RELEVANCE:

This project was motivated by a desire to cover the ceiling and upper walls of a rental with advanced insulating film. The result was a kind of interior thermal tent, with the skinny pillars playing the role of tent poles. (Electrical outlets were protected against short circuiting due to falling film.) To protect your deposit, you don't want to use a lot of fasteners on a rental. With skinny pillars, none are needed.

TO USE:

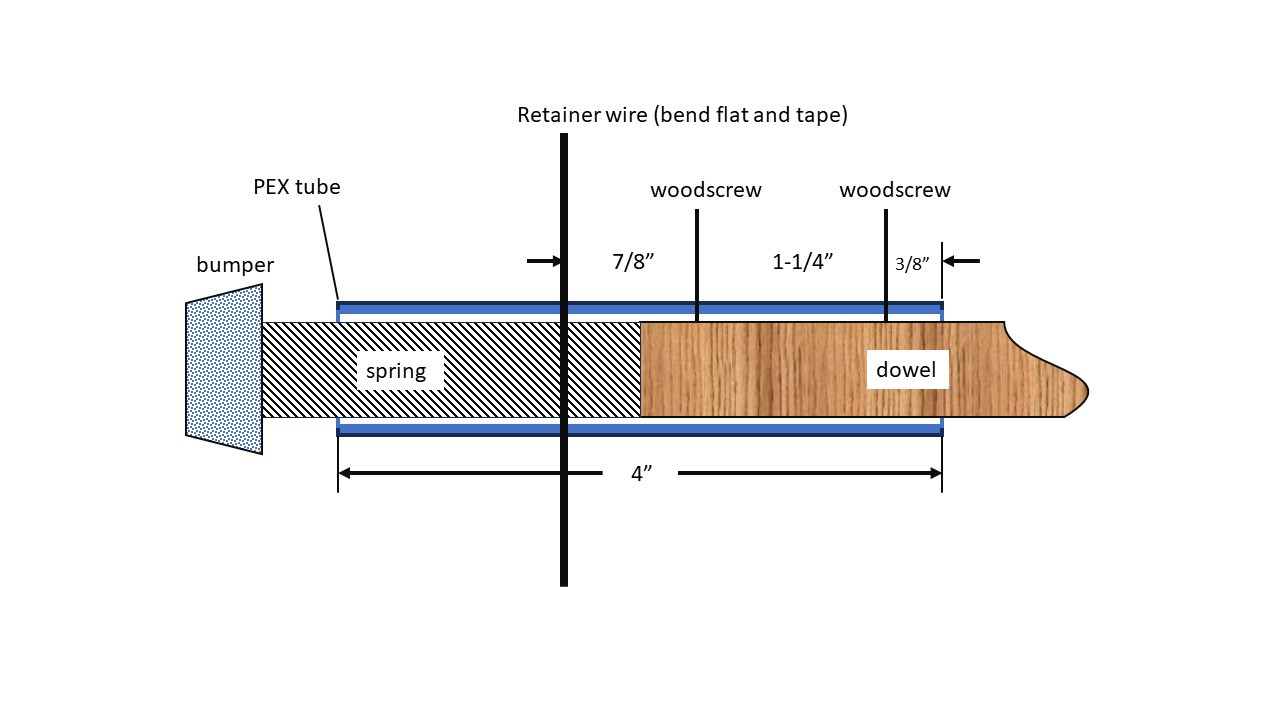

Adjust the top hose clamp for sufficient friction so that the spring can be compressed against the ceiling upon extension of the telescoping section but will stay at least somewhat compressed when the pillar is released.

If putting up plastic film, apply a stick-on anti-slip pad (pictured) to the ceiling side of the film at each corner and position the top of the pillars on those spots to install.

A 6’ x 6’ span can be supported on the ceiling in this way with 4 skinny pillars.

You can use the pillars two-fisted: one to hold up the film and one to be installed. No step-stool required.

BUILD:

The upper two dowels overlap by 6”; the splice woodscrews are 1/2” from the ends. The uppermost dowel is shortened to 30”.

I used a drill-press vise to hold the parts while I was drilling pilot holes. I used a pointed file to make the awl marks to start the twist drill. I counted three sizes below the woodscrew pass size, and commonly landed on a drill diameter of 1/8”. When drilling into the ends, care must be taken not to split the wood. Therefore, center the hole carefully.

MISCELLANEOUS:

21 components

PEX tube is not stable to solar ultraviolet.

Supplier for this project: Home Depot

Variations:

1) Replace the compression spring and tube assembly with just a rubber bumper and use half-inch diameter dowels that bend when in compression. Then the dowel itself is the spring. This is faster to build but not as secure when installed. Due to a better selection of lengths in the half-inch size, I use one six-foot length instead of splicing a four-foot length to a 30” length.

2) Skip the splice section and upper 30” of dowel. The resulting short skinny pillar is suitable for spanning between table tops and the ceiling.

3) Combine variations 1) and 2), but do not touch after installation.

David Matthew Mooney

David Matthew Mooney

Alex Rich

Alex Rich

Tinkers Projects

Tinkers Projects

Quinn

Quinn

Michael Ratcliffe

Michael Ratcliffe