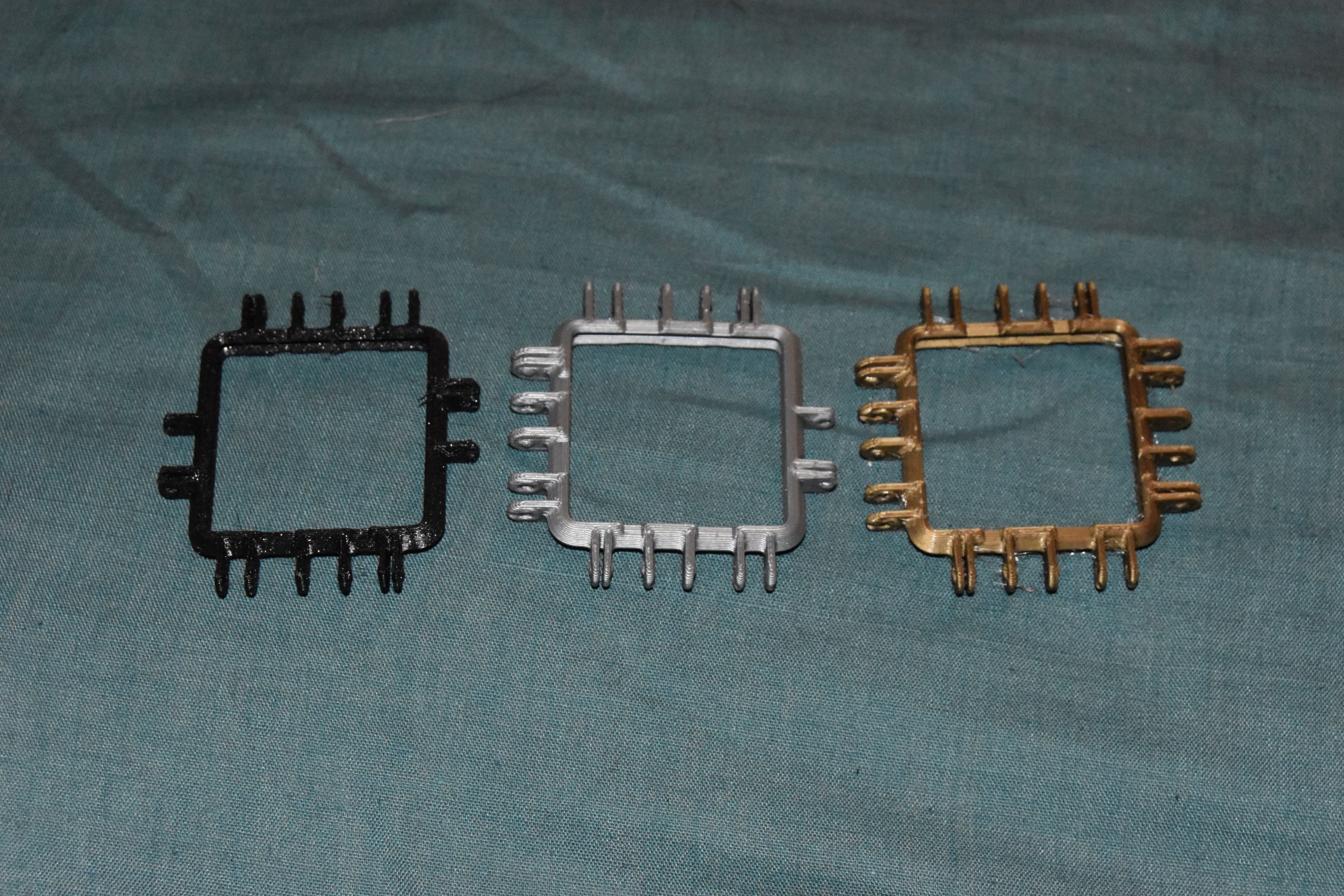

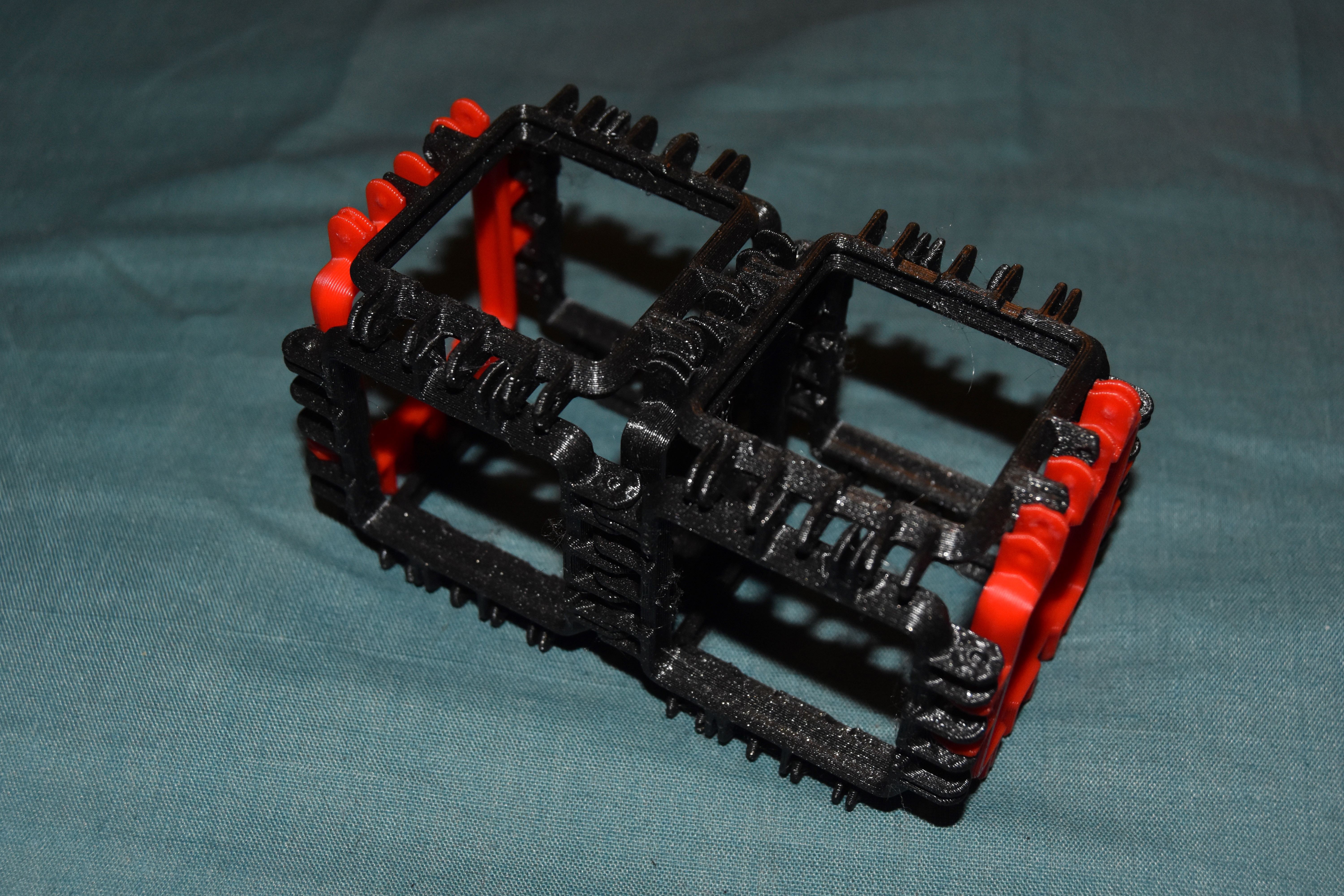

Base Squares

The base of the system is composed of squares, which can be joined together to make a cubic grid of any shape and size. Details of how the system works can be found here, although those are the older iteration of the panel design. My latest design is a bit better and simpler (to be released soon), but the basic building pattern and panel types (A,B, and C) are the same.

