The bicycle has existed for so long, so let’s leave well enough alone, right? No. The bicycle is a great engineering tool. Its inner workings are not covered up. You can prod and poke and see what each component does. This leads the adventurous and inquisitive to make changes. Thousands of garages and basements are full of welders, bent tubes, and homemade bikes.

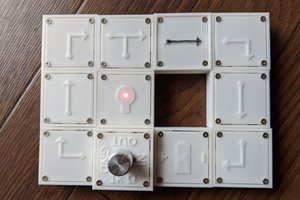

I decided to invent another kind of bicycle but also to create a system in which people can put together a bicycle from scratch and then have enough knowledge to make some changes. I wanted the bicycle kit to be inexpensive which means using mostly off the shelf parts and staying away from welders, tube benders, ventilation, shop space, and other tools which are out of reach for most people.

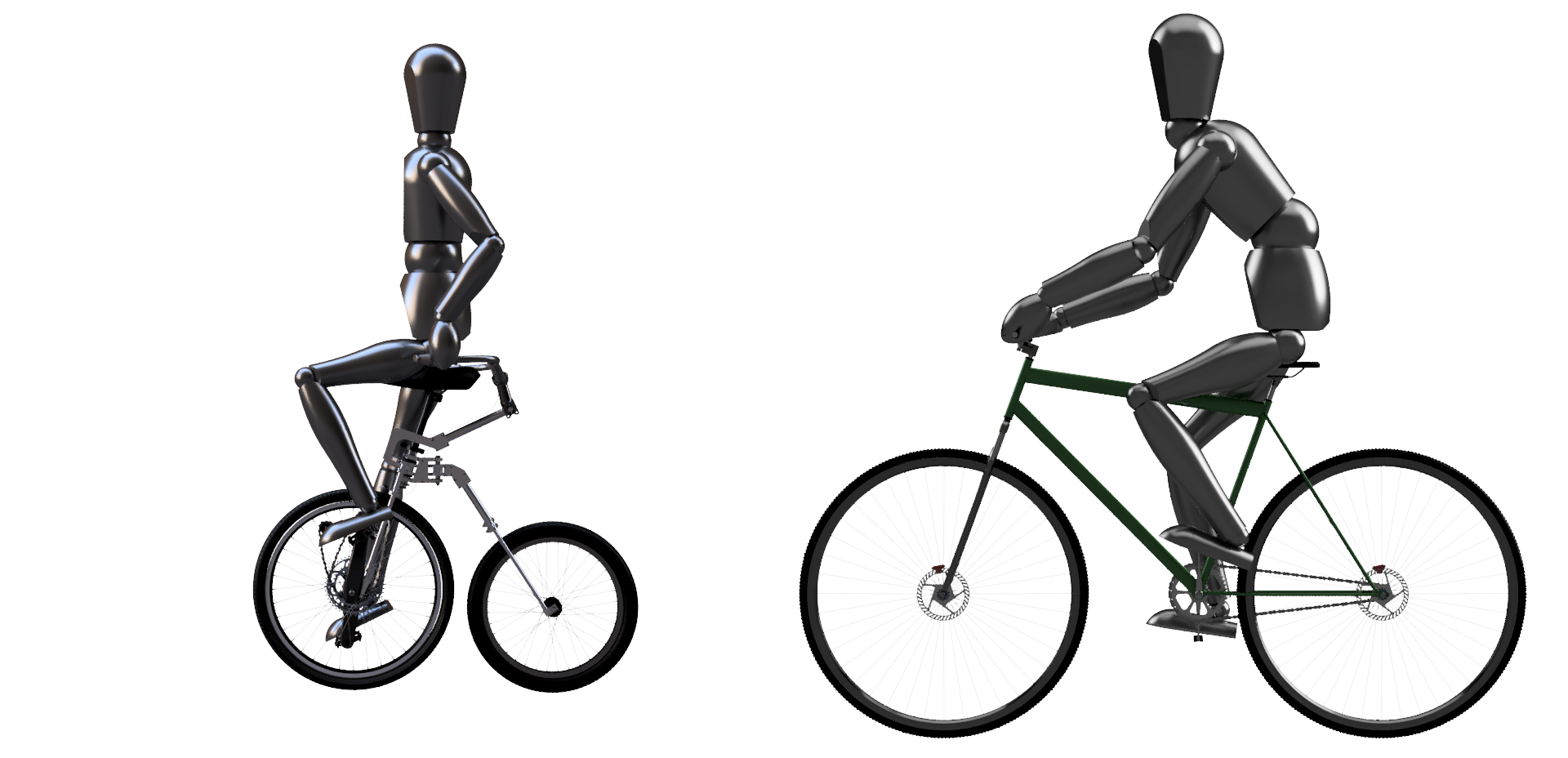

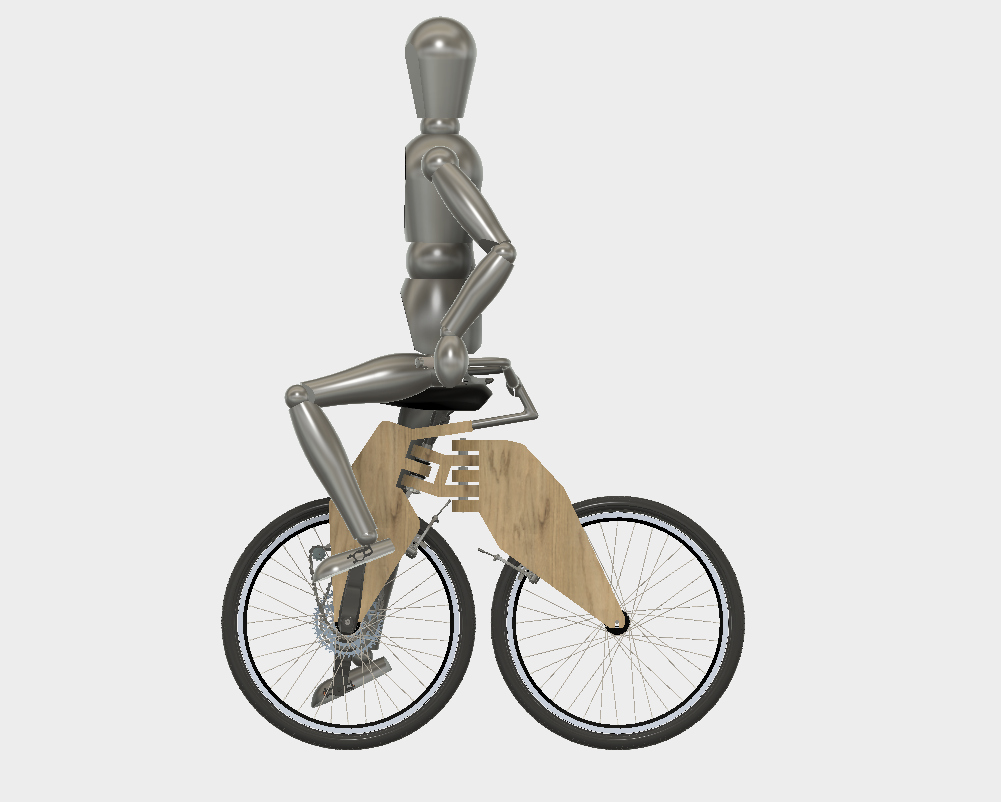

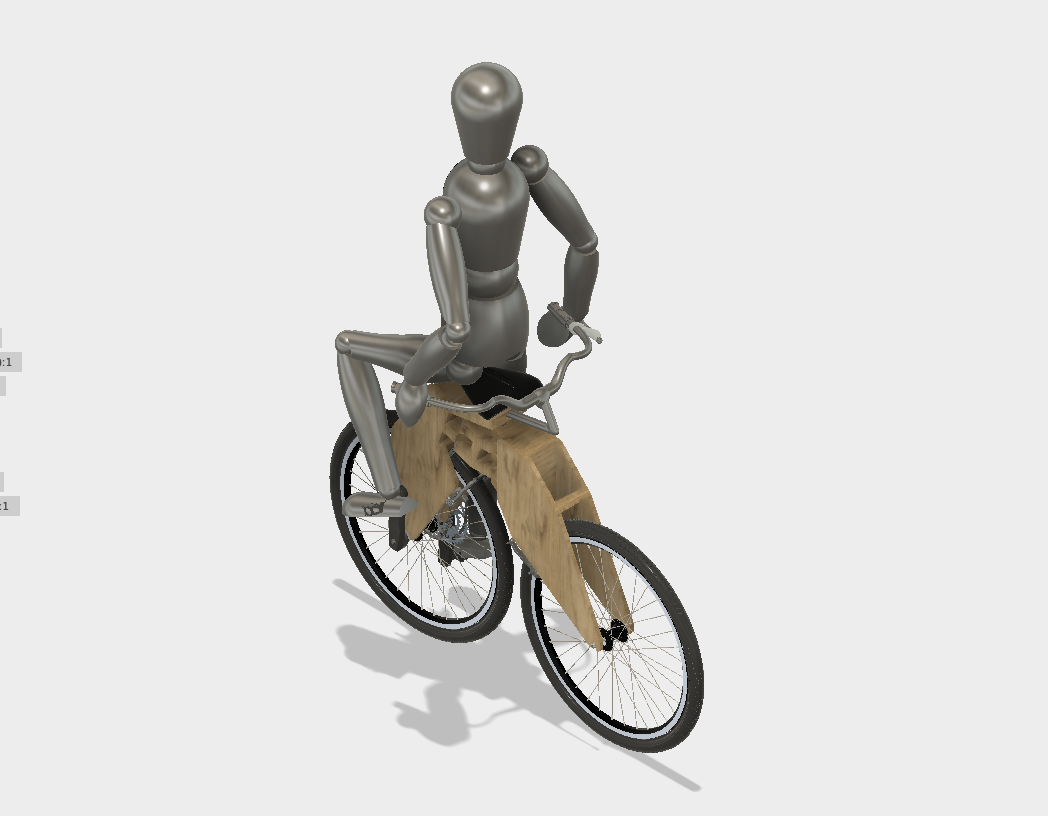

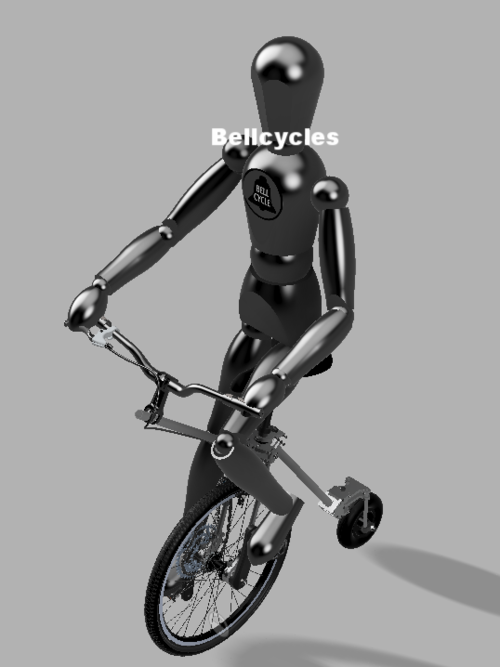

The Bellcycle is compact. That’s because the diamond frame on a normal bicycle that separates the two wheels and houses the bottom bracket is gone. The wheels of the Bellcycle can be nearly touching. The cycle cannot get shorter.

The Bellcycle is front wheel drive. The pedal axis is through the front wheel of the bicycle. The user sits in the middle of the bicycle with their hands either in front of them or naturally by their side, depending on your configuration

The Bellcycle currently has both single speed and nine speed versions with standard bicycle chains, sprockets etc. However, in the future a inexpensive hub gear could be designed and produced which would simplify the cycle even further.

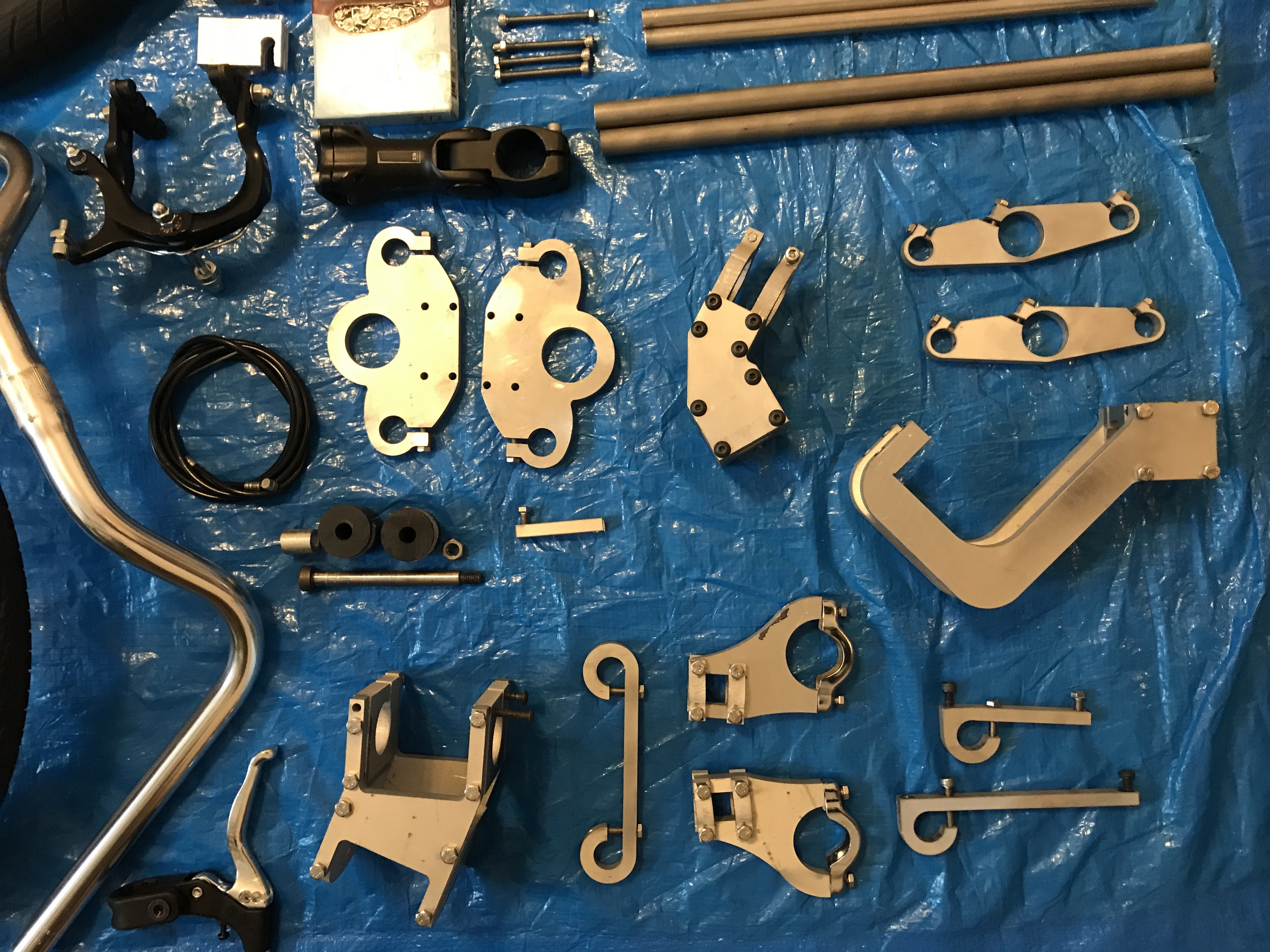

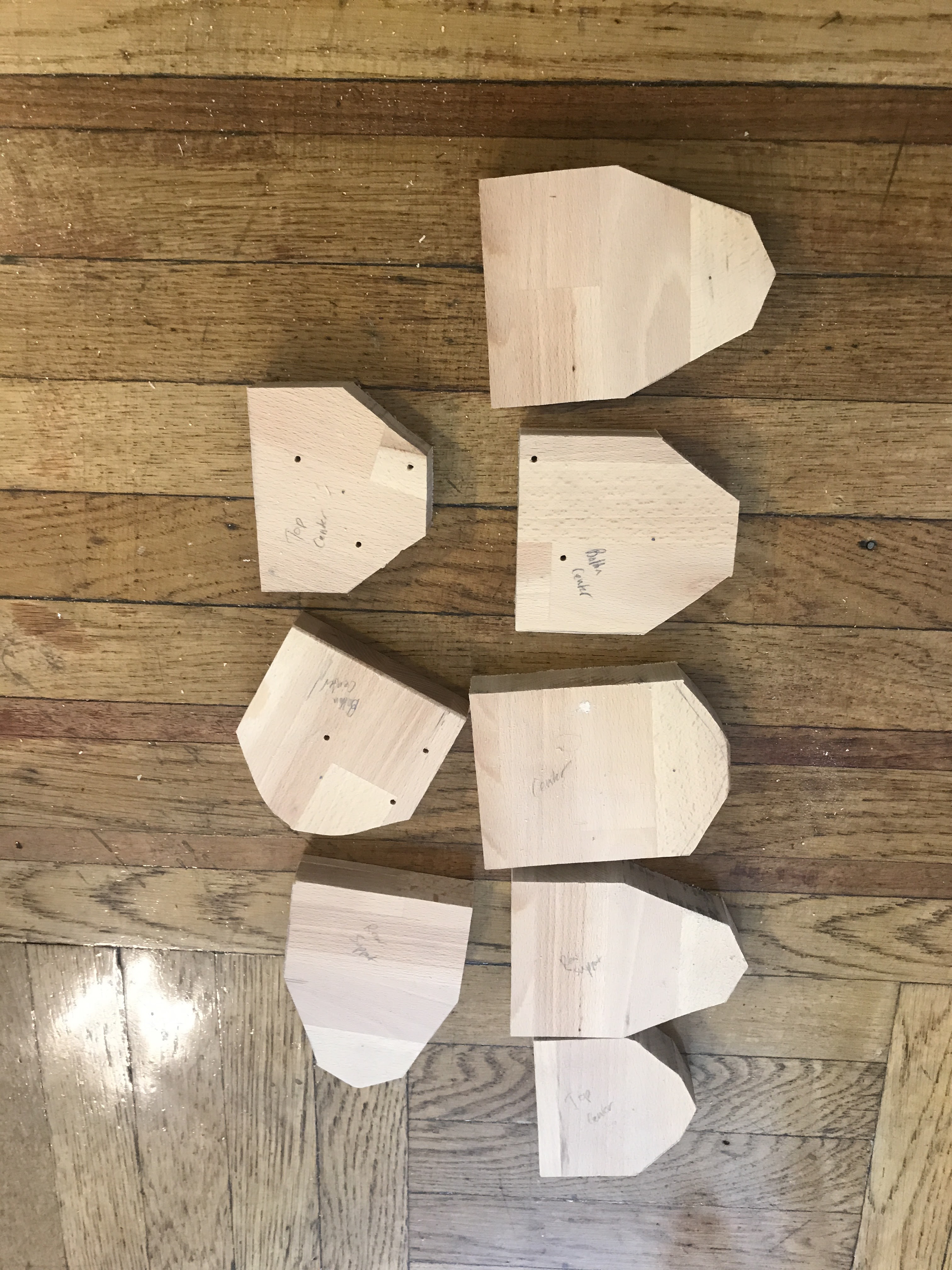

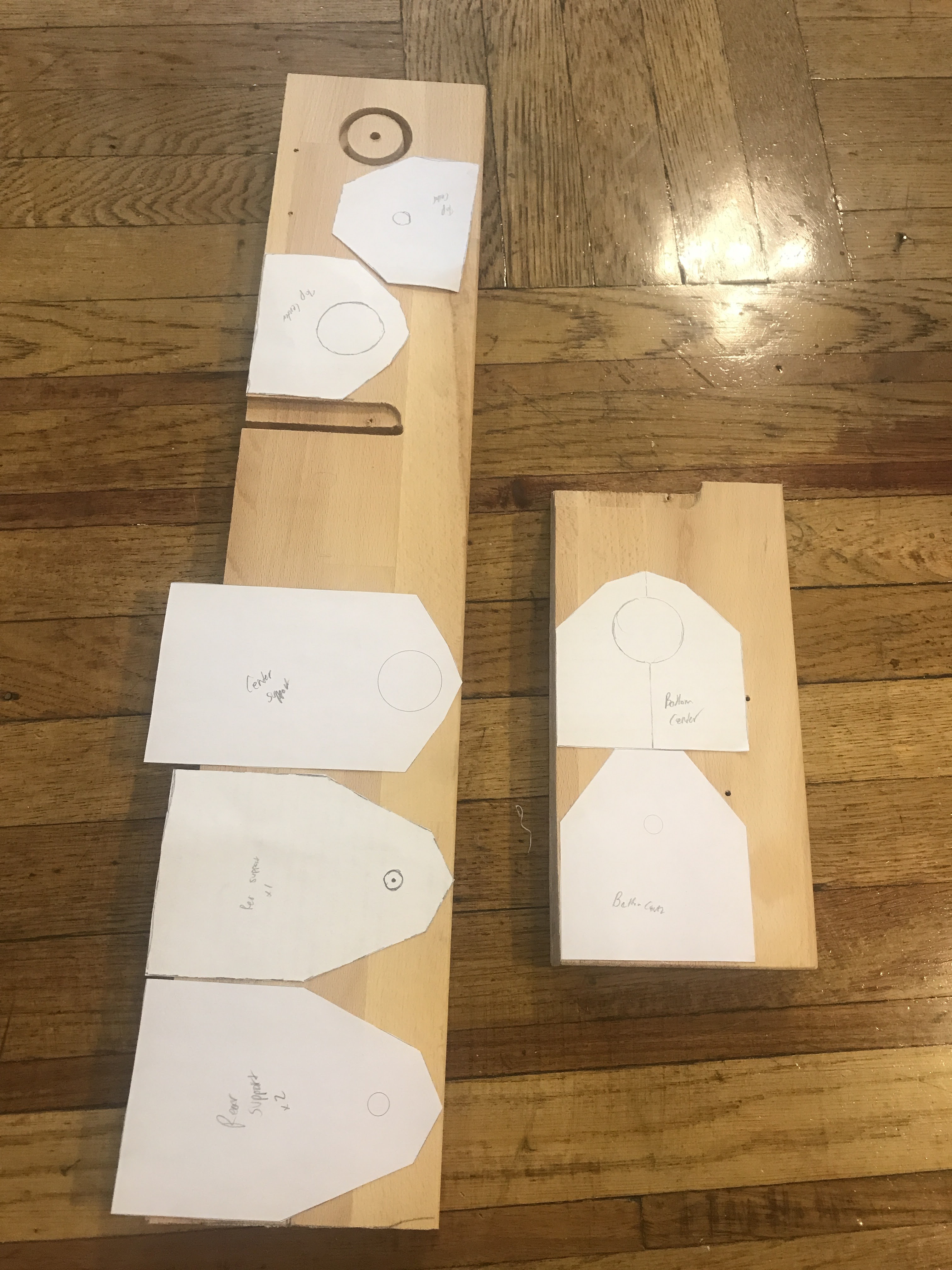

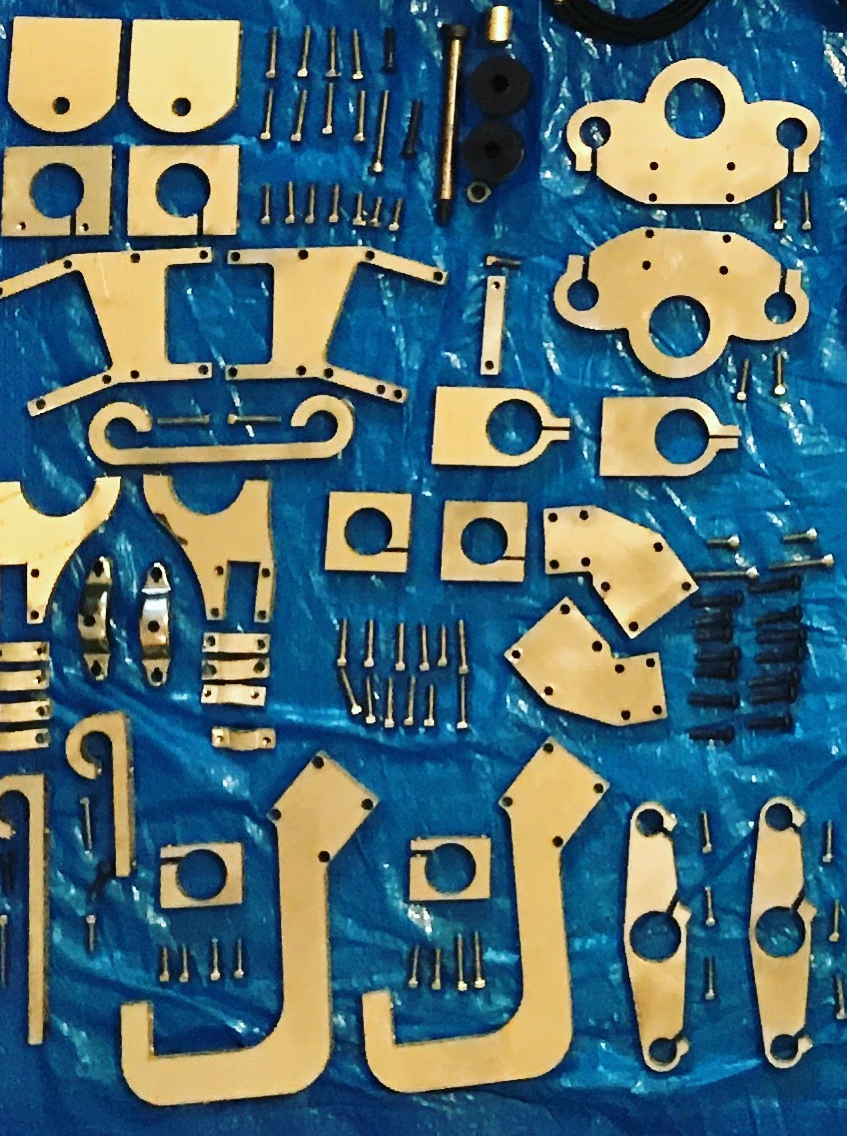

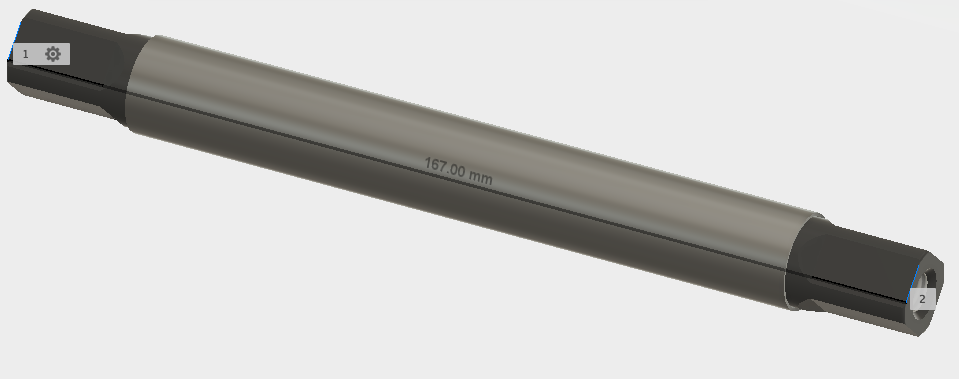

The frame is made of tubes connected to plates. In the current version the tubes are 2043 Aluminum and the plates are 6061 aluminum. However, some prototypes have had steel tubes, carbon fiber tubes, and even wood frames. Currently the plates are waterjet cut and holes drilled and tapped for bolts. However, in early prototypes the plates were cut using a bandsaw and hacksaw.

I hope to offer a kit version of the cycle soon which will contain all the parts needed to assemble the cycle.

The CAD is all open source and included in the component and file list.

Alex Bell

Alex Bell

Chris Low

Chris Low

Maximiliano Palay

Maximiliano Palay

sebwiers

sebwiers

this is very tempting for my commute (short ride to bus, easy to put on the bus), while avoiding some of the pitfalls of foldier bikes (un/foldtime), as long as it's not heavier than a regular bicycle. one of the ways to make that commute use-case even nicer might be to avoid a chain entirely -- chains being things that hit your pant legs and such. though perhaps now you have to worry about tire spokes...

oh, after a random find on this page, i see you've already thought of something like this: "However, in the future a inexpensive hub gear could be designed and produced which would simplify the cycle even further." i was going to mention this planetary gear hub is very nice looking (though expensive, $500!!):

http://www.efneo.com/gearbox/

but because of it's external interface, it would still require a chain. anyhoo, regarding any future plans for bellcycle v2 or v3, what are your thoughts/ideas for this hub gear? i think it could be a big selling point if marketed well :).