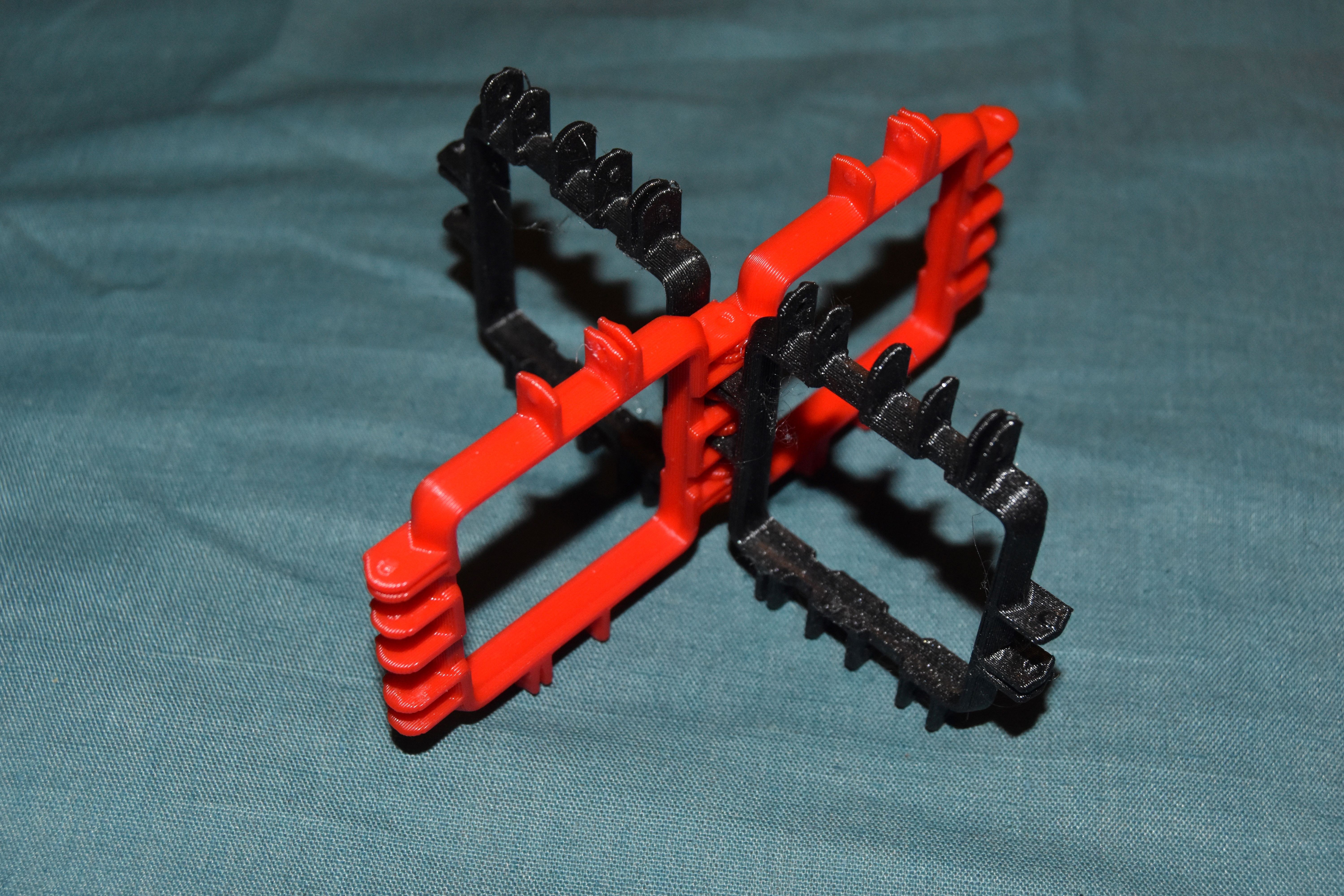

Shafts

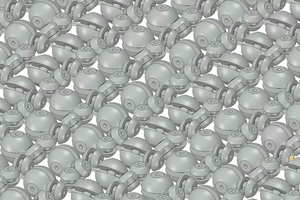

The main form of motion transfer is through shafts, allowing rotation and sliding motion, with a flat bottom to key components to it and pin holes for locking parts along it.

Shafts can be joined together with 'Joiners' and pins to make longer shafts (although they will be available in 32 different lengths for printing). I think the optimium lengths to print are binary lengths: 1,2,4,8,16,32 units long, as they can be added together to make any custom length (but a custom length printed shaft is always ideal).

Joined shaft.

The joiners that...

Read more » Brien Allison

Brien Allison

Oskar

Oskar

tobychui

tobychui

zapwizard

zapwizard

finallyfunctional

finallyfunctional